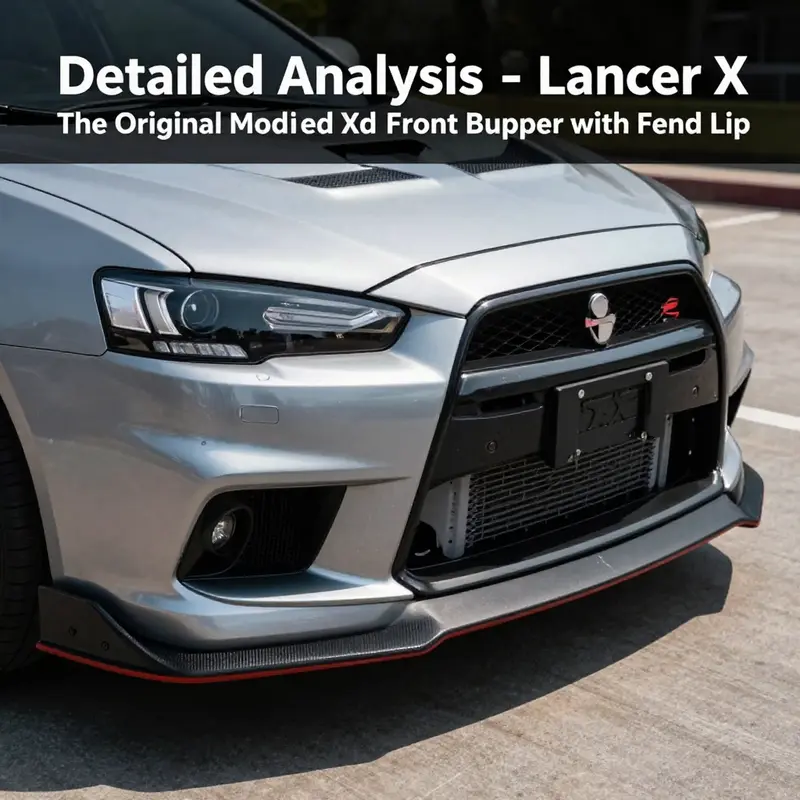

The original modified Lancer Evo X front bumper with front lip represents a significant advancement in automotive parts catering to driving enthusiasts. This innovative component not only enhances the vehicle’s appearance but also contributes to better performance and handling. With a focus on high-quality materials and design, this article investigates the multifaceted benefits and considerations surrounding this modification. Each chapter delves into specific aspects such as a detailed analysis of the front bumper and lip, the aerodynamic benefits they offer, the premium materials used in their construction, and current market trends affecting their economic impact. Together, these insights provide a holistic understanding for business owners looking to engage with this segment of the automotive aftermarket.

Aerodynamic Precision: An In-Depth Look at the Original Modified Lancer Evo X Front Bumper with Front Lip

The front end of a high-performance car is an engineered interface between the vehicle and the airstream. For the Evo X front bumper with lip, materials, geometry, and fitment work together to deliver improved cooling, downforce, and stability while preserving OEM cues. This chapter outlines how choice of materials reduces weight without compromising rigidity, how the lip profile adds controlled downforce with minimal drag, and how ducts and vents guide air to the radiator and intercooler. It also covers OEM-specific fitment designed to align with factory mounting points and gaps, keeping a cohesive look with the hood line. Finishing options, certification considerations, and the broader performance strategy around a front-end upgrade are discussed to show how a single component can influence dynamics as well as aesthetics. In short, the bumper-lip package embodies a balance of form, function, and factory compatibility that appeals to enthusiasts who want track-ready performance without sacrificing street usability.

