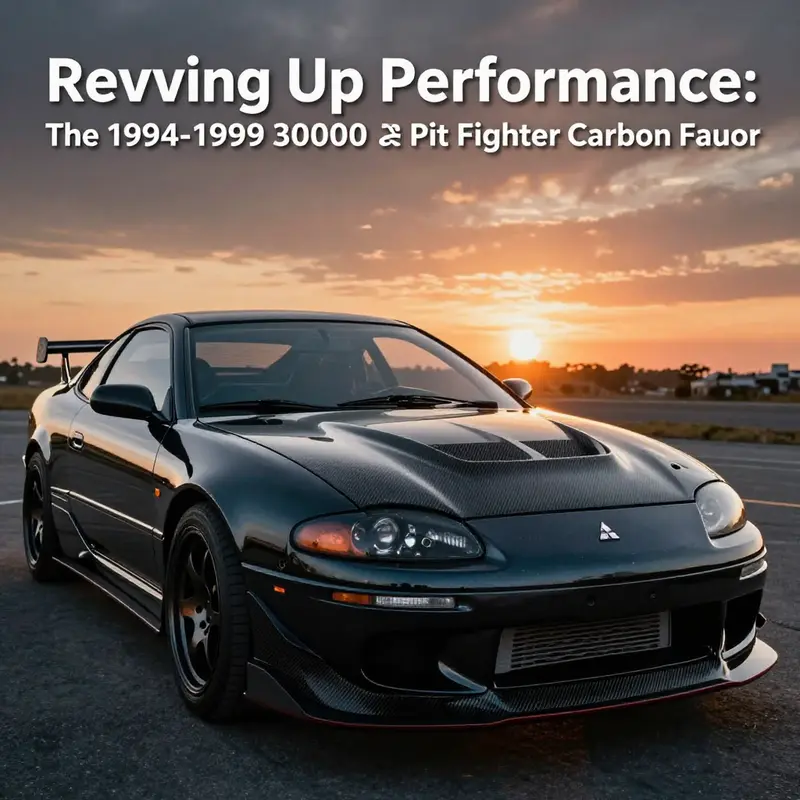

The 1994-1999 Mitsubishi 3000GT, particularly the high-performance VR-4 variant, stands as a symbol of automotive innovation. One of the most sought-after aftermarket modifications for this iconic model is the ‘Pit Fighter’ carbon fiber hood. This article will delve into the intricate design and material construction of this modification, highlighting the performance benefits it offers, as well as its market demand and collector’s value. Each chapter will focus on a key aspect of the Pit Fighter hood, painting a complete picture of why it remains a respected component among car enthusiasts and business owners alike.

Pit Fighter Carbon Fiber Hood: Design, Materials, and Construction for the 1994–1999 Mitsubishi 3000GT

A focused look at how the Pit Fighter carbon fiber hood marries form and function for the 1994–1999 Mitsubishi 3000GT, explaining the weave, resin systems, manufacturing approach, fitment nuances, and the performance benefits that make it a sought-after upgrade.

The Pit Fighter carbon fiber hood for the 1994–1999 Mitsubishi 3000GT is more than an aftermarket aesthetic; it is a purposeful reimagining of the vehicle’s frontal architecture that balances lightweight engineering with visual aggression. Built to echo OEM proportions while improving thermal and structural performance, this hood represents a class of upgrades that appeal to owners seeking both authenticity and tangible handling gains. The design intent is clear: reduce weight over the front axle, support improved airflow into the engine bay, and preserve original mounting and fender alignment so the upgrade looks and fits like it belongs.

