The Mitsubishi Lancer Evolution X, particularly its Final Edition, represents a pinnacle of automotive performance, revered by enthusiasts and professionals alike. At the heart of its driving excellence lies the 6-speed dual-clutch transmission (DCT470), engineered for seamless shifts and unmatched reliability. This article explores the intricacies of the reconditioned DCT470 gearbox, focusing on its technical specifications, market dynamics, brand heritage, and performance enhancements. Each chapter provides insights essential for business owners looking to engage with this unique automotive sector, making clear how this gearbox can drive profitability in the high-performance vehicle market.

Between Precision and Power: Reconditioning the SST DCT470 for Evo X’s Final Edition

The Mitsubishi Evolution X has long stood as a benchmark for track-ready thrill, a machine where the line between driver intention and machine response blurs in a fraction of a second. Among the elements that defined its most aggressive, heart-pounding iterations was the Sport Shift Transmission, known in shorthand as SST, and its six-speed dual-clutch variant, the DCT470. This gearbox, renowned for its immediacy and relentless pace, represents more than a mechanical unit; it is a distilled expression of a philosophy that prizes seamless torque delivery and razor-sharp throttle response at the moment the driver asks for it. In the context of the Final Edition Evo X, the SST DCT470 sits at a crossroad between heritage and high-performance engineering. It is a rare, purpose-built piece born from the collaboration between Ralliart, the Mitsubishi performance division, and Dodson SSP, a supplier with a reputation for pushing the boundaries of what a transmission can do in real-world race conditions. The unit’s legacy is tethered to a specific era when the Evo X’s appetite for speed met a transmission system capable of bending time with every shift. Although the final models of the Evo X officially offered a five-speed manual configuration, the marketplace still carries the memory of a six-speed dual-clutch solution. The last recorded sale price, reported when demand and condition aligned, hovered around a few thousand pounds, a quiet testimony to both rarity and the specialized expertise required to service such a component. The DCT470 reconditioned units thus occupy a niche position in the performance aftermarket: they are not mass-produced replacements but carefully refurbished cores that promise the feel and performance of a higher-rpm, more aggressive gearing strategy while addressing the practical realities of maintenance, reliability, and fitment in aging platform architectures.

