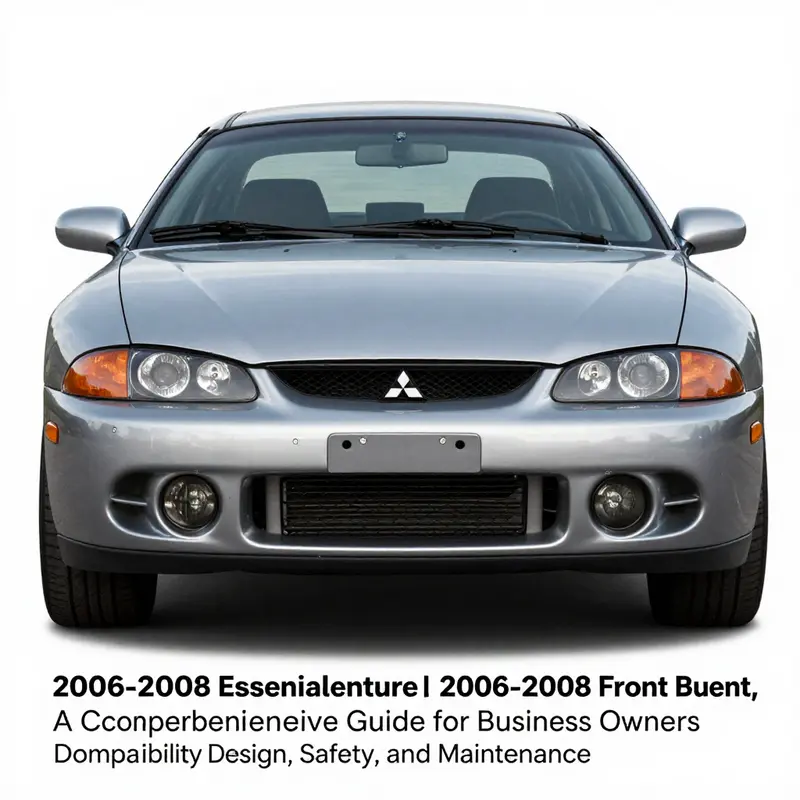

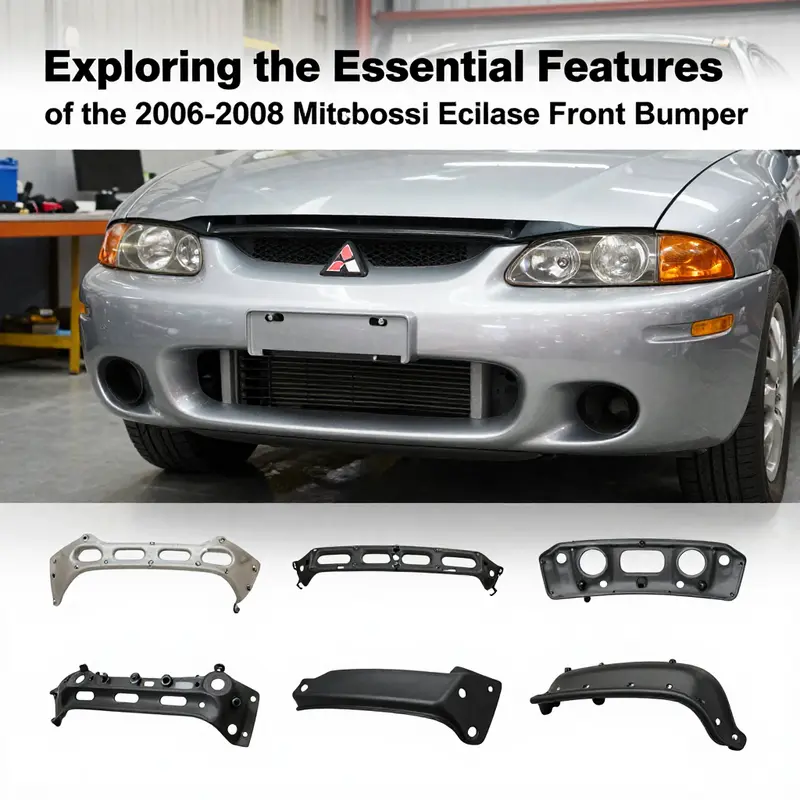

The front bumper of the 2006-2008 Mitsubishi Eclipse plays a crucial role in both aesthetic appeal and safety performance. As business owners in the automotive industry or aftermarket parts sector, understanding the options available for these bumpers can inform better inventory choices and customer solutions. This article delves into four key areas: compatibility and market options, material and design implications, the importance of alignment and safety features, and the procedures for replacement and repair. Together, these chapters provide a holistic view of the front bumper, ensuring you are well-equipped to serve your customers and maintain a competitive edge.

