The Mitsubishi Galant, a name synonymous with automotive evolution, spans nearly five decades of innovation, especially in engine technology. This article delves into the Galant’s engine history, tracing its journey from early, performance-centric models to modern, technology-driven variants. Each chapter will unpack significant advancements in engine design and performance, while also addressing the aftermarket opportunities available for business owners involved in the automotive sector.

From OHV to Overhead Cam: The Early Engine Evolution of the Mitsubishi Galant

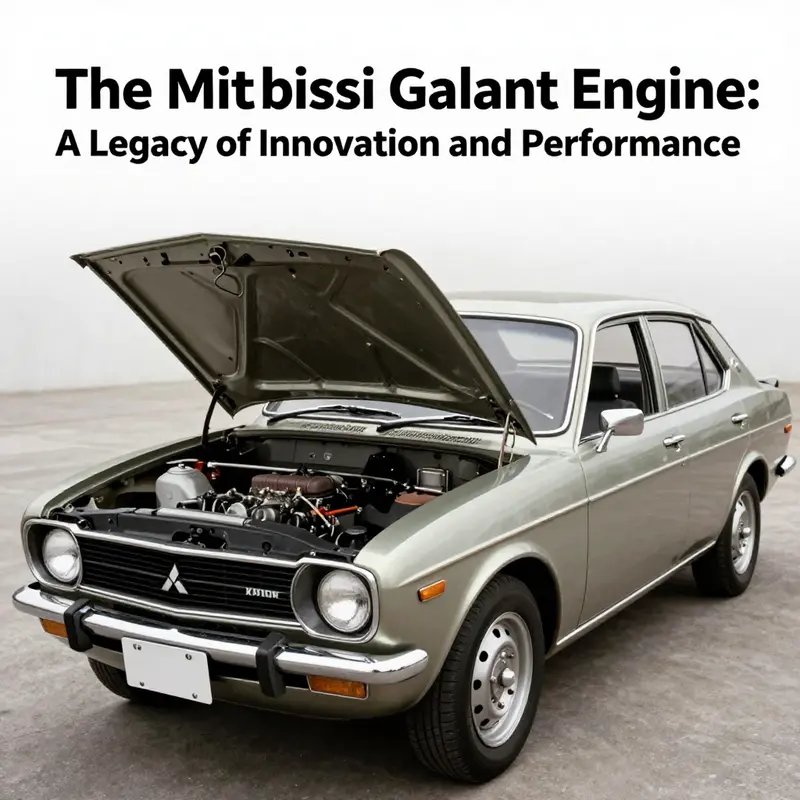

The Mitsubishi Galant began life in a period when automotive engineering was rapidly learning to balance simplicity with performance, reliability with ambition. In its earliest generations, the Galant paired compact exterior dimensions with powertrains designed to prove Mitsubishi’s commitment to practical efficiency as much as to driving enjoyment. The initial engines were small-displacement, straightforward four-cylinders built around OHV (overhead valve) configurations. These early powerplants—1.3-liter and 1.5-liter variants—delivered modest performance but earned a reputation for durability and low maintenance, a combination that would become a throughline in the Galant’s long history. In those years, the objective was less about spectacular numbers and more about dependable usability—ideals that the Galant would carry forward as it matured into a more refined, capable sedan. The shift from simple OHV layouts toward more advanced configurations signaled Mitsubishi’s intent: to extract more efficiency and breathing from each engine without sacrificing the reliability that families counted on day after day. In this climate, even the smaller mills began to hint at the future, with the introduction of overhead camshaft (OHC) designs that would redefine the Galant’s character in the years ahead. The move to OHC, with its improved valve timing and better cylinder head breathing, was not merely a technical enhancement; it was a statement that Mitsubishi would pursue higher efficiency and more responsive performance even in a model aimed at practicality and everyday reliability. In parallel, larger displacement offerings began to appear, including 1.6-liter and, eventually, 1.7-liter configurations. The 1.7-liter unit—famously associated with the high-performance FTO variant—illustrated a crucial trajectory: the Galant could be tuned for more than quiet, steady travel. While the FTO’s spirited reputation specialized in a niche, the engineering lessons embedded in that period—the importance of air flow, combustion efficiency, and robust componentry—fed back into the Galant’s broader engine strategy. The early chapters of the Galant’s engine history thus wove together a thread of reliability with a willingness to explore higher-output potential when the market demanded it, and when engineers believed they could extract it without compromising durability or serviceability.