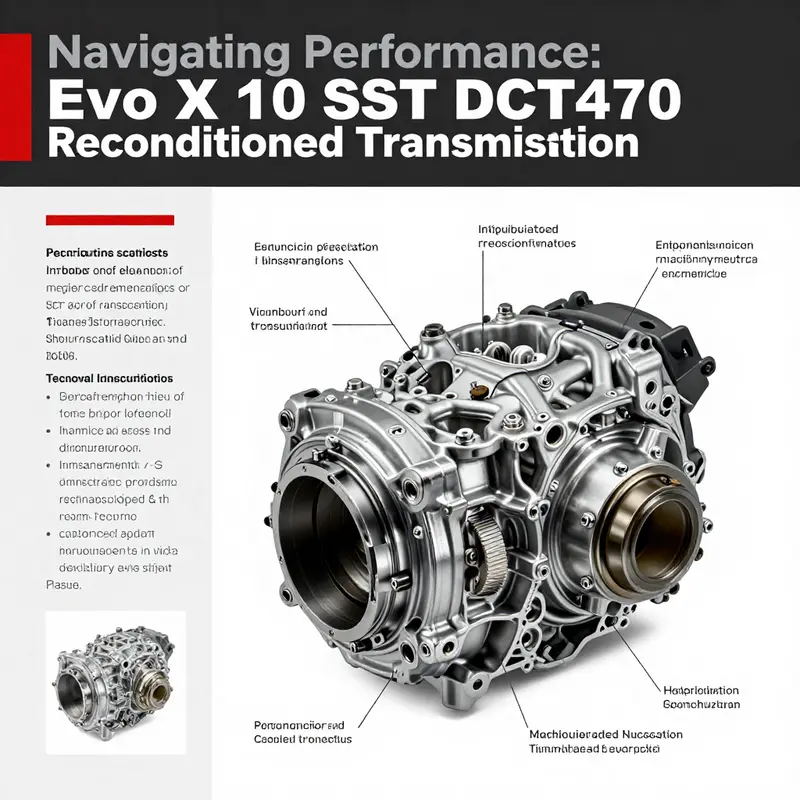

At the heart of the DCT470 is a dual-clutch system that choreographs traction and speed with a precision that a traditional torque-converter box cannot match. The concept relies on two separate clutches, each gearing up for odd or even gear sets, which enables pre-selection of the next gear. That pre-selection translates to astonishingly fast shifts, with published figures often cited near the one-tenth of a second mark under ideal conditions. The impact on acceleration is tangible: smoother transitions across torque curves, reduced drivetrain interruption, and a sense that the car is always ready to spring forward at the slightest touch of the throttle. Behind that instantaneous shift capability lies an intricate oil path system, a network of conduits and nine small electronic pumps that maintain lubrication, pressure, and cooling even as the gearbox works under the most demanding track or road conditions. The complexity of that system highlights why the DCT470 demands professional handling; the interplay between hydraulic actuation and electronic control is delicate, and a reconditioned unit must be restored to exacting manufacturer specifications to preserve both performance and longevity.

The reconditioning process itself is a narrative of meticulous care. It begins with a comprehensive inspection to identify wear, micro-cracking, or any data-trace that reveals past stress points. Disassembly follows, not as a routine teardown but as a controlled deconstruction where every plate, gear, bearing, seal, and sensor is cataloged for precise assessment. Worn parts are replaced using original manufacturer specifications, a step that matters far beyond superficial appearance. It is not merely about restoring a visual standard; it is about returning the geartrain to the exact tolerances that designed it, ensuring the oil pathways and pump system feed the gears with consistent pressure and temperature control. Cleaning then removes the residue of heavy use, while reassembly requires a disciplined sequence to guarantee correct alignment of the clutches, hydraulic circuits, and electronic sensors. The reassembled unit is then subjected to testing regimes that simulate a spectrum of operating conditions—cold starts, hot thermal cycles, high-load shifts, and controlled slip events—and only units that clear these tests are considered fit for sale as reconditioned cores.

The expertise required to perform such a reconditioning cannot be overstated. It blends mechanical precision with an understanding of electronic management, hydraulic control complexities, and the software calibrations that govern clutch engagement, torque transfer, and shift timing. In practice, a reconditioned DCT470 represents a careful balance: it must preserve the brisk, race-informed character of the original SST while ensuring reliability for customers who intend to push their Evo X in demanding environments, whether on smooth racing surfaces or on spirited highway drives. The collaboration between Ralliart and Dodson SSP in supplying these units is not incidental. It signals a track-proven pedigree; both brands have earned respect for their contributions to performance automotive parts, and their involvement lends a level of legitimacy and confidence to the refurbished assemblies. This is not a generic remanufacture; it is a curated process built around specifications that have endured scrutiny in competition settings, where even the slightest inconsistency becomes a liability.

In the broader market, the Evo X Final Edition occupies a paradoxical space. Officially, the Final Edition was associated with a 5-speed manual transmission, yet a meaningful contingent of enthusiasts and specialists pursued the six-speed DCT470 as a premium compatibility option for those who valued the unique drive feel that the SST platform offers. The reason goes beyond nostalgia. The DCT470’s torque handling, its rapid clutch engagement, and the ability to pre-stage gears for rapid acceleration remain appealing to builders who aim to maintain the original driving character while extracting additional performance in controlled ways. Consequently, even though new units are not a staple of current production lines, refurbished DCT470 modules remain relevant in the aftermarket. They provide a pathway for owners who seek to preserve historical configurations or who are restoring or upgrading cars that were originally equipped with the six-speed SST arrangement. It is a reminder that high-performance engineering does not end with a car’s last year of production; it evolves through the careful preservation and continued operation of parts that defined its moment on the road and on the track.

For a reader tracing the lineage of the Evo X’s transmission experience, the significance of a reconditioned six-speed DCT470 lies not only in raw performance figures but in the philosophy it embodies. This is a piece that exists at the intersection of speed, precision, and the humility of maintenance. It invites questions about fitting a legacy system into newer or rebuilt platforms, about ensuring that the hydraulic-pneumatic balance remains stable as oils age and seals degrade, and about calibrating software in a way that respects the mechanical integrity of the unit. The conversation that emerges is not merely about replacing worn components; it is about honoring the engineering intent that gave the Evo X its edge. It is about recognizing that a car’s most immediate contact with the road—the moment when the driver commits to a shift—depends on a chain of decisions that begin long before the pedal reaches the floor. In that sense, a reconditioned DCT470 is more than a part; it is a commitment to a driving experience that the Evo X’s lineage helped to crystallize.

