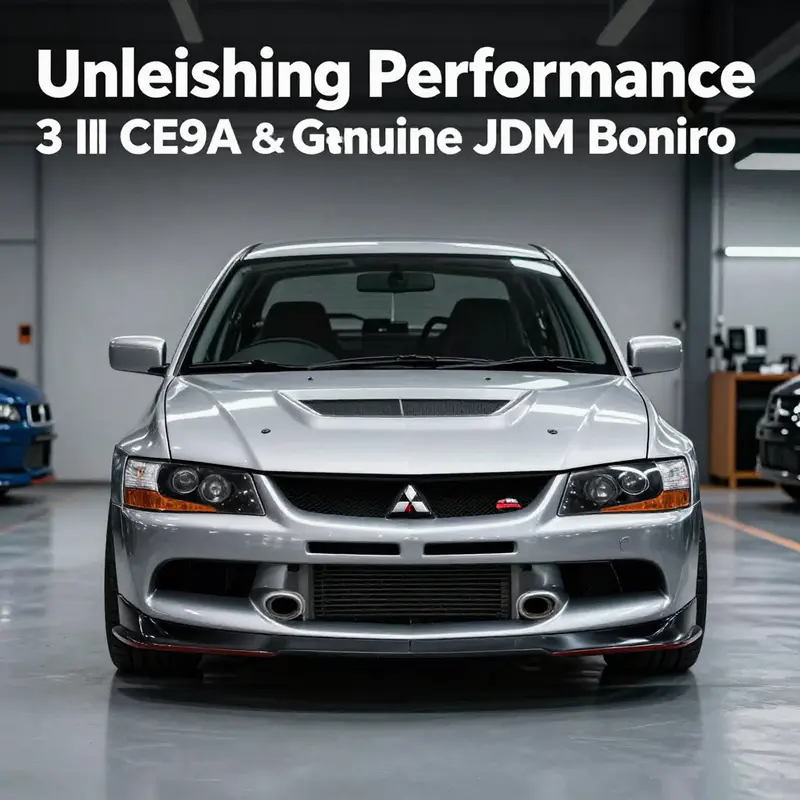

The Mitsubishi Lancer Evolution III (CE9A) is revered among automotive enthusiasts for its performance and design-driven heritage. Central to its identity is the Genuine JDM Bonnet, an essential component that not only enhances functionality but also preserves the vehicle’s aesthetic lineage. This article delves into the intricate specifications, standout design features, and the market applications of this bonnet. Readers will gain a comprehensive understanding of how the CE9A Bonnet contributes to the vehicle’s reputation, performance, and collectible value in today’s automotive landscape.

Genuine JDM Bonnet for the Evolution III: The Authentic Core of Restoration and Performance

The bonnet is more than a cover for the engine bay; it is the front-line steward of a car’s character, a tangible link to a factory’s engineering intent, and, for collectors and track enthusiasts alike, a decisive factor in how a car breathes, cools, and presents itself. In the context of the Evolution III lineage, the genuine JDM aluminium bonnet stands as a rare fusion of purpose-built design, material discipline, and factory-truth fidelity. It embodies an era when Mitsubishi, and the broader Japanese performance community, treated the bonnet not as a mere sheet of metal but as a crucial component of the car’s aerodynamics, weight balance, and thermal management. Restorers who chase the look and feel of the original car—without surrendering to modern aftermarkets that might dilute its heritage—recognize this part as a keystone. Its presence signals an intent to preserve the vehicle’s DNA, while its design allows for the precise integration of all downstream performance dreams, from track-ready cooling to show-car presentation.

Design philosophy in this space is inseparable from the car’s era. Built specifically for a late-1990s chassis, the genuine bonnet adheres to OEM specifications that balance rigidity, weight, and airflow. The aim is not to reinvent the wheel but to reproduce the exact guardrail that left the assembly line, ensuring a perfect match to the fenders, grille line, and hood lines that define the car’s aggressive face. The aluminium construction is no accident. Aluminium alloy provides an optimal mix of lightness and stiffness, a critical consideration for a performance-focused hatchback that relies on swiftly responding suspension dynamics and precise steering feedback. The standard weight, verified in supplier documentation, lands around twelve kilograms, with a narrow tolerance that signals a gauge of material thickness designed to withstand high heat from a high-revving engine while resisting fatigue. This is not a piece that should feel flimsy or flexible under load; it should feel robust, a deliberate counterpart to the high-performance goals of a daily driver that might also be pressed into the role of a weekend racer.

