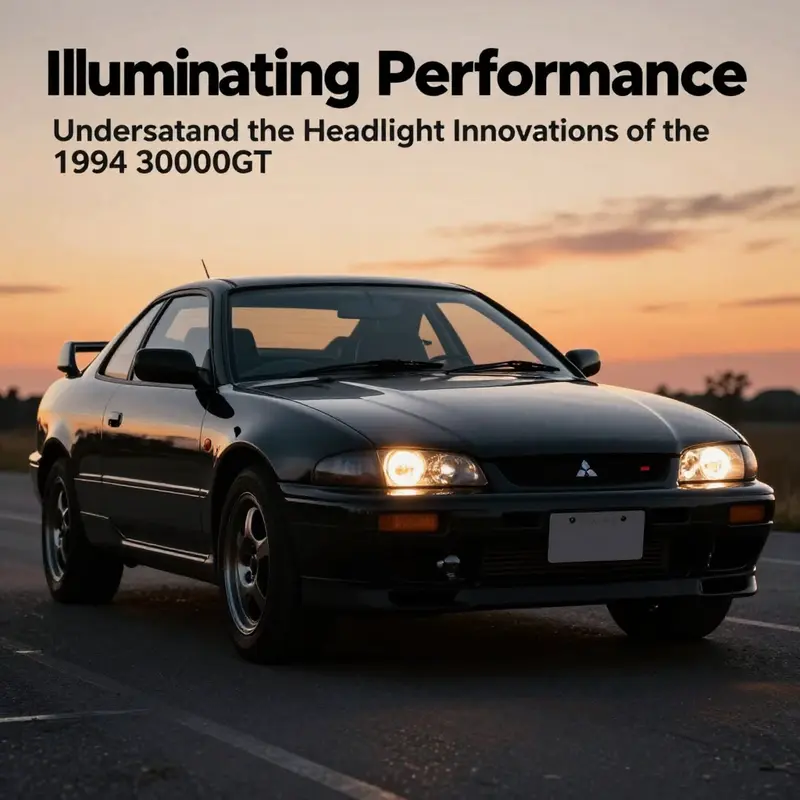

The 1994 Mitsubishi 3000GT stands as a testament to automotive innovation, particularly noted for its striking headlight design. With a unique pop-up mechanism in early models transitioning to fixed headlights in later batches, these lights are not merely functional but fundamentally tied to the vehicle’s aesthetic appeal. Understanding the nuances of these headlights is essential for business owners in the automotive industry, from restoration specialists to aftermarket part suppliers. Each chapter will delve into the design features, compatibility specifics, purchasing options, aesthetic impact, and maintenance strategies associated with the 1994 Mitsubishi 3000GT headlights, providing a comprehensive overview that caters to the needs of various stakeholders in automotive services.

From Jumping Beams to Fixed Lines: The Headlight Design Evolution of the 1994 Mitsubishi 3000GT

Headlights are more than a functional necessity on a car; they are a defining element of its face, a signature that can tell you, at a glance, whether a machine is poised to race or to cruise. In the case of the 1994 Mitsubishi 3000GT, the headlights functioned as a compact narrative of transition. The model year bookends a period of bold experimentation in lighting technology, where form followed ambition and the engineering team wrestled with new regulatory realities and evolving ideas about reliability. What began with a celebrated pop-up mechanism—an automotive icon of the late 80s and early 90s—evolved in 1994 into a fixed, sealed-beam arrangement. That shift did more than change the way the car looked when its lights were on or off; it reflected a broader shift in lighting strategy across the industry, where simpler, more dependable units were increasingly favored for everyday driving and safety reasons, even as enthusiasts clung to the drama and allure of the earlier, rising-and-closing beams. The year 1994, therefore, marks not just a facelift but a pivot in design philosophy, a moment when the 3000GT’s front end carried two very different personalities within the same model year.

