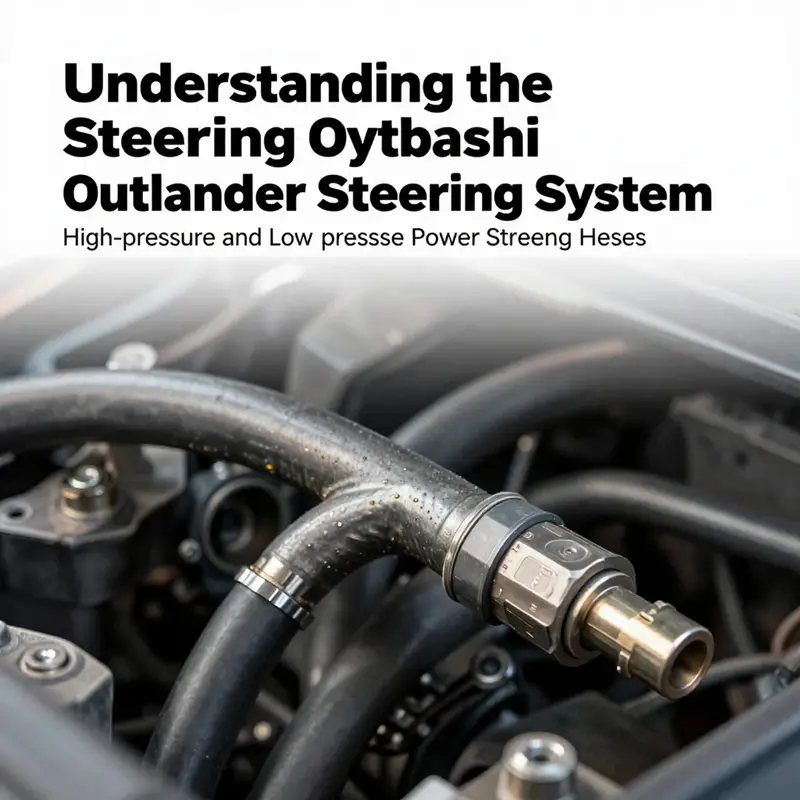

The Mitsubishi Outlander, known for its reliability and performance, boasts a sophisticated steering system crucial for optimal driving experience. The steering system is integral for ensuring smooth maneuverability, allowing business owners to navigate with confidence. Understanding its core components—particularly the high-pressure and low-pressure power steering hoses, as well as the inner rack end—is vital. Additionally, the innovative steering wheel controls and cruise control features enhance driving convenience. Proper maintenance and awareness of component functionality can greatly impact overall vehicle longevity and safety. This article delves into each facet of the steering system, offering valuable insights that aid business owners in making informed decisions about their Mitsubishi Outlander.

null

null

The Inner Rack End: The Hidden Link That Keeps the Mitsubishi Outlander Steering Precise

The steering system of a Mitsubishi Outlander is a symphony of parts that must move in perfect harmony. At the center of this orchestration sits the inner rack end, a component rarely celebrated in shop talk but absolutely essential for translating the driver’s input into precise wheel action. This small but mighty joint sits where the steering rack connects to the inner tie rods, which then relay motion to the outer tie rods and, finally, to the steering knuckles that turn the wheels. When everything is new, the rack end and its mates cooperate to deliver a crisp, linear feel, with the steering wheel oscillating a little and the wheels following with confidence. But as miles accumulate and tires wear, the inner rack end becomes a fulcrum of wear and fatigue. Its condition often sets the tone for how tightly the Outlander responds to steering commands, how quickly it returns to center after a corner, and how much steering wheel play a driver perceives before the wheels actually begin to pivot.

From the factory, the inner rack end and its companion joints are designed to endure frequent reciprocating motion and rotational stress. The inner tie rod end, which threads into the steering rack, forms a pivotal connection that must accommodate small angular movements as the wheels roll across pavement. The boot around the joint protects the grease inside from dirt and moisture, a shield that is essential for maintaining smooth, low-friction operation. When this boot tears or the grease leaks away, the joint begins to lose its precision. The effect is subtle at first—perhaps a little looseness when the car is stationary or a faint clunk when striking a shallow dip—but it can quickly escalate to a noticeable delay between a steering input and wheel response. The Outlander’s steering then feels less confident, more vague, and the driver may find it harder to place the vehicle exactly where intended, especially at highway speeds or when negotiating tight curves.

