The rear bumper of the Mitsubishi Lancer Evolution X, manufactured from 2008 to 2015, serves as both an essential structural component and a vital element in vehicle aesthetics. For business owners in the automotive sector, understanding the various options for these bumpers—from OEM parts to high-performance aftermarket upgrades—is crucial. This guide explores the different types of rear bumpers available, the customization opportunities that add value to the vehicle, material choices that determine performance and durability, and key considerations for installation. By delving into these aspects, business owners can make informed decisions that enhance their offerings and meet customer demands effectively.

null

null

Sculpting the Evo X’s Backside: Aesthetic and Aerodynamic Rear Bumper Customization (2008–2015)

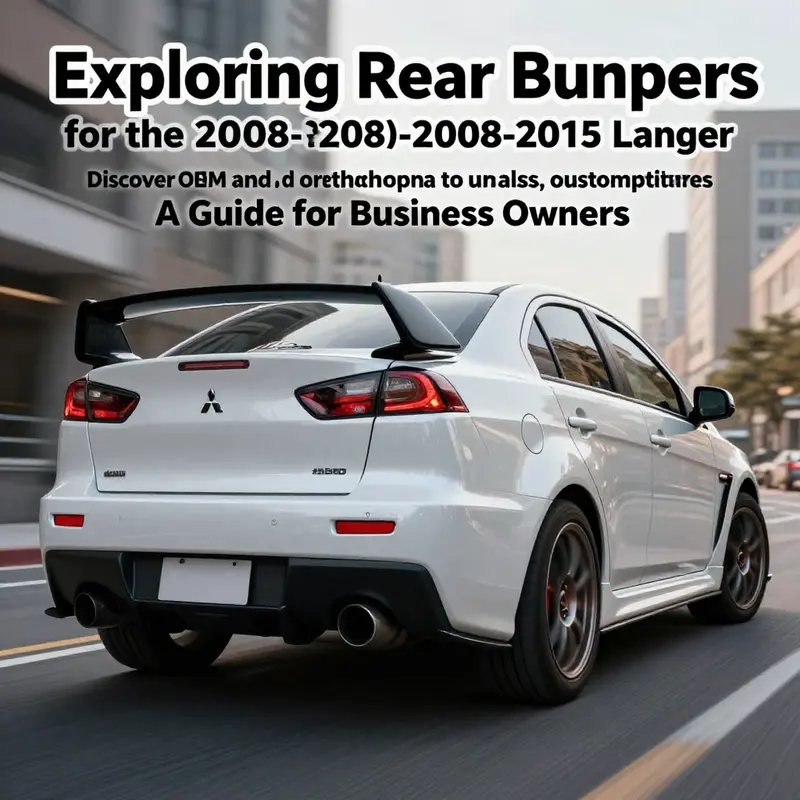

The Mitsubishi Lancer Evolution X, produced from 2008 through 2015, carved a distinct identity in the world of compact performance cars. Its rear end, with taut lines and a downturned stance, acts as a visual anchor for the whole silhouette. But the rear bumper is far more than a visual statement. It defines how the car breathes at speed, how air follows the car’s wake, and how the light catches the car’s tail in a way that turns heads on the street or on the track. Enthusiasts who want to personalize this aspect of the Evo X are drawn not only to looks, but to a deeper blend of aesthetics and function. The rear bumper becomes a canvas for expressing aggression, refinement, and a track-ready readiness that stays coherent with the car’s inherently bold character. Across the 2008–2015 window, a thriving aftermarket ecosystem emerged to address that desire, offering everything from refined styling tweaks to full-on aero packages. The goal remained the same: to preserve the Evo X’s sharp, purposeful lines while pushing the visual and aerodynamic envelope just enough to stand out without feeling contrived. In this precise balance, the rear bumper becomes more than a cover—it’s a strategic interface between the car’s form and its performance ambitions.

Customization options for the Evo X rear bumper span a broad spectrum, but they share a common thread: the pursuit of a factory-finished, high-performance look that requires careful fit and thoughtful material choice. At the subtler end of the spectrum, owners can opt for aesthetic refinements that refine the edge of the bumper or emphasize its existing contours. These adjustments can include redesigned diffuser elements, tailored side vents, or integrated accents that reinforce the car’s muscular stance without altering its fundamental shape. Yet for many, the true wow factor comes from swapping to more aggressive, race-inspired pieces that preserve the Evo X’s signature geometry while exaggerating its stance. For examples of this direction, imagine upgrades that extend the bumper’s lower section or alter its rear profile to better channel air toward a diffuser or exhaust area. In practice, the range of options allows a driver to dial in a look that’s both bold and cohesive with the vehicle’s overall aesthetic narrative.