As the 1970s rolled into the 1980s, Mitsubishi pursued a more aggressive evolution of its inline-four lineup. The arrival of the 4G6 family, introduced in the late 1970s and reinforced through the early 1980s, marked a pivotal moment in the Galant’s propulsion. These engines, including the notable 4G62 and 4G63 variants, heralded a shift from straightforward carburetion to more sophisticated fuel delivery and breathing strategies. The twin-carburetor setups of the era underscored Mitsubishi’s early understanding of how precision fuel metering and flow management could translate into more usable power without compromising economy. This period also saw the gradual adoption of fuel injection, a move that would become standard in later generations as electronics and control systems matured. The 4G6 family stood out not only for its improved performance but for its robustness and adaptability. The 4G63, in particular, earned a reputation for durability and potent potential, a combination that would later become legendary in the broader Mitsubishi lineup. This engine would eventually power high-performance platforms far beyond the Galant, including the Lancer Evolution lineage, where it demonstrated an impressive capacity to endure spirited use while delivering usable torque and response. The engineering philosophy behind these engines emphasized a practical balance: airflow improvements, dependable ignition, and robust bottom ends that could tolerate spirited driving yet survive the rigors of daily transport. This balance was not a luxury; it was a design imperative born from Mitsubishi’s experience in a diverse array of markets where cars faced varied climates, road conditions, and service ecosystems.

Alongside the shift in breathing and fuel delivery, Mitsubishi also tackled engine smoothness through mechanical innovation. One notable feature employed in several Galant engines around this era was the balance shaft—an element designed to dampen primary vibration and stabilize rotational dynamics. The introduction of balance shaft technology addressed the often overlooked reality that even a small four-cylinder mill can deliver a thesis on noise, vibration, and harshness if not properly managed. By mitigating unwanted oscillations, Mitsubishi improved cabin refinement and long-term durability, making the Galant more appealing to buyers who valued a quiet, composed ride in addition to reasonable performance. The cumulative effect of these developments—OHC refinement, enhanced intake and exhaust flow, early electronic control concepts, and vibration damping—was a Galant that could be both efficient and engaging when called upon. It is worth noting that these early choices also prepared the ground for later turbocharged variants and further engine technologies that would shape Mitsubishi’s approach to performance without abandoning the core values of reliability and ease of maintenance.

The Galant’s engine journey through these decades was more than a catalog of displacement figures and output numbers. It was a story about how a compact sedan could evolve into a platform capable of hosting advanced engineering ideas that would ripple through Mitsubishi’s entire lineup. The 4G6 family did not merely offer power; it delivered a blueprint for how to engineer a powerplant that could be tuned, refined, and scaled for different models and markets. The reputation built during this era—robust construction, dependable performance, and a willingness to adopt new technologies—became a touchstone for the brand’s engineering culture. Enthusiast communities would come to recognize the Galant as a vehicle through which Mitsubishi demonstrated its ability to pursue higher performance ideas within a framework of daily usability. The interplay of improved cylinder head design, smarter fuel delivery, and careful attention to engine balance created a more accessible path to performance than might be imagined from the era’s modest initial outputs. In this sense, the early Galant engines functioned as both transport solutions and laboratories, where engineers learned how far an inline-four could be pushed before the perimeters of reliability and cost constrained ambition.

The narrative of these early engines is also a reminder of how engineering progress often travels in incremental steps rather than dramatic leaps. A small gain in valve timing efficiency here, a new balancing technique there, and a modest shift toward early fuel injection all accumulate into a broader capability that defines a model’s character across multiple generations. The Galant’s evolution during this period was not about chasing the latest buzzword but about constructing a practical, resilient, and adaptable powertrain family that could satisfy a broad spectrum of drivers, from those seeking steady, economical commuting to those who wanted a little more pep from a family sedan. In that context, the Galant’s early engine lineage is a foundational chapter in a longer story about Mitsubishi’s enduring commitment to engineering that balances performance with everyday usability.

