For business owners in the automotive aftermarket, understanding the specifications and options for the 1999 Mitsubishi 3000GT headlights is essential. This vehicle, known for its iconic pop-up headlight design, combines both aesthetics and functionality, making it a favorite among car enthusiasts and collectors. The original halogen bulbs can now be replaced with advanced options, like LEDs, offering greater visibility and longer lifespans. This article delves into the specifics of the headlights, evaluates aftermarket choices, provides installation guidelines, and includes comparisons of various upgrades. As the automotive industry embraces innovation, equipping your customers with the latest information on 1999 3000GT headlights can boost your business’s relevance and customer satisfaction.

Pop-Up Brilliance Revisited: The 1999 3000GT Headlight System and Its Aftermarket Awakening

The headlights of the 1999 Mitsubishi 3000GT carry more than illumination; they carry a story about an era when performance cars wore their technology as a visible badge. The pop-up headlight design, a defining feature of the model from the mid 90s through the end of the decade, married function with flair in a way that still resonates with enthusiasts today. Under the hood and behind the retractable covers lies a compact, purpose driven system that balanced brightness, aerodynamics, and the theater of driving at night. The combination of halogen light sources, a carefully shaped reflector, and a mechanism that could vanish into the body at speed or stand sentinel at idle created a look that was both menacing and practical. This chapter traces the original specifications, the engineering philosophy behind the pop-up approach, and the ways in which the car’s headlights have continued to influence aftermarket thinking, even as the lighting world has moved toward LEDs and clever, computer assisted beam control.

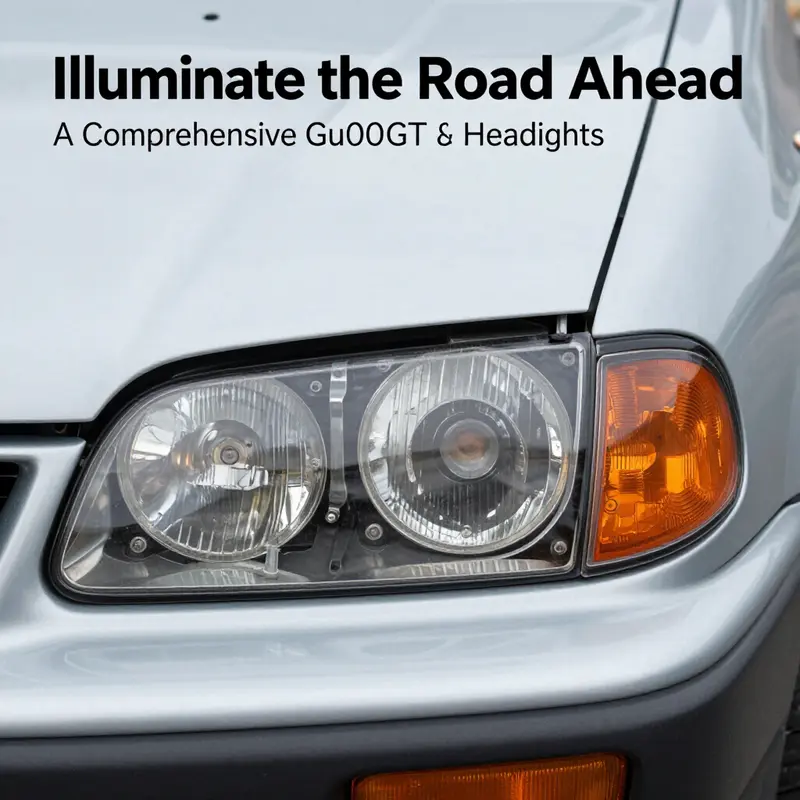

At the core of the 1999 3000GT’s headlight package were halogen lamps. Across the model line, the system used traditional, reliable halogen bulbs with dual filaments designed to deliver both low beam and high beam functionality from a single unit. In the factory configuration, the standard fixtures embraced a pair of dual filament bulbs that combined to offer the necessary illumination for nighttime driving, with the electrical and optical design tuned to the car’s overall performance profile. The historical specification notes a common level of power in the halogen category, with the dual filament arrangement providing both the near and far light outputs required by the driving conditions of the late 90s. The lamps themselves were matched to a reflector and lens assembly that directed light with a focus on broad, uniform spread, while also preserving the distinctive headlight silhouette that could be seen peeking from behind the hood when the car was stationary and the pop-up mechanism retracted.