To understand why this small linkage matters so much, imagine the steering rack as a linear conveyer of motion and force. The inner rack end is the hinge that converts that linear movement into the dual, opposing rotations required by the left and right front wheels. If the hinge develops play, the toe angle of the front wheels begins to drift. That drift manifests as steering wander or oversteer/understeer tendencies that hide in plain sight: uneven tire wear from toe misalignment, steering wheel off-center while maintaining straight-line travel, or a subtle but persistent steering kick when hitting pavement seams. In the Outlander, where the driver relies on both mechanical and electronic assists to stabilize steering, any looseness at the inner rack end can magnify the work the electronics must do to maintain the expected feel and response. This is particularly true when the vehicle is cruising on uneven surfaces or negotiating a corner that requires a quick, precise adjustment of the wheel angle. In short, the inner rack end is more than a joint; it is a gatekeeper of steering precision and predictability, and its health often sets the baseline for the entire driving experience.

From a diagnostic perspective, the telltale signs of a deteriorating inner rack end are measurable and sometimes audible. A common symptom is steering play or “slop” that becomes apparent when turning the wheel from lock to lock. You may notice that the wheel has to travel a certain amount before the wheels begin to respond, or you might feel a slight looseness when you hold the wheel steady in a straight-ahead position. Tire wear patterns can betray the issue too: toe misalignment caused by a worn inner end tends to wear the inner edges of the front tires more aggressively, creating pulsing noise and uneven contact with the road. Another clue is the presence of intermittent clunks or squeaks when traversing over bumps or potholes, especially if the noise coincides with steering input. When you perform a hands-on check, you can carefully inspect the boot seal at the inner tie rod end for cracks or grease leakage. A torn boot invites dirt and moisture to invade the joint, accelerating wear and leading to increased play. A more rigorous assessment involves objectivity: using a pry bar to gently rock the tire assembly at the 12 and 6 o’clock positions, you can detect unwanted movement in the steering linkage that suggests looseness at the inner rack end or an adjacent joint. If the movement exceeds the normal tolerance, or if the movement is accompanied by a grinding or metallic rubbing sound, it is a clear signal that service is warranted.

Accessing and servicing the inner rack end is not a routine, one-click job. The Outlander’s chassis layout often requires removal of certain components to gain visibility and room to work, and the work can involve disassembling parts of the lower dash or nearby undercarriage components to reach the rack end and the associated joints. When replacement is necessary, technicians typically choose between replacing the inner tie rod end as part of a refreshed rack assembly or replacing the end joint itself if the rack remains in good condition. Either path demands careful restoration of alignment afterward, because even a small change in toe can transform steering feel dramatically. After you reinstall the components, a professional alignment is essential to ensure the front wheels sit at the correct toe angle across the steering range. Without precise toe alignment, the steering response may feel inconsistent, and tire wear will become uneven with time. The operating principle here is straightforward: restore the intended geometry, restore the natural balance of steering load across the wheels, and allow the steering system to regain its precise, predictable behavior.

To widen the lens beyond the mechanical, the inner rack end interacts with the Outlander’s broader steering ecosystem, including electronic control systems that support steering assistance. The Electric Power Steering (EPS) system, for instance, uses torque sensors and an EPS-control unit to modulate steering assist based on vehicle speed and dynamic conditions. While the EPS reduces steering effort, it does not replace the need for accurate mechanical alignment. If the inner rack end is worn, the stability that the EPS hopes to achieve is diminished. The EPS can compensate to a point, but excessive play from the rack end will still degrade steering feel and responsiveness. For drivers who frequently drive at higher speeds or in demanding road conditions, the combination of worn joints and a stressed EPS can result in fatigue as the system works harder to maintain control, and the feedback through the steering wheel may become less intuitive.

Within the electronic ecosystem, wiring diagrams and connector locations—such as those in the official service documentation for the 2017 Outlander EPS—reveal how the EPS-ECU communicates with other control units like ETACS-ECU to coordinate steering response and safety features. Although the procedural details sit in service manuals, the practical takeaway for a cautious owner is simple: if steering feel changes and you suspect a mechanical issue, do not rely solely on electronic compensation. Inspect the inner rack end and related joints first, because electrical adjustments cannot fix a fundamental mechanical wear problem. The two worlds—mechanical integrity and electronic control—must work in concert to deliver consistent steering performance. When one part begins to fail, the overall system becomes reactive instead of proactive, and that is a condition that invites compromised control in critical driving moments.