For readers who want a deeper, more technical view of how Mitsubishi framed its engine development across generations, the official archives provide a comprehensive overview of the company’s engine history. This resource traces the progression from the early OHV and OHC layouts through the later generations and highlights the evolution of key technologies, including the 4G6 family’s breathing improvements and the adoption of more advanced fuel delivery systems. It is through this documentary lens that one sees the Galant not merely as a car but as a rolling laboratory where an entire era of Japanese automotive engineering was tested and refined, yielding a lineage that would influence Mitsubishi engines for decades to come. The enduring takeaway from these early developments is clear: reliability, thoughtful engineering, and an eye toward future potential defined the Galant’s approach to power, and the engines that powered it laid the groundwork for the sophisticated, efficiency-minded propulsion systems that would follow.

Readers seeking a highly concrete, engineering-focused connection to the broader story can explore one specific facet of this evolution in depth through a dedicated resource that showcases a later evolution of the same family. The Evolution Evo-4-9 engine short-block, paired with a complete 4G63 setup, offers a vivid example of how the engineering mindset established in the Galant’s early years would culminate in high-performance applications. This connection highlights the continuity of Mitsubishi’s inline-four development—from reliable, efficient commuters to legendary performance platforms—underscoring the Galant’s place in a long arc of engine innovation.

For a more expansive historical context on engine history at Mitsubishi, see the official Mitsubishi Motors archive: https://www.mitsubishi-motors.com/en/technology/history/engine.html

Performance Evolution: Turbocharged Horizons and High-Output Legacies in the Mitsubishi Galant

The Mitsubishi Galant has long stood at the crossroads of practicality and performance. Over generations its engine lineup moved from compact, efficient four-cylinders to turbocharged and high-output powerplants that shaped the model’s sporting identity. The VR-4 and the 4G63T engine are highlighted as central moments in Mitsubishi’s performance philosophy, emphasizing balance, drivability, and real-world acceleration rather than mere peak numbers. The Evolution III’s turbo upgrade and the accompanying drivetrain refinements showcased how higher boost, stronger internals, and a capable four-wheel-drive system could translate power into confident on-road performance. Beyond the VR-4, Mitsubishi applied its high-output strategy across markets, expanding engine choices while preserving everyday usability. Even after production ended, the Galant’s performance heritage lives on in the aftermarket and in the broader memory of enthusiasts who value a connected, predictable driving experience.

Turbo Threads and Refined Velocity: Modern Engine Technologies in the Mitsubishi Galant