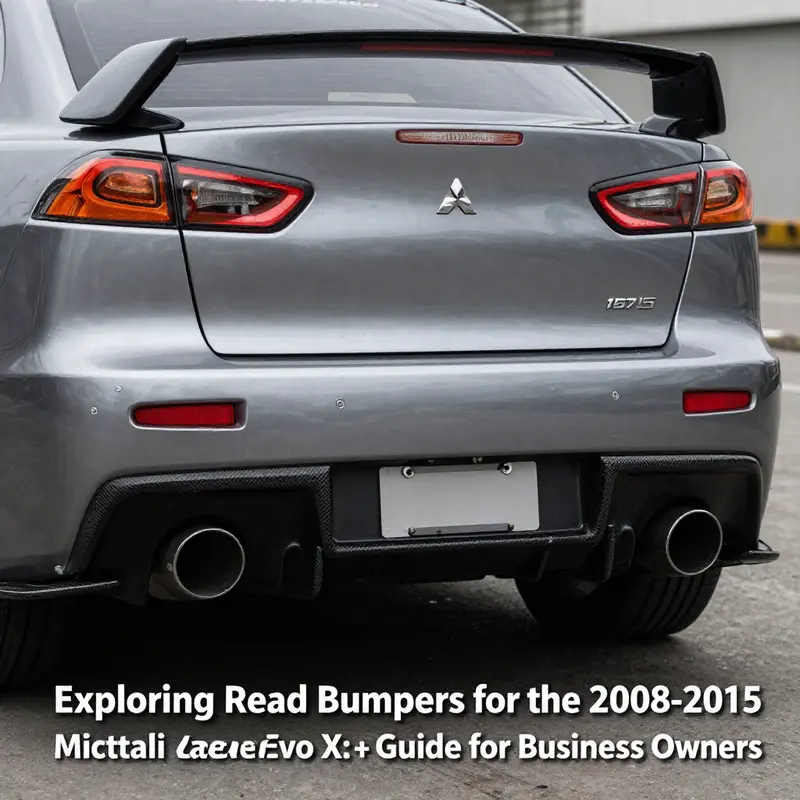

Material technology has evolved in tandem with design ambitions. Carbon fiber extensions and reinforced fiberglass bumpers sit at opposite ends of a shared goal: strength with a favorable weight profile. Carbon fiber extensions provide a premium appearance and a discerning, race-bred texture that complements the Evo X’s angular creases. They are designed to tuck into the factory geometry with minimal modification, preserving the bumper’s fit while delivering a visual depth that catches the eye from multiple angles. These extensions don’t just look lighter; they contribute to a perception of precision and performance. On the other side, reinforced fiberglass bumpers offer a more budget-friendly pathway to a broader, more assertive rear end. They can mimic the visual punch of higher-end options while providing compatible mounting surfaces and a sturdy core that handles daily driving and occasional track sessions alike. The trade-off, of course, lies in weight and finish, but for many builds, fiberglass remains a satisfying middle ground that embraces the Evo X’s hard-edged personality without overpowering it.

Aerospace-grade or sport-grade polypropylene, used in many conversion bumpers, represents another core path for Evo X owners chasing a distinct silhouette. Polypropylene-based bumpers are popular for their lightness and price point. They can be molded into shapes that echo the Evo X’s aggressive lines, while still delivering an overall reduction in mass compared with traditional sheet metal. In practice, these bumpers often feature redesigned diffusers, integrated exhaust outlets, and bold side intakes that amplify the car’s muscular stance. The visual impact is immediate, and the weight savings are meaningful on a car that thrives on balance between power and handling. The choice between carbon fiber and PP-based designs often centers on intent and budget: a purist, track-focused build may lean toward carbon fiber for the look and weight savings, while a street-driven project might favor PP’s cost-to-impact ratio and ease of installation. In either case, the goal is a body kit that respects the Evo X’s original proportions while pushing the rear end into a new, more purposeful profile.