The control method for these headlights was straightforward yet reliable. Activation could be achieved through a dashboard switch that sent signals to the headlight motors, or in some configurations, via a pull of the lever or a similar user interface. Importantly, the system was designed to automatically raise the lamps when the vehicle started and the transmission engaged, ensuring the headlights were visible and ready to illuminate the road as soon as the driver pressed the accelerator. This automatic pop-up behavior was more than a convenience; it helped the car maintain its dramatic front fascia while also delivering the practical benefit of a fully deployed lighting system when the night demanded it. The aerodynamic logic behind the pop-up design was a tangible part of the engineering envelope. When the headlights were retracted, the front end presented a smooth, uninterrupted surface that reduced drag and contributed to the car’s celebrated high speed stability. When extended, the lamps carved a light path forward without imposing a heavy, flat obstruction to the air, maintaining a balance between form and function.

The aesthetic impact of the pop-up headlights cannot be overstated. The 1999 facelift models brought subtle refinements to the front fascia, including a more integrated lower lip and a revised fog light arrangement that reinforced the vehicle’s battle helmet-inspired look. The headlights, in their raised position, hugged the edges of the bumper and air intakes, forming a compact, aggressive front end. In the lowered state, they still hinted at power and presence, the outlines of the lamps serving as a signature cue of the model’s design language. This dual identity—an aggressive, ready stance when up and a sleek, low profile when down—was a key part of the 3000GT’s visual storytelling. The engineering team did not treat the headlights as a mere utility; they treated them as an expressive component that spoke to a customer base that valued speed, precision, and character in equal measure.

For those who study the evolution of automotive lighting, the headlamp assembly of the 1999 3000GT offers a clear snapshot of a transitional moment. Halogen lighting, with its warm, familiar glow and robust durability, dominated this era. The 55 W to 60 W range for dual filament bulbs was typical for low and high beam operation, and the 9005 (HB3) and 9006 (HB4) designations indicated standardized socket and filament configurations that allowed for straightforward replacement in the field. The use of these bulbs harmonized with the car’s electrical system and with the optical design of the reflectors, which together were optimized to maximize light output while ensuring the beam is well controlled on the road ahead. The optical path, with its carefully curved lenses and reflective surfaces, was tuned to minimize stray glare while maintaining adequate distance contrast for quick cornering and high-speed highway driving.

The practical realities of driving at night in a performance coupe of this era further underscore why the pop-up design endured as a defining characteristic. The headlights’ retractable mechanism, while elegant, also required thoughtful maintenance. The motors and linkages that raised and lowered the lamps had to survive daily use and the on/off cycling of the headlight system as the engine started, a sequence that was part ritual and part reliability test. The design team integrated this system with the front end’s overall aerodynamics, ensuring that the components did not become an unnecessary drag or a vulnerability during high-speed runs or adverse weather. The result was a cohesive front fascia that communicated power while delivering practical, measurable benefits in terms of airflow management and visibility.

From the perspective of the modern collector and the garage-based hobbyist, the original headlight package remains a benchmark for how to achieve a strong visual identity without sacrificing daytime practicality. The pop-up mechanism is often cited as a case study in how to reconcile a signature design cue with a modern safety and performance mandate. The front end’s wiring, the switch logic, and the mechanical travel of the lamp housing all side by side with the bumper and air intakes illustrate a holistic approach to design. Even though the factory halogen components have long since gone out of production in most markets, the underlying principles persist in today’s discussions about headlight upgrades. Enthusiasts have long sought ways to preserve the look while improving nighttime visibility, a balance that is particularly delicate when the original housing sits behind a retractable shell.

The aftermarket landscape has responded to this desire with a spectrum of options. One path has been to preserve the factory appearance while modernizing the light source. LED headlight kits, pitched as a means to achieve brighter output, longer life, and lower maintenance, have been adapted to the 1994–1999 3000GT platform. The concept behind these upgrades is straightforward: replace the halogen source with a modern LED array or modules that deliver a crisper white light, while maintaining a similar color temperature to the original lamps so that the overall aesthetic remains recognizable. The practical appeal is not merely about brightness; it is also about endurance and consistency across years of use, including in challenging weather. LEDs can offer extended service intervals and reduced heat buildup within the housing, though integrating them into a pop-up architecture demands careful attention to heat management, resistor or controller requirements, and compatibility with the housing’s sealing and venting schemes. The discussion around compatibility is not merely about the electrical connectors; it also encompasses beam pattern and aiming. A headlight upgrade that quietly shifts the cutoff or misaligns the beam can create glare for oncoming drivers or fail to illuminate at distance in a manner that compromises safety. Consequently, a responsible upgrade plan emphasizes a matched combination of LED module type, ballast strategy, and precise aiming to preserve the functional and legal integrity of the system.