In the original, early-production configuration, the pop-up headlights were more than a technical feature; they were a design statement. When closed, the units contributed to an aerodynamically clean silhouette, a low, aggressive line that betrayed the car’s performance intent even before the engine fired. The mechanism itself—hidden behind a sculpted headlight shell—was a dramatic theater piece: the glass would rise with a precise mechanical theater of gears and springs, revealing a bright array of lamps that could punch through night with a purpose-built beam pattern. But what truly set the 3000GT apart was how those pop-up units didn’t exist in isolation. They were integrated with the side-mounted daytime running lights, a pairing that felt almost surgical in its precision. The front fascia paid a visual debt to the car’s overall philosophy: speed, science, and a touch of futurism. This cohesion created a front end that read as both warning and invitation, signaling a car designed to hurry toward its own limit while presenting a poised, almost artful aggression to bystanders.

Yet the 1994 facelift announced a different tale. Regulatory safety standards that had loomed on the horizon for years now pressed down with renewed urgency. The fixed headlights, sealed-beam and later improved by modern lumens and reflector geometry, emerged as a practical necessity. The change was not simply aesthetic. It spoke to a broader commitment to reliability and lower maintenance over the long arc of a car’s life. The new headlights offered stronger, more predictable illumination in varied conditions and a more straightforward service path. This was not a wholesale rejection of the old design so much as a recalibration of priorities: the cars still carried the same leaf of aggressive styling, but the face that greeted night driving adopted a different, more utilitarian set of eyes. The shift also reflected a moment in automotive lighting history when the industry began to codify a new language of performance—the language that, decades later, would see many classics reimagined with LED and other high-intensity technologies. The 1994 3000GT thus stands as a bridge between a pop-up era and a fixed-lens era, each with its own virtues and its own risks of obsolescence as lighting technology evolved through the rest of the decade.

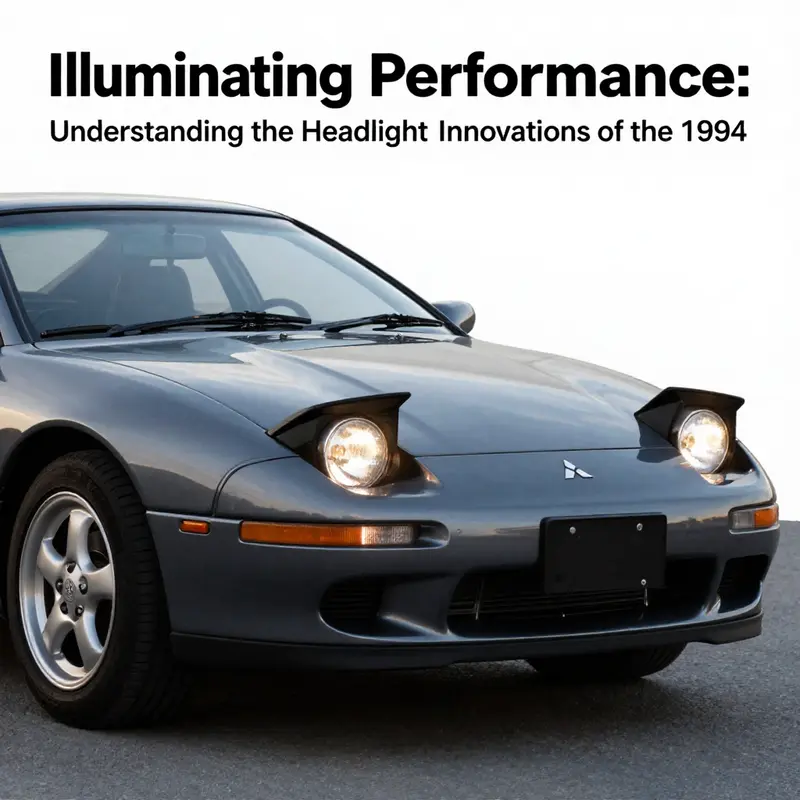

Architecturally, the transition from pop-up to fixed headlights was more than a swap of parts. It changed the way light was projected and the way the vehicle communicated its stance at night. The early system’s geometry allowed designers to tuck the headlamp assembly into the fender line and the hood in a way that preserved an uncluttered, sculpted nose. The pop-up mechanism could be tuned to minimize drag when not active, maintaining the silhouette that fans of the car remember fondly. In contrast, the fixed units embraced a broader, more steadfast presence, with the glass, reflector, and lens working as a single, rigid system. The resulting front end appeared more resolute, a reflection of the broader industrial move toward fixed, high-efficiency lighting in the 1990s. Later aftermarket upgrades would seize on that fixed baseline to introduce modern LED arrangements and higher color temperatures, such as the 6000K range, with lumens that could rival traditional multisource systems. These improvements, while enabling dramatically better nighttime visibility, speak to a larger theme: the ongoing dialogue between authenticity and enhancement in classic-car lighting.