Within the ecosystem of the Evo X, enthusiasts and professionals alike may consider ancillary components that support a holistic build. For instance, when planning a drivetrain refresh or a performance-oriented restoration, components such as a half-cut, or subassemblies that enable a clean, integrated rebuild of the front-end and mid-body sections, can be essential. One practical touchpoint is the Evo X halfcut, a preparation piece that can simplify the transition between donor and recipient vehicles and help ensure that the transmission ecosystem aligns with other critical axis components. For those exploring this path, the Evo X halfcut is a logically connected reference point in the broader conversation about rebuilding and upgrading the Evo X platform. See the resource listed here for a focused look at that component: evo-x-halfcut.

Looking outward, external technical grounding remains invaluable for anyone who wants to understand the deeper mechanics of this transmission family. A comprehensive, technical framework is provided by the Mitsubishi SST Technical Guidelines, which delve into the structure, operation, and maintenance considerations of the SST system, including the DCT470 variant. This resource offers detailed diagrams, tolerances, and procedural notes that complement the hands-on experience of practitioners who recondition and service these gearboxes. For readers seeking that deeper dive, the guideline document is a worthwhile reference point: https://www.scribd.com/document/594673954/Mitsubishi-SST-Technical-Guidelines.

In sum, the reconditioned DCT470 units—spawned from the collaboration of performance engineering teams and refined through careful restoration—embody a specific balance of heritage and modern capability. They reflect a mindset that values the immediacy of a dual-clutch system, seeks to preserve it in a form that can be trusted under demanding use, and recognizes the responsibility that comes with handling a component that influences how a high-performance car translates instruction into motion. The Evo X Final Edition’s legacy, then, is preserved not only in its silhouette or its exhaust note but in the continuity of its transmission philosophy. A reconditioned six-speed SST becomes a bridge between past and future, a way to honor the car’s lineage while continuing to push the envelope of how quickly a machine can respond when the driver speaks with the pedal and the prompt of the gearbox follows in perfect concert.