Channeling Air and Precision: The Aerodynamic and Structural Promise of the Original Modified Lancer Evo X Front Bumper with Front Lip

The Mitsubishi Lancer Evolution X occupies a unique space in the minds of driving enthusiasts: a car that pairs engineered aggression with a chassis that begs to be tuned. When the conversation turns to front-end aerodynamics, a particular modification trend stands out for its thoughtful balance of function and form. The original modified Evo X front bumper with a front lip embodies this balance by integrating a purpose-built lip and a redesigned surrounding structure that honors the vehicle’s factory geometry while pushing its performance envelope. The essence of this upgrade lies not in dramatic, one-off styling but in the careful shaping of airflows at the vehicle’s most critical juncture—the point where the car first meets the wind. A front lip, when engineered as part of a complete bumper assembly, does more than add a sportier silhouette. It subtly directs air in a way that reduces lift, enhances downforce, and stabilizes behavior at high speeds. This confluence of aesthetics and engineering is precisely what gives the Evo X an expanded performance envelope without sacrificing the reliability and fit that enthusiasts rely on for daily driving and occasional track days.

From a physics standpoint, the front bumper and its lip act as a guide rail for air entering the engine bay. The lip’s lower edge disrupts and redirects the boundary layer, delaying separation and increasing the pressure differential along the car’s front. The result is a measurable decrease in lift, which translates to more consistent grip through fast undulating corners and long, sweeping straights alike. The integrated design means the lip works in harmony with the bumper’s upper surfaces and side ducts, creating a cohesive aerodynamic profile rather than a collection of add-on parts. This harmony matters because misaligned floes or disparate gaps can generate turbulent wake behind the front wheels, which can undermine stability at the very speeds where a tuned Evo X earns its keep. By contrast, a purpose-built lip and bumper combination maintains predictable airflow, which helps the driver apply throttle with confidence and pace through corners that require precise line control.

The bumper lip’s impact on high-speed behavior is complemented by the way the redesigned intake and vent geometry channels air more efficiently around the radiator and intercooler. In a performance-focused Evo X, engine cooling is not merely a matter of keeping temperatures within a safe range; it is a limiting factor on sustained performance. When the front-end geometry is optimized, air can be directed toward cooling cores with fewer obstructions, reducing bottlenecks that typically arise during aggressive driving. A well-executed front bumper assembly opens up pathways for heat to be removed from the engine bay more effectively, enabling the turbocharged powertrain to maintain its performance over longer intervals without heat soak eroding output. This is particularly relevant for drivers who push a stock-tuned layout toward the upper limits of its capability, whether on a winding mountain road or a tightly defined track layout.

Beyond raw performance figures, the integration of a front lip with the Evo X bumper respects the vehicle’s OEM specifications. The appeal for many owners is not a radical departure from factory geometry but a refinement that preserves the proven fit and factory aesthetics. The original modified configuration is designed to slot into place with precision, minimizing the need for intrusive modifications or extensive rework. This matters because the integrity of the crash structure, mounting points, and alignment tolerances are part of what keeps a vehicle safe and predictable under a broad range of conditions. When a bumper lip is engineered to match the factory contours and mounting locations, the owner gains both a sharper visual profile and a predictable interface with the rest of the bodywork. The look remains coherent with the Evo X’s lines, while the function makes the front end more capable without implying a trade-off in safety or structural reliability.

Material choice plays a central role in achieving that balance. Carbon fiber stands out as a material of choice for high-performance front-end components due to its stiffness-to-weight characteristics and its ability to retain shape under aerodynamic loads. The 3K plain or twill weaves often referenced in this context signal a level of engineering that aligns with serious performance intent. A front bumper lip made from carbon fiber offers meaningful weight savings over traditional plastics, which translates to a small but appreciable improvement in overall vehicle responsiveness. Reducing unsprung mass, when possible, contributes to crisper steering feedback and more precise braking responses. However, the real value comes when that weight savings are not achieved at the expense of rigidity or impact durability. In a properly engineered system, the composite construction behaves consistently across a spectrum of temperatures and loads, from cool mornings to the heat of a day on track.

Where carbon fiber is a performance hallmark, other reinforcement materials—such as glass fiber or reinforced ABS blends—offer alternative balances of strength, cost, and weight. These variants can yield improved impact resistance or different finishing characteristics while still delivering the aerodynamic advantages of a lip and a redesigned bumper. The choice of material affects not only the performance metrics but also the maintenance notes. Carbon fiber, for instance, requires attention to clear coats and care to minimize surface imperfections, while ABS or fiberglass blends may present different aging profiles but can be easier to repair if damage occurs. For many Evo X owners, the decision rests on a nuanced equation that weighs weight savings, durability, and the desired aesthetic outcome. What matters most is that the finished system remains an integrated whole, preserving the vehicle’s structural integrity while delivering measurable improvements in aerodynamics and performance.