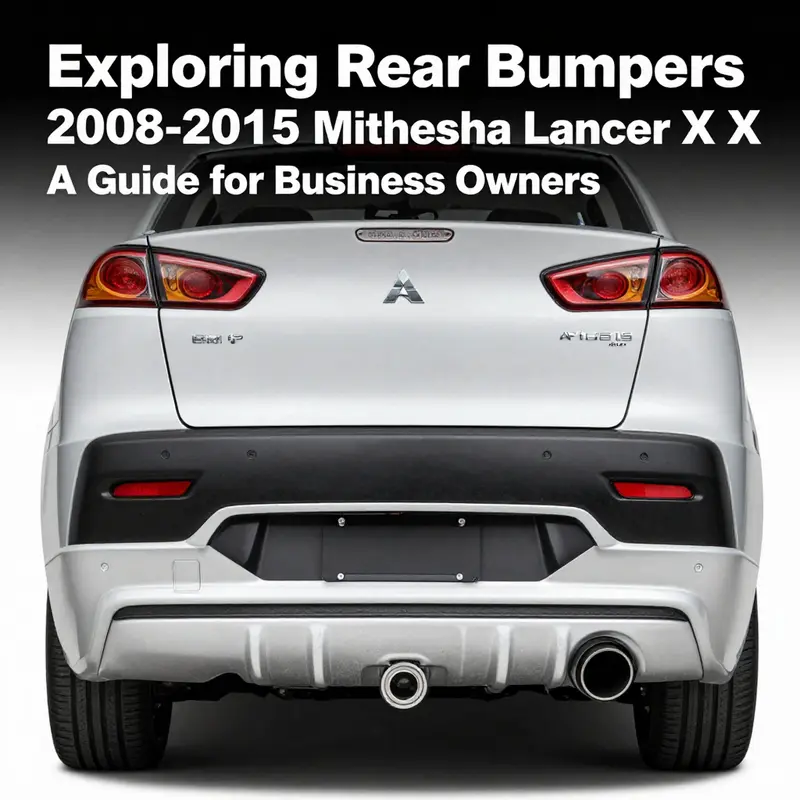

The practical realities of installation and fitment play a pivotal role in whether a rear bumper modification truly pays off. The Evo X’s rear architecture is relatively modular, but it is not a plug-and-play system for every off-the-shelf part. Subtle gaps, mismatches around the taillights, or misaligned diffuser cutouts can undermine the intended look and performance gains. Therefore, buyers often expect some preparatory work: light sanding to achieve a seamless surface, gap filling to address minor deviations between aftermarket pieces and the factory body lines, and, in some cases, minor bodywork to ensure a flawless finish after paint. This is where the dialogue between the part and the car becomes most critical. A bumper that fits well and chemistry-checks with the factory light clusters will look as if it rolled out of the factory in a limited-edition variant, while a poorly prepared install can make even the most impressive design feel half-baked.

Another layer of consideration centers on authenticity and provenance. Some Evo X owners look toward regional manufacturing hubs where injection molding and paint processes can deliver consistent results at scale. For example, parts sourced from manufacturers in a major Chinese province known for automotive accessories can offer high-quality replicas that stay faithful to the original lines and also benefit from rapid production cycles. The proximity of molding, tooling, and paint facilities means faster turnaround from order to fitment and more uniform color matching when repainting is needed. Yet, with any aftermarket path—whether carbon fiber, fiberglass, or PP-based designs—there is value in verifying compatibility with the Evo X’s rear bumper assembly and ensuring that the chosen option aligns with the vehicle’s overall weight distribution and aerodynamic goals. Enthusiasts who take the time to confirm fitment before purchase often save time and avoid the frustration of parts that require significant modification just to align with factory mounting points.

Aesthetics in this space are inseparable from aerodynamics. The Evo X is known for its sharp lines and deliberate air management cues. When a rear bumper is redesigned or extended, those cues must be carefully echoed in the diffuser geometry and the contours that feed air to the underbody and rear wing or spoiler setup. The result is a coherent silhouette in which every line appears intentional rather than cosmetic. In practice, a well-chosen rear bumper upgrade can create a more aggressive visual profile without sacrificing the car’s stability or its ability to maintain predictable handling at speed. For track-focused builds, the added diffuser language and tighter, sportier stance can reduce turbulence at the rear and potentially improve high-speed cornering behavior. For street-driven cars, the improvement may manifest as a more purposeful rear presence that enhances street credibility while remaining within the bounds of daily usability.