Precision Under Pressure: Reconditioning the DCT470 for Evo X’s Final Edition

The evolution of a high-performance four-wheel-drive machine hinges as much on its transmission as on its turbocharged heart. In the final facts of the Evo X lineage, a reconditioned DCT470 stands as more than a repair part; it is a carefully rebuilt promise of consistent, race-inspired shifts when depth of engineering is measured in milliseconds and torque envelopes. This chapter threads the distinctive lineage of a sport-tuned, dual-clutch transmission with the realities of availability and repair in a market that long ago embraced the value of reconditioned components. From the workshop floor where experienced hands sort through clutch packs and dampers to the tarmac where engineers calibrate control algorithms with the vehicle’s ECU, the DCT470 story unfolds as a case study in how a single component can anchor both performance and reliability for a revered, late-generation performance car. The narrative is anchored by the collaboration behind the unit—Ralliart, the brand that defines Mitsubishi’s performance division, and Dodson SSP, a name associated with high-performance engineering know-how. Together, they have produced a reconditioned transmission that speaks to enthusiasts who seek both precision and endurance, especially for the Evo X Final Edition, a model whose production run marks the twilight of a generation and the beginning of a collector’s chapter. Even as the market for this exact unit receded, with the final sale price cited as a few thousand pounds in the used market, the technical and experiential implications of such a rebuild endure. To understand why, one must trace the anatomy of the DCT470 and the way it integrates with the broader Evo X drivetrain ecosystem, a system that rewards a holistic view of the vehicle rather than a piecemeal swap of parts. The reconditioned transmission does more than swap gears; it fuses a robust mechanical core with an electronic intelligence layer that keeps pace with modern chassis dynamics. The very idea of a reconditioned DCT in a Final Edition car invites a broader reflection on how enthusiasts approach aging performance hardware. The DCT470, in its essence, is designed to handle demanding torque outputs while delivering the shift speed and stability necessary for both spirited acceleration and confident cruising. When the unit is built or rebuilt by specialists, the process emphasizes not just restoring nominal gear engagement but reclaiming the micro-dynamics that define a smooth, predictable drive. In the Evo X’s ecosystem, alternate parts like the evo-x-halfcut play a synergetic role in maintaining drivetrain rigidity and ensuring proper alignment across the long, loaded power path that connects engine, clutch, gears, and final drive to the wheels. The Evo X intellectual property map—how energy travels from pedal to wheel—rests on the assumption that each component performs its role without surprise. A reconditioned DCT470 therefore becomes not merely a replacement but a recalibration of the entire drive system’s pulse. The practical allure of a reconditioned package lies in the balance it offers: the performance envelope of a newly engineered component at a fraction of the cost. It is a calculated concession, a decision that weighs the benefits of factory specifications against the realities of wear, modification, and the escalating demand for higher torque in capable Evo X builds. In a Final Edition chassis, where the SST dual-clutch arrangement represents a specific outgrowth of the era’s engineering philosophy, the reconditioned unit must reconcile the original control logic with the threshold of modern calibration. The result is a drivetrain that remains faithful to factory intent while providing a stability that experienced drivers recognize as the hallmark of a well-tinished DCT. The technical narrative is clear: the transmission is a seven-gear dual-clutch arrangement that uses a twin-plate, dry clutch system to bridge engine torque with road speed. It is engineered to deliver shifts that occur in about 80 milliseconds, a figure that translates into a sensation of nearly instantaneous engagement when the accelerator pedal is pressed with intention. The torque capacity—designed to handle roughly 470 Nm—made it a natural fit for Evo X platforms that have evolved beyond stock configurations through turbo refinements and exhaust and intake upgrades. In practice, this means the transmission is not just resilient; it is adaptable to a range of modified states, provided the rest of the drivetrain is brought into alignment with the torque and RPM envelope that the DCT470 is capable of controlling. The transmission’s control architecture works in concert with the vehicle’s ECU and stability control systems. This integration is not cosmetic; it ensures that shifting behavior remains predictable even when the chassis is subjected to aggressive cornering, dynamic braking, or rapid throttle modulation. The reconditioned unit’s success, then, rests on two pillars: mechanical fidelity and electronic harmony. The mechanical fidelity rests in the painstaking attention to the clutch assembly, the damper mechanism, and the friction materials—the elements that govern how smoothly the clutch engages under load and how it handles thermal cycling during repeated shifts. The electronic harmony hinges on ensuring that ECU-driven commands align with the mechanical response, preserving drive feel across a broad spectrum of operating conditions. Within this framework, the role of components such as the original 6DCT470 clutch assembly with damper becomes clear. These parts are not mere replacements; they are critical to suppressing drivetrain vibrations and maintaining consistent shifting behavior under demanding use. In high-performance contexts, even minor deviations in clutch plate material or damper stiffness can ripple into the vehicle’s overall torque delivery and cornering stability. This is why reputable reconditioners emphasize the quality of friction plates and damper components as essential to the long-term operation of a sophisticated DCT system. The end-to-end quality control also extends to ensuring that seals, venting paths, and hydraulic circuits meet the same standards that originally defined the unit. For owners who plan to pair a reconditioned DCT470 with a heavily modified Evo X engine, the conversation extends beyond the gearbox itself. It touches the broader philosophy of maintaining an integrated powertrain where the transmission can absorb higher torque peaks without compromising shift integrity. In such contexts, the reconditioned DCT becomes part of a system that includes upgraded intercooling, upgraded intake, tuned engine management, and carefully chosen gearing strategies. The practical implication of this orchestration is a driving experience that preserves the car’s character—the eager throttle response, the crisp gear changes, and the sense that every input from the driver is translated into measured, controlled motion rather than strain or hesitation. The Evo X Final Edition, with its SST lineage, is a car whose ownership often centers on the narrative of performance heritage. For collectors and enthusiasts, the decision to maintain or restore a DCT-equipped platform is a story of stewardship as much as it is a technical choice. The rarity of the configuration, the prestige of the collaboration behind its rebuild, and the alignment with a high-performance culture all contribute to a sense that this is more than a component swap. It is a commitment to sustaining a vehicle that embodies a particular moment in performance history. And in the hands of adept technicians, the reconditioned DCT470 remains a living piece of that history—an artifact that continues to perform as if new, while carrying with it the experiential weight of the Evo X’s finest years. The broader automotive community often remembers these units not just as hardware but as a convergence of engineering ethos and enthusiast culture. The investment in a reconditioned DCT470 is as much about future reliability as it is about revisiting the car’s defining moments on the road or at the track. It is about ensuring that a Final Edition car can still deliver the immediacy of gear selection, the confidence of traction control, and the tactile satisfaction of a well-timed shift under load. The internal ecosystem—driven by parts such as the evo-x-halfcut and other drivetrain components—forms a continuous loop of compatibility and performance potential. It is this loop that makes the reconditioned DCT470 a compelling choice for those who value a balance between authenticity and modern reliability. For readers who seek a deeper technical baseline, the Mitsubishi Motors Technical Service Manual for the Lancer Evolution X CZ4A provides the authoritative snapshot of how the system is supposed to behave under various operating regimes. This resource anchors the narrative in documented engineering practice and offers a baseline against which reconditioned units can be evaluated and tested. External reference: https://www.mitsubishimotors.com/technical-support

