For business owners in the automotive aftermarket industry, optimizing the performance of vehicles like the Mitsubishi Lancer Evolution is vital for attracting a dedicated clientele. Among the various modifications available, installing a full sequential gearbox stands out due to its potential to revolutionize driving dynamics. This comprehensive guide delves into the defining characteristics of full sequential gearboxes, explores installation options specifically for the Evo IV, IX, and X, and examines practical applications along with critical considerations for their successful implementation.

极致顺序换挡:翼神系列全顺序变速箱的特征与赛道潜力

在高性能驾驶的语言里,全顺序变速箱以极致换挡速度与可预测性为核心。

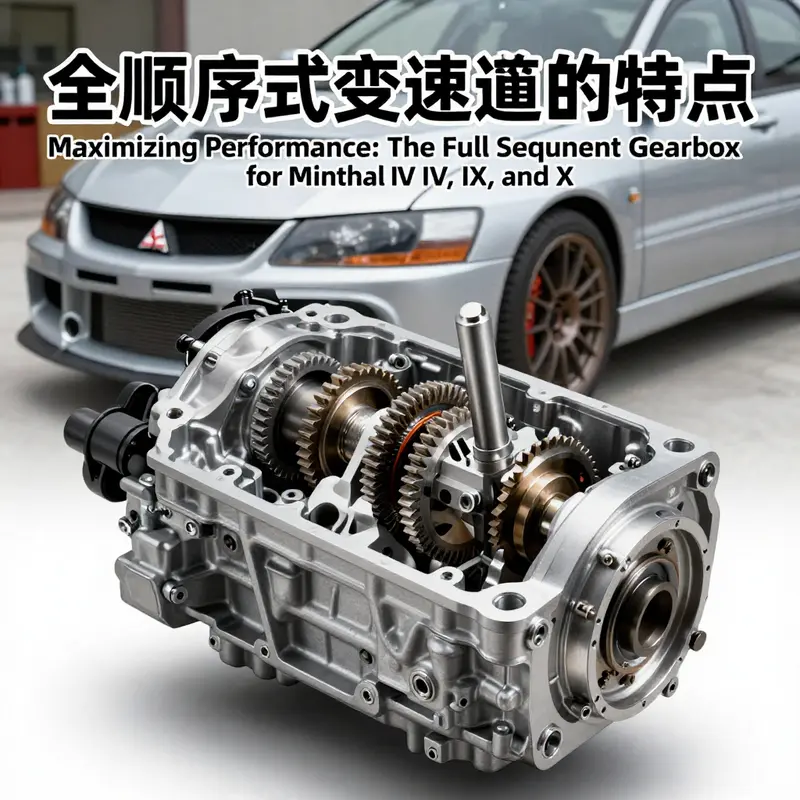

对于翼神系列的改装车型而言,虽然原厂并未提供全顺序化的解决方案,市场上仍有以序列化系统为核心的改装实践。这类系统通过严格的换挡序列、电子或液压执行机构实现快速而稳定的换挡,显著提升赛道阶段的扭矩传递连续性。

换挡节拍的标准化意味着在多组齿轮切换之间,动力输出几乎无缝衔接,有助于在过弯、直线加速和高热管理需求的场景中维持车身姿态与传动效率。

除了速度,结构简化与潜在的重量优化也为翼神系列带来重新布置传动系统的空间,进而提升热管理与前后配重的精准性。但全顺序系统也存在局限,例如在低速或日常驾乘中可能产生明显的顿挫,需要通过改装整车控制策略与驾驶习惯来缓解。