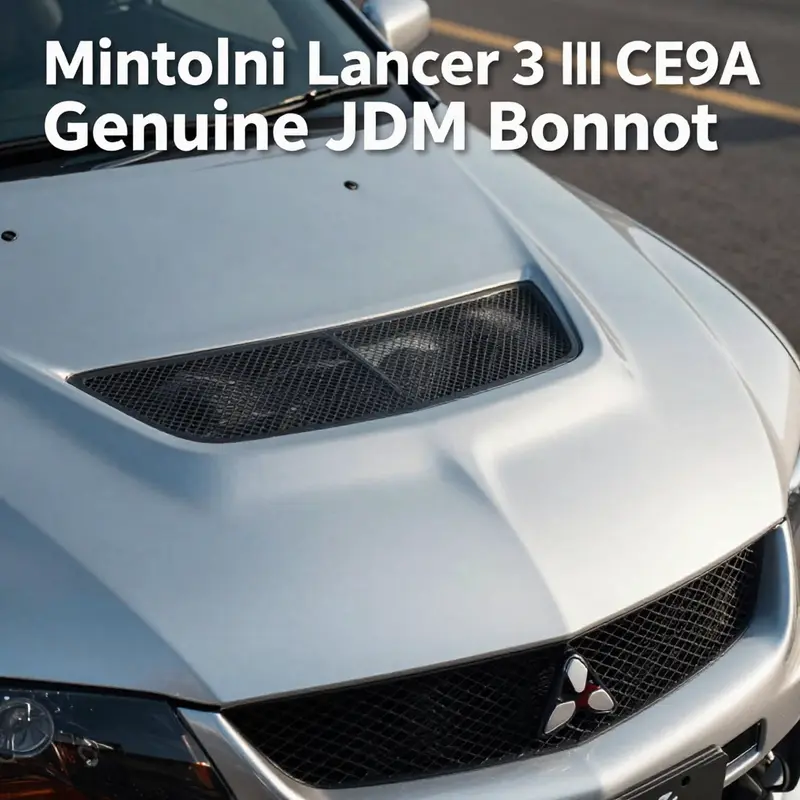

The dimensioning and contouring of the bonnet are equally telling. The original design threads a line of aggression through a broad intake aperture, a feature that serves a dual purpose: it helps manage engine bay temperatures during demanding driving scenarios and it contributes to the car’s visible stance. For the era’s engineering ethos, airflow management was not an afterthought; it was integral to how the car performed at speed. The integrated air intake ducts are engineered to work in concert with the vehicle’s overall aerodynamic package, including a front splitter and rear wing that contribute to downforce and high-speed stability. This is why installing a genuine JDM bonnet is more than a cosmetic swap. It is a step toward preserving the car’s intended airflow paths, the same paths that guided coolant and intake air around the turbocharged heart that defined the model’s performance envelope. The result is a holistic efficiency: the engine breathes more freely, and the brakes stay cooler longer as the airflow through the engine bay reduces thermal buildup that could otherwise sap performance.

Finish and hardware are more than superficial details. The bonnet’s surface—whether left in its raw, factory-ready state or prepared with primer for a meticulous repaint—speaks to the car’s authenticity. The finish is compatible with OEM color codes and repair processes, allowing the piece to blend seamlessly with the rest of the bodywork. For some versions, factory-mounted hinges and latches align precisely with the original body structure, removing guesswork from the installation and ensuring that hood alignment, latch operation, and gap tolerances remain consistent with the car’s original manufacturing standards. This coherence is essential for purists who seek to preserve factory geometry, because even minor misalignments can cascade into rattles, wind noise, hood flutter at speed, or unequal hood gaps that upset the car’s visual balance. The genuine bonnet’s tolerances are a reminder that, for this particular model, genuine parts are not optional luxuries but practical necessities for upholding the car’s designed performance and iconic look.

Beyond the cosmetic appeal, the lightweight aluminium construction contributes to real-world handling benefits. Reducing unsprung weight by even a small amount can sharpen steering response and improve suspension articulation, especially on a chassis that already carries a characteristic balance between grip and agility. In a car where the engine bay is a visible theater for performance drama, the bonnet’s lightness pairs with the rest of the platform’s weight distribution to preserve the intended front-end feel. This matters on the street, where quick direction changes demand immediate, predictable responses, and on the track, where every kilogram shaved from the front end translates into crisper turn-in and more consistent cornering under load. The balance between mass and rigidity is no accident. It reflects nuanced engineering choices about how to maintain structural integrity across the bonnet’s fields, while ensuring the panel resists thermal expansion and deformation under the heat of a turbocharged air stream and hot brake rotors nearby.