To connect the dots between daily upkeep and long-term durability, consider how routine inspection and timely replacement of worn components at the inner rack end contribute to reliability and safety. Even the best EPS and steering wheel controls cannot salvage a steering system that has grown sloppy at the heart of its linkage. A regular inspection cadence that includes boots, grease presence, and boot integrity can prevent early degradation. This approach not only preserves steering fidelity but also reduces the risk of tire wear irregularities that stem from toe misalignment. In practice, treat the inner rack end as a living part of the steering choreography, one that benefits from proactive maintenance and timely attention, just as you would monitor the health of hoses that carry the hydraulic fluid under pressure and the related fittings in the steering circuit. By staying attentive to these connections, the Outlander maintains a nimble and confident steering personality across a wide range of driving situations.

For readers curious about hands-on maintenance paths, a practical tip is to verify access routes to the steering rack. Access may require removing certain shielding or trim panels, but the effort pays off when you can see the inner rack end clearly and assess boot integrity and joint movement. If you decide to pursue replacement or repair, consult the service manual to observe the correct torque specifications and sequence for reassembling the steering column, inner tie rods, and rack components. After service, a careful road test is essential to confirm alignment, steering responsiveness, and the absence of unusual noises. In the broader context of the Outlander’s steering system, the inner rack end represents a critical point where mechanical precision and electronic support converge. Its condition often shapes how smoothly the vehicle communicates with the driver and how safely it behaves when confronted with bumps, seams, or sudden steering input.

Steering at the Core: Unpacking Wheel Controls and Cruise Control in a Modern SUV

The steering system of a contemporary SUV is more than a mechanical link between the road and the driver. It is a compact orchestra of human input, electronic feedback, and highway confidence. Among its most visible conductors are the steering wheel controls and the cruise control system. Together, they transform routine highway cruising into a calmly composed experience, allowing the driver to stay focused on the road while still managing media, calls, and speed with quick, deliberate touches. This integration is not merely about convenience; it is a deliberate design choice aimed at reducing distraction, improving safety, and preserving comfort over long journeys. When we reach for a familiar button on the wheel, it is not a small gesture but a small restoration of control—an intentional action to keep the eyes on traffic, the hands on the wheel, and the mind in the moment. The layout and behavior of these controls are a reminder that modern steering is as much about human factors as it is about hydraulic pressure or electronic sensors. The wheel becomes an interface, a personal command center that couples the driver’s intent with the car’s responsive behavior, and it deserves careful attention in both everyday use and routine maintenance.

The steering wheel controls that most drivers use daily are designed to be intuitive and immediate. The goal is simple: minimize the need to reach away from the wheel to perform common tasks. In practice, this means tactile buttons for volume, media track changes, and phone calls, as well as voice activation to summon virtual assistants or dial a contact without lifting a hand from the rim. The psychology behind this arrangement is thoughtful: when a driver’s hand never fully leaves the wheel, the cognitive load of driving remains lower, which helps sustain attention on the road and reduces the possibility of errors caused by shifting gaze or posture. For many drivers, the rhythm of the road is steadier when these controls respond with consistent feedback—an affirmative click, a subtle haptic pulse, and a screen image that confirms the action without demanding a full glance away from the traffic ahead. In this sense, wheel controls are less about luxury accessories and more about a steady, reliable bridge between intention and action. They reflect a design philosophy that values the driver’s time and safety, recognizing that even small conveniences can accumulate into meaningful reductions in fatigue during long trips.

Yet the heart of the driving experience often beats strongest through the cruise control system. The rotary control used to manage this feature offers a different form of ease. Rather than stepping out of the cruising lane to adjust throttle, the driver can set a desired speed, resume a previously set pace, or nudge the vehicle up or down to match the flow of traffic with gentle, incremental changes. This is not a substitute for attentive driving but a partner that helps manage energy and comfort on extended stretches of highway. The Set, Resume, Accelerate, and Decelerate commands—each accessible with a simple twist or push of the knob—translate the driver’s intent into a steady velocity. In practice, this reduces leg fatigue and can contribute to more consistent fuel usage, especially when road conditions are steady and traffic is light to moderate. The tactile interface of the rotary control—its resistance, the audible or tactile feedback, and the way it accepts small, precise inputs—becomes part of the vehicle’s responsible driving personality. The driver learns a rhythm: one turn to settle into cruising speed, a light touch to adjust, and a moment where attention returns to the echo of tires on pavement rather than the cadence of the accelerator.