From a collector’s perspective, the dual-natured 1994 headlight history adds a layer of nuance to restoration and parts selection. For purists, the early pop-up configuration remains a coveted specimen, with the particular challenge of sourcing authentic units that still function after decades of aging. For others, the fixed headlights of later 1994 production are perfectly legitimate, offering easier maintenance and a different but equally authentic look that aligns with the era’s safety-minded ethos. The decision is not merely about appearance but about the car’s overall integrity, period-correctity, and the mechanical compatibility of the entire front-end assembly. Restoration, as with many classic vehicles, often becomes a balancing act between preserving original intent and embracing practical upgrades that improve safety and reliability without undermining the car’s historical character. Those who want to retain the classic drama of the face might consider a carefully selected, period-authentic fixed-headlight setup, while others may lean into modern conversions that honor the original lines but add a contemporary brightness and beam control.

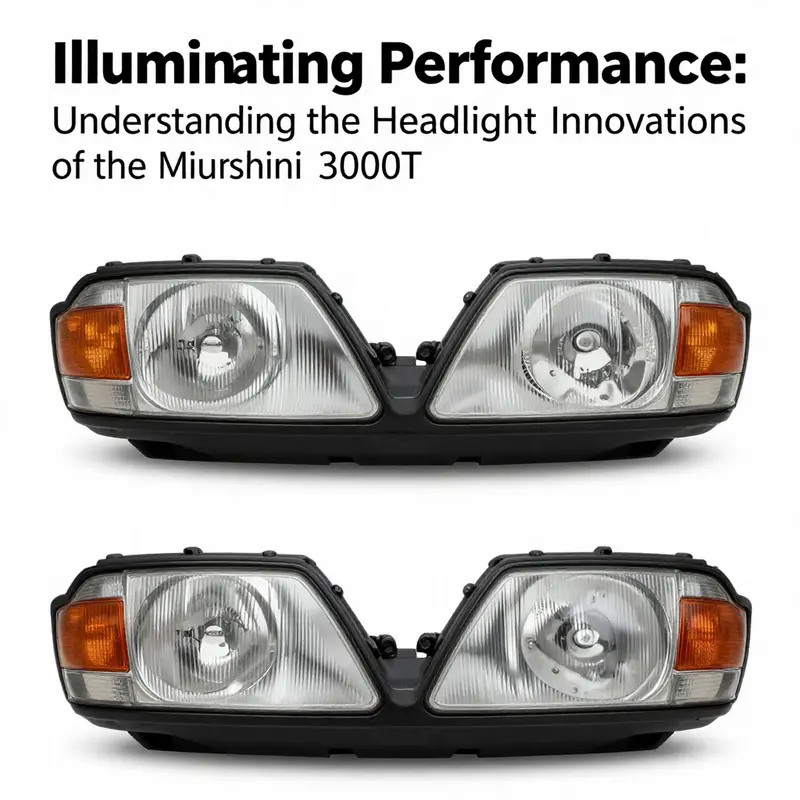

Part of that practical equation involves sourcing the right parts and confirming fitment. The market for 1994-1998 headlight assemblies is scattered across enthusiast networks and specialty retailers, with a notable emphasis on authenticity and condition. It is common to encounter listings for OEM- or aftermarket-style glass headlights that can restore the car’s original front view. For instance, listings in the marketplace illustrate glass headlights suitable for the 1994 to 1998 3000GT/Stealth range, with prices commonly listed around the mid four-figure range plus shipping. Those numbers reflect the dual demand: some buyers pursue exact reproduction to preserve the car’s emotional truth, while others may search for compatible items that satisfy a restoration budget while still delivering solid light output. The important caveat remains constant: verify the exact production year and configuration of the car before purchasing. The 3000GT’s early and late 1994 configurations, and the broader 1994-1998 family, can carry distinct part numbers, mounting points, and wiring schemes, all of which affect fit and performance.

