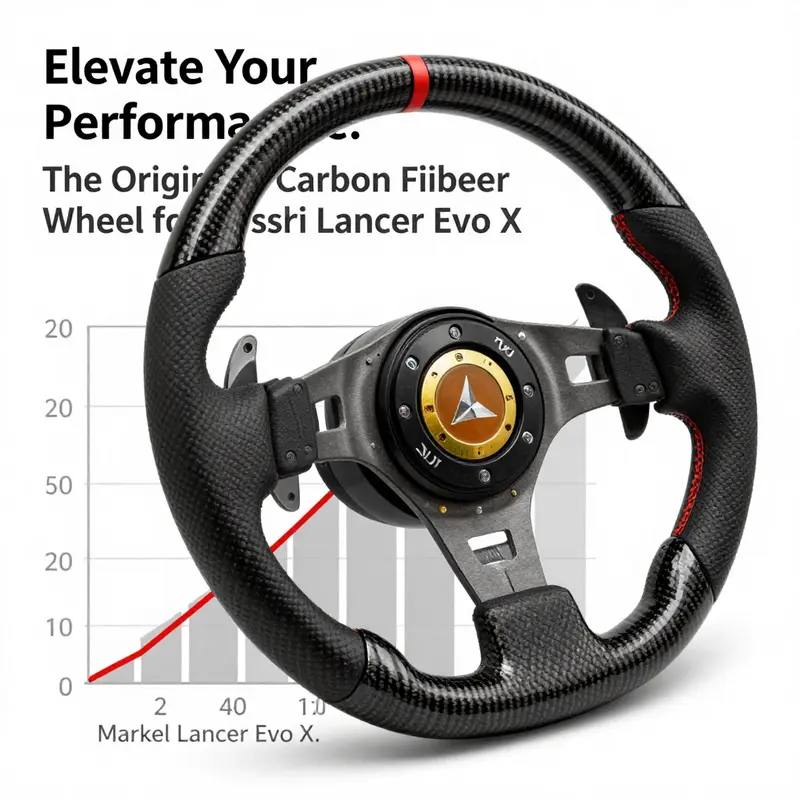

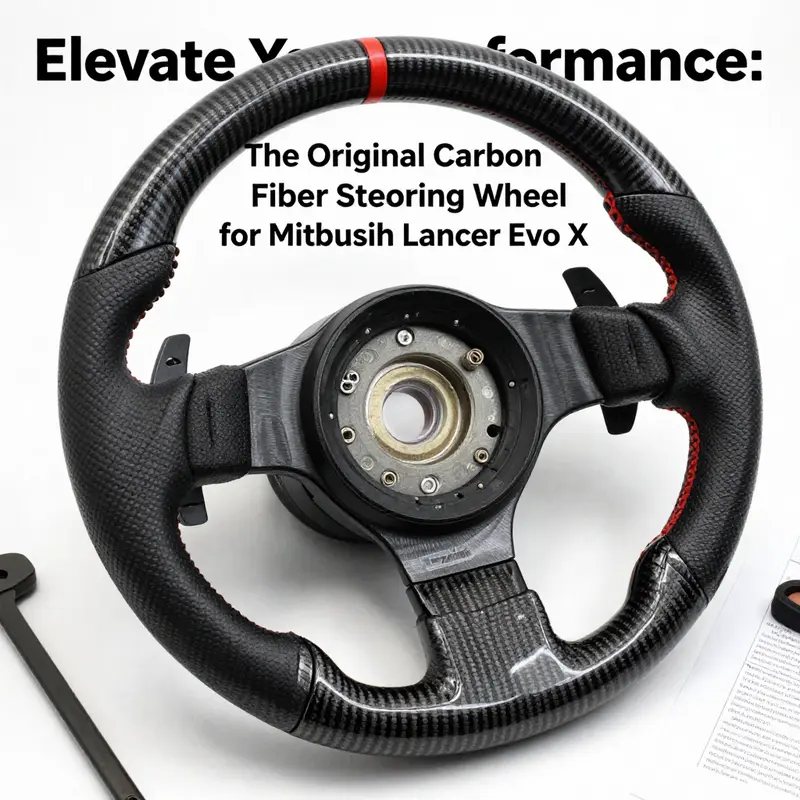

The Mitsubishi Lancer Evo X has carved a niche in the automotive landscape thanks to its performance and agility. Among its standout features is the original carbon fiber steering wheel, designed between 2007 and 2015. This advanced steering wheel is not just an aesthetic enhancement; it offers substantial benefits in terms of weight reduction, improved handling, and a premium driving experience. The following chapters will delve into the steering wheel’s benefits, technical specifications, market positioning, and some potential drawbacks, providing valuable insights for business owners considering this performance upgrade.

Weight, Grip, and Precision: How a Carbon Fiber Wheel Reframes a Performance Sedan’s Cockpit

Across the cabin of a storied performance sedan from the late 2000s, the steering wheel is more than a control; it is the first handshake with the road, a tangible link between driver intent and machine response. The original carbon fiber variant offered for that era represents a tangible shift in how weight, texture, and feedback converge to shape every bend, accelerate, and nail the line through a challenging corner. It is not simply a matter of aesthetics or bragging rights. It is a deliberate engineering choice that speaks to a driving philosophy: every gram of mass that can be removed from the steering assembly translates into sharper, more immediate responses, a calmer angular momentum, and a cockpit that feels more connected to the tarmac beneath the tires. The argument for such a wheel rests on a blend of material science and human physiology, with the driver as the central focus of the design conversation.

The most immediate and measurable benefit is weight reduction. In the context of steering wheels, mass is not only about the outer rim but includes the hub, the spoke structure, and the ancillary hardware that carry and transmit forces from the hands to the steering rack. A carbon fiber wheel, in this context, typically offers a 30–50% reduction in weight compared with standard OEM units. That is not merely a number to admire; it translates directly into a lower rotational inertia. With less mass spinning at the rim, inputs translate to faster wheel response. The driver can make smaller, more precise corrections, and the car responds