For readers curious about OEM-oriented options from earlier Evolution generations, see the 03-06 Mitsubishi Evolution 8-9 JDM rear bumper OEM page. This reference helps illustrate how rear-end design language has long informed compatibility, fitment, and the potential for cross-generation styling cues. The Evo X’s rear end benefits from this lineage, as designers and builders often integrate ideas from earlier models to maintain a sense of continuity in the Evolution family while pushing forward with modern materials and manufacturing techniques. The result is a spectrum of choices that lets a builder tailor the rear end toward a look that feels both authentic to the Evolution lineage and distinctly contemporary in execution.

In the end, aesthetic enhancements to the Evo X rear bumper are about more than surface appeal. They are about creating a visual and tactile impression of speed, precision, and care. Each option—whether a carbon fiber extension, a reinforced fiberglass bumper, or a PP-based conversion piece—speaks to a particular vision of how the Evolution X should present itself at rest and in motion. The best builds achieve a seamless integration with the car’s body lines, a sense of weight balance that complements the powertrain, and a finish that stands up to the demands of real-world driving. The journey from stock bumper to customized rear end is a craft, one that requires an eye for proportion, a respect for engineering realities, and a willingness to engage with a dynamic aftermarket ecosystem that thrives on the Evo X’s enduring appeal. The result can be a rear end that not only turns heads but also serves the broader goals of handling, aerodynamics, and personal expression. External research and user feedback emphasize that the most satisfying transformations emerge when fitment, finish, and function are all in harmony, rather than when one element dominates at the expense of the others.

For those who want to explore practical fitment and a deeper understanding of rear bumper options, the following resource provides a concrete example of aftermarket conversion concepts tied to the Evo X era: https://mitsubishiautopartsshop.com/03-06-mitsubishi-evolution-8-9-jdm-rear-bumper-oem/. This link illustrates how, even across generations, the rear-end language of the Evolution family informs the design and the installation realities that enthusiasts must navigate when crafting their own unique Evo X look. As the chapter moves forward, readers will encounter more about how to balance personal taste with mechanical reliability, and how to choose an approach that preserves the car’s handling and structural integrity while delivering a striking rear-end statement.

External resource: External Amazon listing

Material Matters: How Polypropylene, Glass Fiber, and Carbon Fiber Shape the 2008–2015 Mitsubishi Lancer Evo X Rear Bumpers