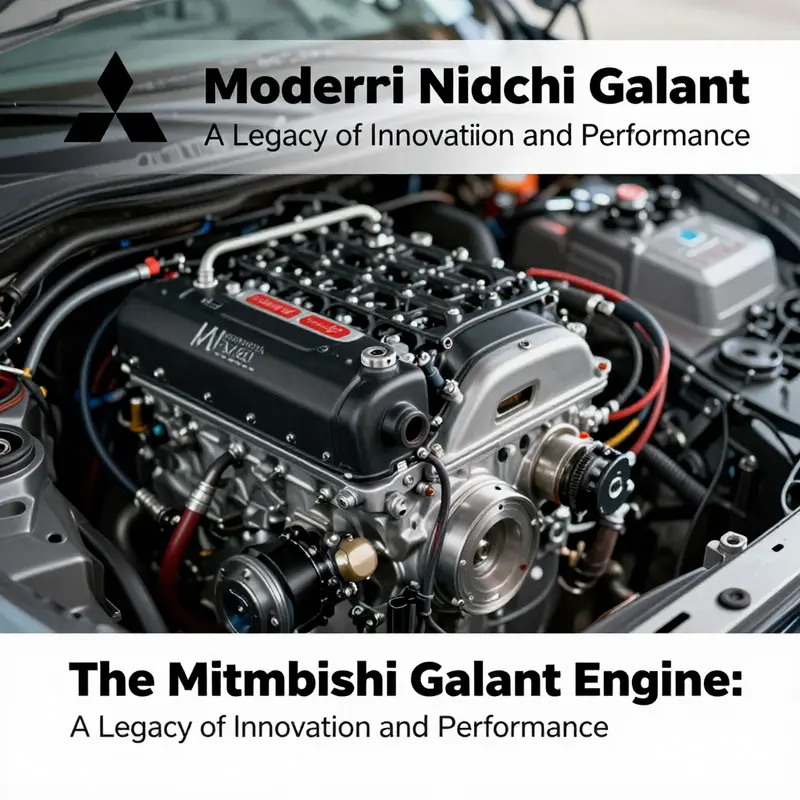

The Mitsubishi Galant has always occupied a nuanced space in the automotive landscape. It began as a compact with a penchant for efficiency and practicality, then evolved into a mid-size sedan that could balance comfort with a willingness to stretch its legs. The engines that powered these shifts tell a quiet story of Mitsubishi’s engineering philosophy: push for performance when it suits the market, then lean into sophistication and efficiency as demand tilts toward everyday usability. In the modern era of the Galant, the engine developments are less about raw, unabashed sprint and more about a seamless blend of turbocharged capability, thermal discipline, and intelligent valve control. The result is a lineage that reads like a careful apprenticeship in balance—turbocharged potential that remains controllable, a sense of immediate responsiveness without sacrificing refinement, and an increasing emphasis on reliability under higher loads. This chapter threads those ideas together, tracing how the Galant’s engine technology matured from its earlier performance options into a modern framework where turbo kits, thermal management strategies, and electronic timing solutions define the driving experience for enthusiasts and everyday drivers alike.

Across generations, the Galant’s engine family reveals a constant tension between power delivery and smoothness. Early performance-focused iterations leaned into displacement and tuning, with motors that rewarded the driver with immediate urge but could be spirited to the point of urgency in everyday traffic. The VR4 variant—a flagship in the Galant lineup—encapsulates this philosophy: a factory turbocharged, all-wheel-drive platform that offered a bridge between rally heritage and sedan practicality. The modern discussion, however, is less about the thrill of a single corner-leaning burst and more about how to maintain reliability as peak torque climbs and boost pressures rise. At the heart of this shift lies a suite of technologies that Mitsubishi refined or adapted for the Galant’s needs: turbocharging systems designed to meet dynamic demand, cooling and exhaust management capable of absorbing heat without choking response, and valve-timing controls that awaken torque across the rev band without flaring fuel consumption or emissions.

The turbocharged narrative in the Galant is not merely about squeezing more horsepower from a given engine, but about engineering a coherent ecosystem around that horsepower. The Galant VR4, in particular, shows the early recognition that a high-performance engine needs to be supported by robust hardware and a drivetrain tuned to cope with additional heat, pressure, and power flow. Key components in this regard include reinforced exhaust manifolds and high-flow intercoolers, which address a fundamental challenge of turbocharged engines: maintaining intake air density under pressure. When air is compressed, its temperature spikes, and hot air is less dense, lowering the efficiency of the combustion process. A properly designed intercooler mitigates this, delivering cooler, denser air to the cylinders and preserving the turbo’s responsiveness across driving scenarios. The VR4’s turbo kit and associated hardware embody this approach, emphasizing reliability and balance. The upgrades are not about edge-of-adhesion performance in a straight line; they’re about sustaining higher power while keeping control predictable in everyday driving and during spirited accelerations.

The logic of turbocharging in the Galant’s modern arc extends beyond simply fitting a kit to an engine bay. It involves a careful calibration of boost control to prevent driveline shock and to preserve the longevity of turbomachinery, pistons, and bearings. Precision-tuned boost control systems allow drivers to push the engine harder while the control software modulates fuel delivery, ignition timing, and wastegate behavior to maintain tractable torque curves. This kind of management is essential when you consider the Galant’s broader market role. In many markets, customers valued a blend of performance-minded capability with the everyday quietness of a refined sedan. The result is a programming discipline that favors broad usability: torque arrives early enough to feel responsive in city traffic, peak power is achievable without a harsh mid-range, and the engine remains calm and predictable under load. The modern Galant thus becomes a study in how turbocharged performance can coexist with smoothness, something that has long been a Mitsubishi staple as the company extended its performance heritage into more refined platforms.

Thermal management sits at the core of this balance. A turbocharged engine generates far more heat than a naturally aspirated one at similar power levels, and heat is a silent adversary to both performance and longevity. The Galant’s modern engine approach treats heat not as a side effect to be managed but as a central design constraint to optimize around. In addition to high-flow intercoolers, robust oil cooling paths and carefully staged cooling circuits help keep temperatures within a predictable band. This reduces the risk of knock, preserves turbo longevity, and contributes to a more consistent power delivery across long drives and demanding road conditions. The Galant’s fans, radiators, and oil coolers form a symbiotic system where airflow and coolant temperatures are tuned to match the engine’s boosted state. In this sense, the car’s performance credentials are not simply about raw boost but about how the entire thermal envelope remains stable as boost pressure climbs and pressure cycles through daily driving and extended highway runs.