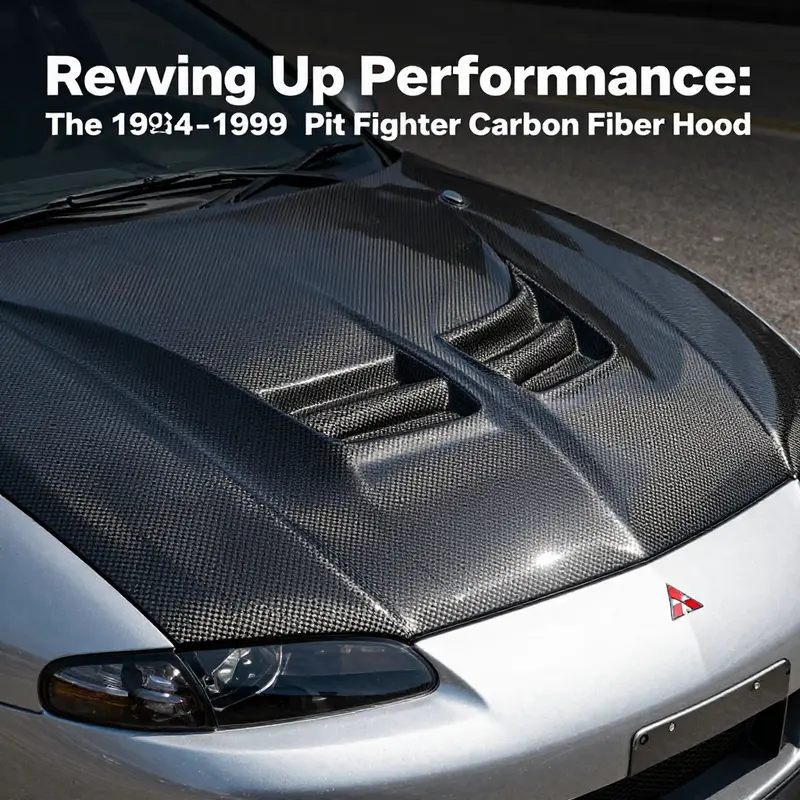

At the heart of the Pit Fighter hood is the carbon fiber weave. High-density woven fabric is used across the visible surface to achieve a consistent, mirror-like pattern that signals quality. This weave is not merely decorative. The orientation and ply schedule of the carbon cloth determine how the panel resists bending and how it distributes loads from aerodynamic pressure and road vibration. In practical terms, manufacturers prioritize a balanced layup that combines unidirectional plies in key load paths with a twill or plain weave skin ply for cosmetic continuity. The result is a skin that is stiff under the hood’s long-span bending while remaining resistant to localized deformation around fasteners and vents.

Complementing the fabric is the selected resin system. A premium epoxy matrix is standard for high-quality aftermarket hoods due to its superior mechanical bonding and thermal stability compared with polyester alternatives. The carbon/resin ratio is a key metric: high carbon content reduces weight and increases stiffness, but the resin must be sufficient to fully wet the fibers and bond layers without introducing voids. Precision-controlled resin infusion or vacuum-bagging techniques are commonly used to achieve an optimized carbon/resin balance. These methods draw excess resin away and compress the laminate, producing a denser, stiffer part with fewer imperfections. The advantage is twofold: weight reduction and an increase in structural rigidity, which improves panel longevity and decreases susceptibility to oilcanning under varying temperatures.

Surface protection and finish quality complete the material story. A clear, high-solids urethane or specialized poly shield clearcoat is applied over the cured carbon to protect against UV degradation and minor abrasions while showcasing the weave beneath. This transparent layer must be flexible enough to resist cracking at bonded joints and around vents but robust enough to stand up to road debris and repeated washing. Proper surface preparation and UV-stable topcoats are essential for longevity—poorly finished pieces can yellow or lose gloss, undermining both aesthetics and perceived quality.

Beyond materials, the Pit Fighter hood’s form follows functional motivations. Venting and scoop geometry are often incorporated to improve engine bay cooling and to relieve under-hood pressure at speed. Strategically placed vents allow hot air to escape and fresh air to enter through the front fascia, aiding intercooler and radiator efficiency on turbocharged VR-4 models. These vents are not decorative afterthoughts; they are sized and angled to complement the car’s original ducting and grille openings so that airflow paths remain efficient. When combined with the hood’s lower mass, the cooling benefits can be measured at reduced intake air temperatures and marginally improved sustained performance under stressful driving conditions.

Fitment is another area where the Pit Fighter hood distinguishes itself. Designed to match the original contours of 1994–1998 3000GT bodywork, the hood seeks precise alignment with factory fenders, bumper lines, and mounting points. This OEM-style approach minimizes the need for extensive trimming or custom bracket fabrication during installation. Small tolerances at the latch, hinge, and bumper interfaces ensure that panel gaps look factory-calibrated rather than aftermarket improvised. For the 1999 model year—where the front fascia adopted a slightly more aggressive lower lip and integrated fog light housings—Pit Fighter variants were refined so the hood integrates with those styling shifts while preserving mounting compatibility. That adaptability makes the hood a practical choice for restorations or period-correct modifications.

The actual construction commonly uses a two-part approach: a premium carbon fiber top skin laminated to a composite or resin-backed core. This hybrid approach combines the visual and stiffness benefits of a visible carbon outer layer with a robust inner matrix that resists impact and supports hardware. In many builds a composite core of reinforced resin, sometimes with foam or additional woven layers, provides energy absorption and attachment points. Bonding techniques are critical: high-strength adhesives and controlled clamping during cure ensure full contact and a durable bond line between the skin and core. When done correctly, the assembly achieves a part that resists delamination and maintains shape under thermal cycles.