For many models, the cruise control experience extends beyond a simple speed hold. Higher-grade configurations introduce adaptive cruise control (ACC), an evolution that reads the traffic ahead and modulates speed to maintain a chosen following distance. The effect is almost human: the car senses the vehicle in front and responds with measured acceleration and deceleration to preserve safety margins. The integration of ACC into the wheel control suite is important because it preserves the driver’s hands on the wheel while automatically handling speed in response to real-time conditions. This combination is particularly valuable on long, open highways or busy corridors where pace and spacing vary, yet the driver remains responsible for the surrounding environment. The driver, in turn, becomes a curator of rhythm rather than a mere regulator of throttle. It is a subtle shift—less pedal work, more cognitive oversight, and a smoother journey as traffic ebbs and flows. The result is not a self-driving feature but a refined driving assistant that reinforces good habits, such as maintaining safe following distances, monitoring lane discipline, and staying alert to changing road surfaces and weather.

The value of steering wheel controls and cruise control in concert goes beyond convenience. It is about safety through reduced distraction and fatigue. When a highway run becomes a sequence of tasks that can be accomplished on the wheel—dimming the cabin lights for night driving, answering a call, switching music to match a mood, or activating a voice assistant—there is less need to reach for a center stack or a touchscreen. Notifications can be consumed on the instrument cluster, allowing the driver to validate information without looking away from the road. Similarly, precise control of speed through cruise functions helps smooth out acceleration patterns, which can contribute to more predictable vehicle behavior at high speeds and in variable traffic. The synergy between wheel controls and cruise control represents a design philosophy that emphasizes driver retention of control—a core principle in modern vehicle ergonomics.

Of course, with any suite of automated or assisted features comes a responsibility to understand their limits. The automated speed adjustments of ACC are contingent on sensor inputs and correct calibration. Adverse weather, dense traffic, or sensor occlusion can reduce effectiveness. The rotary knob remains an advisory tool; the human operator must stay vigilant, ready to intervene if the surrounding traffic demands a faster reflex or a swift alteration of course. This synergy relies on clear feedback channels: the driver must know when ACC is engaged and how much distance is being kept, and the vehicle must communicate its status through instrument displays and audible cues. The best practice is to treat these features as accelerators of safety rather than substitutes for driver attention. When used with discipline, wheel controls and cruise controls can help maintain a calm, controlled tempo, letting the driver allocate more attention to potential hazards and road conditions rather than repetitive throttle management.

From a maintenance perspective, keeping these controls reliable means regular checks and gentle care. Buttons on the steering wheel can accumulate grime or suffer from wear that dampens their tactile response. The rotary cruise control knob should feel deliberate and comfortable, with no looseness or lag in response. If the wheel controls become sticky, unresponsive, or mismatched with the displayed options on the cluster, a professional inspection is warranted to ensure that the control logic transitions smoothly from input to vehicle response. Similarly, if the adaptive feature seems to lag behind the driver’s intended speed or distance, a calibration update or sensor inspection may be necessary. In practice, a routine service can preserve the value we place on tactile reliability and clear feedback, ensuring that the wheel remains an intuitive interface rather than a source of confusion. Maintenance also extends to the electronics and the software that govern these features. Software updates can refine how the system interprets inputs, optimize the timing of accelerations and decelerations, and improve the harmony between driver actions and vehicle responses.

Integrating these insights into daily use requires mindful habits. When entering a long trip, a quick check of the wheel controls and cruise settings sets the tone for the journey. If the day’s traffic looks variable, engaging ACC with a comfortable following distance and linking it to the radar-based sensors can reduce stress, particularly on multi-lane highways. The wheel controls should be used to manage not just media and calls but also to keep attention anchored on the road. A simple rule is to limit manual interventions to essential adjustments and rely on the wheel-and-rotary combination for routine tasks. In this way, the steering system becomes a partner in steering a comfortable, efficient, and safe trip rather than a source of constant manual labor.

For readers seeking a tangible reference to vehicle hardware and service considerations, a model-specific hardware guide can shed light on related components in the steering assembly. A practical quick link that points to a relevant hardware reference is available here: front-bumper-mitsubishi-outlander-19/. While it focuses on chassis components rather than steering controls, it underscores how a model’s integrated hardware ecosystem supports the overall driving experience, including the reliability of control interfaces and their interactions with other systems on the vehicle.