A related thread in the Galant’s modern engine story is the adoption of variable valve timing concepts that align with Mitsubishi’s broader engineering ethos. While MIVEC became more prominently associated with the Evo family, the underlying principles—adjusting valve timing to optimize torque at low rpm and breathing at high rpm—resonate in Galant iterations that pursue both lively response and efficient cruising. The Galant’s later 2.4-liter engines, aided by variable timing and electronic control, demonstrate the practical benefits of this approach. The engine can switch into a more torque-rich state at lower revs, delivering confident acceleration from a standstill or a city merge, while still revving cleanly to higher speeds with a refined top end. The result is a powertrain that rewards smooth, progressive driving rather than sudden, sharp surges. It is a refinement that embodies Mitsubishi’s philosophy of making performance feel natural and accessible rather than forced or contrived.

This balance also plays into the Galant’s chassis and drivetrain integration. The VR4’s all-wheel-drive system represents a deliberate choice to align power output with grip and control. When paired with a well-tuned turbo kit and a responsive boost strategy, the result is not simply speed, but a controlled, confident acceleration that feels as stable on a rainy city street as it does on a dry highway. The vehicle’s handling characteristics—steady midrange torque, predictable throttle response, and measured delivery of power through the driveline—are the direct beneficiaries of this approach. In a broader sense, the Galant’s modern engine technologies reflect a philosophy that places driving confidence at the center. Power is an enabler, not a showman; efficiency and stability are cultivated through precise engineering choices that help the car remain comfortable and dependable day after day.

The modern Galant is also mindful of the realities of maintenance and ownership. The search for performance in the aftermarket is tempered by a recognition that durability matters if a car is to be enjoyed over years of use. The turbocharged route, in particular, requires attention to components that may wear more quickly than their naturally aspirated counterparts. Bolts, gaskets, intercooler cores, and turbo bearings demand thoughtful choices and proper servicing. Yet the availability of robust, engineered parts demonstrates that Mitsubishi’s platform is capable of accommodating updates without compromising reliability. In this sense, the Galant’s engine story is not one of reckless modification but of disciplined enhancement. Owners who pursue performance typically do so within a framework that respects the engine’s thermal limits, respects the drivetrain’s capabilities, and adheres to tuning practices that preserve the vehicle’s long-term integrity.

From a broader historical perspective, the Galant’s engine evolution mirrors the industry’s shift toward sophisticated control strategies and integrated powertrains. The fifth generation’s introduction of a 2.0-liter turbocharged option—famously associated with spirited, rally-inspired performance in markets like Australia and New Zealand—illustrates how Mitsubishi leveraged turbo technology to broaden appeal without sacrificing ride quality. Later generations refined this concept. The ninth generation emphasized refinement and efficiency, channeling attention toward smoother operation and better fuel economy through technologies like MIVEC-enabled timing control on the 2.4-liter engines. While turbocharging in the Galant may not have been the default configuration across all models, its presence in select variants underscores a key theme: performance technologies do not exist in a vacuum. They must interact harmoniously with the car’s mechanicals, electronics, and the expectations of a diverse group of drivers.

What emerges from this integrated view is a clear throughline: the modern Mitsubishi Galant embodies a philosophy of intelligent power. Its engines are not simply about more torque or higher peak horsepower; they are about delivering usable, repeatable performance in a way that feels natural. Turbocharged power is tempered by efficient cooling, by sophisticated control systems, and by an engine architecture that remains robust under repeated, dynamic use. The involvement of valve timing strategies—whether the exact term MIVEC or a closely related control philosophy—reveals a forward-facing approach. It speaks to a generation of engineers who understood that modern driving requires not only speed but also cut-and-dried reliability in everyday conditions and long-term ownership.

For enthusiasts who crave deeper customization, the Galant ecosystem offers pathways to pursue higher performance within a framework of safety and reliability. Engine upgrades, when designed with thermal management and driveline balance in mind, can yield tangible gains in response and acceleration without the typical equipment failures associated with unbridled boosting. The modern Galant’s story, therefore, is not a single tale of horsepower chasing the horizon. It is a narrative of how to marry turbocharging, valve timing, and heat management into a coherent, enjoyable driving experience that remains faithful to the car’s core identity as a refined, capable sedan.

