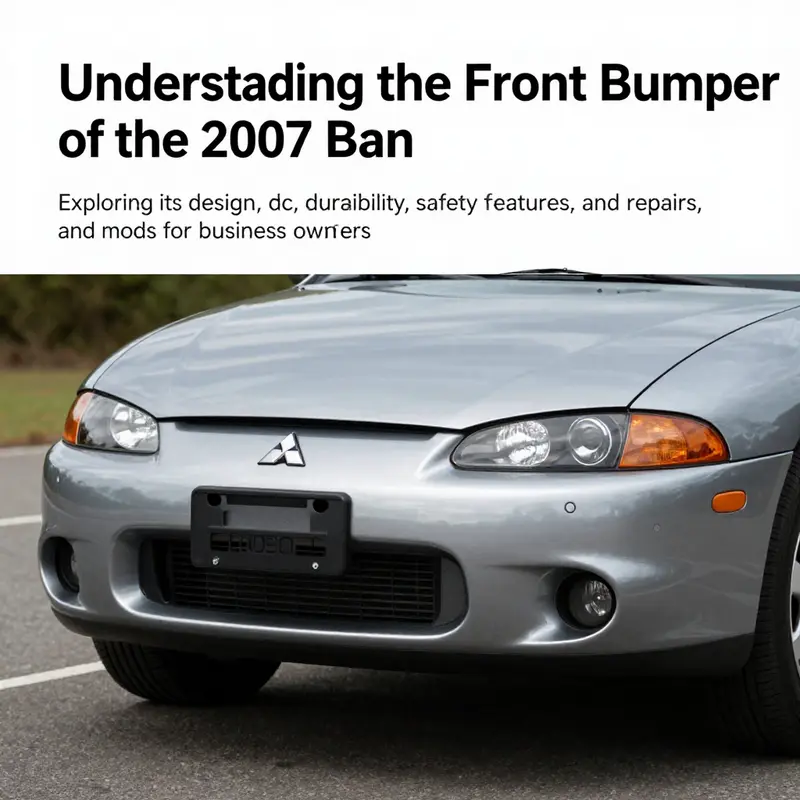

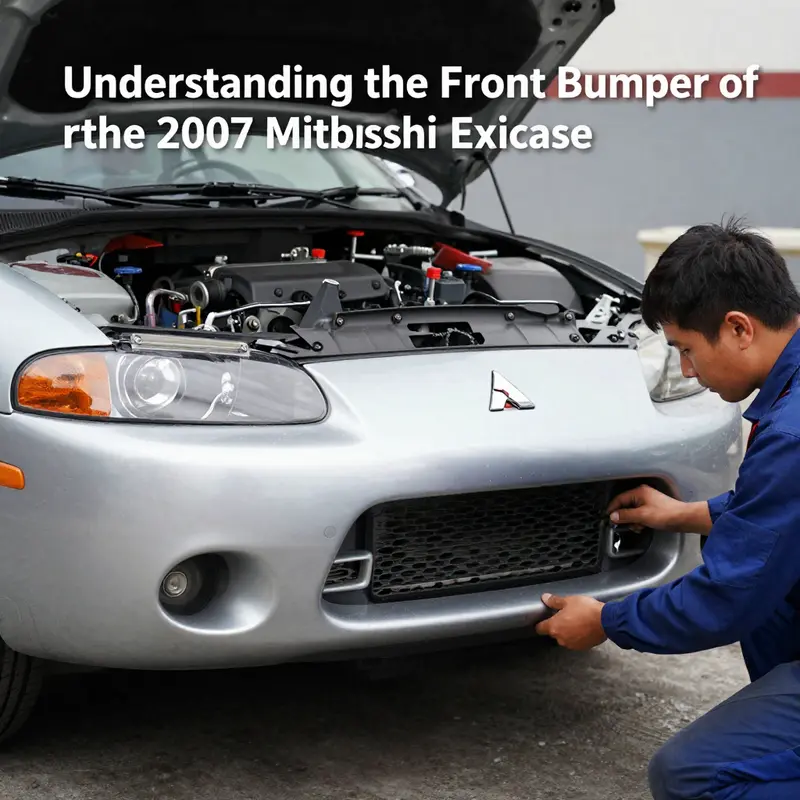

The front bumper of the 2007 Mitsubishi Eclipse is more than just a protective component; it’s a crucial element that blends safety, durability, and design. For business owners involved in automotive services or products, understanding this bumper is essential for maintaining customer satisfaction and safety on the road. In the upcoming chapters, we will delve into its specific design features, material durability, critical safety integration, and the options available for replacement or repair. Each aspect plays a vital role in ensuring that the bumper not only looks good but also performs its intended function effectively, thus supporting the overall mission of providing quality automotive care.

Design Features Reimagined: How the 2007 Mitsubishi Eclipse Front Bumper Shapes Performance and Style

The front bumper of the 2007 Mitsubishi Eclipse is more than a shield against impact; it is a statement of how form and function can align to deliver both everyday practicality and a sprint of performance. In the Eclipse, the bumper acts as the first line of interaction between the road and the car’s intent. Its design embodies an attention to aerodynamics, a respect for durability, and a commitment to modern safety features. When one looks at the bumper, one sees a careful orchestration of elements that together support the car’s dynamic character, winter readiness, and long-term resilience against the elements and road rash. The throughline is simple: the bumper must blend protection with propulsion, aesthetics with accessibility, and engineering with experience on the road.