In sum, the steering wheel controls and cruise control system form a foundation for comfortable, safe, and efficient travel in a modern SUV. They are a reminder that driving is not simply about getting from point A to point B; it is about shaping that journey with intention, ergonomics, and a well-tuned partnership between human judgment and machine support. The most effective way to harness their benefits is to use them as intended, respect their limits, and maintain them with regular care. When done well, the experience feels effortless: a driver who can cue music, answer a call, and set a steady pace with the touch of a finger or a careful twist of a knob—while keeping full attention on the road ahead. External reference: https://www.mitsubishiparts.com/outlander-power-steering-hose

Steering for Stability: A Deep Dive into the Outlander’s Hydraulic Hoses, Rack End, and the Path to Precision Handling

The steering system of the Mitsubishi Outlander is the vehicle’s nervous system. It translates the driver’s intent into precise, controllable wheel movement and balances road feel with the comfort of effortless steering. When the road twists, the steering system works behind the scenes, delivering leverage and feedback that let the driver gauge grip, traction, and cornering load. In this chapter we trace the backbone of that system, focusing on two crucial hydraulic lifelines—the high-pressure and low-pressure hoses—that shuttle fluid under pressure, and on the inner rack end, the quiet hinge that transforms linear motion into wheel angles. We also consider how the vehicle’s electronic aids—the steering wheel controls and cruise control interface with the mechanical core—so that the driver can stay relaxed and attentive on varying road conditions. The aim is a cohesive view of what keeps steering precise and predictable over the long haul, without losing sight of how each component depends on the others to maintain consistent, linear response.

At the heart of the Outlander’s steering is the hydraulic path that supplies and returns pressure fluid to the steering gear. The high-pressure hose stands as the conduit from the pump to the steering mechanism, and it faces a demanding life. It must endure high fluid temperatures, continuous vibration, and repeated flexing around bends and joints. To withstand these stresses, manufacturers reinforce the hose with multiple layers of reinforced rubber and fabric or even steel-wired textiles. This construction provides the strength needed to carry hydraulic oil at pressures typical of assisted steering, yet it also creates potential weak spots. Bends near fittings, worn or cracked sections, or aging reinforcement can lead to cracks, bulges, or gradual fatigue. When such damage progresses, the hose can leak or fail, instantly diminishing assist and leaving the driver fighting a heavier wheel that demands more effort to move. The risk is not only reduced steering ease but the possibility of a sudden loss of assist when relief is most needed, such as during tight turns or evasive maneuvering. The low-pressure hose, while operating at a much gentler pressure, plays an equally essential role. It returns the hydraulic oil from the steering gear back to the reservoir and pump, completing the hydraulic loop. If this hose sags, cracks, or leaks, the system’s ability to re-circulate oil suffers, which can cause the pump to work harder, overheat, or lose copious quantities of fluid. Together, these hoses form the circulatory system of the steering, and their integrity directly informs how the Outlander’s steering feels: smoothly assisted at low speeds and stable yet responsive at higher speeds.

The inner rack end sits at the wheelhouse of steering geometry. It is a pivotal connector that links the steering rack to the outer tie rods, translating the straight-line motion of the rack into the left and right wheel angles that steer the vehicle. In a well-maintained system, the inner rack end maintains tight tolerances, minimizing play and ensuring the wheel returns to center promptly after a turn. This precise geometry is what gives a driver that crisp, responsive feel—the sense that the steering wheel is an extension of the hands rather than a separate component. With miles and time, however, wear accumulates here as the internal surfaces wear and the linkage loosens. The outcome is subtle at first: a faint wander, a slight vagueness through progressive steering inputs, or a barely perceptible lag between a steering command and wheel response. As wear progresses, the effect can become more pronounced, with increased steering effort required to achieve the same moment of change. Replacing an inner rack end is more involved than swapping a wheel bearing or an outer tie rod. It may require partial subframe access or jack-and-stand work in conjunction with specialized tools, and the labor cost tends to reflect the component’s complexity. Yet the payoff is substantial: restoring the original steering geometry and eliminating unacceptable slack so that the Outlander again responds with the immediacy and confidence that drivers expect from a modern crossover.