In the aftermarket conversation, durability and weather sealing play a prominent role. Some high-quality upgrade kits come with IP rated housings or assemblies that are designed to resist water intrusion and dust ingress, a consideration that gains importance in climates with heavy rain, snow, or road spray. The housing geometry matters as well; since the 3000GT’s pop-up assembly folds back into the body, the LED or HID components must be compact enough to fit within the available space and must not obstruct the movement of the pop-up mechanism. This constraint has driven the market toward compact LED modules and adaptable mounting brackets that can be secured within the housing while leaving enough space for the glass to seal properly. The result is an upgrade path that preserves the car’s distinctive face while delivering improved visibility, higher reliability, and a modern light output that meets contemporary road standards.

One can still learn a great deal from the factory’s own approach to headlamp design. A key takeaway is that the headlight assembly represents a tightly integrated system in which optical performance, mechanical reliability, and aerodynamic considerations are treated as a single package. The lenses, reflectors, and the housing’s geometry were tuned in concert with the bumper and air intake layout to minimize drag while maximizing the efficiency of light delivery to the road. The 1999 facelift, with its more battle-ready lower lip and refined fog light integration, demonstrates how small changes to the front end can alter the perceived weight and purpose of the vehicle. This is not a mere cosmetic note; it reflects a broader design philosophy that recognizes headlights as an essential element of the car’s strategic communication with the driver and the world at large.

For readers who want a closer look at the specific headlight configurations that shipped with the 95 to 99 models, a detailed resource is available that catalogues the clear glass variants for the driver and passenger sides. This page offers a precise visual and dimensional reference for those seeking to understand what the original units looked like behind the glass and how they sat within the overall assembly. 95-99 Mitsubishi 3000GT SL/VR-4 clear headlights

Beyond maintaining fidelity to the original aesthetic, the modern approach to upgrading these headlights centers on safety and consistency. The LED upgrade path, while exciting, requires careful attention to beam pattern and retrofit compatibility to ensure the car remains compliant with local traffic regulations. It is prudent to verify that any change in light output, color temperature, or beam cutoff does not create glare that would hamper other road users. In many regions, regulators require that the beam pattern remains within defined parameters, and some jurisdictions impose limits on total lumens or peak intensity for on road use. The practical takeaway for any owner contemplating this path is to approach the upgrade as a systems problem: you must consider the light source, the optical housing, the mounting hardware, the electrical wiring, and how all of these interact with the car’s original design goals. A well-planned upgrade will merge the dramatic presence of the pop-up mechanism with the brightness and clarity of modern light technology, preserving the vehicle’s character while enhancing night driving safety.

Ultimately, the 1999 3000GT headlights are more than just a lighting system. They are a statement about an era when form followed performance and when a car’s face could tell a story as compelling as the engine that lay beneath. The halogen pop-up arrangement is a reminder of how engineering constraints, aerodynamic thinking, and aesthetic boldness could converge in a single, iconic feature. The aftermarket response—an embrace of brighter, longer lasting light through LED options and other improvements—reveals a broader shift in how enthusiasts value visibility as part of a car’s overall character. The road warrior identity that the pop-up headlights cultivated remains a touchstone for new builds and restorations alike. When we peer into the night through that original glass, we glimpse not only the road ahead but also a moment in time when headlights could be both machines of precision and symbols of a driving way of life. For those who seek to honor that legacy while embracing the present, the rebuilding and upgrading of these lights offers a path that respects the past while stepping into the future. The conversation around compatibility, safety, and legality continues to shape how owners approach these upgrades, ensuring that the 1999 3000GT can still stand, lit and ready, on the modern road.

External resource for further exploring modern upgrade concepts: For a real world look at an LED headlight kit widely discussed in the aftermarket community, see this external reference LED headlight kit on a popular marketplace.

Beyond the Factory Glow: Aftermarket Headlight Options for the 1999 Mitsubishi 3000GT

The 1999 Mitsubishi 3000GT carries a silhouette and a lighting signature that defined an era of performance aesthetics: the pop-up headlight, a mechanical flourish that married function with drama. In daylight it was a clean, sculpted face, but when night fell, those lenses played a crucial role in shaping the car’s presence on the road. The original setup relied on halogen bulbs, with near lights powered by a 9005 (HB3) and far lights by a 9006 (HB4). This arrangement fulfilled the era’s technical standards while preserving the vehicle’s aerodynamics and distinct shape. As a result, the headlight assemblies were not just light sources; they were an integral part of the 3000GT’s identity. Yet as the years progressed and technology evolved, so did the possibilities for upgrading these lungs-on-wheels to deliver brighter, more efficient night illumination without erasing the car’s classic character. This chapter traces how enthusiasts navigate the world of aftermarket headlight options for the 1999 model, balancing improvements in visibility with a respect for the car’s original design language and the practicalities of installation, legality, and long-term reliability.