Durability and environmental resistance are engineered into the part as well. UV-stable resins and clearcoats prevent sunlight from degrading the carbon fibers or causing resin discoloration. Impact resistance is enhanced by the composite core and the use of tougher epoxy systems. The net effect is a hood that can withstand daily driving stresses, temperature swings, and the occasional stone strike without losing structural integrity. Of course, repairability varies by construction; solid laminates with a bonded inner core are repairable by qualified shops familiar with carbon composites, but repairs require specialized materials and techniques to retain strength.

From a performance perspective, the most immediate benefit of the Pit Fighter hood is weight reduction at the vehicle’s front end. Lighter mass ahead of the front axle reduces polar moment and improves turn-in responsiveness. Drivers often report a perceptible increase in steering quickness and a slightly more neutral balance when compared with the stock metal hood. On VR-4 models with all-wheel-drive and turbocharging, the reduction of unsprung and rotating mass is not the main factor, but the redistributed weight can complement suspension tuning and tire contact patch behavior through successive corners. For acceleration, trimming front weight can free up traction distribution and assist wheel hop mitigation in aggressive launches, though gains are context-dependent and subtle.

Beyond the measurable, the Pit Fighter hood delivers an unmistakable visual statement. The exposed carbon weave and often aggressive venting underscore the 3000GT’s sporting pedigree and align with the VR-4’s wide, low-slung front profile. This visual authenticity is a strong reason why these hoods remain popular on the second-hand market; they signal both performance intent and attention to detail. Enthusiasts searching for a period-correct yet performance-minded modification frequently favor this hood because it blends OEM-style integration with motorsport-inspired cues.

There are, however, practical considerations for owners contemplating the upgrade. Installation still requires careful alignment and sometimes minor shimming or hinge adjustment to achieve perfect gaps. Hardware selection—hood pins, insulation pads, and proper latch calibration—affects both safety and NVH (noise, vibration, and harshness). Additionally, owners should confirm that vents and scoops match their car’s cooling layout; while many Pit Fighter hoods are designed to work with stock ducts, some variations may need complementary ducting work or rely on aftermarket intercooler piping adjustments.

Finally, selection and verification matter. Quality levels vary among third-party manufacturers. Buyers should seek examples with consistent weave appearance, documented layup and resin information, and reviews or images showing fitment on the 3000GT platform. A well-built Pit Fighter hood will clearly list its material processes and demonstrate careful finishing. For one practical reference that details product images, dimensions, and manufacturer notes—useful for confirming build claims—consult the external product listing here: https://www.ebay.com/itm/1994-1999-Mitsubishi-3000GT-Carbon-Fiber-Hood-OEM-Style-Pit-Fighter/ .

For those documenting a build or comparing parts, community write-ups and shop notes can be helpful. A short project overview on the shop blog offers useful ancillary context and can guide installation expectations: https://mitsubishiautopartsshop.com/hello-world/. Taken together, the Pit Fighter carbon fiber hood is a measured upgrade: it delivers weight savings, improves airflow management when vented appropriately, fits the 3000GT’s lines with an OEM-style presence, and presents a durable finish when manufactured with proper materials and techniques. Its blend of cosmetic authenticity and engineering focus is why it continues to be a pragmatic choice for owners who want a visible performance upgrade that respects the original car’s proportions.

Performance Benefits of the 1994-1999 Mitsubishi 3000GT Pit Fighter Carbon Fiber Hood

The 1994–1999 Mitsubishi 3000GT, especially the VR-4 variant, occupies a storied niche in the world of performance cars. Its design language, turbocharged heart, and advanced all-wheel drive layout made it a favorite among enthusiasts who sought both straight-line speed and cornering poise. Among the many upgrades that defined the era’s tuning culture, the Pit Fighter carbon fiber hood stands out as a foundational piece. It’s more than a cosmetic upgrade; it represents a deliberate shift toward optimizing weight distribution and engine cooling while preserving or enhancing the aggressive silhouette that already defined the model. What makes this hood especially compelling is how its purpose-driven design aligns with the broader goals of the platform: to balance blistering performance with usable manners, so the car remains tractable on a daily street, yet remains a credible machine on a race track when pushed hard.