Between OEM Precision and Aftermarket Adaptation: Front Bumper Choices for the 2006–2008 Mitsubishi Eclipse

The front bumper of the 2006–2008 Mitsubishi Eclipse is more than a cosmetic panel; it is a carefully engineered interface between the road and the car’s most exposed under-hood components. It channels air to coolers and engines, accommodates lighting assemblies, and, in modern configurations, integrates sensors and assistive systems that contribute to safety and driver awareness. When that bumper sustains damage, from a parking lot scrape to a stray rock on the highway, it triggers a chain of practical considerations: compatibility, fit, color matching, and the critical calibration needed to keep onboard systems functioning as designed. For owners faced with replacement or upgrade, the decision is both practical and strategic.

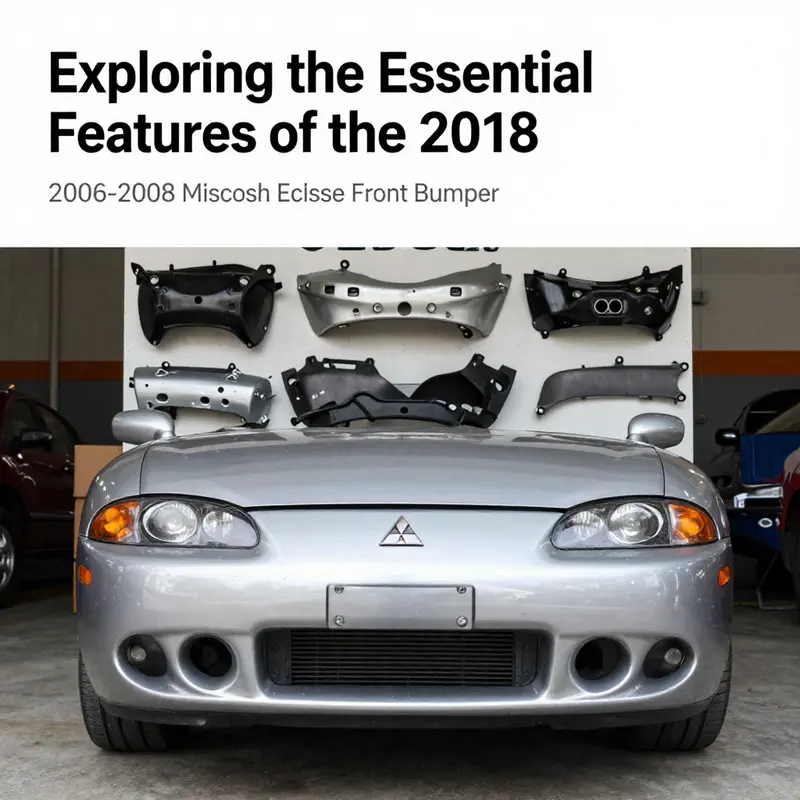

Direct replacements designed to match OEM specifications are the backbone of the repair market for these model years. These bumpers are crafted to align with the Eclipse’s mounting points, preserve the position and size of fog light openings, and maintain the anticipated gap tolerances that affect both visual harmony and sensor performance. In practice, such options are built as direct replacements that can drop into the car with minimal alteration, preserving the factory geometry that ensures proper hood alignment, bumper-to-grill continuity, and seamless body panel lines. They come in a primed state, ready for painting to the vehicle’s color code, which keeps color-matching workflows straightforward for body shops and DIY enthusiasts alike. The primed approach is popular because it allows color matching without committing to a final gloss or texture until the finish is decided, and it reduces the risk of cosmetic mismatches after installation. For owners who prefer a ready-to-spray path, there are also bumper covers finished with a base coat or a painted look that, while slightly more expensive, can shorten the time to a finished exterior appearance.

The market also recognizes the demand for genuine OEM-style parts that emphasize exact replication of the original fit and finish. These direct replacements are designed to mirror the Eclipse’s factory front-end architecture so that the bumper sits where it should, aligns with the radiator support, and allows the headlights and any integrated lighting to sit in their intended positions. In this space, the emphasis is on structural integrity and geometric fidelity. Beyond mere appearance, a properly matched bumper supports the precise angles that affect airflow and cooling, a factor that, in the era of more advanced driver-assistance systems, takes on additional importance. A bumper that is not properly aligned can create unwanted gaps, draw through moisture, or interfere with sensor fields, diminishing the reliability of features such as collision warning or forward-looking radar.