with a snappier feel. In a car designed to balance speed and control, that refinement is a quiet but meaningful enhancement. When a driver steers with a wheel that weighs less, there is a perception—often accurate—that the chassis is more willing to follow the input, especially when the velocity is high and the line is delicate. The wheel ceases to feel like a passive interface and becomes a living instrument that rewards subtle, deliberate movements rather than brute force.

The craftsmanship behind the wheel matters almost as much as the weight savings. The material quality is described in terms of high-grade Japanese carbon fiber, with a seven-step handmade process that ensures both strength and a premium visual appeal. The weave, the resin, and the curing methodology all contribute to a uniform texture that remains consistent under heat and stress. When a driver rests a palm on the rim, there is a tactile assurance that the wheel was built with care, not cast in a factory line. The seven meticulous steps imply checks for fiber orientation, resin distribution, surface finish, and edge treatment. That level of attention helps ensure that the wheel’s stiffness links directly to predictable handling. It is not just a glossy surface; it is a structural element that resists fatigue while maintaining the exact feel the driver expects as pressure builds in a high-load corner.

The ergonomic design is another piece of the performance equation. The wheel is described as D-shaped with a flat bottom, a contour that is often associated with sport steering for quick access to the pedals and improved legroom when the driver hustles the car through a corner. The anti-slip, leather-wrapped surface adds another layer of practical performance. In spirited driving, grip matters as much as geometry. A textured, leather-wrapped surface helps prevent slip under conditions where hands sweat or when pressure ramps up during aggressive maneuvers. The flat-bottom shape also serves a functional purpose: it reduces reach fatigue during long sessions and lets the driver pull the wheel closer to the chest when the car is pointed into a brisk corner, enabling finer control with less forearm fatigue. The combination of a rigid carbon fiber core and a maintained tactile surface delivers a kind of sensory precision that cannot be matched by a softer, heavier wheel.