The rear bumper of the 2008–2015 Mitsubishi Lancer Evolution X is more than a cosmetic panel; it acts as a critical interface between the car’s aero dynamics, structural integrity, and everyday practicality. For owners seeking to refresh, improve, or optimize their ride, the material choice behind the bumper matters as much as the design lines that catch the eye. In the Evo X era, aftermarket solutions offered a spectrum of options, from OEM-style replacements to performance-oriented upgrades. The interplay between cost, weight, strength, and fit becomes especially important when the bumper must endure street speeds, occasional track sessions, and the inevitable encounters with curbs, gravel, and weather. As with any substantial cosmetic and functional component, the material determines how well the bumper performs under stress, how it interacts with the car’s underbody and diffuser, and how it holds up over time against sun, heat, and mechanical shocks. The broader narrative of these choices centers on balancing three priorities: durability, weight, and aesthetics, each pulling in a slightly different direction depending on how the car is used. When we look at the spectrum of materials—polypropylene, glass fiber, and carbon fiber—we can trace a path from affordable, practical replacements to high-end, race-inspired upgrades, each with its own set of advantages and trade-offs. The goal is not merely to select a material that looks right but to choose one that behaves predictably under real-world conditions, ensuring proper fitment and long-term satisfaction. A thoughtful approach to material choice also speaks to the owner’s broader intentions for the vehicle, whether it is a daily driver, a weekend track toy, or a showpiece that still sees road time. The rear bumper, after all, is a key piece of the car’s overall aerodynamics. The shape of the bumper, its vents or lack thereof, and how it works with a diffuser or a spoiler depend on predictable, repeatable performance. In many builds, the bumper is one of the first areas where function and form converge, making the material selection a decision with lasting consequences for handling, braking stability, and even cabin comfort through reduced wind intrusion. Within this framework, Polypropylene (PP), glass fiber, and carbon fiber each offer a distinct philosophy of performance. A practical starting point for most builders is the ceiling of what is affordable and functional, which often aligns with a polypropylene bumper. PP injects well, resists impact, and remains forgiving when the car is bumped by careless parking or gentle hits during spirited driving. Its light weight can contribute to minor gains in acceleration and handling, particularly when the rest of the suspension and tires are tuned for performance. Yet PP is not without limits. It can be susceptible to UV degradation and heat cycling over many years, which can lead to chalking or microcracking if it is not adequately protected with protective coatings or a UV-stable formulation. This makes PP a sensible option for buyers who want a reliable, cost-conscious replacement that preserves the OEM silhouette and paint finish with minimal fuss. When the objective includes stiffer response and higher rigidity without a major budget jump, glass fiber forms the middle ground. A glass fiber–reinforced bumper offers improved resistance to deformation under load, and it can better resist cracking when the bumper encounters a curb or a heavy load from behind during rough parking maneuvers. The increased stiffness also benefits the integration with a diffuser, mounting brackets, and any decorative or functional vents that channel air away from the underbody. For endurance-oriented enthusiasts who push the car harder, glass fiber presents a balanced option: superior durability compared to standard PP, more predictable behavior under heat, and a price point that sits between the baseline PP and carbon fiber. This material can be molded to precise contours, supporting accurate fitment across model years within the Evo X family. It remains feasible to wrap or finish glass fiber bumpers in a way that matches the car’s color and gloss, ensuring the final look remains cohesive with the exterior styling and reflectors. Progressing into the upper tier, carbon fiber represents a different performance philosophy. The appeal of carbon fiber lies in its exceptional strength-to-weight ratio and high stiffness, providing tangible gains in overall weight reduction and structural rigidity. In front geometry, such a material often translates to more immediate feedback through the chassis and better energy management during impact. On the Evo X rear bumper, carbon fiber delivers an unmistakable aesthetic that many owners pursue as part of a broader carbon aesthetic language across the vehicle. However, carbon fiber is not merely a weight-saving feature; it introduces its own set of considerations. The higher cost is the most obvious constraint, but there is also the need for careful engineering to prevent brittle failure at mounting points if the bumper is subject to heavy impact. Carbon fiber panels can crack or delaminate if hit hard enough, particularly at edges where mounting brackets connect the panel to the car. The surface finish can also be more sensitive to scratches and chips, demanding diligent maintenance and, often, professional refinishing to keep the glossy, show-worthy look. These realities push carbon fiber into the realm of enthusiasts who are not merely chasing a look, but who are willing to accept higher repair costs and potentially longer lead times for order fulfillment. In practice, many Evo X owners adopt a hybrid approach: keep the OEM silhouette and consider carbon fiber accents or partial bumpers, such as carbon fiber diffuser surrounds or bumper lips, rather than a full carbon bumper. This strategy preserves the distinctive visual language of carbon while mitigating the risk and expense associated with a full carbon rear panel. It also maintains ease of repair and replacement should track days or road experiences leave marks that require cosmetic attention. The material choice also interacts with how the bumper mounts to the chassis through brackets and reflectors, an area worth understanding for a car that often runs with aftermarket rear diffusers or extended lips. When a bumper is designed to integrate with other aerodynamic components, the