The spectrum of options is not limited to OEM-style pieces. Aftermarket bumpers, designed to resemble the original shape while delivering different materials, finishes, or light-cutouts, offer a way to customize the Eclipse’s face without sacrificing compatibility. In practical terms, aftermarket options have to respect the same core interfaces: mounting tabs, fastener holes, fog light cutouts, sensor housings, and the curved surface that defines the vehicle’s character from the curb. Some aftermarket variants strive for a lighter weight through engineering plastics or composite materials, balancing durability with cost efficiency. Others emphasize a more aggressive aesthetic by widening or reshaping the opening for the fog lights or adjusting the lower valance to enhance the vehicle’s stance. While these directions can be appealing, they also introduce considerations about sensor clearance, bumper reinforcement compatibility, and the need for potential recalibration after installation. The 2006–2008 Eclipse, with its mid-2000s tech profile, sits at an interesting junction where old-school mechanical alignments meet newer sensor-forward design language. In other words, choosing a front bumper for this car is not merely a color and trim exercise; it is a decision about how a vehicle perceives and responds to its environment.

The practical process of sourcing these bumpers tends to be straightforward for those who value direct compatibility. A typical scenario involves bumpers that are primed and ready for color matching, shipped in a non-folded condition to preserve structural integrity. For repair shops, the ability to access a primed, direct-replacement piece through a broad network of retailers helps maintain the integrity of the repair plan, avoids improvisation, and keeps the post-repair appearance aligned with factory standards. It is worth noting that, in the supply chain for these parts, there is an emphasis on verified fitment and compatibility across the Eclipse’s trim spectrum, including common variants found in the GS, GT-P, and GT SE lines. The goal is to deliver a part that not only fills the opening but also preserves the geometry that ensures proper hood fit, headlight alignment, and bumper-to-grill continuity. The practical upshot is that owners can pursue either OEM-like precision or a carefully chosen aftermarket interpretation without sacrificing the ability to service sensors or maintain the car’s visual identity.

From a sourcing perspective, reliable access typically comes through major retailers that offer new, primed bumper covers designed for the 2006–2008 Eclipse. The marketplace recognizes the need for options in both OEM-style and aftermarket families, ensuring a repair or upgrade path that respects the vehicle’s distinctive lines while offering alternatives for color, texture, or materials. The presence of fog light cutouts on these bumpers is a practical reminder of the need for precise fitting: the holes must line up with the existing lighting assemblies, and the paths for wiring and mounting hardware must be clear. When a bumper is damaged and requires replacement, the process reaches beyond simply bolting in a new panel. It often necessitates careful alignment checks and, where sensors are involved, calibration procedures to re-establish the intended field of view. Without this step, even a perfectly fitted bumper can fail to integrate with the car’s safety and driver-assistance systems, compromising performance rather than enhancing it.

A broader look at market dynamics reveals a balance between preserving original specifications and allowing for personal expression. For many Eclipse owners, maintaining a factory-like silhouette is important not only for resale value but for ensuring that the vehicle retains its recognizable identity on the road. Others may view the bumper as an opportunity to refresh the car’s appearance with clean lines or a more modern contour. The choice often hinges on the intended use of the vehicle and the level of commitment to color matching and finish durability. A primed bumper cover can be a prudent choice if the owner or shop plans to apply paint that perfectly matches the vehicle’s original color, finish, and even subtle metallic or pearl tones. Meanwhile, an aftermarket piece may offer a refreshed look or a design tweak that complements updated wheels, lighting, or aero add-ons, while still preserving the essential mounting geometry.

In recommending a sourcing approach, the emphasis should rest on verified compatibility, a clear understanding of the Eclipse’s trim differences, and the supplier’s guidance on installation and sensor integration. The market increasingly favors transparency about fitment and calibration requirements, particularly as front-end technology becomes more sophisticated. For purchasers who value documented fit and a straightforward installation process, consulting official parts databases or trusted automotive suppliers is advisable. A practical path is to verify the model year, the trim designation, and the intended finish, while confirming that the bumper cover includes the necessary openings for fog lights and any integrated sensors or cameras. Moreover, when possible, it can be helpful to review installation guidance or warranty terms that address alignment and calibration. This approach reduces the risk of misfit, minimizes post-purchase frustration, and helps ensure that any replacement bumper will perform as intended in terms of both safety and aesthetics.

To illustrate how these considerations translate into a tangible shopping path, imagine navigating a catalog for a new primed front bumper cover designed to fit 2006–2008 Eclipses. The listing would emphasize the direct replacement nature, the primed finish, and the inclusion of fog light cutouts. It would note that the part ships unpainted to preserve the chance to achieve a precise color match, and it would indicate that the product is designed to align with the Eclipse’s mounting points and sensor housings. The listing might also highlight compatibility with multiple trim levels and stress the importance of careful installation and potential sensor recalibration if necessary. In this ecosystem, the bumper becomes a critical yet approachable element of the vehicle’s repair or upgrade plan—one that balances function, form, and the realities of modern automotive electronics.