But the wheel does not exist in isolation. Its true value emerges when it fits seamlessly into the vehicle’s safety and control systems. A well-designed carbon wheel must preserve or enhance the integrity of the airbag system and horn circuits while not interfering with the steering column geometry. In this case, the wheel is presented as a product that claims an exact fit and reliable integration, designed to maintain the safety and functional standards of the era’s vehicle architecture. The wheel’s connection to the steering shaft, the alignment with the centerline of the vehicle, and the position of the horn contact are all carefully balanced so that the upgrade does not degrade the system’s reliability. The result is a cockpit that remains a safe, familiar space even as it adopts a more aggressive, performance-oriented instrument cluster.

From the driver’s perspective, the effect of these design choices manifests as improved steering feedback. The carbon fiber wheel transmits road textures, tire grip, and transitional forces with a clarity that enriches the sense of connection. A driver can feel how the front tires bite as they approach the limit, how the chassis responds to a subtle pull on the wheel, and how the vehicle’s weight distribution shifts under throttle, braking, and cornering. This feedback loop is essential for drivers who push the car toward its dynamic boundaries, where the balance between understeer and oversteer is negotiated with micro-adjustments rather than brute force. The road becomes less a background to the drive and more a partner in steering. The driver can trust that a small input will produce a predictable, repeatable response, which in turn elevates confidence during aggressive entries and precise mid-corner corrections.

That sense of precision is also shaped by how the wheel communicates with the car’s broader dynamics. Lighter steering mass helps the driver feel the engagement between steering input and the car’s response more quickly. In a performance sedan of that era, steering effort is also a gatekeeper for feedback. Too heavy, and the driver’s inputs become dull and delayed; too light, and the driver may feel disconnected from the road. The carbon wheel, with its stiffer weave and lower mass, tends to strike a compelling middle ground: the heft is reduced enough to sharpen responses, yet the wheel still provides a resistive, tactile feel that anchors the driver’s sense of control. It is a balance that can make moments of late braking, mid-apex stabilization, or a precise feathering of the wheel feel almost intuitive.

There are, of course, trade-offs to consider. Carbon fiber wheels carry a premium cost and present repairability challenges. The material composition, while strong, can be less forgiving than metal in the event of impact or crash, and repairs to a carbon structure are typically more involved and expensive than those to metal components. This means buyers should weigh the performance gains against the financial and practical realities of replacement should the wheel sustain a damaging impact. Another factor is the sense of luxury versus durability. The premium leather wrap, the serial craftsmanship, and the visible carbon weave all contribute to an elevated interior aesthetic—an interior that signals intent and performance even when the car sits in a showroom or a garage. This premium feel can enhance the psychological aspect of the driving experience, aligning the driver’s perception of the car with its capabilities. Yet those same premium details may impose maintenance considerations, such as careful cleaning, wax and sealant compatibility, and the potential for the wrap to show wear over many miles of spirited use.

The original wheel is emblematic of a broader design ethos that honors lightweight performance without sacrificing safety or everyday practicality. It demonstrates how the best performance components operate at the intersection of material science and human-centered design. The driver’s hands, the wheel’s geometry, and the road’s surface all participate in a dialogue that is richer when the wheel is both lighter and more communicative. In that sense, the wheel is more than just a component; it is a statement about how performance engineering translates into the driver’s lived experience. It signals a willingness to trade some mass for more precise, responsive handling, a choice that suits a car engineered to blaze a trail through corners as much as to deliver straight-line speed.

For readers who want to place this upgrade within the broader ecosystem of era-specific performance parts, it helps to consider how such a wheel might interact with other chassis and cockpit enhancements. Not every enhancement is compatible with every steering column or airbag module, so an exact fit and verified mounting approach are crucial. The integration story—where a wheel’s geometry, grip, and weight align with the rack ratio, the airbag system, and the vehicle’s interior tolerances—becomes a central part of the value proposition. In practice, this means choosing a wheel that is designed with an eye toward safe deployment of safety components, as well as one that preserves the tactile and visual cues drivers expect from a high-performance cockpit. The texture, the tension of the leather, and the crisp edges of the rim all contribute to a cockpit that feels intentional, not merely upgraded.

