Mitsubishi Outlander bumpers play a crucial role in not only enhancing the vehicle’s aesthetic appeal but also ensuring safety during collisions. For business owners, understanding these components is essential when considering fleet safety or resale value. This guide dives into the design and functionality of Outlander bumpers, explores the material differences between OEM and aftermarket parts, and discusses possible enhancements for better performance and appearance. Each chapter is meticulously crafted to provide valuable insights, helping you make informed decisions for your automotive needs.

Safeguarding Style and Safety: The Design and Function of Mitsubishi Outlander Bumpers

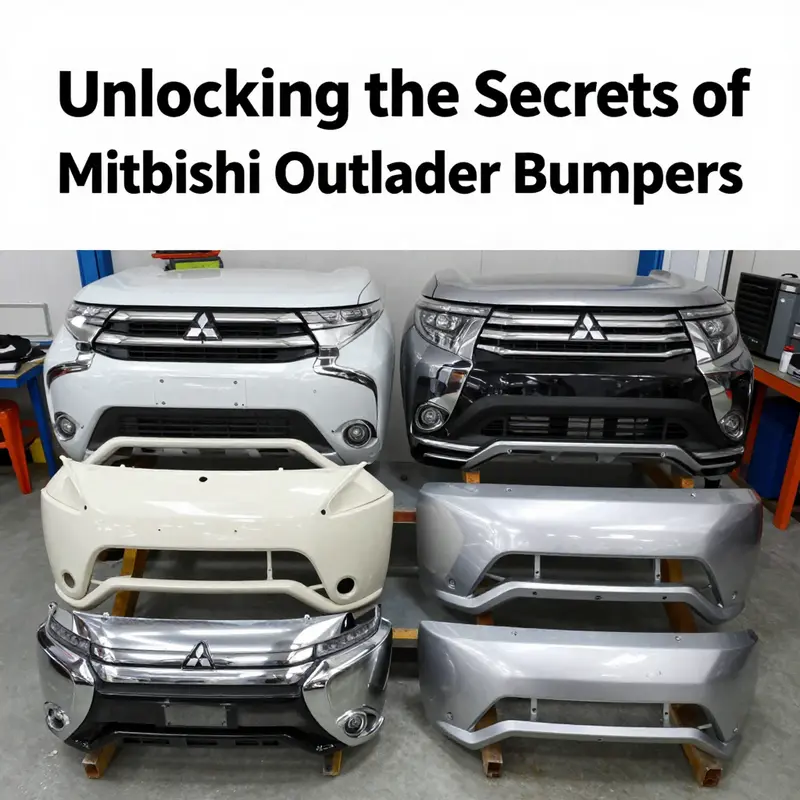

In the broader conversation about how a vehicle feels on the road, bumpers rarely get top billing, yet they anchor a car’s first line of defense and its visual language. For the Mitsubishi Outlander, bumpers are more than plastic shells over chrome and paint; they are carefully engineered interfaces that blend aesthetics, aerodynamics, and energy management into a single, purpose-driven system. Each model year and generation receives a bumper design that is tuned to its specific contours, weight distribution, and sensor layout. The result is a seamless fit with no perceptible gaps, an appearance that remains true to the vehicle’s lines, and an ability to work with the car’s active safety systems. In this respect, the Outlander’s bumpers do double duty: they keep pedestrians and occupants safer while contributing to a refined, cohesive look that signals modern engineering at a glance. The conversation about design and function begins at the front, where the bumper assembly is most exposed to the hazards of daily driving, from errant shopping carts to fender-bender fumbles, and ends with how that same component supports the car’s efficiency and handling on the highway and beyond. The front bumper assembly is not a single piece, but a small ecosystem of parts—each chosen for its role in absorbing impact, guiding energy away from the engine and cooling systems, and maintaining the precise geometry that keeps the headlights, sensors, and grille aligned with the rest of the body. The bumper cover itself is typically crafted from high-impact plastics or composite materials. While light, these materials are engineered to resist deformation during low-speed impacts and to return to their original shape with minimal cosmetic damage. The cover’s fit is not an afterthought; it is molded to the exact curvature of the Outlander’s nose, ensuring a seamless transition from the hood line to the fenders and grille. Within this exterior skin lies a structured interior that performs the real task of safety. The structural reinforcement bar—or energy-absorbing bar as engineers often describe it—shapes the first line of defense. This component, forged from high-strength steel or, in newer designs, lightweight aluminum, is designed to yield in a controlled manner during a collision. Its job is to distribute collision forces evenly across the frame, reducing the likelihood of damage to critical organs such as the radiator, engine, and cooling system, while also lowering the risk of injury to occupants by keeping the cabin more intact. In pedestrian safety terms, the reinforcement bar also plays a role in energy dissipation that reduces peak forces transferred to the exterior, contributing to safer outcomes in the unlikely event of a collision with a person. This theory translates into real-world performance through measurements aligned with global safety benchmarks such as the Insurance Institute for Highway Safety (IIHS) standards and Euro NCAP tests. Achieving favorable results depends on precise tolerances and consistent assembly across every production line. The result is a bumper system that not only protects but also preserves the Outlander’s aerodynamic profile, minimizing drag and maintaining stable airflow at highway speeds. The front bumper’s life is a balance between rigid energy absorption and controlled deformation. The bumper cover and the reinforcement bar form a sandwich of materials and geometry that is meant to behave predictably in the kind of low-speed collisions typical in urban driving. The energy management logic in these assemblies is built around the concept of “crumple zones”—areas that intentionally deform to absorb energy early in a crash, reducing the magnitude of forces transmitted to the vehicle’s passengers and its most delicate mechanical systems. Aluminum is increasingly seen in modern vehicle architectures for its favorable strength-to-weight ratio and corrosion resistance; it’s an attractive option for the Outlander’s reinforcement components when weight savings translate to improved fuel economy and handling. However, the trade-off comes with higher manufacturing and repair costs and the need for specialized tools and procedures during replacement. In contrast, high-strength steel offers exceptional stiffness and crashworthiness at a lower raw material cost, with well-trodden repair workflows. Some manufacturers even combine materials, using aluminum where weight savings matter most and steel where cost or robustness takes precedence. The choice is never arbitrary; it is driven by overall vehicle architecture, safety targets, and the logistics of service and