For readers who want to explore related content on bumper replacements and how similar parts are managed across Mitsubishi platforms, an adjacent resource offers a broader context about OEM-style bumpers and related hardware for related models. This linked page provides a sense of how manufacturers and suppliers frame compatibility and how second-source parts approach the Eclipse’s front end as part of a wider ecosystem of Mitsubishi components. (03-06 Mitsubishi Evolution 8-9 JDM rear bumper OEM)

External resource: https://www.walmart.com/ip/Primed-Front-Bumper-Cover-For-Mitsubishi-Eclipse-2006-2008/101-50177

null

null

Aligned for Impact and Efficiency: The Front Bumper’s Safety and Aerodynamics on the 2006–2008 Mitsubishi Eclipse

The front bumper of a 2006–2008 Mitsubishi Eclipse is more than a face that greets the road; it is a carefully engineered shield that blends aesthetics with vital safety and performance functions. In this generation, the bumper is expected to respond to a spectrum of demands, from the subtle flows of air around the grille to the harsh consequences of a low-speed collision. When a bumper is properly aligned, it preserves the intended aerodynamic profile, which in turn supports stable handling, fuel efficiency, and a quiet ride at highway speeds. Misalignment, even if it seems minor, can alter the air currents that split and rejoin around the vehicle’s front end. The result can be subtle but meaningful: increased drag, wind noise, or a tendency for the underbody to experience additional lift at speed. The front fascia is therefore not merely cosmetic; it is a functional component that tunes the balance between drag and downforce, warmth and temperature management under the hood, and the overall sense of precision that the Eclipse projects on the road.

In practical terms, alignment matters because the bumper cover is designed to work in concert with a set of closely related systems. It sits over the radiator and condenser package, guiding airflow to cooling cores so the engine maintains optimal operating temperatures even when the car is pressed to its limits by highway climbs or long stretches of desert sun. If the bumper is set off-axis or mounted with even a slight misfit, the result can be muffled cooling, which, in turn, can push the radiator and cooling fans into greater duty cycles. The damage may be incremental rather than dramatic, but over time it can contribute to reduced efficiency and increased heat soak under hard use. In a car like the Eclipse, where the engine bay is compact and the front section carries a high proportion of the vehicle’s frontal stiffness, this is not a trivial consideration.

Beyond aerodynamics and cooling, the bumper is a primary line of defense in the vehicle’s crash energy management system. It is engineered to absorb and dissipate energy in the moments when a low-speed frontal impact occurs, protecting more delicate and expensive components behind it—the headlights, the radiator, and the engine block itself. The energy-absorbing capacity of the bumper is distributed through reinforced zones designed to deform in a predictable way, absorbing energy without transferring the full hit to the rigid frame. Proper installation ensures these deformation zones align with the car’s structural members and with the force paths that the vehicle’s engineers intended. When a bumper is damaged or poorly aligned, these energy paths can shift, risking greater damage to critical components or compromising the bumper’s ability to shield them. In this sense, alignment is not just a matter of appearance; it is a matter of preserving the integrity of the protection system that keeps drivers and passengers safer in the event of a collision.

The 2006–2008 Eclipse front bumper is also a conduit for modern safety features that began to ride more visibly on the vehicle’s under-hood and front-end architecture. Many replacement bumpers are designed to accommodate and maintain compatibility with factory-installed sensors and lighting systems. This means the bumper cover must not only fit the slotting and mounting points precisely but also preserve the calibrated position of any proximity sensors, daytime running lights, fog lights, and camera systems that may be integrated into the bumper or the surrounding fascia. Even small misalignments can shift sensor readouts or create misalignment in lighting, reducing the driver’s visibility or the system’s ability to detect obstacles with accuracy. In vehicles of this era, the emphasis on sensor integrity and lighting alignment continues to be a critical factor in safe operation, ensuring that alerts, adaptive features, and illumination work as intended when they are most needed.