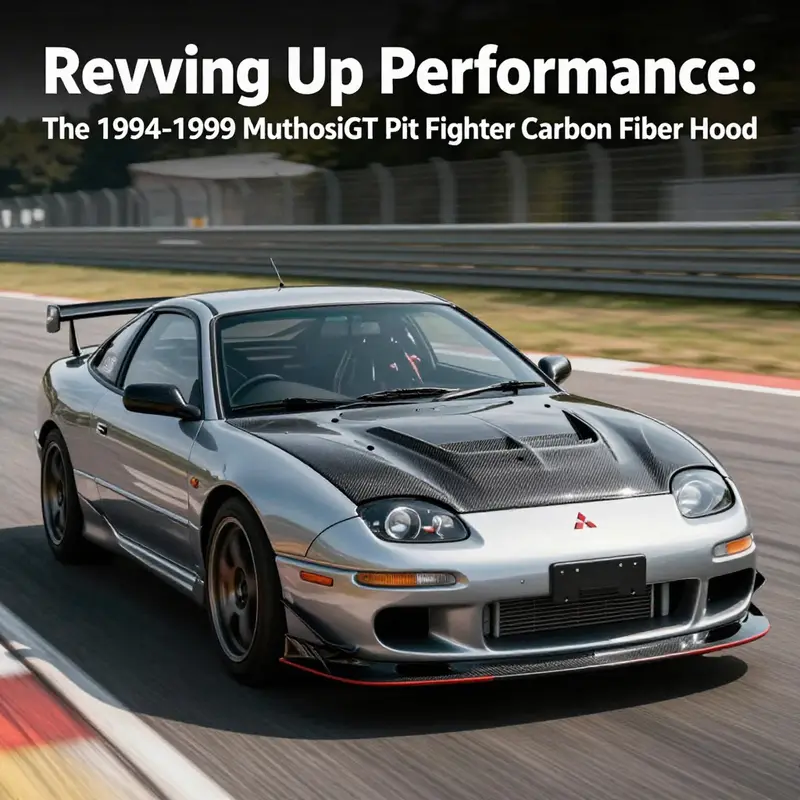

The most immediate and tangible benefit of the Pit Fighter hood is weight reduction. The factory hood, constructed from steel, contributes a noticeable mass at the front of the vehicle. Replacing it with a carbon fiber alternative translates directly into weight savings that are concentrated where the car’s dynamics are most sensitive: the front end. In real-world terms, the typical carbon fiber Pit Fighter hood trims front-end weight by about 25–35 pounds (11–16 kg). That may not sound dramatic at first glance, but it subtly changes the ship’s balance. A lighter front end reduces the inertia the car has to overcome during quick steering inputs and through rapid transitions. The result is a more responsive steering feel and improved grip during acceleration, especially when the turbos are driving torque to the same front wheels that steer the car. As drivers learn to exploit the lighter nose, they experience a more immediate sense of connection with the pavement, a feeling that translates into more confident, precise handling and a tighter overall chassis response at the limit.

A key aspect of the performance picture is the way weight reduction interacts with weight transfer during cornering. The lighter hood lowers the overall front-end inertia, contributing to a modest but meaningful drop in the front’s contribution to the vehicle’s moment of inertia about the yaw axis. In practice, that means the 3000GT can react to steering inputs with crisper timing. Traction under acceleration, especially when exiting turns or lifting mid-corner to rotate the chassis, feels more predictable. The reduction in front-end weight also interacts with the car’s suspension geometry, allowing the driver to push harder before the chassis begins to understeer excessively. It’s not a magic bullet for grip, but it is a foundational improvement that makes the car feel more willing and more balanced at the edge of adhesion.

Beyond the front-end benefits, advancing thermal management is another cornerstone of the Pit Fighter hood’s value proposition. The 3.0L V6 twin-turbo configuration in the 1990s 3000GT has always demonstrated a strong capacity for sustained performance, but it also benefits from cleaner, more efficient airflow through the engine bay. The Pit Fighter hood is designed with airflow management in mind, including features that guide air more efficiently across critical components. By optimizing the path of high-velocity air over the radiator and intercoolers, the hood helps maintain cooler engine temperatures during high-load situations. This is especially important when the car is being driven aggressively on twisty roads or on a track, where turbocharger efficiency and consistent boost levels can otherwise deteriorate under heat soak. In practical terms, better thermal management translates into more stable power delivery and reduced risk of heat-induced power drops during repeated sessions or spirited laps.