For readers who want to explore authentic parts in more depth, the restoration path includes an accessible touchpoint with a dedicated listing that covers 95-99 models and offers, among other options, clear, driver-side and passenger-side headlight assemblies. The URL slug itself—95-99-mitsubishi-3000gt-sl-vr4-clear-driver-passenger-side-headlights-glass—reads as a direct invitation to explore period-correct pieces for the later production phase of the model. For convenience, you can follow that link to assess whether a particular unit aligns with the car’s year, trim, and build date, ensuring compatibility with the mounting hardware and electrical connectors. This approach reduces the risk of mismatched lenses or misaligned beam patterns that can plague restoration projects.

The modern landscape of headlight upgrades also invites a pragmatic, performance-minded approach. Enthusiasts often consider LED or advanced projector conversions to improve nighttime visibility, bolstered by higher color temperatures and sharper beam patterns. These upgrades, while not original to the 1994 era, offer a way to enjoy safer night driving without losing the car’s iconic silhouette. The fixed-headlight configuration of the 1994 model provides a stable platform for such enhancements, offering predictable cutoffs and beam reach that can accommodate aftermarket modules while preserving the vehicle’s overall proportions. The dialogue between vintage styling and modern illumination continues to shape how owners perceive the car’s nighttime presence, bridging decades of automotive lighting evolution in a way that keeps the 3000GT relevant to today’s roads.

In closing, the 1994 Mitsubishi 3000GT headlights tell a compact but resonant story about design, safety, and the evolving ambitions of a performance icon. The jump from a dramatic pop-up system to a fixed-beam assembly marks a turning point in how this car expressed its identity at night. It is a story repeated across the era—a period when engineering teams were consolidating reliability with performance, ultimately aligning with a broader industry shift toward fixed, efficient lighting. For those who relish the car’s history, the two paths available within a single model year offer a tangible reminder that design is seldom a static choice. It is a conversation between lines and light, a conversation the 3000GT carries with a certain bravado even as it adapts to the rules and realities of the road. For restorers and curious readers alike, that conversation remains an invitation to look closely at lenses, reflectors, and the glow they cast on the night ahead, and to appreciate how the relationship between form and function continues to illuminate the story of a beloved classic.

For late-1990s restorations, see the listing here: 95-99-mitsubishi-3000gt-sl-vr4-clear-driver-passenger-side-headlights-glass.

External reference: for technical specs and replacement options summarized in a broad, practical way, consult CarParts’ headlight overview at https://www.carparts.com/mitsubishi/3000gt/headlights.

Shifting Light: Compatibility and Evolution of the 1994 Mitsubishi 3000GT Headlights

The 1994 Mitsubishi 3000GT carries a curious architectural moment in automotive lighting. Its headlights are not merely a functional element; they are a design fingerprint that speaks to an era when form and mechanism walked hand in hand. At the outset, the early 1990s version of the 3000GT relied on pop-up headlights that emerged with a mechanical poise, a feature that married drama with practicality. When the era closed its first chapter for the model year, Mitsubishi introduced a facelift that replaced the iconic pop-up units with fixed headlights. This change did more than alter the car’s facial expression; it shifted the underlying architecture of the headlight housing, wiring, and bulb configuration. As a result, the 1994 model year exists as a transitional epoch within a single generation, encompassing two very different headlight realities: the nostalgia-inducing pop-up setup of the pre-facelift vehicles and the more conventional fixed assemblies that followed, at least in North American specifications. The dual-path reality prompts a careful look at compatibility, not as a single answer but as a nuanced map of what fits and what does not when a headlight project moves from concept to completion. In restoration or modification circles, understanding this twofold history helps owners avoid mismatches that could compromise daytime visibility, signaling, or even the electrical integrity of the car’s front end. When discussing compatibility, the conversation centers on design intent, the physical housing, and the electrical ecosystem that makes these lamps function as a coherent whole rather than a simple, replaceable part.