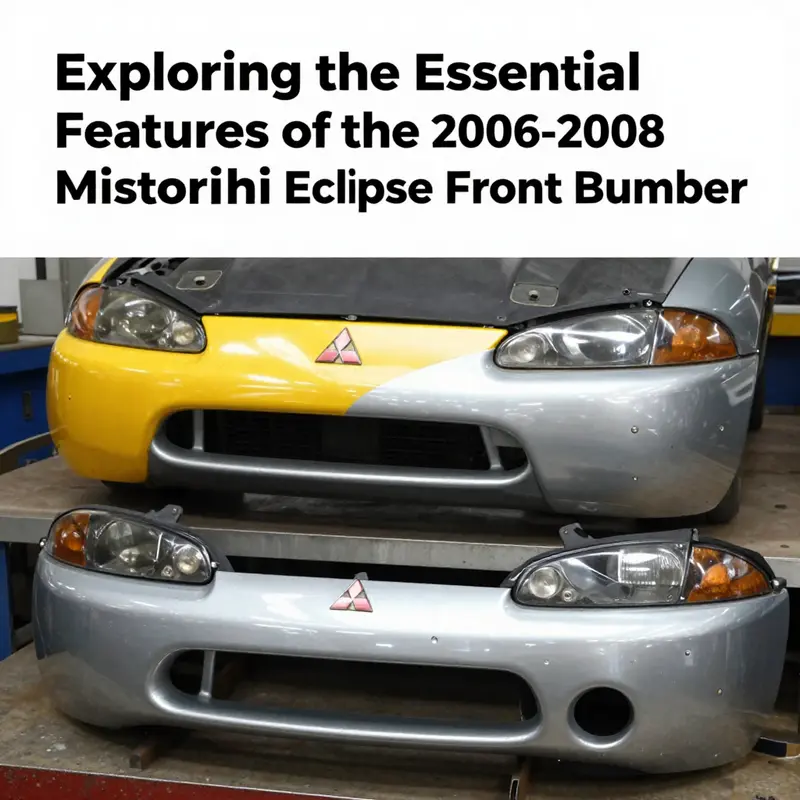

The decision to replace or upgrade a bumper—whether to restore factory performance after an incident or to pursue a fresh look—should be guided by a careful understanding of these safety- and performance-sensitive roles. Replacement parts come in a spectrum that ranges from simple, primed, oe-style covers to more elaborate aftermarket designs that incorporate reinforced structures, upgraded mounting points, and sometimes aesthetic tweaks such as revised grilles or integrated light housings. In all cases, the goal is to maintain or restore the bumper’s original fit and finish so that the alignment, sensor compatibility, and lighting functions are preserved. The primed bumper covers, in particular, are commonly chosen by owners who want a seamless repaint match to the vehicle’s color while ensuring that the surface is well prepared for final finish. Their fitment is typically developed to OE-style specifications, which helps ensure the cover aligns with the vehicle’s mounting points and continues to present a uniform, cohesive front profile.