不同代际的安装点、互联接口和传动比组往往不同,改装方案通常以代际为单位定制,因此对工程团队提出更高的跨代协同要求。

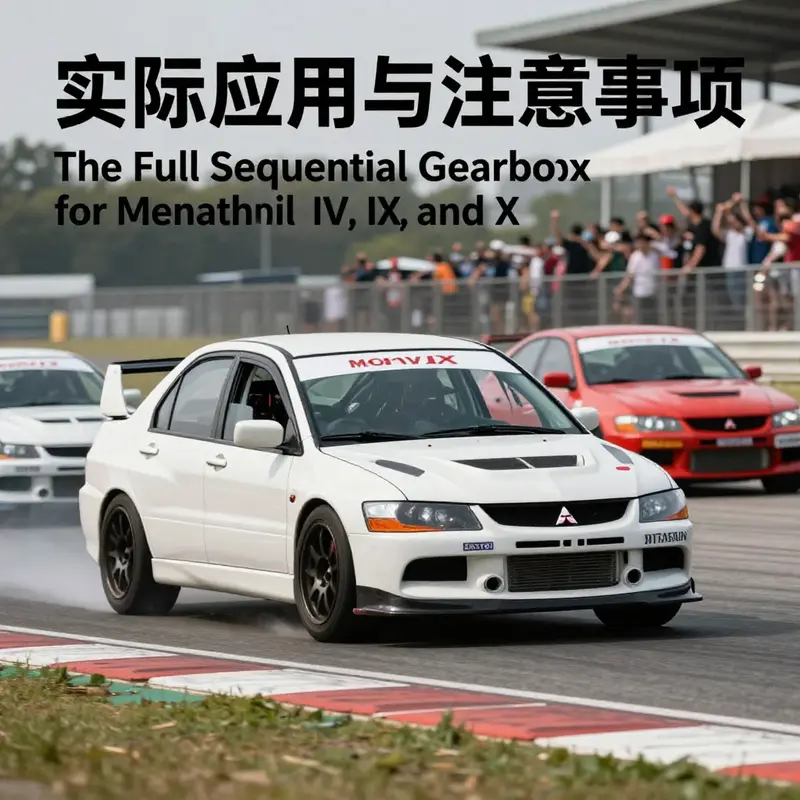

在实战层面,改装不仅关注变速箱本身,还要考虑发动机管理、传动轴、差速器与底盘的协同优化。对翼神系列而言,目标是实现输入扭矩、传动比与轮端载荷之间的匹配,在训练与比赛中达到稳定且可重复的换挡性能。

未来趋势在于提升系统的可维护性、热管理与控制算法的鲁棒性,使其在赛道工具化的同时仍具备日常使用的可控性。

总结而言,翼神系列的全顺序变速箱改装不是为了短期的极致换挡,而是在特定竞技场景中实现更高的响应速度、动力传输的连续性与驾驶信心。)

null

null

Gearing for the Track: Real-World Realities of Fitting a Full Sequential Gearbox to Evo IV, IX, and X

The appeal of a full sequential gearbox for Evo IV, IX, and X is clear: faster shifts, consistent timing, and a driver-centric interface that can sharpen on-limit performance. Yet the path from concept to track-ready installation is constrained by packaging, driveline integration, and the realities of endurance-style testing.

Packaging matters because a sequential system with actuators, hydraulic lines, and a shifter sits outside stock tunnels and crossmembers. The Evo IV and IX were designed around a five-speed manual with a cable-like interface; the X introduces new weights and electronic dependencies. A true upgrade requires reinforced mounting points, tunnel clearance checks, and careful routing of hydraulics and wiring, all while preserving safe crash behavior and dynamic balance.

Beyond the gearbox itself, the AWD system must be recalibrated for the new torque delivery and shift cadence. This includes cooling, oiling strategies, and differential tuning to absorb the changed engagement profile without unsettling the chassis through corners. The driver experiences the change as a different cadence and a wheel that communicates shifts via the steering wheel rather than a pedal, demanding disciplined adaptation, feedback, and practice.

Reliability on track day is essential. Actuators must cycle reliably, lines must resist vibration and temperature, and the control software must respond deterministically. Teams often implement multiple software maps for varying conditions and data-logged validation to ensure repeatability under load. The broader rule is that the gearbox cannot be treated in isolation; a robust upgrade integrates cooling, chassis rigidity, and driveline components to maintain balance and long-term durability.

In practice, developing a practical upgrade involves a staged approach: verify mechanical fitment, map control electronics on the bench, validate on a dyno, and finally test on track with a patient driver who can push the system while preserving a safety margin. A holistic strategy also recognizes that performance comes from the synergy of the drivetrain, chassis, brakes, and aero, not from the gearbox alone. Where Evo X compatibility kits and catalog resources exist, they can provide a blueprint for assembling a cohesive package that respects the car platform while unlocking new capabilities. The goal is repeatable, manageable performance with clear data-driven validation of gains.

Final thoughts

Equipping Mitsubishi Evo IV, IX, and X with a full sequential gearbox can dramatically enhance driving performance, making it a compelling upgrade for automotive businesses. With the right modifications, vehicles not only achieve quicker, more precise gear shifts but also cater to the demands of performance enthusiasts and competitive drivers. As automotive trends evolve, incorporating such upgrades into your service offerings can position your business steadily ahead in a competitive market.