The heat-management strategy of this hood doesn’t just keep temperatures in a safer range; it preserves the engine’s performance envelope. Turbocharged engines depend on maintaining a carefully controlled thermal balance to sustain boost pressure and prevent detonation. The improved airflow helps keep radiator and intercooler temperatures under control, reducing the likelihood that heat soak will erode performance during multiple accelerations in quick succession. That resilience is especially welcome on track days, where a few hard laps can push a car toward the edge of its cooling capacity. In a car like the 3000GT, where the turbocharged setup and active handling are already pushing the envelope of mid-90s technology, any incremental improvement in thermal stability becomes a meaningful contributor to repeatable performance and driving confidence.

From a materials perspective, the Pit Fighter hood embodies a careful balance between strength, stiffness, and weight. Carbon fiber, with its high specific strength and stiffness, provides a structural advantage over sheet metal without the penalty of substantial mass. The typical carbon weave used in these hoods is paired with a high-strength epoxy resin that binds the fibers into a rigid, wind-tolerant panel. To protect this delicate composite from environmental wear, the surface is finished with an ultra-clear coat that resists UV exposure and scratches. The result is a durable, visually striking panel that can maintain its shine and structural integrity under challenging conditions. In the long run, the hood’s finish contributes to its value in the used-market ecosystem, where collectors and enthusiasts often weigh both performance and aesthetics when assessing a part’s desirability.

The “Pit Fighter” moniker captures more than a racing vibe; it signals a philosophy of function over form, with an emphasis on air management and aggressive styling. The hood’s vents and cut lines aren’t just for show. They evoke a fighting silhouette that aligns with the 3000GT’s front-end design language, which many observers describe as a modern helmeted stance facing forward like a battle helm. The venting and contouring reinforce that image while also serving a practical role: by shedding more air from the engine bay and reducing the likelihood of heat trapping in the core, they contribute to a cooler, more efficient powertrain during performance driving. This synergy between appearance and function is a hallmark of the era’s tuning culture, where the line between aesthetics and capability was consistently blurred in favor of a more integrated, performance-centric approach.

The practical realities of installing such a hood are worth noting for potential owners. The replacement is designed as an OEM-style replica, intended to fit the 1994–1999 models without requiring substantial modification to the surrounding structure. However, as with many aftermarket carbon fiber components, fitment sometimes depends on condition and alignment of the original hood hinges and surrounding panels. The weight reduction is achieved by substituting a lighter substrate while preserving a shape that aligns with the vehicle’s front fascia and overall aerodynamics. The result is a hood that can be bolted in with a degree of straightforwardness but may demand careful inspection and alignment during installation to ensure a clean gap pattern and secure latch operation. In other words, the hood is a performance upgrade that rewards careful fitting and quality craftsmanship during installation.

An integrated perspective on the market helps illuminate why the Pit Fighter carbon fiber hood remains a sought-after modification. For collectors and enthusiasts who place high value on both immediate effect and long-term usability, such a hood represents a tangible upgrade. It is the kind of component that can be installed to improve daily drive confidence and, with a bit more commitment, to enable more confident lap times on a circuit. Even if a track-day session remains the exception rather than the rule, the benefits—quicker steering input, improved front-end bite, and better heat management—combine to create a more coherent, responsive driving experience. The result is not just a lighter hood; it is a more composed, predictable car that asks for more from its driver, and rewards that attention with a more direct, communicative feel from the front axle.

In the broader arc of the model’s legacy, the Pit Fighter hood embodies a period when enthusiasts translated performance data into visible, tangible upgrades. It became a symbol of a philosophy that valued weight efficiency, cooling performance, and a cohesive aesthetic that matched the car’s battle-ready mien. The Hood’s look, its own heat-management behavior, and the way it changes the chassis dynamics collectively tell a story about a time when aftermarket components were seen not only as bolt-on parts but as essential tools in the pursuit of a well-balanced, track-ready machine. While it sits in a niche market today, the hood remains a reference point for what high-performance engineering aimed to achieve during the late 1990s and serves as a reminder that in the world of performance tuning, every kilogram saved and every degree of cooling improved can contribute to a more confident, predictable, and exhilarating driving experience.

For readers who want to explore related avenues in the broader ecosystem of modern hood options, similar approaches to weight reduction and thermal management exist across many performance platforms. Hood designs today continue to tackle these same two challenges—lightweight construction and efficient heat dissipation—while integrating contemporary materials and manufacturing techniques. The underlying principles, however, remain consistent: reduce unnecessary mass, channel air effectively, and ensure the component can stand up to the rigors of performance driving without compromising reliability or fitment. In that light, the Pit Fighter carbon fiber hood for the 1994–1999 3000GT can be seen as an early exemplar of a holistic approach to performance tuning, one that honors both the machine’s engineering heritage and the demands of modern driving dynamics.