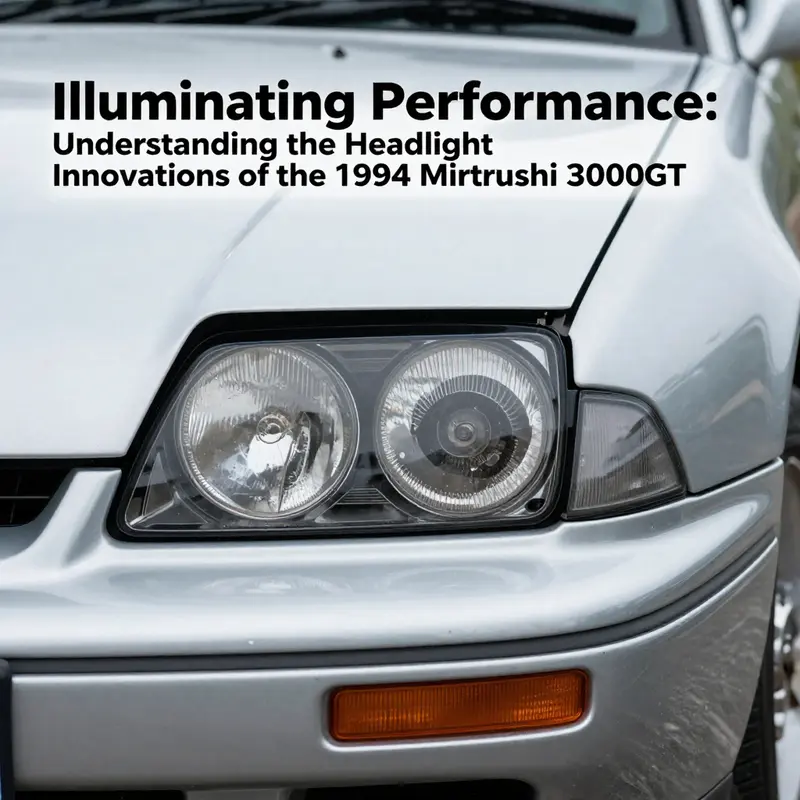

The design change itself is more than a cosmetic reshuffle. The pop-up headlights, celebrated for their theater-like rise and fall, were not simply about style; they created a distinctive silhouette that integrated with the turn signals while preserving a taut, aerodynamic line when closed. The switch to fixed headlights during the 1994 facelift—especially evident in North American configurations—reflected evolving safety standards and aerodynamic optimization. Fixed headlights simplify the opening and closing of the fascia, reduce the mechanical complexity of the pop-up mechanism, and offer a more predictable light distribution pattern. Yet for enthusiasts and restorers, the fixed-housing version also means different bulb types and different mounting points. This is not just about swapping a bulb; it is about understanding how the entire headlight system was reimagined to meet contemporary performance metrics and regulatory expectations. That reimagining matters because it determines which parts are compatible and which are not whenever someone pursues replacement, restoration, or modern upgrades.

To parse the practical implications, one must distinguish between the pre-1994 and post-1994 configurations in terms of housing geometry and the bulb ecosystems they support. The pre-1994 setup, with its pop-up mechanism, typically had a different interior reflector geometry and a distinct ballast or wiring route that powered the motorized iris of the unit. In contrast, the fixed-headlight models introduced in the 1994 facelift present a more conventional reflector and lens arrangement, with a different silhouette and a new labeling of bulb sockets. The net effect is that you cannot assume a bulb or a kit sized for one version will automatically fit the other without inspection. The risk of a mismatch extends beyond a simple wonky beam pattern; it can manifest as electrical gremlins that trigger warning indicators, or as misalignment that leaves sections of the road dark at critical moments. For anyone diving into the maintenance, replacement, or upgrading of 1994-era headlights, a careful year-by-year verification remains essential. This is a reminder that compatibility is not a single checkbox but a layered assessment that respects the factory design choices and the practical realities of aging automotive components.