In sum, the appeal of this carbon fiber steering wheel lies in its synthesis of weight efficiency, material excellence, ergonomic design, and precise integration. It offers a more immediate conduit from driver inputs to road behavior while sustaining the safety and quality expectations that define modern performance interiors. The result is a cockpit that communicates with the driver in a way that is both intimate and exacting—a place where every turn of the wheel promises a more direct, more controlled experience and where the road response feels immediate enough to influence the line you choose to ride through a corner. The choice to adopt such a wheel is a choice about how you want the road to feel when you are in command: lighter, crisper, and more connected to the moment of steering than ever before.

For readers who want to explore related topics within the same era and platform, you can find related discussions on how other cockpit components were aligned with the performance goals of that time; for instance, a detailed exploration of exterior upgrade components demonstrates how a cohesive program can yield a more complete, unified driving experience. See this internal reference for more on compatible bodywork options from the same production window: 2008-2015 Mitsubishi Lancer Evo X rear bumpers.

External resources further illuminate the discussion of carbon fiber steering wheels and the broader context of interior material choices. An authoritative external examination emphasizes how a genuine carbon fiber wheel can blend structural integrity with a premium tactile feel, reinforcing how such components contribute to the overall driving experience. External reference: https://www.carinterior.com/real-carbon-fiber-steering-wheel-for-mitsubishi-lancer-evolution-evo-x-10-2008-2015.html

Weight, Grip, and Feedback: The Carbon Fiber Steering Wheel Behind a Rally-Bred Compact’s Control

In a cockpit where every ounce and every touch matter, the steering wheel does more than steer. It is the primary interface between the driver and the machine, a living conduit for input, feel, and intention. The carbon fiber wheel, designed for a specific era of a rally-inspired compact, embodies a philosophy that values lightness without compromising strength, and tactile engagement without distracting ornamentation. It is not merely a cosmetic upgrade; it is an engineered companion that fines tunes the balance between the driver’s hand and the road. To understand its impact, one must begin with the material and the geometry, and follow how these choices cascade into the nuanced driving experience that serious enthusiasts chase on back roads and race tracks alike.

The core of the wheel is a three-kilogram real carbon fiber construction, a choice that immediately signals intent. The 3K weave is recognizable at a glance, a tightly interlaced pattern that speaks of rigidity, stiffness, and lightweight resilience. This is not a forged alloy or a thick plastic shell wearing a veneer of sport; it is a real carbon composite that resists deformation under high lateral loads while keeping the overall mass to a minimum. The result is a substantial reduction in rotational inertia. When the driver flicks the wheel from lock to lock, the sensation is instantaneous and direct. The steering becomes a more responsive instrument, a tangible extension of will. The reduction in mass makes the wheel feel freer, while the response time of the steering system improves, translating into quicker initiation of steering inputs and more immediate feedback as the tires meet the pavement.

Size and shape are the quiet heroes of the upgrade. The diameter remains nearly identical to the stock wheel, a deliberate choice that preserves the familiar three-spoke silhouette and the overall steering geometry that seasoned drivers rely on for consistency. The thickness and rim profile are calibrated so that the grip sits naturally in the fingers, the thumb positions resting in comfortable hollows rather than fighting against an unfamiliar contour. The most visible design signature is the flat-bottom form, a feature shared with many performance-oriented interiors. This geometry clears space for aggressive driving postures, facilitates easier ingress and egress when the cockpit is crowded with racing gear, and reduces the chance of the wheel brushing the knees under tight maneuvers. The effect on the driver’s sense of control is profound: the wheel feels like a precise tool rather than a passive accessory.

Compatibility matters as much as character. The wheel is engineered to be a direct replacement for the factory-installed unit, designed to slot into the same mounting points and to interface with the vehicle’s clock spring without modification. In practical terms, this means a straightforward installation that preserves the integrity of the vehicle’s airbag system and safety electronics. For a driver who spends weekends on a track or just enjoys spirited canyon runs, that seamless integration is essential. The engineering philosophy here is clear: performance should be accessible without creating new safety concerns or requiring invasive tinkering with the car’s essential systems. When installed by a professional or an experienced enthusiast, the upgrade promises not only a more engaging steering feel but also a preservation of the vehicle’s standard safety envelope.