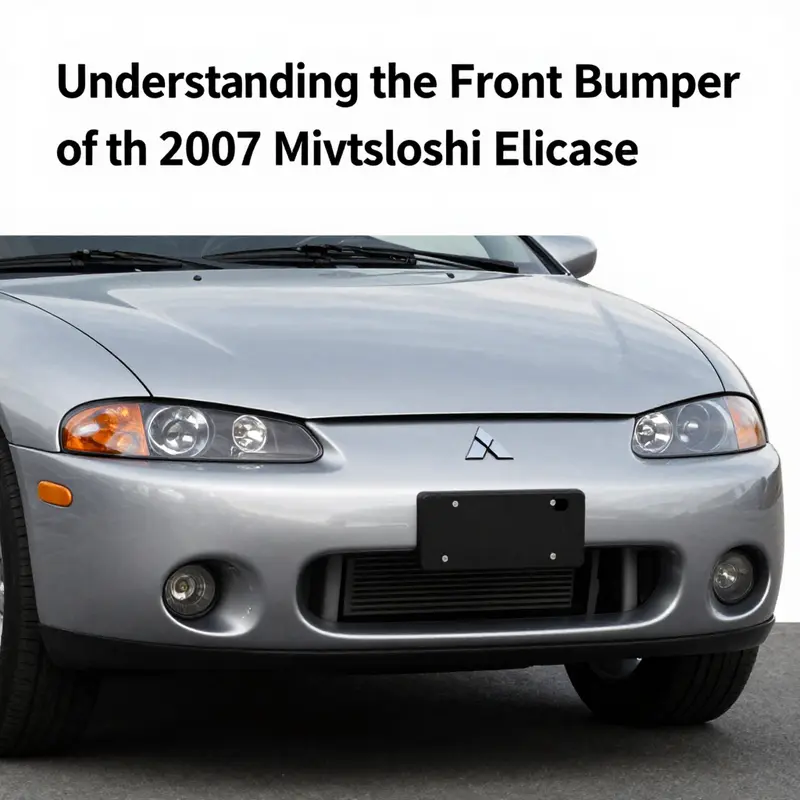

From a functional standpoint, the Eclipse front bumper is shaped to manage airflow around the vehicle with a clear eye toward reducing drag. Aerodynamic efficiency is not just about top speed; it translates into steadier ride quality, improved fuel economy, and better stability in gusty conditions. The streamlined contours channel air to slide past the front fascia, guiding it with subtle rhythms that minimize turbulence. This is not merely about shaving grams or millimeters; it is about creating a cooperative relationship between the car and its environment. In practical terms, reducing air resistance helps the engine work less to push the same distance, which, over the life of the vehicle, can contribute to steadier fuel consumption and a calmer highway experience. Within this design philosophy, every cut, curve, and aperture is purposeful.

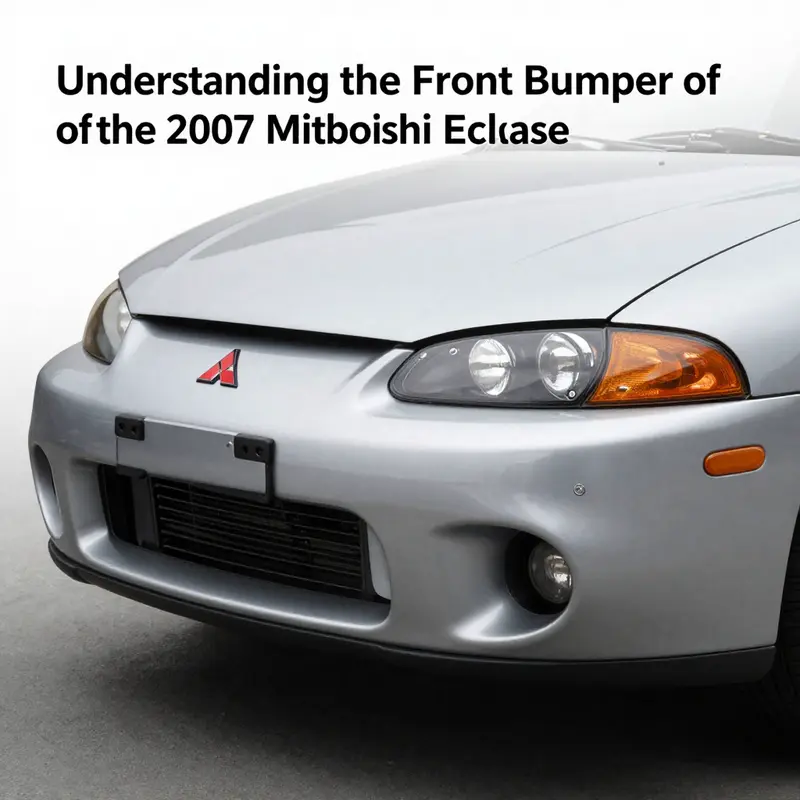

Durability equally defines the Eclipse bumper’s character. The bumper is constructed from materials chosen for resilience in the face of everyday hazards—pebbles, salt, minor collisions, and the seasonal challenges of winter weather. The goal is a balance: a shell tough enough to absorb low-speed impacts and resist environmental exposure, yet flexible enough to avoid transferring every bump into the car’s chassis. This balance matters because the bumper is the first line of defense for components beneath, including the radiator, headlights, and the mounting points that secure critical safety hardware. The notion of durability extends beyond raw rigidity; it encompasses the bumper’s ability to recover its shape after encounters with obstacles like parking curbs or stray debris, maintaining alignment and preserving the integrity of the associated systems.