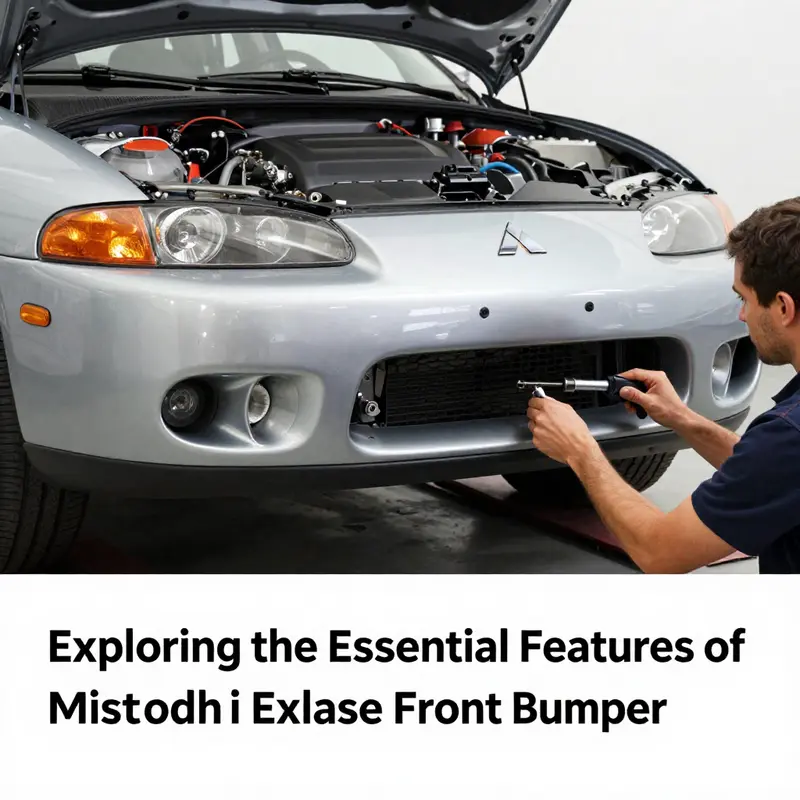

From a practical standpoint, the process of selecting and fitting a front bumper for the Eclipse involves more than selecting a piece that looks right. It requires an assessment of how the bumper will work with the vehicle’s structural supports, crash beams, and attachment hardware. It also requires attention to the stance and the gaps between adjacent panels—the fenders, the hood, and the headlights—so that the overall geometry remains harmonious. When hands-on maintenance or modification is undertaken, the alignment procedure often includes ensuring the bumper cover sits flush with the surrounding body lines and that the lower edge sits at or near the intended height relative to the road surface. This alignment is vital not only for aesthetics, but also for ensuring consistent air sealing across the lower fascia, which can influence downforce and the efficiency of cooling intakes and grilles. As part of the installation, technicians examine the mounting points for any signs of wear, crack, or elongation, because these can subtly shift the cover out of position over time, especially after an impact.

In terms of materials, the standard front bumper in mass-market configurations is typically engineered plastic, chosen for its balance of impact resistance, weight, and production cost. Across the aftermarket spectrum, variations exist. Some higher-end or performance-oriented designs may incorporate reinforced sections or alternative materials in key zones, sometimes with metal grille accents or trim pieces to improve durability or to achieve a particular aesthetic. These choices influence not only weight and appearance but also the way the bumper behaves during a collision and how quickly it can recover its shape or be replaced after an impact. Even with reinforced or upgraded features, the fundamental principles remain: a well-aligned bumper preserves the intended energy management, keeps sensor and light systems functioning correctly, and sustains the vehicle’s visual identity with clean lines and precise gaps. When owners decide to replace a damaged bumper or to upgrade to a primed, ready-to-paint cover, the emphasis should be on a precise fit that restores the original geometry rather than merely swapping out the surface layer. A precise fit ensures that the gap tolerances around the headlights, the grille area, and the lower valance are consistent with factory references, thereby maintaining the car’s designed airflow and the integrity of the lighting and sensor systems.

The practical realities of this generation also involve the installation and subsequent calibration process. Replacement bumpers, particularly those that seal to the car’s front with an integrated sensor or camera interface, may require calibration of adjacent sensors or re-learn procedures for safety systems if the vehicle employs any adaptive or automated features. While the Eclipse of this era did not rely on an ultra-complex sensor suite like some modern vehicles, even basic front sensing technologies and illumination systems demand careful mounting to avoid misreadings or misalignments that could compromise performance. Consequently, many owners opt to have a professional handle alignment and installation, especially when the bumper is primed or painted to match the body. The money saved by a DIY approach can be offset by the potential costs of misalignment that ripple through safety functions and the vehicle’s driving dynamics. The result is a simple but powerful lesson: the bumper’s role in the Eclipse extends beyond the eyes; it anchors a chain of interactions that affect cooling, aerodynamics, safety, and daily drivability.

To connect this discussion to the broader ecosystem of Eclipse customization and maintenance, consider how a related range of components complements the bumper’s function. For example, a related Eclipse modification page—covering a carbon fiber hood—illustrates how owners often pursue integrated front-end customization that preserves the vehicle’s proportions and performance characteristics while offering a more aggressive visual stance. This related piece highlights the continuity between front-end components and how they work together to define a car’s overall identity and behavior on the road. See this related Eclipse enhancement page for a deeper look at how one might pair a performance-oriented hood with the robust, precisely aligned bumper system described here.

For readers who want to explore practical, hands-on guidance on choosing a primed, OE-style replacement bumper cover and understanding the real-world implications of fitment and alignment, a comprehensive reference can be found on major retail platforms. This external resource provides insight into how primed covers come from manufacturers with an eye toward factory-like fitment, while also offering a clear sense of the considerations involved in repainting and installation. While the specific models and fitments vary across years and trims, the underlying principles of alignment, sensor compatibility, and proper mounting apply across the Eclipse lineup and its front-end components. For those seeking to extend the discussion to related aftermarket projects, this chapter connects to the broader narrative of how replacement parts preserve safety and performance while enabling a refreshed, tailored appearance for the Eclipse.

Internal link reference for related Eclipse components and styling packages: 2006-2012 Mitsubishi Eclipse Monster GT-style Carbon Fiber Hood. This link offers a related perspective on how owners often approach a coordinated front-end upgrade, reinforcing the idea that the bumper’s function and appearance sit at the intersection of protection, efficiency, and identity.