integrity of fitment becomes crucial. This is where the practical realities of the Evo X’s rear geometry come to the fore. The bumper must align with the vehicle’s rear bar, the shock absorbers, and the mounting points for reflectors or sensors. If a replacement bumper is not a precise match, gaps can trap air in unwanted ways, undermining the intended airflow characteristics and potentially increasing drag or producing odd turbulence that spoils traction at higher speeds. A well-chosen material will not only survive impact but also maintain consistent alignment over time, minimizing the need for corrective adjustments during installation. For those who prioritize performance while maintaining a reasonable budget, the material choice often hinges on how much weight they are willing to shed and how much they value rigidity. In addition to the base bumper, many builders explore complementary components like a diffuser, a carbon fiber lip, or a front splitter, but for the rear end, the bumper’s structural properties are the foundation. This is where the material’s resilience to heat and sun exposure matters, especially for vehicles that are driven year-round in sunny climates. UV resistance matters not only for color retention but also for the integrity of the polymer matrix or composite layers. An aging bumper can become brittle or discolored, which in turn affects its fit and performance. In the end, the owner’s priorities define the choice: a PP bumper will appeal to those seeking a reliable, affordable replacement with minimal risk and simpler maintenance; glass fiber represents a middle path that blends durability with moderate cost; carbon fiber, while premium, serves those who want ultimate stiffness, weight savings, and a distinctive visual statement. It is important to stress that selecting material is not a one-off decision. The Evo X rear bumper should be viewed as part of a broader strategy that includes color, finish, and compatibility with other aero components. If a buyer is considering a true OEM-style path versus a performance upgrade, the choice might hinge on how closely they want to replicate the factory feel and how much they value the prospect of a quick, straightforward installation. For those who want to keep their options open, an OEM-style replacement can preserve the original geometry and mounting positions while allowing a future upgrade to more advanced materials should the car’s use evolve over time. To connect this discussion with practical sourcing considerations, many buyers begin by confirming fitment against the vehicle’s year and sub-model, and then they assess the material’s long-term performance in their climate and driving style. It is also wise to verify the part’s compatibility with existing brackets or reflectors, as these small components can influence the overall assembly and alignment of the bumper. For a broader view of rear bumper sourcing and related topics, see this OEM rear bumper reference: OEM rear bumper for Evolution 8/9. This link provides context on how OEM-style replacements are framed within the market and helps clarify what to expect when chasing a stock-like fitment. While the Evo X generation has its own unique character, the lessons learned from earlier Evolution models about mounting points, bracket reinforcement, and finish quality still apply. The rear bumper is a component that can influence the perception of the entire car by its finish, the color match, and the precision of its join lines with the body panels. In practice, the most successful builds marry a material choice to the owner’s driving profile and the car’s intended environment. A daily driver that occasionally attends track days will benefit from a robust, cost-conscious PP replacement with careful UV protection and a high-quality paint job. A car intended for weekend track supremacy, with a well-tuned diffuser and a set of sport tires, may justify a glass fiber bumper for its improved rigidity and durability, while still avoiding some of the higher costs and complexity of full carbon fiber. Those chasing the pinnacle of performance may opt for carbon fiber or carbon fiber–reinforced options to shave weight without compromising the bumper’s function in high-speed regimes. In all cases, the emphasis should remain on proper fitment and real-world testing. It is essential to install the bumper with attention to the mounting brackets, sealants, and alignment tolerances to ensure a secure, durable assembly that can handle the stresses of cornering, braking, and even rear end impacts. The material chosen should complement the overall aerodynamics, as a poorly aligned bumper can negate the intended effects of a carefully designed diffuser or rear wing. The Evo X rear bumper, regardless of material, is a statement about balance: how a car looks, how it behaves at speed, and how it withstands the realities of road use. The decision to select polypropylene, glass fiber, or carbon fiber should reflect a calculated assessment of cost, weight, and the driving experience a owner seeks to cultivate. It is about making a durable choice that preserves the vehicle’s personality while enhancing the performance envelope. The chapter’s synthesis is straightforward: in the realm of 2008–2015 Mitsubishi Lancer Evolution X rear bumpers, material choices are not cosmetic footnotes but active determinants of how the car feels and performs on the road or track. Those who take the time to weigh the trade-offs—cost versus durability, weight savings versus long-term repair cost, aesthetic appeal versus maintenance demands—will more likely arrive at a decision that sustains both the look and the performance of the vehicle for years to come. External resource: https://www.supplierguide.com/mitsubishi-lancer-evo-x-front-bumper-supplier-guide.

null

null

Final thoughts

Understanding the nuances of rear bumpers for the Mitsubishi Lancer Evolution X from 2008 to 2015 is essential for business owners in the automotive field. By exploring OEM and aftermarket options, considering customization for aesthetic enhancements, evaluating material choices for performance and durability, and keeping installation considerations in mind, businesses can better serve their clients’ needs. As the automotive market continues to grow, staying informed about these aspects can position your business as a knowledgeable resource, ultimately driving customer satisfaction and loyalty.