As the chapter closes on this examination of modern engine technologies in the Galant, it becomes clear that the vehicle’s evolution is about more than chasing peak numbers. It is about building an engine environment where power is accessible, control is predictable, and the chassis can harness the performance without being overwhelmed by it. The turbo-focused enhancements of the VR4 era, the careful expansion into efficient, electronically controlled gasoline engines, and the ongoing emphasis on thermal stability together illustrate a sustained commitment to engineering that respects both performance aspirations and everyday practicality. In short, the Galant’s modern engines are not merely power units; they are the backbone of a driving experience that aims to be both exciting and enduring.

External resource for further reading: https://www.mitsubishiservice.com/galant-turbo-kit-technical-details

Internal link for deeper context on engine platforms: 4G15 engine page

Keeping the Galant’s Heart Alive: Navigating the Aftermarket Engine Landscape for the Mitsubishi Galant

Across three decades, the Mitsubishi Galant carved a reputation as a practical sedan with a surprisingly enduring appetite for robust engineering. Its engines tell a parallel story: a lineage that began with compact, quick-revving four-cylinders and grew into more refined, efficiency-minded powerplants that balanced performance with everyday usability. When a model cycle ends, it is not the heart that vanishes but the availability of fresh, OEM-grade parts that can keep that heart beating. This chapter dives into the aftermarket universe that sustains the Galant’s engines, tracing how global supply chains, regional manufacturing clusters, and dedicated suppliers continue to serve owners, repair shops, and enthusiasts long after the last new Galant rolled off the line. It is not a catalog of parts but a narrative about reliability, adaptability, and the practical realities of keeping legacy powertrains in service in a world where demand for affordable maintenance never truly fades away.

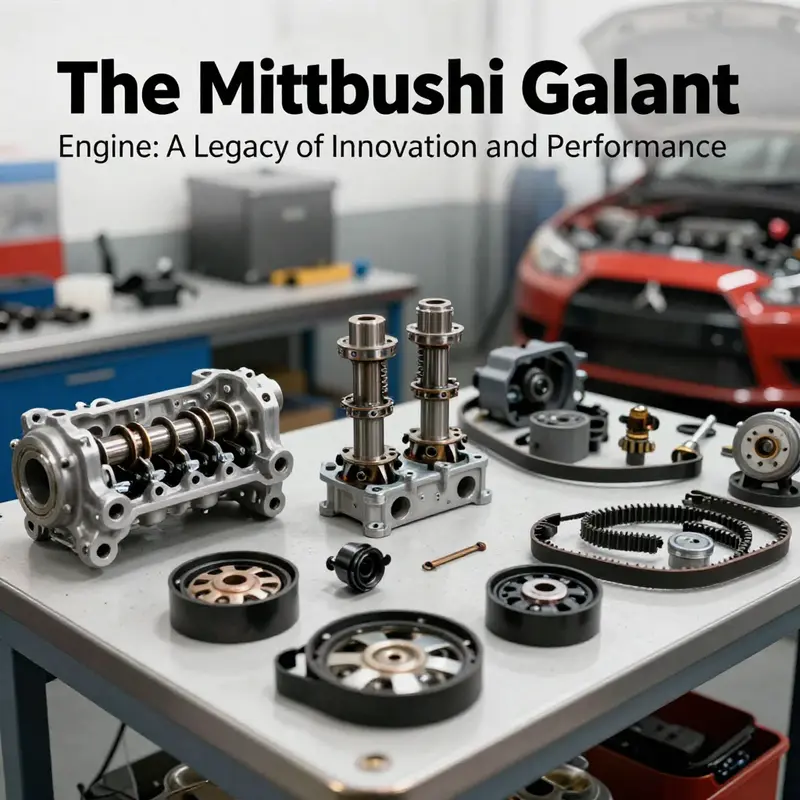

The Galant’s engine history already hints at its aftermarket longevity. Early generations leaned on compact, performance-oriented options that could be tuned or repaired with relatively straightforward components. As the model matured, engine choices diversified to cover a broad spectrum of needs—from efficient daily drivers to more spirited variants with turbocharged potential and a broader torque curve. The aftermarket ecosystem mirrors that evolution. It centers on a durable set of core components—engine blocks, head gaskets, timing systems, water pumps, oil pans, intake manifolds, crankshafts, connecting rods, cylinder heads, and engine mounts—that form the backbone of maintenance and rebuild work. These elements are widely available through specialized third-party manufacturers and distributors, often sourced from a global network that centers its manufacturing clusters in East Asia, notably China and Taiwan. The practical upshot for Galant owners is straightforward: while new Galants may have departed the stage, the parts that keep engines running remain accessible, often with options that balance price, compatibility, and performance.