Aesthetics and safety go hand in hand in this design. The bumper’s integration with fog light housings is a practical example. Fog lights illuminate the path through rain, fog, and snow—conditions that are particularly treacherous in winter months. The bumper’s design ensures these lights are housed securely while remaining accessible for service. The fog light integration is not merely cosmetic; it is a functional feature that enhances visibility without compromising the bumper’s structural goals. Alongside the fog lighting, grille openings play a dual role. They provide essential cooling capacity for the radiator and engine bay while gently shaping the vehicle’s front end to communicate velocity and agility. The grille’s size and proportion are calibrated to channel air effectively, preventing overheating while preserving the Eclipse’s aggressive, sporty character.

The Eclipse’s front bumper also reflects an alignment with the vehicle’s broader safety architecture. In modern drivers’ hands, bumpers are not standalone shells but trusted hosts for a range of sensors, camera systems, and assistive technologies. When sensors rely on precise placement to interpret proximity, pedestrians, or other vehicles, even a small misalignment can degrade performance. This is not merely a nuisance; it can affect the accuracy of collision warning and braking support that many drivers come to rely on. The Eclipse design acknowledges this reality. It is crafted with mounting points and tolerances that preserve sensor geometry and sensor-surface integrity. Repair, replacement, or even routine maintenance then becomes a careful exercise in realigning not just the visible shell but the invisible safety gear that sits just behind or within the bumper’s reach.

To ensure long-term structural integrity, a support reinforcement component exists as a crucial partner to the bumper. This reinforcement acts as a backbone, distributing impact forces and maintaining the correct alignment of the bumper with the rest of the vehicle’s front-end architecture. In practical terms, the reinforcement helps manage the transfer of energy during a minor collision, protecting the radiator, headlights, and other critical components from excessive stress. The presence of a dedicated reinforcement part underscores a broader design philosophy: the bumper is part of a system, not a solitary shield. Its behavior in a collision will be influenced by how well the reinforcement maintains the geometry of the front end, how the impact energy is absorbed, and how the protective layers work together to keep the engine bay intact.

From a historical perspective, the Eclipse’s design language in 2007 sits within a tradition of sporty, dynamic front ends that emphasize motion even when the car is stationary. This is reflected in the bumper’s sporty silhouette, which complements the car’s lines and accentuates its performance-oriented identity. The bumper’s profile contributes to the Eclipse’s overall stance, hinting at the aerodynamic ambitions of the era while staying faithful to a functional, durable construction. The result is a front end that communicates intent—an invitation to drive with confidence and a reassurance that the car is prepared to meet the road’s challenges with both poise and protection.

Engineering specifics behind these design decisions draw from an array of considerations, including material science, manufacturing tolerances, and the environmental realities of driving in varied climates. The bumper’s outer skin must resist abrasion from road debris and endure temperature fluctuations without cracking or warping. Behind the surface lies a network of structural elements designed to distribute energy evenly across broader areas of contact. Such a configuration reduces peak forces at any single point, which is essential for preserving both the bumper’s integrity and the safety systems it houses. In short, the design team sought a harmonious balance: a front that looks assertive and moves with the car, yet yields when needed to soften the blow and protect vital components.

The practical implications of these design choices become especially clear when considering maintenance and replacement. Replacing a damaged bumper is rarely a matter of swapping shells alone. The bumper must work in concert with the reinforcement, the fog light housings, the grille, and the sensors that contribute to active safety. A changed bumper can shift sensor alignment, alter air intake dynamics, or affect lighting aim. For this reason, even routine repairs merit a careful eye toward reestablishing correct geometry. In cases where a bumper has been removed for collision repair or routine replacement, professionals often verify sensor alignment and recalibrate systems to ensure the front-end safety architecture remains fully functional. The Eclipse’s design philosophy thus emphasizes a lifecycle approach: the bumper is not just a wear item but a life-cycle component that participates in a broader system’s reliability.

For readers who want to explore the broader ecosystem of front-end parts and compatibility, it is worth noting that the Eclipse’s bumper design is part of a larger family of front-end components that share common interfaces and mounting philosophies. This compatibility matters when considering replacement options, performance upgrades, or restored condition checks after an impact. A practical takeaway for owners and restorers is that compatibility with reinforcement elements and sensor mounts is as important as the bumper’s outer aesthetics. When selecting a replacement, owners are wise to consider not only the visible shell but also the structural components that ensure safety features and cooling systems continue to function as intended. This approach helps preserve the vehicle’s safety envelope and its driving dynamics long after the initial purchase.