As the conversation about upgrades for classic performance cars continues, the balance between weight savings, thermal management, and visual impact remains central. The Pit Fighter hood exemplifies a disciplined strategy: select a component that is simultaneously lighter, more thermally efficient, and visually aligned with the vehicle’s character. It’s a reminder that even a single, well-executed modification can harmonize with the entire vehicle’s performance envelope, enabling more confident handling, steadier power delivery, and a more engaging driving experience—whether the road is a winding back road or a nascent race circuit. To those who value a coherent blend of form and function, the 1994–1999 Mitsubishi 3000GT Pit Fighter carbon fiber hood stands as a compelling case study in how a lightweight, well-designed component can influence the perception and real-world execution of high-performance driving.

For readers seeking a concrete example of how similar hood designs are marketed on today’s platforms, a related option from the aftermarket scene showcases the continued emphasis on alloy-free construction and aerodynamic venting. This piece offers a window into how contemporary hood variants maintain the same core goals—weight reduction, improved cooling, and a heightened sense of aggression in appearance—while adapting to newer vehicle architectures and materials advances. While the exact configurations and branding evolve, the fundamental tradeoffs and performance incentives remain consistent with those that inspired the Pit Fighter concept on the 1990s 3000GT. The enduring appeal of such pieces lies in their ability to deliver measurable benefits that can be felt behind the wheel, reinforcing the idea that small, purposeful choices can shape the overall driving experience.

Internal link reference: hood options that carry a similar ethos in a different era can be explored through related hood offerings such as the EVO X phantom black OEM hood option, which demonstrates how venting and material choices continue to influence both cooling efficiency and visual impact. hood-phantom-black-oem-u02.

External resource: for a detailed technical overview of carbon fiber hood construction and the kind of specifications that inform these performance choices, you can consult a dedicated carbon fiber hood information page. external resource: carbon fiber hood specifications.

Weight, Heritage, and Edge: Market Demand and Collector Value of the 1994–1999 Mitsubishi 3000GT Pit Fighter Carbon Fiber Hood