From a restoration standpoint, authenticity carries a tangible premium. A genuine OEM part offers a precise fit with the vehicle’s structure—no guesswork about compatibility or fitment tolerances, no compromise on the hood’s line with the fenders. Authenticity protects the car’s value in the eyes of collectors who prize documentation, provenance, and the idea that every component played a specific role in the car’s original behavior. In addition, the aluminium bonnet’s corrosion resistance surpasses typical steel counterparts, an advantage for vehicles living in varied climates or exposed to high humidity during daily use and storage. The material choice and corrosion resistance, coupled with the bonnet’s shape, help preserve not just the car’s appearance but its overall health over decades. For someone who intends to preserve a CE9A-era vehicle for the long haul, this part becomes a long-term investment in the car’s ability to present itself faithfully at shows and on club runs, while still offering the potential to support future performance goals should the owner decide to move toward a more aggressive track configuration.

The compatibility window is another crucial facet. The genuine bonnet was designed for a specific production window of the Evolution III lineage, aligning with the car’s chassis geometry and the front-end assembly that defined the model’s unmistakable silhouette. The February 1995 to December 1997 timeframe marks a period when the chassis and body components were tuned to deliver a precise combination of weight, stiffness, and aerodynamic efficiency. For anyone seeking to restore an example to its original state or to build a family of cars that share a similar design language, this alignment matters because it ensures that the bonnet matches both the structural mounting points and the hood’s curvature with the rest of the forward assembly. It reduces the risk of misalignment or misfit that can plague non-OEM replacements, especially when a car’s exterior cues matter as much as its mechanical performance.

The practical path to restoration, therefore, begins with sourcing through official channels—Mitsubishi JDM parts suppliers or authorized dealerships that can verify authenticity and provide documentation. The importance of this step extends beyond mere provenance. It ensures that the part’s specifications, like the measured weight and the built-in air management features, conform to the car’s original engineering intent. When a owner or restorer discusses a project with such suppliers, they are not just buying a piece of metal; they are acquiring a carefully engineered component whose fit, finish, and performance expectations have been pre-validated by the original manufacturer. In this sense, the bonnet becomes a cornerstone of a restoration plan rather than a simple bolt-on upgrade. It anchors the vehicle’s character in a way that’s verifiable and durable, preserving the integrity of the car’s historical narrative while still accommodating modern expectations for reliability and function during spirited road use or controlled track events.

For those who pursue a broader spectrum of authenticity, the discussion often turns to how today’s aftermarket options compare with the original equipment. While carbon fiber or composite replacements can offer substantial weight savings, they don’t automatically preserve the car’s original silhouette, line, and mounting geometry. The genuine aluminium bonnet stands as a reminder that the Evolution III’s design was a product of careful calibration between weight, stiffness, and airflow, and that maintaining those relationships is essential to achieving a faithful recreation of the car’s intended performance envelope. Yet the presence of alternative materials in other generations—such as carbon fiber bonnets for later models—illustrates the range of options that a dedicated restorer can consider when building a contemporary interpretation or a track-focused derivative. The underlying principle, however, remains: any deviation from the original geometry must be deliberate, justified by measurable gains, and executed with an eye toward preserving the car’s characteristic tactility and visual language. And in the case of the genuine JDM bonnet for the Evolution III, the gains are most evident in the trust it builds with the car’s future self: a vehicle that remains faithful to its beginnings while being prepared for the challenges of modern performance contexts.

To situate this piece within the broader ecosystem of parts and restoration culture, it is helpful to consider how enthusiasts discuss replacements across generations. A representative note is that the carbon fiber bonnet hood developed for a later evolution demonstrates the wide spectrum of aftermarket options available today. If the goal is to preserve the authentic front-end geometry and match the car’s original look and feel, the OEM aluminium bonnet remains the most faithful choice. It ensures that the hood’s curvature, the alignment with the grille, and the line of the bodywork create a single, cohesive image when viewed from front, side, and above. It also makes the hood’s mechanical interface—hinges, latches, and their mounting points—predictable and reliable, which is particularly valuable for boards of purists who participate in concours or display-focused events. In the end, the decision often comes down to the balance between authenticity and the owner’s performance priorities. The genuine JDM bonnet channels a lineage of engineering that valued exactness, durability, and compatibility, and for many collectors and drivers, that is simply the most compelling foundation upon which to build a true, well-preserved Evolution III.