The beauty of an OEM-compatible modification lies in its ability to sit within factory tolerances while delivering an enhanced experience behind the wheel. That is not to say aftermarket upgrades should be invisible; rather, the most successful upgrades are those that respect the underlying engineering assumptions built into the car from day one. The front bumper lip and its companion venting architecture should feel like a natural extension of the Evo X—the kind of enhancement that makes you wonder how the factory might have designed the vehicle if performance ambitions had been the sole priority. In practice, this means a carefully shaped lip profile, a vent array that aligns with the radiator and intercooler geometry, and mounting interfaces that preserve the crash-relevant zones. The result is not merely a more aggressive appearance; it is a coherent, performance-aware transformation that maintains predictable behavior in everyday driving and elevates confidence when the pace is raised.

From a practical standpoint, the upgrade promises an advantage that is easy to feel when the car is on the move. As air is guided more efficiently around the front of the car, the overall drag profile can be reduced, contributing to improved efficiency in certain operating ranges. This is not a claim of dramatic fuel economy gains; rather, it is a nuance of efficiency gained through more streamlined flow. The Lip-Front-Dam combination helps the car cut through the air with less energy wasted in turbulence and wake behind the front wheels. For the driver, that translates into steadier track behavior, cleaner turn-in responses, and a sense that the front end is planted even when the throttle is expressive. And because the system is designed to work with the vehicle’s existing geometry and balance, it avoids the kind of handling surprises that can accompany incompatible, piecemeal modifications.

The practicalities of installation deserve careful attention. While a well-matched kit minimizes the need for extensive modifications, any front-end upgrade demands accurate mounting and alignment. The bumper and lip must sit flush with the fenders, align with the grille, and connect to the same mounting anchors that retain the integrity of the bumper in a crash. When these elements are executed with care, the front end remains robust in the face of road hazards, speed bumps, and routine maintenance. The payoff is a front fascia that looks integrated and functions as a coherent aerodynamic tool rather than a set of separate parts. This is precisely why many Evo X enthusiasts prioritize compatibility with OEM specifications. It is not simply a matter of keeping the factory touch; it is about ensuring that performance enhancements are realized without compromising the safety and reliability that define the car’s best attributes.

Aesthetics and personalization also play a role in the appeal. In a world where appearance communicates intent, a front bumper lip can add a tuned, performance-grade look that resonates with how the Evo X is often perceived—a machine designed to meet the road with precision and purpose. Owners who wish to customize further can choose finishes that suit their broader upgrade plan, from raw carbon fiber to finished black or painted surfaces. The opportunity to tailor the visible portion of the bumper while preserving the integrity of the functional elements makes this upgrade appealing to a broad audience, from daily-driven cars to weekend track enthusiasts.

For those who want to verify compatibility or explore options that align with an OEM-like fit, there is a straightforward path to reliable information and purchase. A genuine implementation that adheres to factory geometry ensures that the bumper lip and the redesigned air intake surfaces cooperate with the latching mechanisms, crash zones, and underbody structures that matter most in terms of safety and durability. To learn more about a genuine configuration that matches the Evo X’s front-end architecture, one can consult the dedicated front bumper page that presents the official fitment and geometry. Mitsubishi CZ4A Lancer Evolution X Front Bumper Genuine.

The discussion around a well-executed Evo X front bumper upgrade also touches on procurement and assurance. In the broader ecosystem of aftermarket performance parts, buyers seek trusted channels that provide certified products and accurate specification data. A dependable marketplace can offer verification of materials, test certificates, and warranty coverage, reducing the risk often associated with less-regulated sources. When a front bumper lip and its associated structural components are backed by safety certifications and real-world testing, the buyer can proceed with greater confidence, knowing that the upgrade preserves the expected crashworthiness and pedestrian safety properties required by modern standards. The emphasis, here, is on a complete system rather than isolated components—an approach that respects the vehicle as a cohesive platform and honors the performance goals that drive Evo X enthusiasts to begin with.