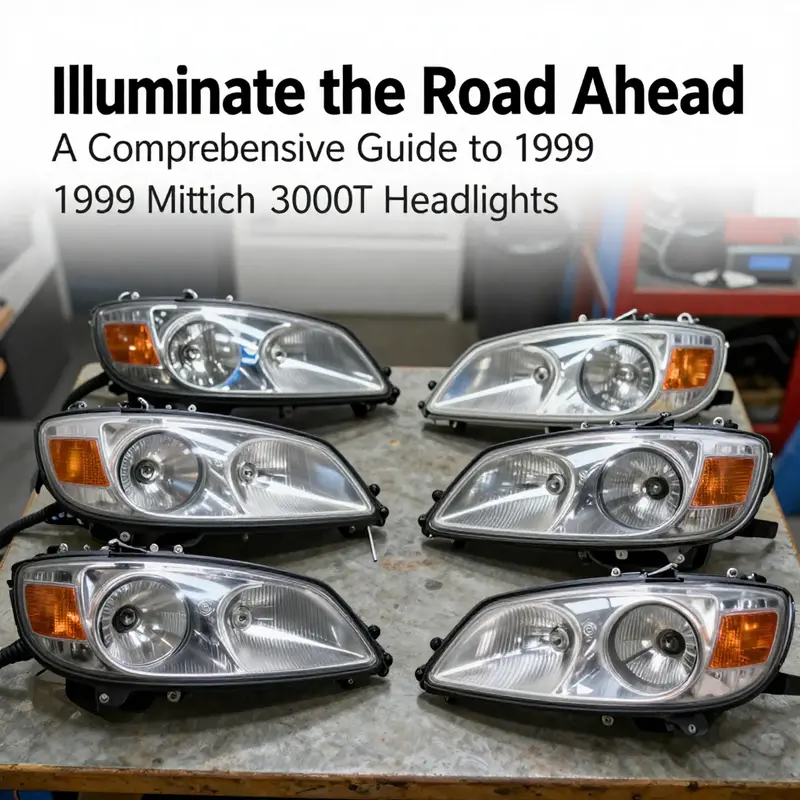

One of the most enduring paths for modernizing the 1999 3000GT headlights is to consider upgrades that preserve the pop-up aesthetic while enhancing performance through contemporary light sources. The decision often comes down to two broad opportunities: replacement headlight assemblies that maintain an OEM-like appearance, and retrofits that replace or augment the internal optics with modern projection and LED or HID technology. Replacement assemblies, particularly those that aim to match the original styling, offer a direct and relatively straightforward route for owners who want to maintain the familiar face of the car. These options minimize the guesswork involved in aligning beam patterns and mounting points because they were designed to fit within the original geometry. However, they may lack the dramatic uplift in brightness that modern light sources can deliver, especially in the case of some older halogen designs.

For those who crave a more pronounced upgrade in visibility, retrofitting the headlight system with contemporary projection and light sources has become a popular path. A two-piece HID projector setup represents a common solution for enthusiasts seeking sharper cutoffs, more precise beam control, and greater nighttime illumination. Conceptually, a projector kit replaces the stock reflector or integrally designed common area with a dedicated projector lens, a pair of mounting hardware pieces, and a ballast-driven lighting source. The appeal lies in the ability to tailor the beam pattern, color temperature, and overall brightness to personal preference while preserving the recognizable silhouette of the 3000GT’s headlight housing. The specific kits used in these conversions are designed to fit a variety of vehicles, but their effectiveness hinges on careful alignment and proper cooling, given the modest space behind the pop-up doors and the need to avoid glare for oncoming drivers. In practice, the installation benefits from a methodical approach that respects the pop-up mechanism and ensures the housing can still close without interference.