Rarity in the Marketplace: The Economic Tale of the Evo X DCT470 Gearbox

The narrative of a final-edition dual-clutch transmission for a legendary performance car begins long after the last car rolls off the assembly line. In the market, the evolved six-speed dual-clutch unit—designed to pair with a sophisticated paddle-shift system and a finely tuned hydraulic control network—has become a study in scarcity, fidelity, and cost. Its lifecycle offers a window into how limited-edition hardware travels beyond factory walls, how enthusiasts assess value when supply dries up, and how a lineage of performance engineering continues to influence current builds and restorations. The Evo X DCT470, as these transmissions are commonly framed in technical and enthusiast circles, marked a pinnacle for a model line that Mitsubishi stopped producing in the mid-2010s. The production cessation did not erase the unit from the road or the workshop; rather, it created a market of reverence and practical challenge—nostalgia tempered by the realities of repair, refurbishment, and aftermarket adaptation.

Official channels no longer stock new DCT470 gearboxes for the Evo X, a consequence of the broader decision to wind down the Lancer Evolution program. The absence of factory fresh units from a brand-aligned supply chain means that buyers and builders now chase opportunities in secondary markets. Across major regions—Europe, North America, and Japan—the landscape is carved by decommissioned Evo X vehicles that still contain these units, or by workshops that specialize in refurbishing and reconditioning. Platforms that are widely used by enthusiasts and professional shops alike, from general marketplaces to performance-focused shops, occasionally present used or refurbished examples. Yet, each listing hides a crucial variable: the potential wear on clutches, seals, and the intricate hydraulic and electronic control architecture that governs seamless, high-speed shifts. The buyer must weigh the allure of near-original hardware against the practicalities of condition, mileage, and the risk profile of refurbished components.