Surface finish and tactile experience complete the picture. The carbon fiber surface is finished with either a high-gloss or a matte coating, each choice offering its own visual drama and touch. UV-resistant coatings protect against fading and micro-cracking that can accompany long hours under sun exposure, helping the wheel retain its crisp appearance and structural integrity over time. Beneath the carbon weave lies an ergonomically tailored wrap zone, where premium leather or Alcantara is applied to the grip sections. This is where the senses come into play: the leather provides a familiar, slightly grippy surface that communicates the wheel’s weight and any impending slip, while Alcantara delivers a soft, sumptuous feel that remains steady as temperatures swing and the hands sweat on a hot day. The combination of a rigid, lightweight core with a refined, tactile grip gives the driver a robust sense of connection; the wheel feels alive in the hands, as if it were an extension of the driver’s own reflexes rather than a passive interface.

All of these choices culminate in a more cohesive driving experience. The wheel’s reduced mass lowers the energy required to change direction, which in turn translates into crisper turn-in and a more precise steering arc. For the driver, that means less effort to maintain line and more confidence in negotiating variable grip, whether on a rain-slick mountain pass or a race-line sprint through a chicane. Yet the upgrade does not abandon comfort or everyday usability. The wheel remains dimensionally faithful to the original, preserving the same grip circumference and finger grip positions that a driver uses during daily commutes as well as high-adrenaline sessions. The D-shaped form factor, a hallmark of performance-oriented interiors, maintains a flat bottom that clears the knees and enhances ingress and egress, particularly when the driver is wearing a racing suit or carrying a helmet. In short, the wheel bridges the divide between track-day capability and daily practicality.

The interior environment around the wheel is not an afterthought. It is an arena where subtle interplays of material, texture, and interface determine how much the driver trusts the car at the limit. The grip zones, often finished with premium leather or Alcantara, are more than a surface treatment; they define the driver’s tactile map of the vehicle. When the hands find the same comfortable grips they subconsciously know from countless miles, confidence follows. The result is not just better grip in a literal sense but an amplified sense of orientation: the driver can discern subtle differences in road texture through the wheel, transmitting tire feedback through a more intimate and precise channel. That feedback is not merely information; it is a conversation with the chassis. It tells the driver when the tires are approaching the limit, how the wheel is interacting with a given corner, and how much steering input will yield the desired shift in trajectory. It is a direct line to the road, and for many drivers, that line is where mastery lives.

From a performance perspective, the saga of this wheel is as much about consistency as it is about feel. The very act of replacing a stock item with a carbon-fiber alternative communicates a commitment to streamlining the driver’s interface with the machine. The carbon fiber’s rigidity translates to stable alignment under dynamic loads, helping the steering respond predictably when the chassis experiences compression or lateral acceleration. The lighter wheel reduces the centrifugal forces that can momentarily bias the steering system during aggressive cornering, allowing for more intentional, measured inputs rather than reactive corrections. The result is a cockpit that feels synchronized with the driver’s intent, a place where intention and execution rhyme in the cadence of a well-tuned drive. In such a space, the car rewards drivers who balance brisk steering with precise lines and who invest in a cockpit that communicates clearly with the driver’s hands and mind.

There is, of course, a practical arc to any modification. High manufacturing costs accompany this kind of upgrade, and the wheel’s longevity is tied to careful maintenance and proper installation. The value proposition hinges on how much a driver prioritizes feedback, weight reduction, and aesthetic elevation against the realities of pricing and potential repair considerations. Yet for those who measure performance in the sense of feel and immediacy, the upgrade delivers a return that extends beyond mere data points. It changes the tempo of driving: inputs arrive with more immediacy, feedback lands with greater clarity, and the overall sensation of control becomes more intimate. The move from a conventional wheel to a purpose-built carbon-fiber unit becomes, in practice, a decision to trade some mass for speed in the mind while preserving the heart of the vehicle’s steering dynamism.