Beyond the raw brightness, the aesthetic transformation that aftermarket options can deliver is meaningful. A modern HID projector or LED option can bring a crisp, white light with a clearly defined cutoff. The overall effect is a more contemporary look that still honors the 1999 model’s proportions. For some builders, the aim is to create a hybrid appearance: a headlight assembly that looks factory from a short distance and behaves like a modern, high-performance unit up close. This balance is delicate; it requires attention to the housing’s interior finish, the projector’s alignment, and the color temperature of the light. The temptation to push brightness higher must be weighed against the need to maintain safe and legal beam patterns. Regulations in many regions govern how bright a headlight can be and how the beam is dispersed. When upgrading, a responsible approach is to design light output that improves visibility on the road without creating excessive glare that could compromise safety or violate local standards.

Within the realm of replacement assemblies, OEM-style units remain an attractive option for many owners. These are typically designed to mirror the original look and dimensions, providing a near-direct fit that minimizes the risk of misalignment or clearance issues with the pop-up mechanism. The trade-off is that these units may rely on the same halogen technology or, if upgraded, will require additional modifications to accommodate newer light sources. Availability can vary, and prices can be substantial. In some listings, OEM-style assemblies for the 1999 model are marketed around the upper end of the price spectrum, reflecting their adherence to the original visual language and the demand for authenticity among purists who want an unbroken lineage of design across the car’s lifecycle. The value proposition, then, hinges on whether the owner prioritizes staying truly faithful to the factory look or whether they are willing to adopt a more aggressive, modern appearance that still nods to the car’s heritage.

For those drawn to the classic lines but seeking a definitive step up in performance, a modern retrofit path offers a robust set of benefits. A two-piece HID projector kit, designed for customization, gives the builder a foundation that blends old and new. Such kits typically feature a black housing with chrome or polished bezels, a contemporary projector lens, and a ballast system to power the HID source. The functional gains are clear: a brighter, crisper beam with a more controlled spread, reduced glare, and the potential for a color temperature that suits the driver’s preference. An important practical note is the kit’s warranty and the support it provides. A typical installation comes with a warranty window that can provide peace of mind during the early miles of ownership, which is particularly valuable given the mechanical intricacies of pop-up headlights that must coordinate with the new optics. The practicalities of wiring, heat management, and ensuring the ballast and control electronics operate reliably in a compact, engine-compartment environment demand careful planning. The installer must ensure that ballast cooling is unobstructed and that the wiring harness does not intrude on the hood’s travel path or the pop-up mechanism. In other words, the best outcomes arise when the project is treated as a thoughtful integration rather than a simple swap.

In conversations about these aftermarket paths, the conversation naturally circles back to the balance between function and form. LED options, in particular, promise longer lifespans and brighter output, along with cooler operation in some designs. Yet LED conversions in the context of a 1999 pop-up headlight system introduce a set of distinct challenges. LED boards and modules have different heat dissipation needs, and their compact array configurations can complicate the beam pattern if not properly designed for the housing and reflector geometry. The color temperature—whether a cool white or a slightly warmer tone—also affects the perceived brightness and can alter how the surrounding plastics and lenses read in daylight. The result is a nuanced decision: LED may offer extended life and lower power consumption, but HID projectors can deliver a more conventional lighting feel with a deep, broad reach that many enthusiasts still find appealing for classic cars. As with any modification, the goal is to improve nighttime visibility while preserving the vehicle’s personality, avoiding a look that feels forced or incongruent with the era of the car.

Legal and practical considerations are an essential undercurrent in any discussion about headlight upgrades. Regulations governing beam pattern, brightness, and color temperature vary by jurisdiction, and failing to comply can lead to problems at inspection or with on-road enforcement. A responsible upgrade plan begins with an honest assessment of local rules, followed by a methodical approach to alignment and calibration. The alignment process ensures that the new optics illuminate the road ahead in a way that does not blind oncoming drivers. It often requires a precise procedure, sometimes using a dedicated aiming screen and a level surface, to replicate the original beam pattern as closely as possible while delivering improved performance. This careful approach protects both the driver and other road users, and it preserves the car’s original intent while inviting the modern benefits of today’s lighting technology.

Within the wider ecosystem of replacement and upgrade options, the availability of OEM-style assemblies and retrofit components has expanded significantly. The aftermarket landscape now includes a spectrum of choices that can suit different budgets and aims. Some owners may prefer to maintain a factory-like silhouette by selecting replacement assemblies that mirror the original housing while updating the light source internally. Others may pursue a more aggressive, modern vibe through projector-based HID or LED setups that retain the iconic pop-up design but push the boundaries of performance. The decision often reflects a broader philosophy about the vehicle: should the 1999 3000GT be preserved as a time capsule of late-1990s styling, or should it be updated with contemporary lighting to ensure it remains practical and safe for night driving? Each path has its merits, and each path demands a commitment to fitment integrity, electrical safety, and regulatory compliance.