maintenance. The bumper system’s outer skin is supported by a network of brackets that anchor the assembly to the chassis. Bumper brackets, made from durable plastic or reinforced metal, ensure the cover remains aligned with the body and minimizes vibration-induced noise. This is not a trivial task; misalignment can cause misfitting panels, door or hood gaps, and even sensor misreads that affect advanced driver-assistance systems (ADAS). A well-integrated bumper is as much about quietness and feel as it is about impact performance. When a vehicle is designed to be a modern, connected SUV, it must accommodate a constellation of sensors, grilles, and lighting features embedded in or around the bumper area. Fog lights, radar and camera sensors, and even certain grille elements may nest within the bumper structure. The engineering challenge is to preserve the intended function of each sensor while ensuring the bumper’s outer skin remains acoustically and aerodynamically harmonious with the rest of the vehicle. The result is a bumper that does more than shield the engine bay; it acts as a critical, integrated platform for the car’s perception of the road, its quiet cabin experience, and its ability to react to the world around it in real time. As with any complex component, future iterations of Outlander bumpers are likely to reflect evolving design philosophies. A rugged, off-road-focused version is reportedly in the pipeline for late 2026, signaling a shift toward increased durability and terrain capability without sacrificing on-road comfort. The plan calls for thicker, sturdier bumpers, higher ground clearance, and specialized tires, all intended to broaden the Outlander’s aptitude for rough surfaces while preserving safety and efficiency. This direction echoes market responses to adventurous crossover enthusiasts who want a capable vehicle that remains friendly to daily commutes and long road trips. Nor is it merely a matter of brute mass; the emphasis remains on maintaining energy absorption performance and protecting the cabin, even as the vehicle grows more capable off-road. The design decisions are informed by comparative benchmarks from other brands in the same category, and by the desire to preserve predictable handling characteristics when a vehicle transitions from pavement to dirt. The mentioned influences, including the approach seen in some off-road-oriented models, inform the Outlander’s future path and its emphasis on resilience, reliability, and a sense that a modern SUV should be ready for whatever the terrain insists upon. For drivers who are returning from a collision and need replacement parts, the decision hinges on the trade-off between fit, safety, and long-term reliability. OEM bumpers are engineered to achieve a precise fit with the rest of the body, ensuring a paintable, seamless finish and compatibility with integrated ADAS features. They provide the most reliable path to preserving factory warranty integrity post-accident, because the bumper’s geometry has been validated in conjunction with the full vehicle safety system. That compatibility extends to sensor calibrations and the alignment tolerances that ensure the cameras and radar units keep their field of view correct after a panel replacement. While OEM options are generally more expensive than aftermarket alternatives, they offer a pathway to reaffirming the car’s safety integrity, preserve component life expectancy, and minimize risk associated with non-standard fitment. The aftermarket scene, in contrast, expands the realm of styling and performance possibilities. For those who prioritize a sportier or more aggressive look, aftermarket body kits may introduce side skirts that streamline airflow along the vehicle’s sides and lend a lower, more dynamic profile. Rear wing spoilers mounted on the trunk lid can contribute to perceived downforce and visual emphasis, while promising benefits to rear stability at higher speeds. Still, there is a caveat: larger spoilers and certain kit configurations can influence rear visibility and may introduce wind noise if not installed with a precise fit and proper sealing. The choice between OEM and aftermarket components is thus a matter of values—safety and warranty versus customization and aesthetic expression—and depends on how a driver uses the vehicle and what they expect from maintenance intervals and potential warranty coverage. The channel between design and function is further widened by the ongoing evolution of safety technologies. The bumper’s inner structure must not only absorb energy but also accommodate sensors and cameras used in lane-keeping assistance, automatic emergency braking, and pedestrian detection. When a replacement is necessary after a collision, it becomes critical that the new part aligns precisely with the sensor array and fog light assemblies; otherwise the entire ADAS architecture can be compromised, reducing the system’s effectiveness or triggering fault codes that require service intervention. OEM parts typically meet these demands through coordinated engineering tests and validated software calibration procedures, making them particularly attractive for drivers who want to preserve the vehicle’s warranty and its safety offerings after an incident. For those who want to explore model-year-specific replacements or verify compatibility with sensor