For readers seeking further context on how this component fits into the car’s broader historical arc, a connected resource offers a wider view of the Evolution family and its engineering evolution over the years. This external reference complements the chapter’s emphasis on original-spec parts, giving a fuller sense of how OEM components anchor a car’s heritage while aftermarket and contemporary engineering push the envelope in new directions. External reference: https://en.wikipedia.org/wiki/MitsubishiLancerEvolution

As a closing reflection, the genuine OEM aluminium bonnet for the Evolution III embodies more than a material choice or a design cue. It encapsulates a philosophy of authenticity that respects a car’s origins while enabling a disciplined approach to modern-day performance and preservation. It is the kind of part that invites a careful, knowledgeable restoration approach—one that values exact fitment, precise tolerances, and a visual language that readers can recognize at a glance. In that sense, the bonnet is not merely a protective cover for the engine bay; it is a statement about how a car’s past informs its future, and how a community of enthusiasts sustains a legend by guarding the authenticity at the very surface that meets the wind.

Breath, Heat, and Flow: The CE9A Genuine JDM Bonnet and the Aerodynamic Identity of the Lancer Evolution III

The Mitsubishi Lancer Evolution III, CE9A, is remembered not merely for its rally-tinged torque and razor-edged demeanor, but for the way every panel and component seems to have been engineered in service of a single purpose: to harness air, heat, and mass with surgical precision. Among the parts that translate that purpose into measurable performance, the genuine JDM bonnet stands as more than a cosmetic statement. It is a functional surface, a controlled entryway for air, and a carefully tuned piece of a larger aerodynamic conversation that defines how this car breathes on a track and settles into rhythm on a twisty road. In the CE9A’s design language, the hood is a central, almost vocal element. Its raised crown—often described in lay terms as a power dome—signals more than aggression. It is a deliberate sculpture that carves a path for cooling, redirects boundary layer flow, and sets up the front end for predictable, drama-free behavior at speed.

The distinction of a genuine JDM bonnet rests first in fitment and material fidelity. OEM origin means the component maps exactly to the geometry of the CE9A’s engine bay and front fenders as the factory intended. This is not a replacement part chosen for a quick fix; it is a restoration of the car’s original aerodynamic profile, a reassembly of the front-end geometry that preserves the wind-tunnel-tested relationships between hood line, grille opening, fender curvature, and bumper silhouette. When the bonnet is mounted, the panels align perfectly at key points—gaps, seam lines, and mounting points—that matter for both performance and longevity. The value of that precision becomes most evident during high-load driving, when every millimeter of clearance or misalignment translates into a deviation in airflow, a shift in pressure distribution, or a minor but cumulative source of drag.

The power dome on the CE9A bonnet is more than a sculptural flourish. It is an air intake channel by design, a path that captures cooler ambient air and funnels it toward the engine bay. The advantage is twofold. First, the intake geometry under the hood helps reduce thermal buildup around the top of the engine, where heat soak can creep in under sustained hard driving or on long, relentless sessions on a circuit. Cooler intake air helps maintain the density and temperature balance that the engine demands for consistent combustion and robust reliability. Second, by shaping the central hood into a slightly elevated, smooth contour, the bonnet contributes to the front-end’s overall aerodynamics. The hood’s curvature guides air across the surface with less abrupt separation, which lowers the pressure drag and minimizes local turbulence that could otherwise spill into the area around the windshield or into the orifice of the grille. It is a subtle but meaningful contribution to the Evo III’s capability to stay planted and linear at speed, a trait that rally heritage and race-inspired engineering both prize.

Material choice and weight competence lie at the heart of the CE9A bonnet’s performance rationale. In its genuine form, the hood is built to strict factory specifications, chosen for a balance of rigidity, impact resistance, and weight. The aim is not to chase the lightest possible component but to ensure a favorable weight-to-strength ratio that does not compromise the car’s dynamic balance. For a vehicle that owes much of its agility to a nimble front end and a chassis tuned for rapid steering inputs, the bonnet must resist flutter and flex at high speeds while remaining responsive to the driver’s inputs at the wheel. A hood that is too heavy dampens the front-end response; one that is too flexible risks distortions under load. The genuine OEM approach, by contrast, emphasizes predictable mass distribution and structural integrity, so that the front clip behaves in a way that inseparably ties to the car’s suspension geometry and tire grip. In a car known for its aggressive, rally-bred persona, that predictability is a form of performance in itself.