As a practical note for readers considering these routes, it is worth acknowledging one concrete option that exists within the landscape of OEM-compatible upgrades. A particular set of classic-style headlight assemblies, designed to closely match the early design cues of the 1990s era, can be sourced as direct replacements that require minimal modification to the car’s front end. For those who prioritize this route, there is value in reviewing the condition of aging lenses, ensuring the clear glass is free of pitting, and confirming that the internal reflectors are free from distortion or wear. A careful selection process—factoring in lens clarity, seal integrity, and the overall optical quality—can yield a result that looks authentic and performs reliably.

For readers who want to explore an authentic OEM look while still pursuing improved illumination, the option to source used or refurbished assemblies can be compelling. These units often come with the added benefit of already proven fitment and alignment characteristics, which can reduce the complexity of a retrofit. The decision to pursue this path should include a thorough inspection for moisture intrusion, cracked lenses, and any signs that the housings have warped or degraded over time. When a buyer finds a well-preserved pair, the combination of a familiar exterior and enhanced internal lighting can deliver a satisfying balance between nostalgia and practicality.

To connect with specific examples or options mentioned in discussions about 1999 3000GT headlights, consider reviewing a well-documented example of the OEM-style pathway and its fit with the vehicle’s original geometry. For instance, the 95-99 Mitsubishi 3000GT SL VR4 clear driver and passenger side headlights glass option represents a direct reference point for owners evaluating authenticity alongside performance upgrades. See more details here: 95-99 Mitsubishi 3000GT SL VR4 clear driver/passenger side headlights glass.

In summary, the aftermarket options for the 1999 3000GT headlights offer a spectrum of choices that honor the car’s distinctive pop-up design while elevating night visibility. Whether a purist pursues OEM-style replacements that preserve the original silhouette or a builder pursues a modern retrofit with HID or LED projection, the path chosen should be guided by a respect for the car’s era, a careful approach to beam pattern and legality, and a pragmatic eye for reliability and service life. The chapter’s recurring themes—fitment, safety, and aesthetic balance—remain constant as the landscape of headlight technology continues to evolve, ensuring that the 1999 3000GT continues to meet the road with both the classic charm and the contemporary clarity drivers expect today.

External resource: https://www.ebay.com/sch/i.html?nkw=1999+Mitsubishi+3000GT+headlights&sacat=0&LHTitleDesc=0&odk=1999+Mitsubishi+3000GT+headlights&LH_BIN=1

Illuminating History and Hardware: Replacing and Upgrading the Pop-Up Headlights on the 1999 Mitsubishi 3000GT

Along the courtyard of automotive design, the 1999 Mitsubishi 3000GT stands as a subtle but potent reminder that a headlight is more than a simple light source. Its signature pop-up headlights married form and function in a way that felt futuristic when the car rolled onto the scene years earlier, and by 1999 the design had matured into a refined, aerodynamic profile. The headlights were more than chrome rings and glass; they were a mechanical ballet, a retractable pair that rose like eyes waking at dusk and settled back into the fascia with a quiet efficiency. To understand how to replace or upgrade them, one must first honor the complex intersection of optics, mechanics, and electronics that defines this model. The headlights are tethered to a precise alignment within the bodywork, connected to an intricate circuit that governs not only the high and low beams but the up-and-down motion of the pop-up units themselves. In the 1999 model year, a light revision touched the front end, giving the car a slightly more aggressive stance while preserving the essential pop-up concept that enthusiasts have long celebrated. If you search for any 1994 to 1999 3000GT with the right stance, you’ll likely find that the headlights were a focal point of the visual identity, the feature collectors remember most vividly when recalling the car’s era of design daring. Replacing or upgrading these units, then, is not a mere swap of glass and bulbs; it’s an exercise in preserving a hinge between old-school mechanical elegance and modern lighting demands.

When one considers replacement, the priority should be compatibility. The 1999 3000GT belongs to a family of components that were tuned around a unique set of tolerances and a particular electronic architecture. Opting for OEM parts or components marketed as fully compatible replacements helps to ensure optical alignment, seamless integration with the vehicle’s body lines, and accurate interaction with the car’s control modules. The challenge is not merely the fit of the headlamp housing but the way the unit communicates with the car’s electric system. The pop-up mechanism, in particular, requires correct connection to the motorized leveling system and the sensors that know when the headlights should rise or lower. An installation that neglects these calibrations risks a lean into misalignment where the headlights fail to rise at all or fail to park properly, possibly stressing the mechanical components or creating glare for oncoming drivers. In the presence of a fog of gray area between aftermarket options, the safest path remains grounded: prioritize OEM or certified replacements that have clear compatibility claims with the 1999 model.