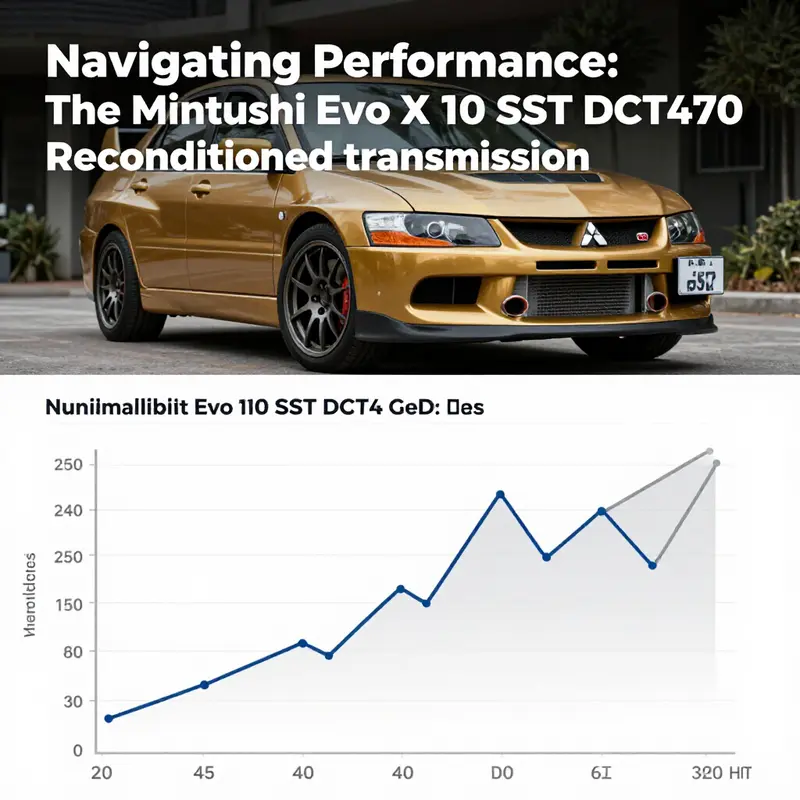

The auction and quote-driven nature of the market injects a price signal into what is otherwise a tale of provenance and engineering. The cost spectrum for a well-maintained used or refurbished gearbox typically sits in a broad range, reflecting differences in warranty terms, included ancillary parts, and whether a performance-oriented refresh accompanies the purchase. A common figure band stretches roughly from two and a half thousand to five thousand U.S. dollars. If a buyer seeks more than a bare swap—say, better clutch packs, refined shifting logic, or higher durability to support boosted power—upcharges of eight hundred to two thousand dollars become part of the equation. In other words, the economic calculus often shifts from “can I obtain it?” to “will the investment translate into meaningful performance, reliability, and return on investment over the long arc of ownership and use?” The answers depend on intent. For a track-day car that spends significant time in high-load conditions or a collector aiming to preserve an era-defining platform, the refurbished DCT470 can be more than a part; it becomes a keystone in maintaining the vehicle’s character.

The maintenance landscape for these transmissions compounds the decision-making process. Dual-clutch architectures are elegant in concept and impressive in operation, delivering rapid shifts with impressive efficiency when everything works in concert. Yet their electronic brains and hydraulic circuits demand meticulous attention. When faults arise, symptoms can range from shift irregularities and jolts to clutch slip and software calibration quirks that ripple through the transmission control unit. Repairs, especially when addressing the core control hardware, hydraulic actuators, and wear-prone clutch packs, can escalate quickly. In a worst-case scenario, a comprehensive overhaul can exceed three thousand dollars, reflecting the specialized labor required and the complexity of the system. This is not merely a price tag but a trade-off: the owner must evaluate whether the experience and performance heritage justify the ongoing maintenance commitments.

From the standpoint of value retention, the equation becomes nuanced. Collectors and enthusiasts who prize historical authenticity and the lore surrounding a high-performance package often assign a premium to the original or near-original gear hardware. The intangible value—the sense of connection to a performance lineage—can temper cost for the right buyer. For most practical owners, however, the economics of ownership tilt toward the maintenance burden and the risk of obsolescence as newer platforms offer similar capabilities with different technology stacks. This dynamic makes the DCT470 a distinctive proposition in the broader performance-parts ecosystem: a rare, high-desirability component whose price signals are driven as much by sentiment, scarcity, and the enthusiasm of the community as by pure supply and demand curves.

The aftermarket sphere—an ecosystem that thrives on niche engineering and the appetite for reliability under high-power conditions—adds another layer to the narrative. Specialist manufacturers have begun offering upgrade or reinforcement paths that aim to improve durability, shift precision, and response under stress. Such upgrade kits often address the specific weaknesses that can emerge in a performance context, such as friction material longevity in high-heat regimes or firmware tuning that tightens the shift windows without sacrificing smoothness. The economics of these upgrades must be balanced against the base cost of a refurbished gearbox and the value of keeping the drivetrain compatible with the original control logic. For owners pursuing competitive reliability or seeking to extract more feedback from driver inputs, the upgrade path can be a compelling complement to the purchase of a used unit, creating a cohesive program of refurbishment that respects the vehicle’s period-correct ethos while embracing modern durability enhancements.