External resource for further reading on primed bumper covers and installation considerations: https://www.amazon.com/dp/B07XZ5KJQV. This external reference provides a practical context for understanding the availability and handling of primed replacement options, while underscoring the importance of choosing a part that aligns with OE-style specifications and supports correct fitment and sensor integration without compromising safety or performance.

Seamless Fit, Strong Shield: Replacement and Repair of the 2006–2008 Mitsubishi Eclipse Front Bumper

The front bumper of a 2006–2008 Mitsubishi Eclipse serves a dual purpose: it frames the car’s face and acts as a first line of defense in low-speed impacts, while also anchoring components such as fog lights and, in some builds, sensors and cameras. Across the market, owners encounter a spectrum of options, from factory-style replacements that aim for exact replication of the original geometry to aftermarket covers that promise a cost-effective path to a refreshed look. The decision to repair or replace hinges on several practical factors—alignment accuracy, integration with lighting and driver-assist systems, paint compatibility, and the overall condition of the underlying structure. A well-chosen bumper solution preserves both the vehicle’s aesthetics and its safety performance, ensuring that the Eclipse not only looks right in the driveway but also behaves correctly on the highway. When you embark on replacement or repair, it helps to picture the bumper not as a standalone panel but as a coordinated module that works with adjacent parts—the grille, fenders, headlights, and the radiator support—so that every interface is flush, every seam even, and every component remains functional after reassembly. For owners of the early-mid-2000s Eclipse, the practical route often begins with a choice between aftermarket front bumper covers that arrive pre-primed and ready for refinishing, and more exact OEM-grade options that emphasize original-fitment fidelity. Either path can yield impressive results, but the true test lies in how the piece mates with the car’s existing mounting points and how it handles the realities of wear, road debris, and the occasional collision. The pre-primed option, in particular, is engineered to reduce the time spent sanding and priming before painting, a benefit that many caretakers of these aging cars appreciate, especially when the goal is to restore a seamless paint match with minimal downtime. Yet even a pre-primed cover requires careful preparation, because primer adhesion and paint compatibility depend on surface conditioning, environmental humidity, and the quality of the recoat. The Eclipse’s bumper line for those years features cutouts intended for fog lights and, depending on trim, may hold additional hardware behind the fascia. The fit, then, is as much about electrical plumbing as about sheet metal; a bumper that looks right but disrupts wiring or sensor alignment defeats the purpose of a pristine exterior. The broader automotive landscape around 2006–2008 stresses not just form but function: the bumper’s role in deflecting debris, guiding airflow to the radiator, and maintaining a predictable bumper-to-body alignment for headlights and the hood gaps. In practical terms, this means verifying that any replacement part mirrors the original geometry closely enough to preserve the intended line and contour of the vehicle. The challenge is not merely to bolt a new piece on; it is to ensure that the bumper sits at the correct height relative to the hood line, that the edges align with the fenders, and that the lower valance tolerances are respected so that the vehicle’s aerodynamics remain consistent and the vehicle’s lighting system remains unobstructed. When considering OEM-grade versus aftermarket solutions, it is important to weigh cost against fit and finish. OEM-grade parts are designed to match the base vehicle’s tolerances, and they often provide the clearest path to an undisturbed alignment with the headlights and grille. Aftermarket covers, while typically more affordable, require meticulous attention to mounting points and sometimes additional trimming or adjustments to achieve the same level of precision. In many cases, the purchasing decision reflects a balance between the intended use of the vehicle, the desired appearance, and how much time the owner is willing to devote to refinishing and fitment. The replacement process, whether you opt for a full cover swap or plan a more conservative repair, benefits from a prioritized approach. Start with a clear assessment of the damage: is the bumper structurally compromised, or merely scuffed and dented? If the underlying frame rails are bent, or the bumper mounts show signs of deformation, replacement is the safer path. If the damage is cosmetic—minor scratches, small dents, or edge chipping—a carefully executed repair may suffice and preserve the original panel. The nuance here is that even cosmetic repairs can influence sensor alignment and lighting performance. For example, if fog light housings are damaged, a full replacement might be the most straightforward route to restore both function and appearance. The narrative of a successful bumper swap for the Eclipse begins with tools and preparation. Gather the basics: a complete socket set, screwdrivers, specialty trim tools to lift plastic fasteners without tearing them, a new bumper cover or its OEM-equivalent, and the necessary primer and paint supplies if the replacement part arrives unpainted. It is essential to disconnect the battery as a precaution. This reduces the risk of accidental short circuits when disconnecting fog light wiring or any connectors tucked behind the bumper area. As you remove the old bumper, you’ll encounter a choreography of fasteners: bolts securing the bumper to the frame, clips that anchor it to the fenders, and potentially hidden fasteners behind the grille or under the bumper lip. Patience here saves paint later. When