In the broader context of the Evo X, the front-end upgrade is one part of a chain of enhancements that can collectively elevate both performance and confidence. The lip, the bumper’s redesigned intake arrangement, and the surrounding geometry together influence how air navigates the vehicle’s front end, how heat is managed in the engine bay, and how the car communicates with the road through the steering and brake systems. The result is a car that remains approachable for daily driving but reveals a refined character when pushed toward higher speeds. The original modified Evo X front bumper with front lip thus represents more than a cosmetic upgrade; it embodies a philosophy of engineering that treats aerodynamics, cooling, safety, and aesthetics as a single, integrated discipline. For owners who crave a coherent upgrade path that respects the car’s OEM foundations while unlocking more aggressive performance, this approach offers a compelling balance between form and function. External resource: https://www.amazon.com/dp/B07ZJ6Y9QV

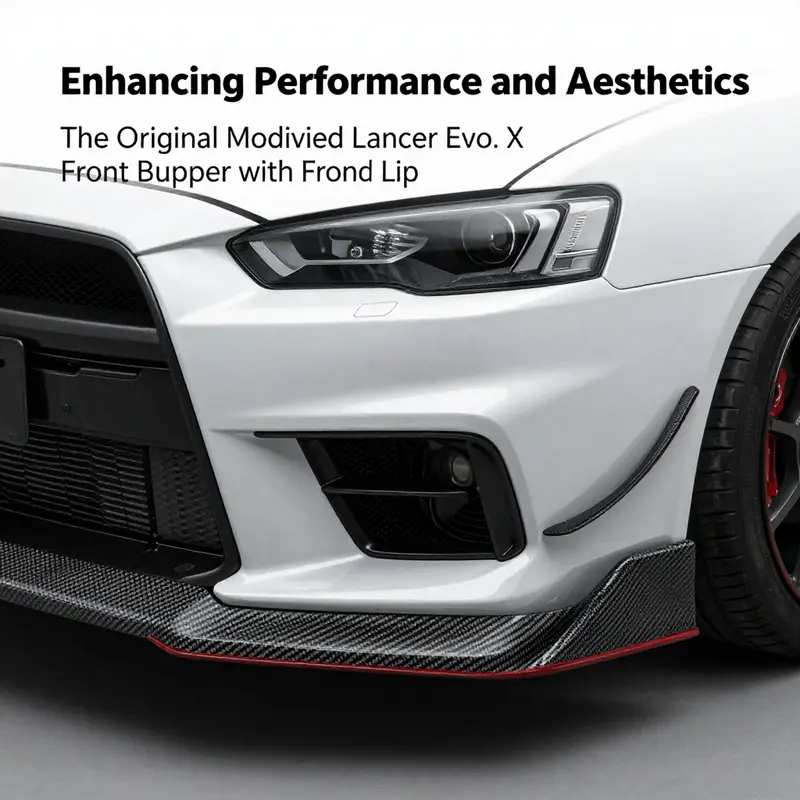

Engineered for Precision: Material Integrity and Quality Behind the Original Modified Lancer Evo X Front Bumper with Front Lip

The front end of a high-performance sedan is where form and function converge, and nowhere is that fusion more evident than in the original modified bumper paired with a front lip. In the realm of aftermarket upgrades, the material system chosen for this component is not a cosmetic decision alone; it is a calculated choice that dictates durability, performance, and longevity in demanding driving environments. This chapter examines how material composition and manufacturing quality shape the real-world behavior of the bumper, how the lip integrates with the broader aerodynamic package, and why these factors matter to enthusiasts who demand both aesthetics and reliability from their daily drivers or track-day machines.

At the heart of the bumper’s performance is polyurethane, a versatile polymer that offers a favorable balance between flexibility and rigidity. In climates with extreme heat, dusty roads, and abrupt temperature shifts, polyurethane’s resilience becomes evident. Unlike more brittle plastics, urethane tends to absorb minor impacts without cracking, returning to its intended shape after light collisions or parking mishaps. This elasticity is especially valuable at the front of the vehicle, where the bumper encounters road debris, curbs, and the occasional off-line moment during aggressive driving. In practical terms, the material’s shock-absorbing qualities help preserve the bumper’s geometry and its finish, reducing the likelihood of paint cracks or surface deformation that would otherwise require costly repairs.