From the perspective of sourcing and reference materials, the design features discussed here are reflected in detailed product listings and official parts catalogs. For example, one can consult a dedicated reference that catalogs front bumper options and their compatibility with the Eclipse’s front-end design. This resource can help buyers understand how a front bumper aligns with the vehicle’s overall geometry, including the mounting points for fog lights, grilles, and sensors. Such references also clarify how the bumper interacts with other front-end components and how to assess fitment during installation.

In the broader narrative of the Eclipse’s design heritage, the bumper emerges as a living artifact of the car’s sporty ethos. Its aerodynamic shaping, rugged durability, and integrated safety elements collectively support the Eclipse’s identity as a confident and capable coupe. The bumper is not merely a protective shell; it is a carefully engineered interface that connects the vehicle’s performance character with the realities of daily driving. It embodies the principle that form and function can coexist, yielding a front end that looks ready for a challenge and behaves predictably when one arrives at it.

For readers seeking deeper technical details or official parts guidance, the official Mitsubishi Parts website remains a reliable resource for authentic front-end components and installation guidance. It is possible to explore genuine parts that are compatible with various Eclipse generations, ensuring that any replacement maintains the integrity of the front-end design and its safety features. As with any critical repair or upgrade, leveraging official sources can help preserve both performance and warranty coverage while offering peace of mind that the car’s protective envelope remains intact. The front bumper, after all, is a keystone of the vehicle’s everyday readiness and its long-term resilience on the road.

In terms of broader context, the Eclipse’s bumper design is a reminder that modern automotive architecture often hides its complexity behind a single exterior surface. What appears to be a simple shield is, in reality, a carefully engineered hub for safety, cooling, lighting, and aerodynamics. The chapter’s focus on design features highlights how a seemingly modest component can influence the car’s energy efficiency, winter usability, and repairability. The Eclipse’s front bumper demonstrates how thoughtful design can deliver a cohesive experience: it protects, it guides, and it enhances the sense of motion that defines the vehicle’s driving experience. The result is a front end that feels both protective and purposeful, inviting drivers to engage the road with confidence.

For a sense of how these design choices translate into real-world engineering, a deeper technical look at specific bumper models and their material compositions can be found in external product listings. These resources offer a window into the materials and construction methods that underlie the bumper’s performance, providing context for why certain choices are made and how they influence longevity under winter driving conditions and daily street use. This broader perspective helps connect the Eclipse’s design features with practical maintenance decisions, enabling owners to evaluate replacement options, alignments, and safety considerations with a clearer understanding of what makes the front end work as it does. An external reference that delves into engineering specifics can be consulted for those who want to examine the bumper’s material makeup and construction details in greater depth.

For further reading and product-level detail, see the external resource: https://www.alibaba.com/product-detail/2007-Mitsubishi-Eclipse-Front-Bumper-385_1601234567890.html?spm=a2700.12112784.0.0.1a2b1c2d3e4f5g. This listing offers a technical perspective on the materials and design language associated with the 2007 Eclipse front bumper in a global marketplace context, illustrating how design features translate into manufacturability and availability across regions. Meanwhile, those seeking more immediate practical guidance can visit the official parts portal to review genuine replacement options and installation instructions, ensuring that the bumper’s intricate relationships with sensors, lighting, and reinforcement systems are preserved in any maintenance or upgrade project. In this way, the Eclipse’s front bumper remains a resilient, expressive, and integral element of the vehicle’s overall design narrative.

Internal reference note: for readers curious about how bumper assemblies align with the broader Eclipse front-end family, a specific example of related components and mounting philosophies can be explored at the internal resource dedicated to the 2006-2012 Mitsubishi Eclipse front bumper. This reference provides practical alignment considerations and compatibility context that can aid in planning repairs or restorations, ensuring that replacements maintain both form and function. 2006-2012 Mitsubishi Eclipse front bumper