Within the broader ecosystem of cockpit upgrades, the wheel is most effective when understood as part of a holistic approach to ergonomics and materials. It harmonizes with seats that hold the body firmly in place, pedals that respond precisely to the driver’s throttle modulation, and a dash layout that keeps critical information in the line of sight. In this integrated frame, the wheel’s weight, grip, and geometry are not isolated attributes; they are threads woven into a larger tapestry of driver experience. The result is an interior that feels engineered from the driver’s perspective, a space where every touch contributes to a sense of confidence and control even when the road becomes unpredictable.

For those considering the upgrade, the message is clear: this is more than a swap of components. It is a re-calibration of the driver’s relationship with the machine, a reimagining of how weight, grip texture, and steering geometry come together in the pursuit of precision. The wheel acts as a translator—converting intended actions into tangible, on-road outcomes with a fluency that only carbon fiber and considered ergonomics can deliver. It invites the driver to lean in, to trust the feedback, and to push toward the edge of grip with a cadence that is both controlled and exhilarating. The cockpit becomes less about a machine obeying commands and more about a dialogue between human intent and mechanical response.

In closing, the carbon fiber steering wheel embodies a philosophy that has long governed high-performance automotive thinking: strip away the extraneous, reinforce the core, and tune the interface so that the driver’s hands and the road’s truth align with immediacy. It is an upgrade that respects the original design while elevating it through material science, precise geometry, and attention to tactile detail. The result is a cockpit that feels lighter, more connected, and more honest about what is asked of it in the heat of a fast corner. It is, for those who chase precision, a meaningful enhancement that remains faithful to the essence of the car’s driving character—an essence forged in the relentless pursuit of balance between weight, grip, and feedback.

To explore the broader world of cockpit refinements and interior performance parts, consider a related interior upgrade that demonstrates how cabin components can work in concert with the wheel to shape the overall experience. See dashboard-focused interior parts for a sense of how the cockpit’s ergonomics and tactile cues can be harmonized with a carbon-centered steering feel. This contextual link offers further insight into how cockpit upgrades contribute to a cohesive, driver-centric environment.

External reference: https://www.alibaba.com/product-detail/Carbon-Fiber-Steering-Wheel-for-Mitsubishi-Lancer-Evolution-X_1601257971775.html

null

null

Weighing the Shine: Navigating the Drawbacks of the Original Carbon Fiber Steering Wheel in the Evo X

In the Evo X cockpit, the carbon fiber steering wheel is more than a flashy upgrade; it is a statement about how far a driver is willing to go to shave seconds off lap times and hand over control to a lighter, allegedly more responsive interface. The original carbon fiber wheel, when specified, promises a lighter overall mass, a more direct connection to the road, and a cockpit that looks as if it were cut from a race car. The appeal is undeniable. But the lure of a weight-just-right piece of hardware must be weighed against a set of practical realities that often come with high-performance interiors. The scope of what a steering wheel does goes beyond aesthetics. It sits at the intersection of safety, ergonomics, and the mechanical lifelines of the vehicle’s airbag system. In practical terms, this is where joy meets risk, and the difference between a weekend upgrade and a maintenance headache is the degree to which the installation aligns with the car’s safety architecture and daily usability.

Safety sits atop the list of concerns because it touches the fundamental reason drivers are even on the road. The airbag system in a modern sports sedan is not merely a cushion; it is a tightly orchestrated set of components designed to deploy in a calibrated manner across a wide range of crash scenarios. When a carbon fiber wheel is installed, the form, mass, and mounting strategy can alter the deployment dynamics. The carbon fiber wheel, being stiffer and lighter, can interact differently with the airbag inflator and the clockspring harness. The risk is not simply that the airbag won’t deploy; it is that its timing, inflation force, or direction could be altered enough to reduce protection. The truth is harsher in some cases: a wheel that does not pass through the exact same tolerances as the factory piece can produce fault codes, warning indicators, or a degraded sense of deployment reliability. The installation might require an airbag module replacement, or at least a re-termination of the harness, or an adapter kit whose reliability and compatibility may vary by supplier and production batch. In practice, this means that a buyer may be stepping into a project that requires not only a wheel but also a careful, technically informed evaluation of the airbag’s integrity and the wiring harnesses involved. The scale of risk grows if a non OEM or non-approved adapter kit is used, as these solutions can introduce unknowns regarding inflation timing, force distribution, and even the wheel’s steering angle when the bag inflates. In the end, the safety equation is simple enough: any perceived gain in weight savings or steering feel should be cross-checked against the possible communication errors with the airbag system, the likelihood of an alert, and the risk of unintended consequences in a collision.