The UAE and other hot, arid environments pose particular challenges for exterior components. Polyurethane’s heat tolerance complements its impact resistance by maintaining structural integrity when ambient temperatures push the panel toward the upper end of a normal operating range. UV exposure is another critical consideration for exterior plastics, and modern polyurethane systems are formulated with UV stabilizers that retard color fading and surface chalking. A well-formulated urethane bumper remains vibrant and smooth after long hours under intense sun, while the gloss and clearcoat maintain their integrity.

Aesthetics and aerodynamics go hand in hand, and the lip that accompanies the bumper plays a pivotal role in defining both. While the main bumper cover provides the broad silhouette, the lip or spoiler acts as a dedicated aerodynamic element. In many upgraded configurations, the lip is designed to work in harmony with the bumper to channel air effectively across the lower front of the car. The lip’s contribution to airflow—reducing separation, guiding the air toward the radiator intake, and smoothing the path of high-speed air around the lower bumper—translates into tangible handling benefits. Even modest gains in aerodynamic efficiency can manifest as improved high-speed stability, reduced front-end lift, and a more planted feel through corners. Although the lip itself may appear as a small detail, its engineering is integral to the overall performance package.

In this context, the option to pair polyurethane with a carbon fiber lip or spoiler reflects a pragmatic approach to optimizing both weight and stiffness. Carbon fiber is renowned for its stiffness-to-weight ratio, which supports the lip’s functionality without adding unnecessary mass to the front end. A lip built with carbon fiber weave—often characterized by a 3K plain or twill pattern—signals premium engineering. The weave pattern communicates a level of sophistication in the material’s layup, indicating deliberate control over density, stiffness, and surface finish. When the lip and bumper are integrated, the combined system benefits from a cohesive load path. The bumper absorbs the energy from minor impacts, while the lip maintains a consistent aerodynamic profile at the leading edge, ensuring that the airflow remains predictable even during aggressive driving.

From a manufacturing perspective, the quality of the bumper is as crucial as the material itself. High industrial standards in molding and finishing translate to precise fitment and durable performance. Advanced molding techniques allow for tight tolerances that ensure the bumper aligns with mounting points, sensors, and adjacent panels without pre-load stress or gaps. The surface quality—cosmetic and functional—depends on controlled curing, mold release, and post-mold refinement. A well-executed process yields a panel that resists warping under heat, holds paint reliably, and remains consistent across temperature fluctuations. These attributes matter not just for show but for real-world reliability, where a misfit or early paint failure can compromise both aesthetics and protection.

A crucial factor in the discussion of material composition is how the bumper interacts with other integrated systems. Modern vehicles rely on sensors, fog lights, and ambient light detectors that live at or near the bumper line. The polyurethane matrix must not distort under load or during a modest impact, which could misalign sensors or obscure lighting. OEM specifications and reputable aftermarket sources acknowledge this integration, underscoring the importance of precise fitment and correct geometry. In practice, this means compatibility with mounting points, wiring harnesses, and sensor housings, as well as tolerance with respect to fog light openings and their illumination patterns. When these systems are properly integrated, the driver benefits from consistent operation, reliable sensor feedback, and predictable lighting performance—critical aspects for both safety and usability in dynamic conditions.

A practical point for buyers and builders alike is the material’s paintability and repairability. Polyurethane surfaces lend themselves to color matching and refinishing, enabling owners to maintain a showroom-like appearance even after road hazards or track sessions. Scratches, scuffs, and minor abrasions can be addressed with standard automotive refinishes, reducing the long-term cost of ownership and downtime associated with exterior repairs. In contrast to some thermoset resins that may require specialized fillers or inconvenient repair methods, polyurethane can be repaired in typical body shop settings, preserving the bumper’s structural and cosmetic integrity.