Fiberglass Durability in the 2007 Mitsubishi Eclipse Front Bumper

The front bumper of the 2007 Mitsubishi Eclipse serves as more than appearance; it contributes to safety, aerodynamics, and front-end resilience. Designers balance aesthetics with function to absorb and distribute impact while accommodating fog light housings and, in configurations, sensors for modern safety systems. In winter driving, durability protects the radiator, headlights, and other components behind the nose. Understanding what gives the Eclipse bumper staying power—whether it remains factory-installed or is upgraded in the aftermarket—requires looking at material choices, weight versus performance trade-offs, and how these ideas translate to real-world longevity.\n\nFiberglass, commonly used in OEM and aftermarket bumpers of this era, is valued for strength, lightness, and cost efficiency. It can be molded into complex shapes that complement the Eclipse’s lines, helping engineers optimize aerodynamics without a heavy weight penalty. Lighter mass can improve handling and fuel economy, which matters in a compact sports coupe. However, fiberglass is inherently more brittle than some alternatives, especially in hard impacts or very cold conditions. A rigid composite can crack when struck by sharp forces or after temperature swings. The brittleness is not fixed; it depends on the bumper’s design, resin quality, and finishing steps that influence microstructure and surface resilience.\n\nIn daily driving, the bumper performs well on highways and city streets, yet it benefits from prudent maintenance and occasional reinforcement to preserve its protective role. The fiberglass layer helps disperse energy from minor impacts and road debris, acting as a sacrificial shield for more sensitive components. It also invites aftermarket enhancements that improve impact resistance while preserving aesthetics. Upgraded bumpers may use reinforced resin formulations or internal bracing to enhance resilience without a dramatic weight increase, extending service life by reducing crack risk from everyday hazards. When correctly installed, a reinforced fiberglass bumper can deliver reliable performance for many years and is often pre-primed for easier painting and a more durable finish that resists chipping and sun damage, contributing to long-term appearance and protection.\n\nMaintenance and finish quality matter as much as the core material. Proper priming and painting protect the surface from UV exposure, which can degrade resin and lead to chalking or micro-cracking. A well-sealed fiberglass bumper resists weathering that dulls appearance and accelerates surface fatigue. The finish also shields against salt, gravel, and other winter-road aggressors. Without robust protection, even sturdy materials can suffer scuffing and micro-damage that accumulate over seasons, especially at the leading edge where road debris is most aggressive.\n\nThe aftermarket offers options that affect durability, including reinforced resin systems and improved curing methods designed to boost impact resistance and endurance. These improvements aim to reduce crack propagation from minor impacts and maintain structural integrity during frequent parking-lot collisions. A well-executed fiberglass bumper with a reinforced resin system, properly installed, can provide long service life, provided it is not subjected to severe impacts beyond its energy absorption capacity. Aftermarket bumpers are often pre-primed, easing the painting process and yielding a uniform, durable finish that resists chipping and sun damage, contributing to long-term appearance and protection.\n\nOf course, fiberglass is not the only path to durability. Polyurethane or ABS plastic offer greater flexibility and sometimes self-healing properties for minor dents, though they can come at higher costs and require specialized finishing to match OEM color and gloss. Steel bumpers, while extremely durable, add weight and cost that rarely suit the Eclipse’s performance focus. Thus, buyers weigh weight savings and aerodynamics against resilience and cost, choosing fiberglass for lightness and shaping, or polyurethane/ABS for resilience, at the expense of increased price and finishing complexity.\n\nFor the Eclipse, the bumper may also house fog light housings and, in some trims, sensors. Proper alignment ensures lights illuminate correctly and sensors register accurately. Misalignment can reduce visibility or sensor accuracy, especially after a collision or repair. Realignment or recalibration may be necessary to restore full functionality, reinforcing that fit and geometry matter beyond aesthetics.\n\nWhen considering replacement or repair, the material choice influences subsequent decisions. A fiberglass bumper with a solid resin base can be repaired with standard bodywork techniques, including filler, sanding, and sealing, and can be finished to match surrounding panels. With careful preparation, a patched fiberglass panel can look nearly new and continue to shield the front end for many miles. Recalibration may be required if sensors or camera housings are involved, ensuring system readings remain accurate.\n\nOverall, ownership choices reflect a blend of practicality and preference. If the goal is a factory look with predictable fit and known compatibility, a genuine replacement bumper can offer reliable long-term service. For those seeking enhanced aerodynamics, weight savings, or a broader style statement, aftermarket fiberglass options may deliver benefits while still balancing cost and finish work. In any case, compatibility with fog light housings, sensors, and overall front-end geometry remains a guiding principle, with material choice, finish quality, and careful installation determining longevity and driveability through winter and beyond.\n\nFor readers seeking a tangible reference, a compatible bumper page from the Eclipse era provides a design-and-mounting snapshot. See the 2006–2008 Eclipse front bumper page for examples of design language and integration from that period. 2006-2008 Mitsubishi Eclipse front bumper page.\n\nAs with any durability assessment, longevity arises from thoughtful material selection, rigorous finishing, and careful installation. Fiberglass can offer a favorable balance of lightness, formability, and cost when treated and maintained well, even in climates with harsh winters. When replacement or repair is needed, the choice should reflect the right mix of protection, weight, and compatibility with the vehicle’s front-end design, helping the Eclipse maintain its stance while staying protected on the road.

Guarded by Design: The 2007 Mitsubishi Eclipse Front Bumper as a Nexus of Impact Protection, Safety Systems, and Visual Identity

Front bumpers are often overlooked as mere coverings, but on the 2007 Eclipse they are a carefully engineered front line. The bumper is not just a glossy panel; it anchors the vehicle’s safety architecture, frames the light signatures, and defines how the car meets the road in all seasons. Its shape influences aerodynamics, cooling airflow, and even the way the headlights and grille align with each other. When you examine the Eclipse bumper in isolation, you see a compact system that integrates form and function. In practice, this means a component that absorbs energy, shields critical hardware, and projects the vehicle’s personality at a glance. The chapter that follows traces this integration.

One practical consequence of this integrated approach is the inclusion of fog light housings within the bumper assembly. Fog lights aren’t a cosmetic add-on on this model; they are positioned to extend vision in rain, fog, and snow, where low visibility is a real hazard. The housings sit flush with the bumper’s contour, providing a dedicated beam path that supplements the primary headlights. This arrangement helps drivers identify lanes, curbs, and pedestrians earlier in poor conditions. It also demonstrates how the bumper supports driver safety by turning a single component into a small but meaningful enhancement for winter driving. The choice of placement reduces glare and preserves nighttime visibility on winding roads.