When it comes to bulb specifications for the fixed-headlight variant, the guidance tends to converge on a practical baseline. In many fixed-headlight configurations of the 1994 model year, replacement bulbs commonly rely on the H4 format, a versatile dual-filament design that handles both low and high beams in a single unit. The H4 standard is favored because it aligns with the fixed housing’s reflector geometry and socket arrangement, delivering a dependable, symmetric light pattern that helps maintain safe nighttime visibility. The emphasis here is on compatibility: confirming that the bulb size, filament arrangement, and socket type match the vehicle’s fixed-headlight configuration. Attempting to force a different design—whether an LED kit, a high-performance xenon substitute, or another non-standard module—into a fixed housing can lead to misalignment, heat management issues, or electrical faults. LED kits, in particular, are a boundary case; while they can offer bright, crisp light and modern color temperatures, they must be engineered for the specific housing and wiring layout. Without proper design alignment, LED offerings can create glare for oncoming drivers, trigger dashboard warning indicators, or fail to illuminate the edges of the lens with the intended distribution.

To move from theory into the practical realm of upgrades and restorations, most enthusiasts consider the broader ecosystem of aftermarket options with a careful eye toward compatibility rather than sheer brightness alone. The interest in modern lighting enhancements—such as halo accents or color-tuned illumination—often appears as a tempting upgrade path for fixed-headlight cars like the 1994 model year. The caveat is that any such kit should be clearly described as compatible with fixed-headlight housings and wired to the same sockets used by the original bulbs. A reliable approach is to treat the headlight system as a single, integrated unit: the lens, reflector, housing, bulb sockets, and the accompanying wiring harness must all be in harmony. In practice, this means verifying the exact bulb size and socket type and ensuring the kit’s control electronics can interface with the car’s electrical system without triggering warnings or draining the battery through parasitic draw. What begins as a simple upgrade can, without due diligence, evolve into a tangle of wiring mods, regulator concerns, and misfit optics that degrade the functionality and the appearance of the front end.

From a restoration perspective, the decision to pursue original appearance versus a modernized look hinges on authenticity versus practicality. For a collector or purist seeking to preserve or return the car to its historical showroom condition, the most straightforward path is to source OEM or OEM-equivalent fixed-headlight assemblies that match the 1994 North American specification. These parts, while potentially more costly than generic aftermarket replacements, are designed to meet the exact mounting holes, screw locations, and electrical interface that left the factory. They also preserve the characteristic beam pattern that the original designers intended, reducing the risk of glare or misaligned light distribution on public roads. For those who are more concerned with performance or aesthetics than strict historical fidelity, the market offers a spectrum of fixed-headlight options. The key is to filter for compatibility, not merely for brightness or color temperature. In practice, this means confirming that any chosen component aligns with the housing’s depth, the lens curvature, and the position of the bulb sockets. The goal is to maintain proper cutoffs and a safe, well-defined beam pattern that doesn’t surprise other drivers once the car is back on the street.

On the topic of parts availability and sourcing, a note from the community highlights the practical realities of mid-1990s headlight components. For those seeking replacement glass headlights for the 1994–1998 Mitsubishi 3000GT or the closely related Stealth model, there are listings on major platforms offering OEM or aftermarket glass assemblies that preserve the original look. Typical pricing for such units can be in the several hundred-dollar range, with additional shipping costs that can push the total into the mid-$500s depending on condition and whether the item is new old stock or used but serviceable. This price band reflects the premium placed on authentic tone and visual clarity, especially for models where the headlight presentation remains a central part of the car’s character. When evaluating these options, it is prudent to verify production year, configuration, and whether the assembly includes the correct glass lenses, reflectors, and gaskets. The risk of acquiring a mis-matched unit is not purely cosmetic; it can entail a failure to seal properly against moisture intrusion, which in turn risks fogging and reduced light transmission. As with any restoration project, a careful balance between authenticity, fitment, and budget will guide the decision.

To help narrow choices and reduce guesswork, one practical step is to consult a specific catalog entry that lists the compatible headlight assemblies for the relevant year window. For example, a listing focusing on the 95–99 Mitsubishi 3000GT headlight glass for driver and passenger sides can serve as a concrete reference point in a shopping plan. The exact wording of that listing makes clear that the part is intended for these years and provides a reliable gauge of fitment. This kind of targeted reference lowers the risk of buying a unit that doesn’t align with the car’s fixed housing, while still allowing for the preservation of the vehicle’s original look and performance. When engaging with sellers and forums, asking pointed questions about year, configuration, and the presence of seals and mounting hardware can save time and reduce the frustration that often accompanies a parts hunt.