Ergonomics expand the conversation from safety into the seat of the driver. The Evo X cockpit is configured for comfort with a wheel that offers cushioning, a tactile wrap, and a shape that suits long drives and spirited cornering alike. A carbon fiber wheel with a sharp, flat-bottom D-shape can deliver a racing-inspired stance, but it can also introduce fatigue after hours behind the wheel. The very attributes that give track-leading responsiveness—the minimal padding, the hard surface, and the stiff weave—are the same traits that can turn a two-hour highway session into a test of grip endurance. The absence of the plush contour and tactile substrate that leather or Alcantara provide means pressing the wheel with the entire palm or clutching with the fingertips can become jarring over time. For daily use, this is not simply about comfort; it is about consistent control. A driver who spends a long day commuting can experience a subtle degradation of grip accuracy as fatigue settles in, especially when the hands must stay in a fixed position during stop-and-go segments. In wet weather, the risk of slippage tends to increase when a wheel offers little feedback through padding and texture. The finish on a carbon fiber wheel, too, has a direct impact on daily usability. A gloss surface may catch the light, producing glare that sits at odds with the instrument cluster’s precision cues. The weave pattern, while visually striking, can also obscure the wheel’s tactile cues in bright sun, requiring the driver to rely more on reach and arm position than on the feel of the grip. All of this underscores a simple reality: the most effective upgrade is one that harmonizes performance desire with the realities of daily driving. The carbon fiber wheel, in its pursuit of a weight advantage and a pure steering feel, often compromises the everyday cockpit experience.

The compatibility with the airbag module is another critical axis where the Evo X reveals a stark divide between performance vision and safety obligations. If the wheel is designed to integrate with the car’s airbag system, it must satisfy stringent standards for deployment reliability. When it does not, the risk extends beyond an isolated warning light. The optical path, the electrical harness, and the wheel’s mounting bolts must align with the airbag module’s expected geometry. A misalignment can degrade the integrity of the crash event, or necessitate alternative, more complicated solutions. In practice, this may entail sourcing a complete airbag replacement or a carefully engineered adapter assembly—work that is not trivial in cost or complexity. The engineering mind cannot help but note that a successful integration turns on minute tolerances in the wheel’s thickness, the mating surface of the mounting hub, and the precise alignment of the horn contact. The driver who pursues a carbon wheel must be prepared for the possibility that the installation will require skilled technicians, specialized fixtures, and perhaps the acceptance of additional vehicle firmware checks and warning-light resets. The result is that a modification of this kind is not a bolt-on swap; it is a system-level change that must be validated to ensure that safety remains intact.

The customization aspect compounds the challenge. Carbon fiber is a premium finish that is highly valued for its modern, minimalist look. However, the aesthetic options are not as broad as those offered by leather or synthetic wraps. If a driver wants more than a singular weave and resin tone, options are limited, and the interior’s overall cohesion becomes a point of consideration. This is not merely about color; it is about texture, sheen, and wear behavior over time. The wheel’s glossy surface tends to reflect light and show micro-scratches sooner, and the lack of padding removes a certain degree of damping that would otherwise tolerate day-to-day scuffs from rings and jewelry. In a daily-driver scenario, these factors influence both the wheel’s feel and the cabin’s atmosphere. The decision to commit to carbon fiber in the steering interface thus becomes a choice between the allure of a race-inspired cockpit and the demand for interior coherence and enduring practicality.