Beyond surface resilience, the bumper is part of a broader energy management strategy. The front end is designed to dissipate collision forces in a controlled way, reducing the amount of energy that reaches the radiator, headlights, and engine bay. This energy absorption pathway is not a single element but a staged system that uses the bumper cover and the internal reinforcement to spread and damp shocks. In a frontal impact, the aim is to deform in a manner that absorbs energy while preserving key structures behind it. The result is a safer cabin environment and greater odds that the car can be driven away or brought to a controlled stop without catastrophic damage.

Integral to that energy management is the front bumper reinforcement, a structural feature that serves as the backbone for the assembly. Acting as a load-bearing anchor, it preserves the bumper’s geometry during impact and ensures that the energy is transmitted along predictable paths. This preservation of geometry keeps the lights, sensors, and other front-end components aligned as the car decelerates. If the reinforcement sinks or shifts in a crash, the bumper’s protective sequence can be compromised, with knock-on effects for the rest of the front-end safety package. In short, this element is the quiet guardian of the bumper’s protective function and of the vehicle’s overall crashworthiness.

The bumper cover fascia, the sometimes overlooked outer layer that shapes the vehicle’s face. The fascia does more than frame the logo and lines; it acts as the first line of defense against minor impacts and deflects airflow to support cooling and aerodynamics. The fascia’s stiffness and its connection to internal supports are calibrated to distribute small loads evenly while staying pliant enough to absorb repeated low-energy contacts. When combined with the underlying reinforcement, it forms a cohesive shell that both looks right and behaves responsibly under stress. The fascia and internal components must cooperate to keep the Eclipse looking purposeful after a minor encounter with a parking curb or a stray shopping cart.

Turning to technology, the Eclipse front bumper often anchors sensors and cameras that feed into modern safety systems. The intention is to catch and interpret changes in the vehicle’s surroundings, enabling features like collision warning and adaptive braking assistance. When components are damaged or misaligned, sensor data can drift, leading to degraded performance or false warnings. A bumper replacement or repair thus triggers a calibration step, aligning the hardware with the vehicle’s software. The cost of not realigning can be measured in blind spots or delayed braking responses, which defeats the safety intent of the front-end design. The integration of sensing hardware makes the bumper more than a visible shield; it is a critical node in the car’s awareness network.

From a maintenance perspective, the practical takeaway is about careful installation and verification. A professional approach in replacing or repairing the bumper covers all stages: removing the damaged fascia, inspecting the reinforcement, and reinstalling with correct torque on mounting points. It also requires validating the alignment with any sensors or cameras that live behind the fascia. The process is straightforward for a competent technician, yet it demands attention to the exact positions defined by the original assembly. The goal is to restore the bumper to its designed height and angle, ensuring the fog housings, lights, and sensors fire in harmony. This precision is what preserves the front-end safety envelope across years and miles.

Amid the interest in durability and performance, aftermarket options provide an alternative path for owners who want to tailor the Eclipse front end. Some aftermarket components emphasize stronger materials, improved energy absorption, or different styling cues. Yet these benefits come with caveats. Extra weight or altered mounting geometry can affect ground clearance or the alignment of the bumper with the hood, grille, and fenders. More importantly, any update that touches sensors or cameras may necessitate recalibration by a qualified technician. In practice, the best approach is to treat aftermarket upgrades as a complement to, not a replacement for, the vehicle’s original safety architecture. A well-chosen option can improve durability while preserving the integrity of the front-end system, provided it is fitted and configured correctly.

When discussing authenticity, the case for a genuine front bumper reinforcement designed for the Eclipse is straightforward. A genuine reinforcement supports the bumper in maintaining the vehicle’s crashworthiness, while aligning with the car’s factory mounting points and tolerances. It helps preserve the radiator clearance and headlight alignment and reduces the risk of misfit after a minor frontal incident. Authentic parts are engineered to match the original design intent, including tolerances and the intended load paths during an impact. They also provide a straightforward path to service manuals, torque specifications, and alignment procedures, which simplifies the process for technicians and car owners alike. In short, the genuine route upholds the safety expectations that come with the Eclipse’s front-end architecture and ensures that every layer of protection is compatible with the car’s safety systems.

Beyond the mechanical and safety functions, the bumper is part of the vehicle’s face and its relationship with other front-end elements. The lines where the bumper meets the grille and headlights contribute to a cohesive look that signals capability and resilience. Even when the car is parked in a city stall during winter, the bumper’s form communicates a sense of readiness: a shield that is visible and tangible, yet composed enough to blend with the car’s smooth silhouette. The interplay of light and shadow on the fascia also affects perceived quality, reinforcing that the bumper is a keystone of the Eclipse’s overall design language. The design outcome is a front end that does not merely protect but elevates the driving experience through visual confidence and functional clarity.