For readers who want to explore a concrete, step-by-step sense of what compatibility looks like in practice, consider examining a dedicated internal listing that speaks directly to the fixed-headlight variant and its unique requirements. The link below offers a concise snapshot of a compatible unit, framed for owners who want to confirm fit before purchase: 95-99 Mitsubishi 3000GT headlights (glass, driver and passenger sides). This resource underscores the main takeaway: when you buy headlights for the 1994 model year, you must confirm the year, the configuration, and the housing compatibility to ensure the beam pattern remains correct and the electrical system remains stable.

In the end, the discussion around the 1994 Mitsubishi 3000GT headlights centers on a simple but crucial idea: compatibility governs reliability. The shift from pop-up to fixed headlights represents a broader shift in automotive design philosophy—one that prizes predictable behavior and standardized interfaces. Yet within that logic lies room for thoughtful enhancement, so long as the upgrade respects the fixed housing, the bulb sockets, and the car’s electrical architecture. The best outcomes come from a disciplined approach: verify year and configuration, insulate wiring and seals, and prefer parts that mirror the original intent and performance. By treating the headlight system as a cohesive module—rather than a collection of discreet, replaceable parts—owners can preserve both the charm and the safety of the 1994 3000GT while embracing upgrades that are genuinely compatible. External references and community wisdom can guide decisions, but the decisive factor remains the alignment of factory design with the realities of modern illumination techniques. For readers seeking further context on fixed-headlight compatibility and broader upgrade options, an external resource provides a reference point that anchors the conversation in practical, real-world constraints: https://www.amazon.com/dp/B07QJ2VX6B

null

null

null

null

Keeping the Light Alive: Maintaining and Upgrading 1994 Mitsubishi 3000GT Headlights

Maintenance and Upgrades

The 1994 Mitsubishi 3000GT sits at an interesting crossroads for headlight maintenance. That model year marked the shift from retractable headlamps to fixed units, which means owners must first confirm which configuration their car carries before ordering parts or planning upgrades. A clear understanding of production timing and VIN details will save time and money. With fitment clarified, maintenance and upgrade paths become straightforward and rewarding.

Start with a careful visual and functional inspection. Look for fogging, yellowing, cracks, or separation of the lens from its housing. Check that the turn signal integration and mounting tabs show no stress cracks. Operate the lights and signals to verify that bulbs ignite reliably and that beam patterns are consistent. Flickering, dim output, or a change in beam shape often indicate old wiring, poor ground connections, or failing bulbs. Make a short checklist: lens condition, seal integrity, bulb type and age, wiring and connectors, aiming and alignment, and mechanical mounting. This list will guide purchases and repairs.

Choosing replacement assemblies hinges on two factors: authenticity and fit. Factory-original assemblies provide the correct mounting points, sealed housings, and expected beam patterns. Aftermarket assemblies can offer improved optics, contemporary styling, or modern lighting technologies. When selecting parts, confirm the exact chassis years and whether the car originally had fixed or retractable lamps. Images and part numbers on listings help, but cross-referencing with the car’s build data is safest. For those restoring period-correct appearance, glass lenses designed for late-90s models often match the original look precisely and can be sourced from specialist sellers. One helpful resource for replacement glass headlights is the 95-99 Mitsubishi 3000GT clear driver/passenger side headlights (glass).

Upgrading to modern illumination yields tangible benefits. Swapping incandescent bulbs for higher-efficiency alternatives can improve clarity and extend lifetime. LED retrofit modules are popular because they reduce power draw and offer crisper light. When choosing an LED conversion, pick kits that maintain the same beam cutoff and aim as the original. Poorly designed retrofits can scatter light, create glare for oncoming drivers, and fail inspections. It is also wise to match color temperature across low and high beams for consistent appearance and performance.

If you choose a halo or color-change accent ring, treat it as a cosmetic addition and separate it from the safety lighting. Accent lighting should not interfere with required signal functions. In many regions, non-standard colored lights are restricted to show or off-road use. Before installing cosmetic elements, verify local regulations to avoid compliance trouble.