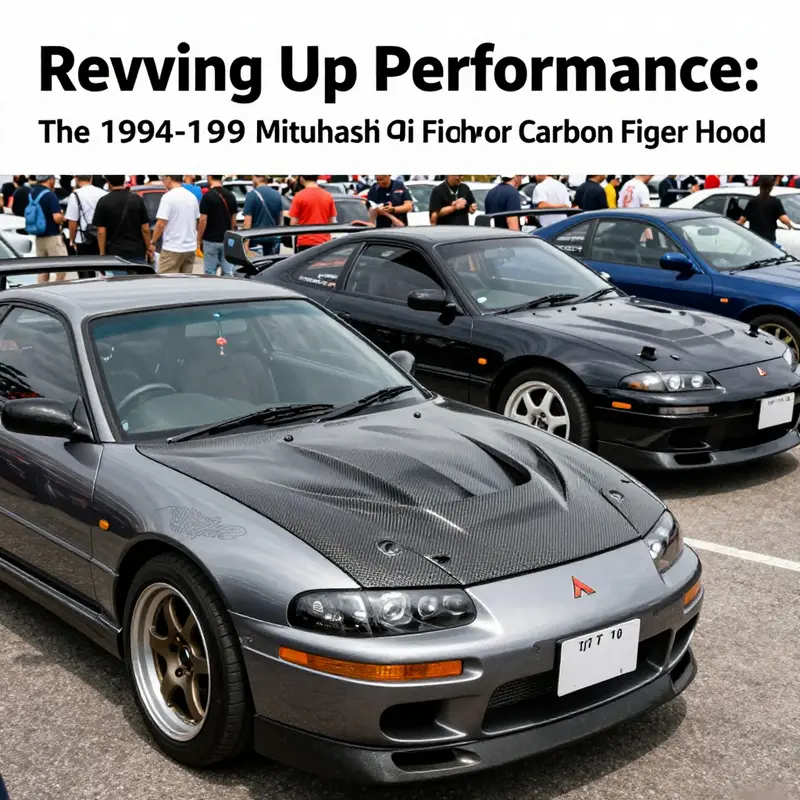

The 1994–1999 Mitsubishi 3000GT occupies a singular niche in the pantheon of late‑century performance cars. Its silhouette, a blend of aerodynamic aggression and refined engineering, carries the weight of a era when Japanese luxury and raw velocity could coexist in one striking package. Within this lineage, the Pit Fighter carbon fiber hood emerges not merely as a component, but as a symbol of how enthusiasts interpret performance philosophy. It represents a practical choice and a philosophical stance: lighter weight, better heat management, and a front end that looks ready for combat. In this context, the market for hoods designed to mimic or extend the performance trims of the era has grown into a quiet, enduring niche. The demand is not driven by mass adoption but by a cultivated reverence for authenticity, balance, and the drama of a car that could so clearly double as a street machine and a track companion when the mood and the mission aligned. The Pit Fighter badge—whether spoken of in enthusiast circles or whispered in restoration shops—signals an attitude as much as it signals a part. The hood, in its carbon fiber incarnation, is a physical articulation of that attitude: it seeks to reduce weight without sacrificing alignment with the car’s original lines, preserve structural integrity under the hood’s stress, and project a visual statement that resonates with the car’s war‑helmeted front end. This shared language of lightness and aggression resonates with collectors and drivers alike, turning a practical aftermarket upgrade into a piece of living automotive history.

What makes the Pit Fighter concept particularly compelling is its alignment with the broader collector impulse—the desire to maintain an authentic appearance while peeling away unnecessary mass. The 3000GT VR‑4, renowned for its torque‑rich V6 and advanced all‑wheel drive system, invites a balance act when any modification is contemplated. Enthusiasts seek upgrades that respect the car’s original proportions and design cues, ensuring that the hood sits flush with factory gaps, that factory hood supports and safety devices continue to function as intended, and that any added vents or cooling features do not disrupt the car’s overall aerodynamics. In this light, the carbon fiber hood becomes a diplomatic gesture: it communicates a commitment to performance and preservation in equal measure. The lightweight material offers tangible benefits. By reducing the unsprung mass and the inertia at the vehicle’s front, the upgrade can sharpen steering response and help the car recover more quickly after braking or cornering. The change is not dramatic on a per‑corner basis, but the cumulative effect can support a more agile driving feel, particularly important for a car that sits in the intersection of boulevard comfort and club‑level performance.

Market dynamics around these hoods reflect a twofold equation: scarcity and desirability. The original factory hood is part of a long‑gone era of steel rooves and heavy front ends; aftermarket equivalents—designed to resemble an OEM‑style silhouette while offering weight savings—satisfy the dual need for authenticity and enhanced performance. In practice, buyers look for hoods that preserve the car’s factory eye‑line, line up with the mounting points, and accept an aftermarket finish that remains resistant to UV and surface wear over time. The best of these pieces stand up to the test of time not just in storage but in daily driving, ceremonial shows, and occasional weekend backroads blasts. Collectors who own a VR‑4 variant commonly weigh the upgrade against a set of practical considerations: fitment integrity, paint compatibility, and the hood’s impact on front‑end balance across a range of speeds and weather conditions. The conversation extends beyond mere aesthetics. It touches on the car’s history, the way a properly executed carbon fiber hood echoes the car’s performance lineage, and the way the piece ages with the rest of the vehicle. In short, the hood becomes a tangible link to a period when automotive designers and engineering teams were more openly engaged in the nuanced art of weight reduction as a performance discipline.

From a historical perspective, the Pit Fighter designation has taken on a life of its own in enthusiast discourse. It is less a formal model name than a shorthand for a philosophy of aggressive styling paired with practical engineering upgrades. This is important for the collector’s market because it creates a storyline—one that buyers and sellers can rely on when evaluating authenticity and provenance. A well‑preserved car that, over the years, has accumulated a small but coherent set of performance‑oriented modifications tends to attract attention in auctions, club events, and online marketplaces where history, maintenance quality, and fitment documentation are valued as highly as the modification itself. The hood, in this framing, is a hinge of memory and intention: it marks a moment when owners chose to emphasize balance and speed with a visible sign that communicates the car’s purpose before the first turn of the key.

Price signals in the current market reflect a cautious but resilient appetite for OE‑style carbon fiber hoods. While the precise piece that carries the Pit Fighter badge does not appear on every shelf, a robust segment of the aftermarket offers OE‑style hoods that match factory contouring and mounting geometry. In practical terms, buyers encounter a pricing range that acknowledges the dual realities of rarity and utility. The value rests not simply in the carbon fiber’s lightness but in the confidence that the hood will align with factory gaps, not require extensive modification, and preserve the car’s silhouette at a glance. In this ecosystem, the strongest positions belong to pieces that offer reliable fitment and a finish that remains visually convincing over many seasons of display and use. The collector’s eye tends to prize those hoods when they arrive with documentation or a known lineage that ties them to the era’s performance ethos, even if they are not original Mitsubishi parts. Authenticity is less about whether the hood is factory‑issued than about whether the upgrade communicates a coherent narrative about the car’s history and intended use.