The electrical canvass around the headlights is intricate. The switch gear, the signal circuits for the turn indicators, and the high- and low-beam functions are all woven into a common control ecosystem that respects the vehicle’s ECU and its command signals. When the assembly is removed and a new unit is introduced, every connector needs to be traced, every wire must be matched to its counterpart, and every ground must be secure. A slip in this area can lead to erratic beam behavior, flickering, or a nonfunctional pop-up action, leaving a driver in a fragile position when night falls. This is not just a mechanical task; it is a careful electrical rebuild that benefits from a service manual that speaks the language of this car’s architecture. And even with the most precise factory guides, the 3000GT’s unique blend of mechanical linkages and electronic prompts invites the prudent to consider professional installation if there is any doubt about the connection map or the calibration process.

For the hobbyist who wants to look beyond the stock setup, the field of upgrades has grown in parallel with broader lighting technology. LED conversions have become popular in recent years as enthusiasts seek brighter output and longer service life. Yet, replacing halogen front lights with LED modules is not a mere swap. LEDs bring a distinctly different thermal profile, color temperature, and beam pattern. To preserve the car’s safe nighttime performance, an upgrade should be approached with attention to beam cutoff and glare management. A successful LED retrofit in this platform often involves a thoughtfully designed LED module that can be integrated within the existing housing or within a carefully chosen aftermarket assembly that maintains the intended light distribution. The aim is not only brighter light but a beam that respects oncoming traffic and local regulations. The color temperature should be calibrated to a white to cool-white spectrum that provides clarity without washing out the road markers or producing excessive blue glare. The installation should also consider heat dissipation, since LEDs soften in performance if heat is not properly managed. The old housing is often not designed with LED thermal paths in mind, so designers of retrofit kits will either modulate the housing with heat sinks or suggest a revised sealing approach to prevent moisture intrusion that can compromise electronics.

Another layer that buyers must acknowledge concerns the housing and the lens itself. The 1999 model year’s front end presents a charming, sculpted silhouette, and the headlight assemblies are designed to nestle within the surrounding fascia with a clean, integrated line. The market has responded with numerous aftermarket headlight assemblies that promise compatibility with the 1999 3000GT, but the lure of a new look must be weighed against the realities of fit. Many replacement assemblies from the broader market are designed to meet generic dimensions rather than the precise tolerances required by this model’s mounting points and sealing geometry. It matters not only that the external dimensions align but also that the internal reflectors are positioned properly to ensure the light interacts with the road as intended. The reflective surfaces, lens curvature, and internal baffle geometry all contribute to the pattern that drivers rely on for night visibility. When a unit does not align perfectly, the resulting beam pattern can surprise other road users or fail to illuminate critical zones like the edge of the road or the shoulder. Given the relatively short production window of the late 1990s, an authentic look and correct optical performance often demand a careful pairing of housing with the lens and reflector assembly that shares the original design intent.

To bridge the practical with the aspirational, many owners refer to specialized sources and communities that discuss the installation process in granular detail. The installation journey highlights a few non-negotiables: first, confirm OEM compatibility, then verify the mechanical linking of the pop-up motor, and finally secure accurate electrical connections with correct ground paths and ECU communication. A misstep in any of these areas can cascade into a failure that compromises safety and comfort. In this light, the installation of headlights is best treated not as a simple parts swap but as a measured procedure that respects the car’s integrated system. The pop-up mechanism, with its own small motor and linkage, demands not only a secure mounting but a calibration that ensures the mechanism travels the correct travel distance and stops at the precise ready position. A unit that rises unevenly or stalls mid-travel will quickly reveal itself through audible strains or misalignment that can, over time, wear the linkage or the gear train. The careful practitioner will test the full travel sequence multiple times, checking for smoothness, consistent rise, and proper parking symmetry on both sides before finalizing any installation.