When contrasting polyurethane with alternatives such as FRP (fiberglass) or ABS, several performance levers become clear. FRP, for instance, can be more rigid and often more prone to cracking under impact or fatigue, especially in heat. ABS, while affordable and easy to manufacture, can suffer from heat-induced warping and a less forgiving impact response. Polyurethane’s edge lies in its balanced combination of resilience, lightness, and repairability under real-world conditions. For daily driving—where encounters with curb scuffs, parking lot encounters, and occasional off-road debris are common—polyurethane provides a sensible equilibrium between resilience and weight. For track-oriented use, the material’s ability to absorb and dissipate energy helps protect the underlying structure while the lip contributes to predictable aerodynamic behavior at higher speeds. This is not about merely choosing a plastic; it is about selecting a material system that aligns with the vehicle’s intended use, climate, and maintenance philosophy.

The question of authenticity and compliance naturally arises for buyers who want the appearance and performance of a genuine upgrade without compromising OEM standards. The path to assurance lies in seeking OEM-licensed or reputed aftermarket sources that insist on original equipment specifications and rigorous quality benchmarks. Such sources typically verify fitment, sensor compatibility, and finishing quality, ensuring that the installation preserves the vehicle’s integrity and warranty posture. In practice, this means evaluating the supplier’s engineering documentation, color-matching capabilities, and return policies, as well as confirming that the bumper’s geometry corresponds to the vehicle’s mounting points and crash-relevant zones.

For readers seeking a concrete point of reference within the broader ecosystem of parts availability, a reliable touchstone is the dedicated front bumper offering for this category of vehicle. See this page for a detailed overview of the front bumper options and the associated fitment considerations: front bumper page. This resource illustrates how a well-crafted bumper solution integrates with existing vehicle systems while preserving the delicate balance between aesthetics and function. The emphasis on fit, finish, and compatibility echoes the core message of material integrity: high-quality plastics, reinforced by thoughtfully engineered lips and a disciplined manufacturing process, yield a component that looks purposeful and performs reliably.

In evaluating material composition and quality, one should also consider the lifecycle of the part. Polyurethane’s repairability translates into practical maintenance, enabling repairs that are cost-effective and efficient. The ability to repaint or touch up the bumper without compromising the underlying structure helps owners retain a factory-like appearance over time, even as you replace or refresh other components on the front of the car. A durable surface finish coupled with a resilient core means fewer trips to the body shop, less downtime, and a more confident ownership experience overall.

From a design perspective, the choice of materials informs more than the bumper’s durability. It shapes the way designers approach edge radii, surface curvature, and the blending between the bumper and front lip. The lip’s geometry must be faithfully reproduced in the mold so that the transition between the two components appears seamless at a glance. A carefully engineered joint reduces visible seam lines, contributing to a cohesive, sportier stance while avoiding double-textured or misaligned edges that could betray a lower-quality installation. Polyurethane’s workability supports such precision because it responds well to careful molding, consistent resin flow, and controlled curing, all of which culminate in a surface that looks uniform under different lighting conditions.

In sum, the material composition and the quality of construction for the original modified bumper with front lip are more than matters of preference; they are essential determinants of performance, durability, and owner satisfaction. The polyurethane base offers a practical blend of flexibility, impact resistance, and repairability, while the optional carbon fiber lip adds a targeted stiffness-to-weight advantage that can enhance aerodynamic performance without compromising the bumper’s resilience. The manufacturing process, with its emphasis on tight tolerances and robust finishes, connects these material properties to real-world outcomes—from smooth fitment and sensor compatibility to paint longevity and repair ease. For enthusiasts who value both form and function, this combination provides a compelling case for a well-considered, high-quality modification that stands up to daily use and the rigors of enthusiastic driving.

External resource: https://www.alibaba.com/product-detail/Mitsubishi-Lancer-Evo-X-Front-Bumper-Supplier_1600348975235.html?spm=a2700.1.wangsen.1.5a4b3d3aYKuFjA

Demand, Materials, and Value: How the Evo X Front Bumper with Lip Shapes a Specialized Aftermarket Market

A focused aftermarket narrative that connects materials, buyer priorities, and economics around the Evo X front bumper and lip.