disconnecting electrical connectors for fog lights, do so with care. Labeling the connections can help ensure that reassembly preserves the original wiring path and polarity. The process is as much about maintaining the integrity of the surrounding panels as it is about removing a single piece of plastic. The new bumper, whether aftermarket or OEM-grade, must be aligned with the car’s mounting points before any bolts are torqued. It is not uncommon to perform minor adjustments to the bumper’s position by loosening and then retightening fasteners in a sequence that preserves the gaps along the hood line and the edges along the fenders. Once the new cover is secured, reconnect the electrical harnesses for the fog lights and any sensors, then perform a visual and mechanical check: confirm that there is even gap all around the bumper, verify that the hood latches properly with the new alignment, and ensure that the grille sits squarely within its openings. If the bumper arrives unpainted and primed, the finishing stage becomes part of the replacement project. Sanding the primed surface smooth, applying a high-quality primer, and then applying paint to match the vehicle’s color are precision tasks. The paint must be applied with even coats and adequate drying time to prevent sags and film defects. It is advisable to blend the edges where the bumper meets the fenders to avoid abrupt color transitions. Weather conditions influence the outcome, so controlling temperature and humidity during the refinishing stage improves the likelihood of a durable color match. Even after the cosmetic aspects are completed, a meticulous check remains essential. The Eclipse owner should test all functions that involve the bumper area: the fog lights, the turn signals if they share the same housing, and any sensors that may rely on the bumper’s proximity or structural position. A misalignment can produce false readings in a parking assist system or alter the behavior of any dynamic safety features present in the era’s equipment. The repair path for minor damage follows a different but equally disciplined line. Small dents or scratches can often be treated with body filler, careful sanding, and selective priming and painting. The key here is to maintain uniform feathered edges and avoid over-building in the damaged area, which would create an obvious contour where the repair exists. When choosing to repair rather than replace, treat the bumper as part of a larger system. If the injury has near-surface cracks that extend toward mounting points, it may be safer to replace the bumper entirely rather than attempting a patch that could fail under a future impact. Across both replacement and repair routes, the alignment between the bumper and the rest of the body is non-negotiable. The trim gaps around the edges are signs of a good fit; even small deviations can lead to wind noise at speed, altered lighting alignment, or door or hood interference. In this context, the choice of part matters. OEM-grade pieces tend to maintain tolerances that minimize iterative adjustments, while aftermarket options depend on the precision of the reproduction and the quality of the mounting hardware supplied with the kit. A thoughtful approach to purchasing also includes verifying compatibility with the Eclipse’s trim level and regional differences. The 2006–2008 Eclipse lineup included multiple configurations, and the bumper’s geometry can vary slightly with trim. The fitment insight is that before ordering any replacement, owners should confirm that the part mirrors the original flange points and the general outline of the bumper’s shape. The broader automotive environment around these years shows how critical it is for the bumper to accommodate not just its own mounting but also the surrounding components. For example, the fog light housings and the potential for integrated sensors mean that even a superficially identical cover can behave differently if wiring paths or sensor mounting bosses do not align perfectly. To navigate these complexities, many DIY enthusiasts consult reference pages that discuss OEM and compatible options for similar models, such as pages detailing bumper replacements in related Mitsubishi lines. For those interested in delving deeper into related topics, one such page offers a structured overview of OEM-referenced bumper options: 03-06-mitsubishi-evolution-8-9-jdm-rear-bumper-oem. While the article speaks to a rear bumper in a closely related model line, the discussion about fitment accuracy, the emphasis on matching mounting points, and the caution about sensor alignment translate directly to the Eclipse’s front bumper replacement considerations. Finally, for readers seeking to connect these concepts with real-world parts listings and purchase considerations, an external reference provides a practical context for how a full bumper replacement may appear in a marketplace listing. This resource helps bridge the gap between the theoretical steps outlined here and the actual parts you would receive, including the attention paid to pre-primed surfaces and the importance of a precise color match when repainting the panel. For more context on available listings and how they present the replacement process in a consumer-friendly format, you can view the following external resource: https://www.ebay.com/itm/353971958781.

Final thoughts

In summary, the front bumper for the 2006-2008 Mitsubishi Eclipse is a multifaceted component significant for functionality and safety. Understanding the diverse options in market compatibility, material impacts, and safety alignments ensures that business owners can better serve their clientele, whether through offering replacements, repairs, or upgrades. The detailed procedures for installation and maintenance further underscore the importance of this element in vehicle safety and aesthetics. Providing high-quality products and services in relation to this essential auto part can greatly enhance customer satisfaction and loyalty.