Inside this market, one can observe a practical, almost pragmatic, approach to sourcing and integration. Buyers often think in terms of the total package: the gearbox, any refreshed or upgraded clutch packs, the control unit calibration, and the necessary ancillary components that ensure seamless communication with the vehicle’s electronic and hydraulic systems. This is not merely swapping parts; it is re-creating a continuum of performance that respects the model’s final edition status while acknowledging the realities of a world where new production has ceased. In this light, the decision to pursue a DCT470 becomes a careful balance between heritage and function, between the romance of a storied platform and the rigors of modern maintenance. The market’s storytelling—how gearboxes travel from factory line to private garage—makes the decision-making process richer, even if the financial lines are occasionally austere.

For readers who want a glimpse into the broader ecosystem accompanying these transmissions, a practical entry point lies in the adjacent deployment of high-performance hardware that surrounds the Evo X lineage. The same ecosystems that support halfcuts, hoods, and other architectural elements of the car’s chassis and body work are often the gateways to understanding how back-end components like the DCT470 fit into a complete restoration or upgrade. For those curious about how the Evo X’s legacy persists through disassembled subassemblies and period-correct refurbishments, the Evo X halfcut page offers a concrete example of how a car’s broader parts supply chain continues to function even as the original powertrain and chassis combinations evolve in newer platforms. Evo X halfcut.

Looking forward, the trajectory of the DCT470 in the market is shaped by a few enduring factors: the enduring appeal of a full-throttle performance coupe, the ongoing desire to maintain originality in a classic high-performance chassis, and the willingness of buyers to invest in reliability as part of a broader, potentially track-focused project. The economics are not static; they hinge on the health of the secondary market, the availability of refurbished cores, and the willingness of the aftermarket to offer remedies that make the platform viable for more extended use. The external resource landscape reinforces this point. For a deeper dive into upgrade options that aim to bolster durability and shift responsiveness for this specific dual-clutch architecture, one can consult specialized upgrade literature and product briefs that map out the typical improvement path for such installations. External reference: https://www.dekacclutches.com/mitsubishi-evo-x-dct470-upgrade/.

In sum, the market for the Evo X’s DCT470 gearbox is a study in rarity, fidelity, and calculated risk. It is a testament to how performance engineering outlives generation cycles and consumer cycles alike. When a vehicle is revered enough to justify preservation beyond its production run, its essential hardware can become a focal point for a dedicated circle of enthusiasts who treat maintenance as an act of custodianship. The price, the risk, and the payoff are all bound up in the same story: a Final Edition symbol that invites both nostalgia and practical decision-making, a reminder that the most engaging performance narratives often unfold in the spaces between factory doors and private workshops.

null

null

Engineering Velocity: The Hidden Craft of a Rebuilt Six-Speed Dual-Clutch in a Final-Edition Rally-Bred Sedan

In the history of high-performance engineering, the final edition of a rally-bred sedan marks a rare blend of heritage and modern craft. The centerpiece of this narrative is a rebuilt six-speed dual-clutch transmission, a component that quietly anchors the car’s most dramatic capabilities. The aim is straightforward: a transmission that can swap gears with minimal torque interruption, synchronized with the engine’s surge, turning a straight line into a stage and a bend into a deliberate maneuver. In practice, the truth is more nuanced. A reconditioned unit is not merely a refurbished box of gears; it is a meticulously restored instrument whose tolerances, hydraulics, and electronic controls must sing in harmony with the rest of the car’s high-performance architecture. When that harmony is achieved, the effect is transformative–speed feels fluid and speed discipline feels intimate rather than brute force.

The final edition of this lineage carries a particular weight in the car-world psyche. It sits at the end of a long arc that began with humble ambition and evolved into a paradoxical blend of road-going practicality and track-day aggression. In that context, the six-speed dual-clutch configuration at the heart of the machine becomes more than propulsion; it is a deliberate statement about reviving a legendary chassis without losing its identity. Refurbishment projects like this strive for reliability under demanding conditions that push parts to their limits—a test of engineering discipline as much as of speed. And speed, delivered through refined gear changes, does not come from brute torque alone. It arises from a precise cadence: a balance between engine torque delivery, transmission ratios, and the suspension’s ability to keep the car planted as it responds to the driver’s inputs.