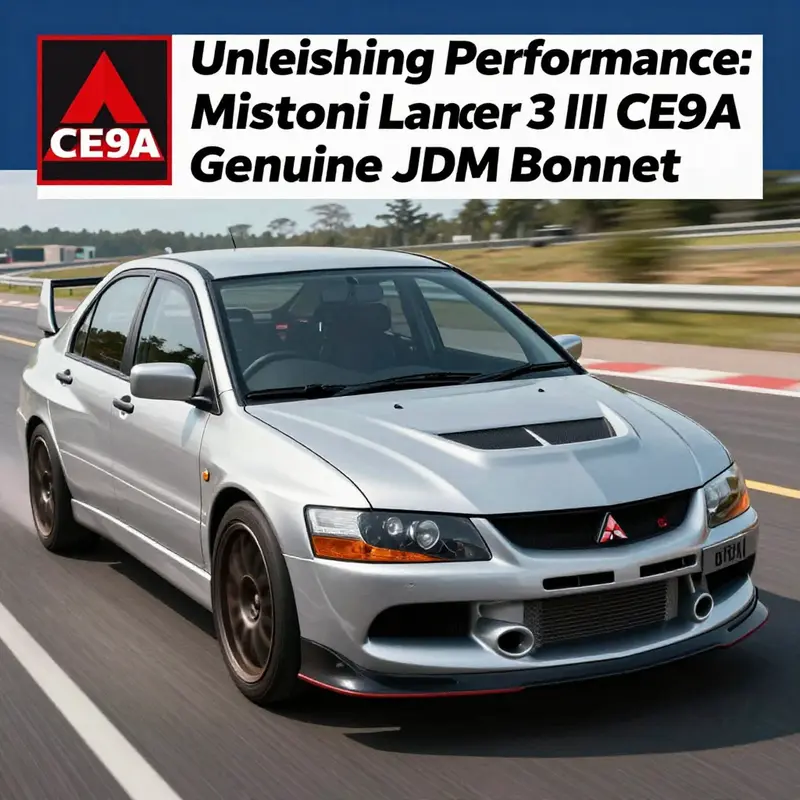

The CE9A bonnet does more than channel cooling air; it participates in the broader aerodynamic choreography of the Evo III’s front fascia. The way the hood curves into the front bumper, and how the central line interacts with the grille aperture and the headlights, matters to the way air travels around the nose. On a high-speed straight, smooth airflow over the hood reduces jagged wake behind the front wheel wells and reduces the chance of buffeting at the base of the windshield. On a corner, where the car’s balance hinges on the front end’s ability to bite into the tarmac without washing wide, the hood’s line helps maintain a coherent flow that feeds into the front fenders and side skirts. Even small changes in geometry—say, a slightly different crown height or a marginal variation in the hood-to-cowl clearance—can alter how pressure builds and dissipates along the car’s leading edge. In this context, owning a genuine CE9A bonnet is a visa into authentic performance; it preserves the exact aerodynamic conversation the engineers intended when the Evolution III left the factory.

The practical implications of authenticity extend well beyond fit and finish. For track days and spirited driving, the difference between a correct, OEM-compliant hood and a non-OEM alternative can be felt in thermal behavior, engine response, and handling feel. The cooling system on the Evolution III is a compact, well-tuned network designed to operate within a specific temperature envelope under demanding conditions. A correctly designed hood with an integrated air intake helps sustain that envelope by ensuring a steady influx of cooler air into the engine bay. In turn, fuel and ignition maps can rely on more stable operating temperatures, which translates to steady power delivery and less thermal fatigue. The bonnet’s design also influences the air that travels over the radiator and intercooler. By providing an optimized crossflow pattern and reducing unnecessary turbulence at the front, the genuine hood helps maintain effective heat exchange, which is particularly valuable during a multi-lap session where repeated high-load duty cycles can push the cooling system to its limits.

For enthusiasts pursuing authenticity, the decision to source a genuine bonnet is, in part, a decision to restore a particular sensory and mechanical feel. The hood’s weight, its latch geometry, its spring tension, and even the subtle acoustic signature of the front-end under load are all part of the Evo III’s character. Restoring a CE9A to factory specification—whether for daily driving, weekend track duties, or as a piece of a broader collection—means honoring a design language that balances aggression with discipline. It means acknowledging that the vehicle’s look—its air intake silhouette, its crisp edges, the way the hood meets the fenders—was part of a holistic aerodynamic system calibrated around the CE9A’s engine, its turbocharged heart, and the road or rally stage for which it was built. In a modern context, that fidelity matters not only to purists but to anyone who seeks a car that behaves as the factory intended when driven at the limit.

The value of sourcing through official parts channels is not simply about guaranteed fit. It is about ensuring that the hood you install is consistent with Mitsubishi’s engineering intent, down to the micro-level tolerances that affect assembly and maintenance. When a genuine part is acquired, it comes with the reassurance that the hood’s hinge geometry, the under-hood seal lines, and the central reinforcement are aligned with the car’s original manufacturing standards. This alignment matters when you consider future serviceability, paint matching, and the integrity of the hood’s surface over time. In the world of classic and rally-inspired performance, where many owners pursue restoration or faithful replication, the ability to reference official documentation and confirm authenticity is a practical advantage that resonates through the car’s resale value, its driving experience, and the certainty of long-term ownership.