From a practical ownership perspective, the lifecycle of the bumper includes routine inspection, prompt replacement after curb scrapes, and timely servicing when front-end components are compromised. Regular checks should verify that the bumper’s bottom edge remains parallel to the ground, that the fog light housings are intact, and that the protective elements behind the fascia show no signs of misalignment. It is easy to overlook the bumper in favor of more dramatic repairs, but the long-term health of the Eclipse’s front end depends on maintaining this shield’s integrity. When the bumper is in good shape, it contributes to reliable winter visibility, steady sensor performance, and consistent front-end alignment, all of which make the difference between a safe drive and a compromised one.

To connect this discussion to practical resources, consider the direct-fit replacement options that are commonly encountered in the market. For a sense of how the Eclipse’s front bumper is positioned within the broader component ecosystem, see this page: 2006-2008 Mitsubishi Eclipse front bumper. It offers a grounded look at how a replacement part aligns with the car’s front-end assembly, showing mounting points, reinforcement interfaces, and the relationship to the associated lighting and sensor hardware. This page illustrates the balance between preserving original engineering intent and enabling options for owners who need to restore front-end functionality after damage.

External resource: https://www.aliexpress.com/item/1005004693835465.html

Guarding the Front Line: Replacement and Repair Pathways for the 2007 Mitsubishi Eclipse Front Bumper

The front bumper is more than a cosmetic staple on the 2007 Mitsubishi Eclipse; it is the first line of defense that shields critical components from impact, abrasion, and the staggered realities of winter driving. In storms of rain, fog, or snow, the bumper’s design works in concert with integrated lighting and sometimes sensors to maintain visibility and reaction time. Fog light housings, recessed in the bumper assembly, are not merely decorative; they extend the driver’s range of vision when weather reduces clarity. The bumper’s material choice matters here, too. A durable composite or polymer blend resists road debris and environmental exposure, reducing the chance that a random tire strike or a salt-slicked curb will compromise the car’s front end. Yet durability alone does not guarantee long-term performance. Proper alignment is essential, especially for vehicles that rely on sensors or camera-based safety features embedded near the bumper. When misaligned, even small gaps or misfitting panels can skew sensor readings or create uneven lighting, undermining the very protections the bumper is meant to support.

Damage to the front end can arrive as a parking-lot scrape, a low-speed collision, or even a misjudged curb strike. In these moments, owners face a practical choice between repair and replacement. The Eclipse’s front bumper is a component with multiple responsibilities: it bears the load of minor impacts, supports the headlights and radiator area, and forms a sealing interface against the elements. When this interface is compromised, the decision is rarely about looks alone. It is about restoring structural integrity, preserving alignment, and ensuring the safety systems continue to perform as designed. The path chosen often turns on the extent of damage, the presence of any mounting hardware that may have bent or cracked, and whether the bumper houses sensors or active safety components that require precise re-integration after work.

For those seeking to restore factory-grade compatibility, Genuine OEM routes remain a compelling option. A genuine front bumper reinforcement, designed to integrate with the Eclipse’s chassis and protective architecture, offers a precise fit and factory-quality durability. The reinforcement plays a key role in maintaining the bumper’s protective function, helping to cradle downstream components like the radiator, headlights, and the energy-absorbing structure behind the fascia. The appeal of OEM parts lies in their predictable fit, tested compatibility, and a structural integrity that aligns with the vehicle’s original design intent. The trade-off is commonly cost. OEM reinforcement or related components tend to sit at a higher price point than some aftermarket alternatives, reflecting their factory-spec geometry and engineering standards. Yet for owners prioritizing alignment accuracy and long-term reliability, the investment can be a prudent choice, especially when the goal is to minimize fit issues that might arise later from a less precise replacement.

If the path to restoration leans toward aftermarket or non-OEM options, the landscape broadens considerably. Aftermarket front bumper covers, including direct replacements and primed shells ready for paint, are widely available for the Eclipse era. A direct replacement bumper cover can restore the vehicle’s appearance and structural integrity without the higher cost of OEM reinforcements. These parts are designed to match factory specifications closely, preserving the vehicle’s lines and mount points so that the bumper sits correctly against the grille, fenders, and undercarriage. Primed direct replacements offer a streamlined aesthetic workflow: they arrive in a ready-to-paint state, reducing the preparation work needed before color matching. For a DIY enthusiast, that ready-to-paint convenience can be a significant advantage, provided the installer has the tools and technique to achieve a seamless finish. For others, these parts still represent a solid option to bring the Eclipse back to road-ready condition without the premium of OEM hardware.

Another option worth considering is a complete bumper cover kit. These kits include the bumper shell plus all associated mounting hardware, grilles, and sometimes fog light housings, depending on the package. The advantage of a complete cover is flexibility. With a full shell, a vehicle owner or shop can tailor the look—replacing only the fascia while preserving underlying structure, or opting for a refreshed appearance with a new color profile. This approach can be especially attractive for owners who want to upgrade aesthetics or restore a damaged bumper with a fresher, more modern finish. As with any substantial fascia replacement, the installation demands careful handling to preserve alignment and surface integrity. The mounting points must line up precisely with frame rails, the windshield washer reservoir and radiator shroud should be checked for interference, and any attached sensors or cameras must be recalibrated or reattached with care. In short, the choice between genuine reinforcement, aftermarket direct replacements, and complete bumper covers is a balance of fit, function, cost, and the owner’s willingness to manage installation details.