Aiming and alignment are often overlooked, yet they make the greatest difference to night driving. Even brand-new assemblies require careful aim to avoid blinding other drivers or reducing your own visibility. Use a flat surface and a wall, or a professional headlight aiming device. Follow the vehicle’s service manual specifications for both vertical and horizontal aim. Consider testing adjustments at night on an empty stretch of road to confirm real-world performance.

Seal integrity and condensation control are crucial for longevity. Over time, sealant can harden, shrink, or fail, letting moisture into the housing. Condensation not only reduces light output but can corrode reflectors and bulbs. If moisture appears, remove the assembly, dry it thoroughly, and inspect the mating surfaces. Replace broken clips and use an appropriate automotive sealant to reseal gaps. For units with removable lenses, heated drying followed by a careful re-seal often restores proper function. Avoid excessive heat that could warp plastic bezels.

Lens restoration is a cost-effective alternative to full replacement. Mild oxidation and yellowing respond well to polishing kits designed for automotive plastics. Work gently and progressively through abrasives and polish. Finish with a UV-resistant clear coat to delay re-yellowing. This method works best when cracks and deep pitting are absent. For heavily damaged lenses, replacement is the safer long-term choice.

Electrical checks protect against premature failures. Inspect pigtails, bulb sockets, and grounds for corrosion or looseness. Clean terminals with contact cleaner and apply dielectric grease to reduce future oxidation. If bulbs blow frequently, test the charging system and voltage regulators. Excessive voltage will shorten bulb life. Conversely, low voltage can dim lights and reduce beam reach. For vehicles with complex harnesses, tracing wires with a multimeter helps locate shorts or high-resistance joints.

Mounting hardware and adjusters deserve attention after any work. Broken adjusters prevent precise alignment and lead to uneven wear or rattles. Replace damaged adjusters with correct-fit parts rather than improvising. If the housing mounts to the bumper or core support, ensure those points are straight and free of rust. A slightly misaligned housing can shift aim and allow water ingress.

For those integrating modern lighting technologies, mind thermal management and airflow. LEDs generate heat at their drivers and diodes, requiring heat sinks or active cooling. Ensure the assembly provides adequate clearance and ventilation. Poor thermal control reduces life and performance. Halogen bulb upgrades increase heat inside the housing. Confirm that the housing materials and lens type can withstand higher temperatures before upgrading.

When considering styling swaps, keep resale and originality in mind. Many enthusiasts value an original look, and period-correct parts command premiums. Conversely, tasteful modern upgrades can increase usability and safety. Balance these priorities depending on your goals. If you plan to show the vehicle or sell as a collector car, document modifications and keep original parts stored safely.

Sourcing parts requires patience and verification. Avoid assumptions based on model year alone. Two sub-variants may exist for the same production year. Compare part numbers, photos, and seller descriptions carefully. When buying used components, ask about lens condition, any previous repairs, and whether bulbs or harnesses are included. For critical items, prioritize sellers who provide returns and clear compatibility information.

Routine maintenance extends service life. Periodically clean lenses, check seals, and verify aim. Replace bulbs in pairs to maintain balanced output. Keep a small kit of spare bulbs and essential tools in the trunk. Regular checks will prevent sudden failures and keep night driving safe.

Finally, respect road safety and local laws. Upgrades that increase visibility are valuable, but not if they create hazards for other drivers. Modify lighting thoughtfully, with attention to beam placement and color. When in doubt, seek a professional inspection or use an authorized shop for aiming and compliance checks. The combination of careful selection, precise installation, and routine care will keep the 1994 Mitsubishi 3000GT shining as intended, whether preserved in original form or fitted with modern lighting technology.

For regulatory guidance on vehicle lighting and compliance, consult the appropriate national authority: https://www.nhtsa.gov

Final thoughts

Understanding the intricacies of the 1994 Mitsubishi 3000GT headlights illuminates their critical role in vehicle aesthetics, functionality, and the restoration market. With their unique design and varied configurations, these headlights not only enhance the car’s visual appeal but also represent a significant aspect of automotive history. For business owners involved in maintaining or selling parts for this iconic model, staying informed about these features is essential for meeting customer needs and ensuring compatibility. Emphasizing the significance of proper maintenance can further enhance vehicle longevity and performance, paving the way for successful business operations in this niche.