From a mechanics’ point of view, the availability of these core components matters most where reliability and temperature management intersect. An engine block or a head gasket is not merely a piece of metal; it is the foundation for a long, steady operation. A timing belt or a sealing solution is the guardian of synchronized rotation and oil circulation. Water pumps and oil pans preserve thermal balance and lubrication, two essential factors for preventing wear and early failure. In a Galant context, these parts must align with the design architecture of the specific generation’s engine family. The aftermarket has responded by developing remanufactured cores, reconditioned blocks, and new gaskets that meet or closely approximate OEM specifications. In practice, this means a repair or rebuild can be completed with parts that are designed to fit, function, and endure in daily use, not just in a showroom scenario. The result is a practical pathway for owners to address wear, leaks, or failure without resorting to a prohibitively expensive new engine.

Sourcing strategies for the 2007 Galant and older models reflect a broader trend in aftermarket logistics: a focus on quality assurance, customization flexibility, and supply continuity. In the current landscape, manufacturers in China’s Guangdong province often handle integrated CNC machining and component production, Zhejiang specializes in precision metalwork and rubber compounds, and Hebei remains a hub for sealing solutions. These regional strengths enable rapid prototyping and scalable production, with typical lead times for stocked items falling into the 15–30 day window. For shops handling multiple lines, that predictability can be a decisive factor when planning inventory and turnaround times. Drop-shipping and direct-to-customer programs further streamline logistics, reducing the distance parts must travel and enhancing the ability to source specific variants or configurations without the need to maintain a large in-house stock. The practical implication for Galant owners is straightforward: a well-curated supply chain means faster repairs, more reliable rebuilds, and a broader set of options when chasing a particular performance goal or a specific fitment requirement.

Yet access alone does not guarantee success. The reliability of the aftermarket rests on the integrity of suppliers and the quality controls that govern their production, testing, and distribution processes. A structured supplier evaluation framework becomes essential for B2B buyers and repair shops alike. The most relevant criteria center on operational capability, technical precision, and transactional reliability. In a market that spans continents and regulatory environments, aligning with suppliers that adhere to international quality systems offers a practical safeguard. Standards such as IATF 16949, broadly recognized in automotive manufacturing, provide a language of quality that helps buyers gauge whether a supplier can deliver consistent performance, durability, and traceability across batches. Even when sourcing from legacy or remanufactured parts, buyers increasingly seek this assurance to minimize the risk of premature failure, which can be both costly and frustrating for owners who rely on their Galants for daily transportation.

When it comes to buying recommendations, the emphasis shifts from chasing the lowest price to prioritizing parts that offer proven compatibility and long-term reliability. For reliable, cost-effective replacements, buyers are advised to favor suppliers with demonstrated track records in legacy automotive parts, particularly those located within the established industrial zones of major manufacturing nations. The logic is simple: proximity to manufacturing clusters often translates into more consistent export practices, better quality control, and clearer documentation for international buyers. In the Galant’s case, this reduces the friction associated with engine repairs and rebuilds—an especially meaningful consideration for owners who rely on older vehicles where a single component replacement can become a gateway to a broader maintenance plan.

The landscape for parts is further enriched by consumer-facing marketplaces and direct seller networks. While platforms vary in their offerings and reliability, a thoughtful approach to procurement can unlock both affordability and quality. For individual enthusiasts and independent repair shops, the balance between cost and fit is often achieved by sourcing from suppliers with a specialization in legacy engines and a willingness to provide technical guidance, rebuild options, and testing data. In practical terms, this means selecting vendors that can supply the right seals, the correct head gasket thickness, or the appropriate valve train components for a specific Galant generation, rather than generic, one-size-fits-all parts. The goal is to maintain engine performance and durability while respecting the unique tolerances that define each generation’s design language.