The Outlander’s steering experience is also shaped by the electronics that sit around the mechanical core. Steering wheel controls, integrated into the rim, let the driver adjust audio settings, answer calls, and switch sources without removing hands from the wheel. This arrangement keeps attention closer to the road, a practical advantage in heavy traffic or during long highway sections. Cruise control adds another layer of convenience, enabling the vehicle to maintain a steady speed with minimal pedal input, reducing fatigue and helping the driver sustain consistent steering input over time. The synergy between these controls and the hydraulic system matters. If a hose leak or pump issue forces the hydraulic system to work harder to maintain assist, the overall steering feel can change, producing inconsistent feedback or variable effort that undermines a driver’s confidence. Conversely, a well-maintained hydraulic circuit allows electronic aids to function as intended, providing a smooth, predictable steering experience even as speeds change or road conditions shift.

The practical path to longevity for the Outlander’s steering starts with regular inspections and a disciplined approach to maintenance. Practical indicators of trouble often show up before a major failure occurs. A drop in power steering fluid level is a clear warning sign that a leak has developed somewhere along the high-pressure or low-pressure lines, or at a seal on the pump or rack. A whine or groan when turning the wheel can indicate an air ingress issue or a pump laboring against reduced pressure, and it is important not to ignore such noises, especially when they accompany changes in steering feel. Perhaps most telling is an increase in the amount of steering effort required at low speeds or during parking maneuvers. If the wheel feels heavy or inconsistent, the system should be checked promptly, because the underlying cause could be a hose issue, a rack end wear, or a compromised seal within the steering gear.

When it comes to replacing worn components, the choice between OEM parts and aftermarket equivalents is a practical decision grounded in reliability, performance, and cost. OEM hoses and connectors are designed to match factory specifications and tolerances, which can be reassuring for a critical system like steering. Modern aftermarket hoses, however, are built with advanced materials—reinforced polymers and enhanced rubber compounds—that resist cracking, swelling, and abrasion under heat and pressure. The result can be a durable, cost-effective solution that preserves the intended hydraulic characteristics: consistent pressure delivery, stable flow, and a straightforward path back to the original steering feel. If the replacement extends to the steering column, it is sensible to consult reliable resources or a trusted technician to determine whether a new or refurbished column best complements the rest of the hydraulic system. For those seeking detailed guidance on component selection and procedures, the Outlander steering column page offers a clear route to the correct parts and steps: [Outlander steering column].

Beyond parts selection, the maintenance framework emphasizes thorough documentation and adherence to procedure. Official service manuals and reputable repair platforms provide torque specifications, step-by-step replacement guidance, and exact part numbers. Correct installation is crucial to prevent air pockets that can compromise system prime and to ensure consistent steering response after assembly. A disciplined approach to bleeding the hydraulic lines, checking for leaks at every clamp, and verifying that fittings are torqued to spec helps protect against early failure and ensures the system remains quiet, responsive, and reliable.

Taken together, the Outlander’s steering system is more than a bundle of hoses and linkage. It is a coordinated ecosystem where hydraulic lines, rack-end tolerances, and electronic aids must function in harmony. When the hoses show their age, or when the inner rack end begins to exhibit play, the steering feel changes—often in small, cumulative ways that erode confidence long before a dramatic failure occurs. A driver who understands this interconnectedness can catch misbehavior early, schedule timely maintenance, and keep the vehicle handling with the steady, predictable precision that characterizes a well-kept Outlander. The goal is not to seek perfection in every moment but to sustain a dependable, intuitive steering experience across thousands of miles of road, weather, and load.

For readers who want to verify technical steps or compare part specifications, there is value in consulting official manuals and trusted manuals databases. They distill torque values, bleeding procedures, and part identifications into a reliable reference that can be followed in a home garage or a professional shop. External resources that summarize these procedures offer an additional layer of assurance, particularly when planning a repair or overhaul that involves multiple components of the steering system. External link to the official manuals is provided at the end of this chapter for convenient access: https://www.mitsubishicars.com/owners/manuals

Final thoughts

In conclusion, the Mitsubishi Outlander steering system encompasses several critical components, each playing a vital role in ensuring smooth, responsive steering. From the resilience of the high-pressure and low-pressure power steering hoses to the precision of the inner rack end, understanding these elements is crucial for optimum vehicle performance. The integration of user-friendly steering wheel controls and cruise control enhances comfort for drivers, particularly in a business context where efficiency is of utmost importance. Regular maintenance checks and being informed about replacements can greatly reduce the risk of failure, ensuring a reliable driving experience, especially for business owners relying on their vehicles. Empowering yourself with knowledge about the steering system not only enhances safety but also contributes to the overall longevity of the vehicle.