As readers consider the CE9A bonnet’s role within the Evo III’s broader aerodynamic and thermal framework, it is useful to reflect on how this component fits into the entire front-end package. The hood does not operate in isolation; it is the first major interface through which air meets the car. The subsequent air handling pathway—across the bumper, into the radiator and intercooler, and along the underbody—relies on precise geometry and coherent surface flow to minimize drag and manage pressure distribution. The CE9A bonnet’s design is thus a keystone in a carefully calibrated architecture. It speaks to Mitsubishi’s philosophy for the EVO series: performance is not a single feature but the result of how a front end orchestrates air, heat, and momentum as a unified system. In that sense, the genuine bonnet is not simply a replaceable body part; it is a key to preserving a machine’s original intent, ensuring that every turn-in, every long straight, and every late-apex exit carries the same aerodynamic intention the engineers first imagined.

For collectors and restorers, the bonnet also provides a tangible link to the CE9A’s era—an era when JDM performance was defined not only by power numbers but by the way form followed function in a compact, highly capable sedan. The bonnet’s presence completes the visual narrative of the car’s front end, a visual cue that aligns with the aggressive stance and the air intakes that signal cooling and performance readiness. Recreating that exact stance requires careful attention to the hood’s curvature, its surface finish, and its alignment with the rest of the bodywork. In practice, this means that even small deviations in hood shape can alter the perceived and measured aerodynamics, affecting how the vehicle engages with air at high speed. The genuine CE9A bonnet, therefore, becomes a practical standard against which restorations or period-correct builds are measured. It embodies a balance of aesthetic intensity and engineering discipline, a physical reminder that performance cars of this class are as much about how air and heat are managed as they are about horsepower numbers.

In closing, the CE9A genuine JDM bonnet is a linchpin in the evolutionary story of Mitsubishi’s rally-bred Lancer. It anchors the front of the car to a dynamic aero profile, sustains the engine’s thermal envelope under pressure, and preserves the car’s original tactile and audible cues that enthusiasts associate with the Evo III experience. For those who seek authenticity and the full potential of this iconic platform, aligning with the OEM bonnet is a step toward honoring the engineering lineage that defined this generation of the Lancer. The bonnet is, in essence, the vehicle’s breathing mechanism, its shield against excessive heat, and its gatekeeper for a front-end flow that allows the Evolution III to carry its momentum with the precision that fans and drivers alike remember from the era when Mitsubishi’s rally-bred sedan carved a bold, unmistakable silhouette onto the stage of performance car history. For readers who want to explore related front-end components or potential restoration paths, consider viewing a carbon-fiber hood option linked to classic performance platforms such as the 1994-1999 Mitsubishi 3000GT Pit Fighter Carbon Fiber Hood, which offers a glimpse of how carbon fiber alternatives have long sought to balance stiffness, weight, and aesthetic aggression in a way that resonates with the CE9A’s ethos. External reference resources: https://www.mitsubishiparts.com/.

Authenticity in Motion: Preserving the CE9A Genuine JDM Bonnet and the Soul of Evo III

A car is more than its silhouette or its engine bay. It is a history lesson in metal, heat, and the careful choices of every creator who designed, built, and finally preserved it. When a genuine JDM bonnet crafted for the CE9A variant of the Evolution III rests on a car that still bears its original character, what you are seeing is not merely a replacement part but a hinge point between past and present. This hood, conceived during the mid 1990s for a market that prized unfiltered performance and direct connection to the road, carries a particular gravity. It is built to endure, to align with factory mounting points, to mirror the exact curvature of the body, and to accept the metal finish that was chosen by the original assembly line. The bonnet is a physical artifact of a moment when hot hatch technology was pushing into a new era of all wheel drive discipline and rally inspired engineering. In this sense, the piece embodies both engineering discipline and the aesthetics of a car line that has earned a lasting place in the pantheon of performance vehicles.

From a functional perspective, the bonnet for this era is designed with intent that extends beyond smooth lines and a broad surface to a meaningful interaction with the car as a whole. Its large air intake is not merely a stylistic accent; it is part of a thermal strategy that recognizes how the engine bay behaves when the engine is pushed toward higher rpm. The raised profile is subtle, yet it contributes to the way the hood interacts with the rest of the aerodynamic kit. The overall effect enhances engine bay cooling and helps manage the flow of air across the hood at speed. When the car sits on the road or a track, the bonnet becomes a component in a larger system that includes the fenders, the front bumper, and the underbody panels. Together, these parts create a coherent aero package that is both functional and visually decisive. Enthusiasts who chase track times or credible show presence understand that these features are not window dressing. They are deliberate choices that can translate into measurable differences in cooling efficiency, engine response, and even cornering stability at the higher end of the speed spectrum.