Market participants—including buyers who are rarely in a hurry and sellers who meticulously curate listings—value the ability to verify a hood’s origin and to confirm that it integrates with the car’s original hardware and mounting points. Condition is paramount: any deformation, delamination of the underlying composite structure, or visible misalignment can degrade both performance benefits and aesthetics. For a model as recognizable as the 3000GT, the hood’s surface must look convincing under bright showroom lighting and hold its gloss under UV exposure for years. The sense of legitimacy—what collectors describe as “the right look, the right feel, the right fit”—often becomes the deciding factor between a piece that sits in a corner of a garage and a part that finds a home in a well‑curated collection.

In terms of availability, the landscape remains active but selective. The broader market for carbon fiber exterior panels from this era shows steady demand, driven by new generations of collectors who discover the car through online archives, vintage car events, and the resurgence of interest in late‑90s performance engineering. The Pit Fighter hood’s appeal endures in part because it remains a striking visual statement—its lines echo the car’s aggressive stance and its vents or proportions communicate an intention to manage heat and airflow in a way that feels integrated with the car’s performance character rather than superimposed. This alignment with the vehicle’s core identity helps sustain a healthy secondary market, where well‑preserved examples can command premium attention relative to unrelated chassis upgrades. The narrative is reinforced by the practicalities of restoration and maintenance: a hood that adheres to original lines and supports consistent mounting reduces the risk of alignment problems and paint cracking at the edges after years of temperature cycling.

Within this framework, one can trace a broader trend in which enthusiasts treat exterior upgrades as investments in both performance and storytelling. The better pieces are those that merge lightness with durability, enabling the car to feel quicker and more agile without appearing modified simply for modification’s sake. The Pit Fighter hood, in this sense, becomes a focal point for a car’s evolving identity—part performance instrument, part historical artifact—that captures how owners perceived the car and how they chose to present it to the world. As the hobby has matured, buyers have learned to look beyond price and shiny finishes to evaluate the hood’s construction quality, the symmetry of the weave, and the resilience of the protective clear layer if present. In evaluating candidates, collectors often rely on documented fitment checks, careful inspection of mounting hardware, and, when possible, conversations with previous owners or restoration specialists who can attest to the piece’s lineage and its journey with the car.

To readers who may be considering a similar exterior upgrade for other classic performance cars, a point of reference can be found in contemporary hood options that emphasize the same balance—weight savings, authentic styling cues, and robust fitment. For a related look at hood options within the broader Mitsubishi family, you can explore a hood option tailored for another prominent model here: 08-15 mitsubishi-lancer-evolution-evo-x-hood-phantom-black-oem-u02. This link serves as a practical reminder that the principles guiding the Pit Fighter choice—respect for model lineage, careful attention to fitment, and a desire for visible performance cues—translate across generations and platforms.

In sum, the market for the 1994–1999 3000GT Pit Fighter carbon fiber hood sits at an intersection of history, engineering, and collector culture. It thrives not on ubiquity but on a shared conviction that certain details—the way a hood sits on the fenders, the way light catches a carbon weave, the quiet authority of a well‑executed vent design—signal a car that knows what it is and what it can do. The hood’s value, therefore, is not merely the weight it saves, but the story it tells about a circle of enthusiasts who, decades after the car’s debut, continue to treat it as a living project rather than a finished artifact. For those guardians of the era’s memory, the Pit Fighter carbon fiber hood remains a meaningful, tangible link to a moment when performance and style collided in a way that still resonates with today’s collectors and drivers alike.

External reference: https://www.redline360.com/products/seibon-carbon-fiber-hood-mitsubishi-3000gt-1994-1999-oem-or-dvii-vented

Final thoughts

The Pit Fighter carbon fiber hood for the 1994-1999 Mitsubishi 3000GT exemplifies the blend of automotive aesthetics and performance enhancement. Its unique design coupled with its benefits in weight reduction and cooling efficiency makes it a coveted upgrade among enthusiasts. Additionally, the collector’s value in the market underscores its importance as an aftermarket accessory. As demand for classic car modifications continues to rise, owning such a hood is not just an investment in performance; it is a tribute to automotive heritage and innovation.