A closer look at the transmission reveals why the reconditioned unit earns its keep. The six forward gears map a broad range of operating conditions—from the low-end torque that powers starts to the higher gears that sustain momentum on longer stretches. The dual-clutch arrangement shines where timing matters most: the instant a driver lifts off or presses the throttle again, the next gear can engage with minimal interruption to the drive shaft’s torque path. In practice, this means near-instantaneous response during quick upshifts on a hot lap, and smooth, predictable downshifts through bends at pace. The refurbishment process is the quiet hero: pivots are reconditioned, worn gears replaced, seals restored to regain precision. Clearances that control mesh engagement are re-established, and hydraulic and control-system logic that modulates clamping pressure and shift timing are calibrated. The aim is not merely to work again, but to operate as if brand-new—with the wisdom of experience borne from years of performance stress.

In this context, the collaboration between engine and transmission becomes crucial. The engine in the final edition delivers robust mid-range torque, and the gearing is set to exploit that torque curve with a short, purposeful spread. When properly tuned, the result is a sprint from rest to road-legal speed that feels cinematic rather than abrupt. A measured 0 to 100 km/h time illustrates the synergy: acceleration is brisk, the chassis keeps the action controllable, and driver timing remains paramount. The vehicle’s character benefits from the transmission’s ability to maintain power delivery through shifts that feel precise and anticipatory. It’s not just a mechanical upgrade; it’s a recalibration of how momentum is managed and how it translates into control under pressure.

The driving experience becomes a choreography of inputs and feedback. A flawless heel-and-toe in a lean corner is met with a cadence that feels almost preternaturally exact. There is a tactile sense of reliability: firm, assured engagement as gears click into place, pedal feel remains linear, and throttle response follows a predictable arc. Enthusiasts praise the immediacy of a well-tuned dual-clutch that preserves the car’s character while meeting modern performance standards. In the final edition, that balance is essential. The chassis was designed to be quick and communicative, not merely fast. The upgraded gearbox respects that design, delivering shifts that feel intentional and smooth, maintaining driver confidence even at the limit.

Why refurbish rather than replace? Durability and performance under demanding driving scenarios define the gearbox’s value. A rebuilt unit is engineered to endure a blend of street use and track-like stress by replacing vulnerable parts before they fail, ensuring heat, vibration, and load do not erode precision. This resilience allows drivers to focus on line and rhythm rather than gear hesitations. In the end, reliability and responsiveness converge to deliver a driving experience where the car communicates clearly with the driver, inviting confident control that suits a storied track pedigree.

Beyond the propulsion, the broader significance lies in honoring heritage while embracing modern reliability. A well-executed refurbishment spices the car with predictable, repeatable performance and a sense that the machine can be trusted in the long run. What results is not merely speed, but a more coherent driving experience: rapid gear changes without interrupting flow, and the momentum needed for dynamic cornering and swift transitions. The rebuilt six-speed dual-clutch becomes a bridge between past glory and present capability, translating a legendary chassis into a contemporary driving experience for daily use or track days.

For readers curious about the ecosystem around this lineage, compatible upgrades such as lightweight, stiffening body components and thermally robust reinforcements can complement the drivetrain while preserving the car’s character. When integrated thoughtfully, these elements reduce parasitic energy losses, maintain stability under load, and enhance shift feel without compromising the vehicle’s essence.

In closing, the story of a rebuilt transmission in a final-edition sedan is as much about the people behind it as the mechanism itself. It honors technicians who restore life to a complex, highly stressed system, engineers who design control maps that coordinate shifts with throttle and braking, and drivers who learn to trust a meticulously rebuilt machine. In this light, the final-edition car becomes more than a car; it becomes a testbed for precision and discipline, a living example of how careful refurbishment can preserve heritage while delivering contemporary clarity on road and track.

Final thoughts

In conclusion, the Mitsubishi Evo X 10 SST DCT470 reconditioned gearbox stands as a testament to high-performance engineering and innovation. Its technical specifications cater to driving enthusiasts and business owners looking to capitalize on the unique advantages offered by this niche market. The partnership between Ralliart and Dodson SSP has fortified the gearbox’s reputation, ensuring its status among automotive aficionados. As businesses engage with this sector, understanding the dynamics of market availability, economic value, and performance capabilities will be crucial for making informed decisions. Embracing these insights allows for better strategic planning and positioning in an ever-evolving automotive landscape.