In the realm of aftermarket opportunities, there is a broad spectrum of options, from repro headlights designed to mimic factory styling to modernized assemblies that aim to deliver contemporary lighting performance while retaining the classic silhouette. Enthusiasts naturally seek brighter illumination, faster response times, and longer service life, but these upgrades must be balanced against the constraints of legal brightness limits and beam pattern rules in many jurisdictions. A straightforward, yet critical, step in the upgrade process is to review local regulations surrounding headlight modifications. Some regions restrict not only brightness but also the precise shape of the beam, the color temperature, and the presence of additional lighting features. For people who live in areas with strict standards, the safest approach is to work with a kit that provides a clear, documented beam pattern and a reliable method for verifying compliance. This includes a thorough documentation of the original pattern, an option for regulated brightness, and a method to confirm the unit’s alignment with the car’s sensor and drive-by-wire systems. When in doubt, a consult with a professional who understands both classic Mitsubishi design and modern lighting standards can prevent a costly misstep and preserve the car’s road readiness.

As with any major modification, the installation process is as much an art as a science. A patient approach yields the best results: begin with a careful removal of the existing assemblies, taking care to preserve the seals and to document the wiring connections. Labeling wires or taking photographs at key junctions can reduce the guesswork when reconnecting. The next step is to perform a precise test fit before committing to the final screws and sealant. The goal is to confirm, in a dry run, that the housing sits flush with the front panel and that the pop-up mechanism travels without interference with surrounding components. The final steps involve reassembly, a controlled power-on test to verify that the headlights cycle correctly, and a road test to observe the actual light pattern on a dark street. Only after these checks should the owner proceed to a final alignment, ensuring that both headlights illuminate in unison and meet the car’s original optical intent.

For readers who want to visualize the broader process of disassembly, handling electrical connections, and reassembly in a context that transcends the 3000GT, a widely viewed tutorial on headlight upgrades offers practical, widely applicable techniques. While this resource centers on LED tail lights, the disassembly, tool usage, and careful handling of electrical connectors share core principles with front-headlight work. The video highlights the careful sequence of steps and the importance of safety when working with high-voltage or high-current systems, even in a car that uses relatively modest power draw for lighting. Owners can take comfort in recognizing that fundamental practices—disconnecting the battery, working methodically, and testing each connection—apply equally to the front-end headlight upgrade. This broader guidance complements vehicle-specific manuals and underscores the value of approaching upgrades with a methodical mindset rather than a quick swap.

With all these considerations in mind, the 1999 3000GT headlights remain a focal point for both preserving a beloved design and enhancing nighttime visibility. The interplay of optics, mechanics, and electronics is not merely a matter of aesthetics; it is a design philosophy that places safety and reliability at the center while inviting personal expression through modernized lighting. For those who want a hands-on path that respects the car’s original intent, the route often begins with a careful choice of compatible parts and progresses through disciplined installation and precise alignment. The result can be a headlight system that honors the car’s classic lines while delivering improved visibility for decades of night driving. For those who prefer to explore the exact compatibility and available options, a particularly relevant source discusses replacement headlights tailored to the 95-99 generation. Accessing this resource provides a direct bridge to authentic fitment discussions and practical guidance, which can help ensure that an upgrade remains faithful to the model’s original stature while delivering the modern benefits that enthusiasts seek. See the following internal link for a precise, model-specific option: 95-99 Mitsubishi 3000GT SL VR4 clear headlights.

Ultimately, the choice to repair, replace, or upgrade the headlights of a 1999 3000GT is a decision that reflects how a driver views safety, style, and the car’s place in automotive history. The car’s pop-up design is a reminder that function and appearance can converge in a way that remains captivating years after the original launch. The practical pathway—prioritize compatibility, attend to the mechanical and electrical systems, respect legal limits, and approach upgrades with a plan for alignment and safety—ensures the headlights continue to serve as a reliable beacon on night drives while allowing the vehicle’s character to shine through in the glow of well-aimed illumination. As the road stretches ahead, the light from these carefully chosen and expertly installed headlights can be a quiet assurance that a classic design remains alive in the modern world, capable of delivering both the security of good visibility and the pleasure of a well-preserved automotive heritage.

External resource for broader context on lighting upgrades and installation practices can be found here: https://www.tiktok.com/@radwood/video/7365894123456789012

null

null

Final thoughts

By equipping yourself with knowledge about the headlights of the 1999 Mitsubishi 3000GT, you can better serve your customers and help elevate their driving experience. From understanding the specifications and availability of aftermarket options to mastering installation techniques and knowing the best upgrades, this guide prepares you for the evolving demands of automotive enthusiasts. As LED technology becomes increasingly popular, the prospects for enhancing vehicle safety and aesthetics make it a worthwhile consideration for any business owner in the auto parts industry. Embrace these advancements and continue to lead by providing valuable insights into these beloved vehicles.