What makes a genuine CE9A bonnet especially compelling is the fidelity it preserves in contention with the rest of the vehicle’s architecture. For collectors and restoration purists, the exact contours, mounting points, and finish are non negotiable. Factory accuracy matters because it preserves the “signature” of the original build. A bonnet that slots into place as the engineers intended ensures that the car’s silhouette, line continuity, and the visual cues that identify it as an Evolution III are consistent with the way the chassis was engineered to be experienced. This is not merely about keeping a badge aligned; it is about keeping the fabric of the car intact. The process of restoration or preservation is anchored in meticulous verification. Authenticity is verified through official channels where possible, and through provenance that documents service histories, prior ownership, and the condition history of the metal. In this context, the bonnet becomes a focal point around which the rest of the restoration or preservation plan revolves. The ability to source an OEM piece that fits perfectly and finishes in line with the original color and texture is a rare and valuable opportunity for anyone aiming to deliver a faithful representation of the factory configuration.

For those who pursue performance builds or show car narratives, the genuine metal bonnet holds a particular place in the spectrum of options. While the era did see lighter alternatives and custom approaches that seek to reduce weight, the metal version remains the most durable and the most faithful to the car’s original character. In many builds, enthusiasts will explore lighter materials such as polyurethane for race readiness or carbon fiber for weight savings and a heightened sense of modernity. Yet even as these alternatives become common in the broader aftermarket, the genuine bonnet still serves as the anchor. It anchors the project in authenticity, ensuring that the car can be shown, judged, or remembered in a way that honors its origins. The discussion about alternatives is not a refusal of progress but a recognition that the metal bonnet is a benchmark for authenticity. It is the baseline against which any modification can be measured for how well it preserves the car’s lineage while enabling the desired performance or aesthetic direction.

This lineage is part of a broader culture that values genuine parts as a key to long term preservation. The CE9A, a conduit to a pivotal moment in rally and street performance, is particularly sensitive to the quality of its original components. When a car in this lineage is restored with a bonnet that mirrors the factory piece, the result is a vehicle whose lines, gaps, and shut lines all speak the same language of engineering intention. The bonnet’s finish plays a role here as well. While modern paints and clear coats provide new vibrancy, the original finish has its own story to tell. The surface texture, the way the paint wears at the edges, and any factory grain or sheen are all clues to the car’s history. The process of restoration, then, becomes a dialogue between the present and the past. It invites the owner to consider how the car has lived, how it has endured, and how it will be perceived by future hands that will evaluate again this moment in the vehicle’s life.

In discussions about value, the market for genuine CE9A bonnets reflects a balance between scarcity and demand. Condition is a central driver of value. A bonnet that shows no rust, no dents, and no compromised mounting points commands a premium because it reduces the risk of misalignment and preserves the structural integrity of the hatch opening. Provenance matters as well. A bonnet that has a documented history with a low-mileage, well cared for EVO III tends to attract a premium. Enthusiasts are willing to pay more for a piece with a story that can be verified, because the credibility of the restoration hinges on more than the part itself. Demand remains robust across the collector and enthusiast communities. The CE9A is widely regarded as a turning point within the Evolution lineage, a model that signaled a fusion of rally pedigree with the convenience and accessibility of a refined street machine. That cultural resonance sustains interest in original parts, ensuring that a genuine bonnet remains a tangible link to a storied era of performance engineering.

As a result, the price range for a used, original condition bonnet tends to reflect these dynamics. Market observers have noted that, in the first months of 2026, values can be expected to sit roughly between three hundred and eight hundred dollars depending on condition and provenance. This range captures the tension between scarcity and the willingness of collectors to invest in authenticity. A pristine piece with documented lineage can command a higher-end value, while one with minor imperfections or ambiguous provenance may settle closer to the lower end. It is important to underline that this is a niche market. While a CE9A bonnet may appear as a single part in a catalog, it is in fact a gatekeeper for the entire restoration or preservation narrative. A unit in sound condition reduces the risk and effort involved for a buyer who aims to complete a proper restoration ballast or to build a credible show car. The decision to purchase such a bonnet often aligns with a strategic long term view: to keep the car as close to its original form as possible, to preserve its historical significance, and to maintain the ability to present the vehicle as an authentic artifact of a specific time in automotive culture.