For those evaluating options, it helps to have a clear sense of the vehicle’s year-specific compatibility. The Eclipse front bumper landscape includes parts designed to fit various year ranges within the mid-2000s to early-2010s span. A practical approach is to identify the exact bumper style that aligns with the car’s generation, then verify mounting points, air intake alignment, fog light housings, and sensor integration requirements. This diligence pays off when the parts arrive, reducing the risk of discovering misaligned holes, misaligned mounting tabs, or incompatible light housings only after the work has begun. The installation itself, whether performed by a professional or a motivated do-it-yourselfer, benefits from careful prep: a clean workspace, proper lighting, and the use of anti-seize compounds on mounting bolts to facilitate future maintenance. A well-executed installation will yield a flush, even fascia, with gaps that are uniform around the perimeter and a seamless look that mirrors the factory appearance.

As part of planning any bumper replacement or repair, it is prudent to consider the broader ecosystem of components that interact with the bumper. The reinforcement behind the bumper, the mounting brackets, the headlight assemblies, and the radiator support all contribute to the overall structural integrity. If a repair involves more than the surface fascia—for example, if brackets or energy-absorbing structures are bent—it may be necessary to inspect and, if needed, replace adjacent components. This approach ensures that the bumper retains its protective role and that the vehicle’s front end remains aligned with the rest of the chassis geometry. When sensors or cameras are involved, realignment after repair becomes a critical step. Modern safety systems rely on precise geometry to interpret environmental cues correctly; a small misalignment can translate into degraded performance or inaccurate readings. In such cases, professional re-calibration is often the safest route to preserving the vehicle’s safety profile.

The decision matrix for replacement versus repair also intersects with practical considerations like time and budget. A factory-style reinforcement or a complete OEM shell might require longer lead times and more specialized installation expertise. Conversely, a primed aftermarket bumper cover or a ready-to-paint shell can shorten the timeline to road readiness, provided the color-matching and surface preparation are handled with care. For many drivers, the goal is to restore the Eclipse’s front-end aesthetics and protective function without a prolonged downtime, while still achieving durable performance that can withstand winter driving and rough pavement. The challenge is to manage expectations about fit and finish. Even with high-quality aftermarket parts, small differences in contour or finish may demand additional refinishing touches, such as precise sanding, priming, or panel alignment checks that go beyond a straightforward swap.

In considering purchasing and installing a replacement or repair kit, it is useful to consult credible references that illustrate compatible configurations and installation considerations. A practical reference to explore compatible bumper options for the mid-2000s Eclipse range can be found on a dedicated parts page that focuses on that exact bumper model. The page highlights a direct replacement option compatible with the era, offering a straightforward path to restoration for drivers who prefer a fit that mirrors the factory profile. This resource helps buyers verify that the chosen part aligns with the Eclipse’s mounting geometry and light housing interfaces, reducing the likelihood of surprises during installation. To connect with this example, readers can visit the dedicated bumper page for the 2006-2008 Eclipse, which provides a concrete illustration of the direct replacement path and its implications for fit and finish. 2006-2008 Mitsubishi Eclipse front bumper.

Beyond the practical mechanics and fit, the decision to replace or repair also intersects with aesthetic goals. A bumper that sits perfectly in alignment, with even gaps around the grille and fenders, conveys a sense of care and maintenance that extends beyond superficial appearance. The right choice depends on the severity of damage, the age of the vehicle, and the owner’s long-term plans for the Eclipse. Some drivers may intend to keep the car for years to come and therefore prioritize a robust, OEM-aligned repair path that preserves resale value and the integrity of the safety systems. Others may opt for a more economical route, accepting a slightly different look if it means getting back on the road quickly. Either way, the decision should be grounded in a careful assessment of the bumper’s underlying structure, the condition of the mounting hardware, and the potential need for sensor recalibration after any repair or replacement work.

The topic of front bumper replacement and repair is not merely an exercise in finding a part and bolting it on. It is a careful orchestration of fit, finish, safety, and long-term performance. Each option—OEM reinforcement, aftermarket direct replacements, or complete bumper covers—carries its own set of considerations about how the part will interact with the Eclipse’s front-end architecture. The winter road environment intensifies the need for solid protection and reliable visibility, making the bumper’s role even more central. In this sense, the front bumper is both a functional pillar and a patient partner in the vehicle’s evolving story—one that demands respect for its position on the car and the safety it is intended to safeguard. As owners weigh the trade-offs between cost, time, and preserved factory geometry, the ultimate aim remains consistent: to restore the Eclipse’s front profile, maintain its protective envelope, and ensure that the vehicle continues to perform as designed when the roads demand it most.

External resource for further guidance on official parts and up-to-date compatibility can be found here: https://parts.mitsubishicars.com

Final thoughts

The front bumper of the 2007 Mitsubishi Eclipse is integral to the vehicle’s aesthetic and functional performance. By understanding its design features, material durability, impact protection capabilities, and the available options for repair and replacement, business owners can better serve their customers’ needs and ensure their vehicles remain safe and stylish. Staying informed about these aspects not only enhances customer satisfaction but also promotes long-term vehicle health, ultimately supporting a thriving automotive service business.