The economic side of owning a carbon fiber wheel is not simply about the sticker price. While the upfront cost may appear attractive to enthusiasts chasing a perceived edge, the long-term financial reality is more nuanced. Carbon fiber, being a composite, is strong but not invincible. A localized impact can create microcracks that propagate under stress or heat, sometimes requiring expensive repairs or a full wheel replacement. When combined with the possibility of airbag module changes or adaptive harness modifications, total ownership costs can be unexpectedly high. And because these wheels are often considered specialty items, the pool of qualified installers and service providers is more limited than for OEM components. That means more time and more risk during installation, and potentially a longer period of vehicle downtime. For some Evo X owners, the weight savings and the claim of sharper steering feel justify the investment; for others, the practical cost of risk, maintenance, and potential safety concerns argues for a more conservative approach. The verdict, therefore, comes down to the user’s expected usage pattern and their risk tolerance. A weekend track warrior who uses the car for a few events each season may view the upgrade as a net gain; a daily driver who logs long commutes may see it as a compromise that adds more friction than joy.

In reflecting on all these considerations, it is clear that the Evo X’s cockpit upgrade path is not a simple equation of lighter equals better. The original carbon fiber steering wheel embodies a philosophy of high performance being pursued through precision materials and purposeful geometry. Yet this philosophy demands respect for the car’s safety architecture, for the driver’s long-term comfort, and for the practicalities of maintenance. For every glow of the carbon weave there is a corresponding caution about SRS integration, ergonomic balance, and the duties of ongoing verification. If the track is the primary stage and the installation is undertaken with a safety-first mindset, the wheel can deliver that direct, race-like feedback that makes the driving experience feel immediate and visceral. When the use case skews toward daily driving, the same wheel risks becoming a focal point of discomfort and concern, with the added burden of verifying airbag compatibility and the cost of potential repairs. The Evo X invites bold choices, but it also enforces responsibility through its safety systems. With the right mindset and careful planning, this upgrade can be navigated successfully, offering a cockpit that feels lighter, more immediate, and visually striking—provided the safety protocols are honored and the installation is treated as a system upgrade rather than a mere swap.

If readers are drawn to the broader carbon fiber ecosystem within the Evo X and want to broaden their understanding of how carbon components interrelate, the exploration of related parts can be instructive. For example, a carbon fiber bonnet presents a parallel case study in how weight savings, stiffness, and surface finish translate across multiple components, maintaining a consistent design language and revealing how such materials influence the vehicle’s overall feel. This kind of cross-component view helps frame expectations and underscores the importance of careful integration across the interior and exterior. carbon fiber bonnet for Mitsubishi Lancer Evo X is one such example that illustrates these themes in a single product category and helps demonstrate that carbon fiber upgrades, when done with care, can contribute to a cohesive upgrade strategy rather than a collection of uncoordinated parts.

So, while the original carbon fiber steering wheel may carry a distinct allure, the decision to adopt it should be grounded in a full understanding of the trade-offs. The airbag safety, the daily ergonomics, the compatibility with the airbag module, the level of customization, and the cost of ownership all contribute to a real-world calculus that cannot be bypassed by enthusiasm alone. The Evo X invites bold choices, but it also enforces responsibility through its safety systems. With the right mindset and careful planning, this upgrade can be navigated successfully, offering a cockpit that feels lighter, more immediate, and visually striking—provided the safety protocols are honored and the installation is treated as a system upgrade rather than a mere swap.

External link: Car Interior article: https://www.carinterior.com/how-to-choose-the-best-steering-wheel-for-evo-x/

Final thoughts

The original carbon fiber steering wheel for the Mitsubishi Lancer Evo X stands out as a premium upgrade that can significantly enhance both the performance and aesthetics of the vehicle. Business owners considering this investment should be aware of the numerous advantages, such as enhanced handling, weight reduction, and the premium feel it provides. However, understanding the technical specifications and being mindful of the potential drawbacks, such as repairability and cost, will help in making an informed decision that aligns with both their operational goals and customer satisfaction.