From a practical perspective, buyers should not overlook the logistics that accompany acquiring a genuine JDM bonnet. The trading environment for these parts is highly specialty-driven. Platforms that offer OEM listings can provide crucial verification signals, yet buyers must approach with a careful eye. The documentation accompanying the bonnet matters—service histories, prior ownership, and any signs of restoration or repainting must be scrutinized. Even the smallest discrepancy between the mounting points and the body lines can create alignment problems or aesthetic issues that detract from the overall presentation. The fit is more than a mechanical issue; it is a reflection of the car’s overall integrity. When installed correctly, the bonnet not only seals the engine bay but also completes the front fascia’s visual rhythm, ensuring that the hood line sits in perfect harmony with the fenders and the bumper. This harmony is part of the magic of owning a collector-grade car. It is the moment when engineering precision, historical significance, and personal passion converge in a single, tangible object that you can touch and look at every day.

For restoration purists who want to go beyond simply maintaining the appearance, the option to couple the bonnet with modern precision tools exists. Enthusiasts can study how contemporary paint processes, rust prevention, and hardware preservation techniques can extend the life of a genuine metal piece while still allowing it to perform its protective role. The idea is not to replace the vehicle’s soul with a new part but to preserve it with respect and care. A well-preserved bonnet can become the centerpiece of a broader restoration project, a focal point around which all other components are organized to achieve a faithful recreation of the factory condition. In this way, the bonnet stands as a reminder that the pursuit of authenticity is not a static exercise but a dynamic practice. It invites ongoing attention to detail, ongoing dialogue with history, and ongoing engagement with a community that continues to celebrate the Evolution lineage.

When looking at the broader context of the Evolution family, the CE9A bonnet exemplifies how a single component can carry a disproportionate amount of meaning. It is a piece through which the car communicates its era and its ambitions. A preoccupation with authenticity does not negate progress; it acknowledges that progress can be measured against the standard that original design set long ago. This is why the bonnet remains a compelling object for collectors, restorers, and show organizers alike. It anchors a project, adds tangible value to a restoration narrative, and helps ensure that the car will be recognized not only for its performance on the road but also for its fidelity to the design that sparked its success. In this delicate balancing act between past and present, the genuine CE9A bonnet proves that parts can be more than their functional utility. They can be carriers of memory, carriers of reputation, and carriers of a culture that continues to revere the spontaneity and discipline of a model that redefined what a high-performance sedan could be.

For readers who want to explore modern lightweight alternatives while retaining a strong link to the original design, consider the broader family of bonnet options that honor the same venting philosophy and aerodynamic intent. A contemporary example of such an approach is the carbon fiber variant for a later evolution, which demonstrates how motor sport heritage can be carried forward with new materials and construction techniques. You can learn more about these lighter, yet faithful, options at this reference page: carbon fiber bonnet for Mitsubishi Lancer Evolution X.

In parallel with the physical parts and their histories, buyers and builders should also engage with the wider ecosystem of verification and documentation. The existence of official part listings online helps establish authenticity beyond visual inspection alone. This is particularly important for a component that sits at the very edge of the vehicle, visible to the eye but deeply connected to the car’s critical performance strategies. With a genuine JDM bonnet, owners gain confidence that their restoration or preservation is anchored in a credible lineage and that their investment is protected by a network of trusted suppliers and verified provenance. The end result is a vehicle that not only looks the part but behaves in a way that honors the engineering decisions of the original designers, from the hood latch up to the windscreen and beyond. In the long arc of ownership, this kind of authenticity becomes a contributor to the vehicle’s character, its future appraisal, and its ability to tell a credible story to the next generation of enthusiasts.

As a final note, the market for genuine components, while sometimes described in numerical terms, is really a reflection of community values. It reflects a shared commitment to preserving the rare, the instructive, and the historically meaningful. The CE9A bonnet is a small but potent symbol of that commitment. It affirms that a car can be more than a machine; it can be a vessel for memory, a tangible link to a moment when engineering and passion collided to create something enduring. For anyone who has ever stood in a workshop, hood open and engine exposed, listening to the faint whine of the radiator, the bonnet becomes a kind of confidant. It is a reminder that every era has its own ways of protecting a story, and in the case of the Evolution III, that story is one of relentless pursuit, practical aerodynamics, and a purity of intent that continues to inspire.

External reference for context on OEM authenticity and listing practices can be found here: https://www.ebay.com/itm/144175954320

Final thoughts

The Mitsubishi Lancer Evolution III CE9A Genuine JDM Bonnet stands out not merely as a replacement part but as a significant facet of the car’s legacy. Its specifications ensure compatibility and performance while its design promotes aerodynamics. Analyzing its applications reveals that this bonnet is crucial for maintaining the EVO III’s authenticity, whether for daily drivers or collectors alike. Therefore, for business owners in the automotive sector, investing in such quality OEM parts can enhance their offerings and appeal to dedicated enthusiasts.