The market for an original-style modified front bumper with a front lip for the Lancer Evolution X sits at a crossroads of aesthetics, engineering, and commerce. Enthusiasts seek more than looks: they want parts that improve stability at speed, integrate with factory lines, and hold value over time. Suppliers respond by blending advanced materials, tight fitment tolerances, and customizable finishes. The result is a niche but active ecosystem where product design, sourcing strategy, and buyer trust determine success.

Material selection drives this market. Lightweight composites such as carbon fiber and reinforced glass fiber dominate buyer preferences. Carbon fiber appeals for its strength-to-weight ratio. A 3K plain or twill weave, for example, signals higher-grade construction, consistent fiber orientation, and predictable stiffness. These characteristics reduce weight and lower the center of gravity at the front, benefiting handling and turn-in. Glass fiber offerings trade some of the prestige of carbon fiber for improved impact resistance and lower cost. Modern glass fiber molds can resist corrosion and absorb road shocks without fracturing. For many buyers, that balance between durability and performance proves compelling because the front bumper must survive curbs, speed bumps, and track contact.

Fitment and finish matter as much as materials. The most successful aftermarket options mimic OEM mounting points and overall geometry. When a bumper and lip are designed to maintain factory fit, installers avoid costly trimming or panel adjustments. Precise alignment preserves vehicle aerodynamics and the original sensor placements. For owners who plan to keep driver-assist features or parking aids, that integrity matters. A bumper that looks aggressive but misaligns with headlights or fender lines quickly becomes a detractor. Consumers therefore reward manufacturers who commit to OEM-specific fitment, measured tooling, and consistent quality control.

Customization remains a powerful demand driver. Many kits ship in a neutral primer or blank white surface, intended for final paint and personalization. That blank canvas attracts two groups: owners who want a color-matched, subtle enhancement; and show-builders who use the piece as a base for graphics, wrap integration, or multi-tone schemes. Customization extends to functional choices too, such as optional vortex generators, splitters, or extra ducts. That modular approach lets buyers add performance features incrementally and preserves aftermarket resale options.

Trust and verification underpin purchase decisions, especially for higher-priced carbon fiber components. Buyers and trade purchasers increasingly rely on verified supplier badges, certifications, and sample testing. Factory audits and third-party certifications like ISO and CE are common checkpoints. Serious buyers often request physical samples and test-fit runs before committing to larger orders. This scrutiny reflects uneven quality across global suppliers and the need to ensure long-term structural durability. In markets where price pressure is intense, visible certification and tested fitment differentiate reputable vendors from commodity sellers.

Price competition shapes both availability and perception. Components sourced from high-volume manufacturers can undercut smaller producers. Listings for carbon trim or fog lamp covers show wide price ranges, indicating different production methods and materials. Lower price points broaden access but create segmentation in buyer expectations. Some owners prioritize the lowest cost for a cosmetic upgrade. Others prioritize weight savings and craftsmanship, accepting a premium for a well-executed carbon weave and a consistent gelcoat finish. This price variance fosters a layered market: entry-level cosmetic kits, mid-tier durable fiberglass parts, and top-tier carbon fiber performance pieces.

Economic value extends beyond the part itself. A well-engineered bumper and lip can improve high-speed stability and airflow to cooling systems. That functional gain translates into tangible value for drivers who track their cars or push hard on highways. When aerodynamic improvements are documented, they can boost an Evo X’s appeal to discerning buyers, potentially increasing resale price. Buyers who invest in complementary components—hood vents, rear diffusers, side skirts—often see cumulative performance and aesthetic returns. This synergy explains why comprehensive packages and coordinated design language sell well within enthusiast circles.

The aftermarket ecosystem around these parts is broad. Manufacturers, mold makers, shipping logistics, paint shops, and specialized installers all share the economic pie. Small fabrication shops thrive by offering installation, reinforcement, and fitment correction services. Larger manufacturers support supply chains that include fiber suppliers, resin formulators, and CNC tooling firms. Jobs in design, quality assurance, and logistics are sustained by consistent product demand. The market’s maturity also supports ancillary services, such as custom paint work, carbon repair, and aerodynamic testing.