To illustrate how this approach translates into concrete choices, consider the way a hobbyist might navigate the workflow of a standard engine refresh. A core group of parts—such as the engine block, head gasket, timing system, water pump, and oil pan—will usually anchor the rebuild. The timing system, in particular, deserves careful attention. Aligning the timing components with the engine family’s specifications is essential for avoiding issues like valve timing slippage, which can cause performance loss and potential engine damage. By prioritizing parts sourced from suppliers with an established track record in legacy engines and by selecting those that come with reliable testing and documentation, a rebuild can proceed with confidence. As a practical matter, many buyers also seek parts that offer a degree of customization without sacrificing compatibility. This can include sealing solutions tailored to the Galant’s design, or gasketing sets that match the engine’s bore and deck height, ensuring a clean, leak-free assembly during reassembly.

The practical ecology of the Galant’s aftermarket ecosystem also highlights how information sharing and cross-border collaboration play a role. A well-documented parts catalog, even when assembled from multiple sources, can give a repair shop the ability to assemble a complete, performance-ready engine from modular components. This is particularly valuable for older models, where the availability of a single source for every part is unlikely. By combining components from different suppliers—each meeting specific tolerances and performance criteria—a shop can tailor a rebuild to the owner’s needs, whether that means restoring original feel, enhancing reliability for daily driving, or pursuing a modest performance uplift within safe operating limits. In such workflows, the role of documentation becomes critical. Detailed fitment notes, torque specifications, gasket thicknesses, and bearing clearances all contribute to a smoother rebuild and a more predictable long-term result. The environmental footprint of these operations also matters. Efficient sourcing, reconditioned cores, and regional manufacturing strengths all contribute to reduced transport emissions and a lower overall cost per mile of service when a Galant returns to the road.

Within this broader narrative, the Galant’s engine heritage continues to inform modern maintenance strategies. The shift toward efficiency and electronic control in later generations—while introducing new complexity—also opened avenues for more robust service procedures and diagnostic approaches. The underlying principle remains the same: a well-maintained engine, backed by a reliable aftermarket supply chain, can deliver years of dependable service. For owners, that means considering not only the immediate repair but the long arc of maintenance—oil quality, gasket integrity, fuel delivery consistency, and cooling system reliability—so that a rebuilt or refreshed engine can operate for many more miles with predictable performance. In practice, this translates to choosing parts not only for their fit but for their proven performance in the Galant’s historical context and for their compatibility with the vehicle’s current maintenance regime. The result is a practical, resilient approach to ownership that honors the Galant’s legacy while embracing the realities of modern parts supply.

For readers who want to explore a specific avenue of the Galant’s engine family, a focused look at a particular engine variant can be instructive. The path to understanding the broader ecosystem often begins with a single, well-documented example that demonstrates how the aftermarket can deliver a complete solution—from a fresh block to a full gasket kit and a calibrated timing set. 4g15-engine-mitsubishi-lancer-cedia-2001-ta-cs2a offers a concrete case study in compatibility, workmanship, and the logistical realities of sourcing parts for a legacy platform. It serves as a reminder that even as model lines evolve, the community of suppliers, repair shops, and informed owners can converge on practical, affordable pathways to keep the Galant’s engine in service.

In closing, the aftermarket engine landscape for the Mitsubishi Galant is not a static backdrop but a dynamic ecosystem that blends regional manufacturing strengths, rigorous quality standards, and a broad spectrum of component options. It supports a practical approach to maintenance and restoration, one that respects the car’s heritage while leveraging modern sourcing strategies to ensure availability, performance, and reliability. For owners and repair professionals alike, the message is clear: the Galant’s heart can endure, provided the path to parts is chosen with care, supported by documentation, and guided by a willingness to engage with a global community of suppliers who share a commitment to value, durability, and informed stewardship of a beloved legacy vehicle.

External resource for further exploration: Engines & Engine Parts for Mitsubishi Galant on eBay. https://www.ebay.com/b/Engines-Engine-Parts-for-Mitsubishi-Galant/183221/bn_1707355

Final thoughts

The Mitsubishi Galant engine journey reflects the brand’s adaptability and commitment to performance and refinement. From its early, high-performance engines to modern iterations incorporating cutting-edge technologies, the Galant illustrates the evolution of automotive engineering. For business owners, understanding this journey is essential, not only for appreciating the vehicle’s legacy but also for leveraging aftermarket opportunities that cater to a dedicated enthusiast base. Engaging with this history enhances the support of their own operations within the automotive sector.