Sourcing strategies influence margins and market health. Many parts originate from regions with cost advantages in composite manufacturing. That low-cost sourcing increases profit margins for retailers and lowers consumer prices. However, it also raises inventory management and quality assurance needs. Importers balance lower unit costs against the expense of ensuring consistent fitment and finish. For B2B buyers, bulk purchasing may include sample testing and factory audits, protecting downstream reputation. For retail customers, warranties and clear return policies help mitigate perceived risk from off-shore sourcing.

Quality variance creates both opportunity and friction. When suppliers produce inconsistent molds, buyers demand rework or refunds. That friction incentivizes tighter specifications and higher quality control budgets for reputable manufacturers. Shops that invest in precise molds and consistent resin mixes reduce warranty claims and build brand loyalty. Conversely, manufacturers who cut corners on layup schedules or cure cycles often face returns and negative reviews. Over time, this feedback loop rewards transparency and traceable production practices.

Regulatory and warranty considerations shape buyer choices as well. Some owners avoid permanent modifications that could void coverage or complicate insurance claims. Others specifically seek parts that preserve crash performance and sensor function. Manufacturers who document testing procedures and material certifications ease consumer concerns. Where possible, providing installation guides and torque specifications helps owners and shops avoid mounting errors that could lead to costly damages.

Marketing in this segment blends technical detail with lifestyle appeal. Buyers invest emotionally in the Evo X identity. Effective messaging explains how fiber layups, lip profiles, and inlet shapes translate into drivability. High-quality photography and fitment demonstrations build confidence. Equally important is clear communication about what a buyer receives: finished part, primer-only, or paint-ready. Transparency reduces returns and fosters repeat business.

For installers and small shops, these parts expand service offerings. Installation fees, paint work, and reinforcement add revenue. Shops can bundle aerodynamic testing or alignment checks after installation, demonstrating tangible performance improvements to customers. That service layering increases average transaction value and strengthens local business ecosystems.

Long-term demand will follow two trends. First, the supply of well-preserved Evo X chassis will decline slowly, making quality aftermarket upgrades more valuable. Second, continued refinement in composite manufacturing will push more performance-oriented parts into the mainstream. As materials become less costly and manufacturing tolerances improve, more buyers will opt for higher-quality carbon pieces over cheaper alternatives. The interplay between scarcity of donor cars and improved part quality will shape future pricing dynamics.

Practical advice for buyers and small retailers centers on verification and alignment. Request fitment references and photos from prior installations. Ask for sample pieces when possible. Check for platform-verified supplier credentials and documented factory audits. Consider the total cost of ownership, including paint, installation, and potential reinforcement. Weigh the trade-offs between glass fiber’s resilience and carbon fiber’s weight savings. For those who value resale, maintain documentation of parts and installation, which helps future buyers assess authenticity and quality.

A final operational note addresses inventory and returns. Retailers that maintain small stock of popular fitment options reduce lead times. They can also offer quick exchange programs for minor fitment issues, turning potential dissatisfaction into loyalty. Clear return windows, straightforward RMA processes, and visible quality control steps improve buyer confidence.

Across this market, materials, engineering, and trust intersect. Enthusiasts reward parts that deliver a convincing combination of fit, finish, and functional benefit. Suppliers that invest in verified processes, durable materials, and honest communication capture the long-term value created by this passionate community. For an Evo X owner, the right bumper and lip are more than cosmetic—they are a statement of intent and an investment in vehicle performance.

For a representative listing on fitment and OEM-style design, see the CZ4A Lancer Evolution X GSR front bumper documentation: CZ4A Lancer Evolution X GSR front bumper.

Further information on supplier verification and sourcing strategies can be found via GoldSupplier Wholesale Marketplace: https://goldsupplier.com

Final thoughts

The original modified Lancer Evo X front bumper with front lip exemplifies the intersection of style and performance enhancements in automotive design. For business owners in the aftermarket part sector, understanding the nuances of this component can unlock significant opportunities. By focusing on the detailed analysis of the bumper’s features, its aerodynamic advantages, the high-quality materials involved, and the prevailing market trends, enterprises can better position themselves to meet the demands of performance-conscious consumers. As the automotive landscape continues to evolve, embracing such products will not only enhance vehicle performance but also appeal to the desires of passionate automotive enthusiasts.