layouts, a dedicated Outlander front bumper catalog exists in official parts catalogs and online retailers. This resource helps ensure the new panel integrates smoothly with the car’s existing systems and maintains the intended look and function. The catalog link provides access to front bumper assemblies designed for different generations, enabling a precise match for 19-model-year Outlanders and their contemporaries. The practical implications of these resources become especially clear when a crash is involved. A correctly matched bumper does more than restore the exterior’s aesthetic. It supports the structure that absorbs energy, preserves crumple zones, and maintains the geometry that keeps safety systems operating as designed. In the event of an impact, the bumper’s protective role extends into the engine bay, guarding components from immediate damage and facilitating a safer, more predictable energy transfer. The Outlander’s bumper system, therefore, is a small but vital theatre of safety engineering. It embodies a philosophy that values not just looks, but the predictable behavior of materials under duress and the stability of a vehicle’s overall architecture after an impact. In this sense, the bumper is not merely a face or a shield; it is a faithful partner in the driving experience, contributing to quiet rides, efficient cooling, and reliable sensor performance. The conversation about replacement parts is not solely about price or availability; it is about maintaining a vehicle’s integrative safety ecosystem. OEM components, with their assured fit and compatibility with ADAS, represent a careful choice for owners who prioritize long-term reliability, alignment accuracy, and confidence after a mishap. Yet the aftermarket ecosystem continues to push the boundaries of personalization and resilience, offering options that can enhance appearance and, in some configurations, even improve airflow or weight distribution when paired with professional installation and calibration. The future direction for Outlander bumpers sits at the intersection of rugged capability and refined engineering. The late-2026 rugged version promises thicker, more protective bumpers that can better absorb the impact of off-road encounters while preserving essential safety functions. Higher ground clearance will affect how the bumper complements the vehicle’s approach and departure angles, and specialized tires will work in concert with revised underbody protection to yield a more capable platform without sacrificing on-road efficiency. These advancements will be guided by real-world testing, with engineers prioritizing predictable, repeatable responses across a broad range of temperatures and driving conditions. As the Outlander continues to evolve, the bumper system will remain a focal point for designers who want to shield the vehicle’s heart—the powertrain, sensors, and cabin—while crafting a visual identity that communicates modernity and preparedness. For a reader considering the practical steps of maintenance, customization, or replacement, understanding the bumper’s role helps frame decisions about parts sourcing, installation, and calibration. It is not unusual to find a range of options from OEM suppliers that guarantee correct geometry and sensor compatibility to aftermarket options that offer stylistic diversity and sometimes weight or cost advantages. The key is to align the choice with the driver’s priorities: safety and warranty versus personal expression and potential performance gains. Put simply, the Outlander’s bumper is a research- and test-driven system that embodies a balance between protection, efficiency, and aesthetics. Its enduring purpose is to allow drivers to engage with their environment with confidence, knowing that the part closest to the road is not only handsome but also scientifically equipped to manage the uncertainties of the road. When addressing replacement or upgrades, one pragmatic approach is to start with the vehicle’s model year and generation to determine compatibility. Then, evaluate the car’s sensor suite and the potential need for recalibration after a panel replacement. The decision to pursue OEM versus aftermarket parts should consider warranty implications, the likelihood of re-calibration requirements, and the overall cost of ownership. The Outlander, with its evolving bumper strategy, reflects a broader automotive trend: a continuous refinement of safety geometry, material choice, and system integration that aims to shield occupants, protect critical components, and sustain a vehicle’s visual appeal over time. In the end, the bumper’s design and function illustrate a philosophy of engineering where safety and style coexist without compromise. The front bumper is the first promise to occupants and passersby that the vehicle is prepared for the journey ahead, a statement reinforced by the chassis, the geometry of the energy absorbers, and the careful alignment of every sensor and light. For readers who want to explore more about model-year-specific options, a dedicated Outlander front bumper catalog is available that highlights the precise fitment and integration features relevant to 19-model-year vehicles. This internal resource, while not a replacement for hands-on professional service, provides clarity when evaluating replacement routes and helps ensure that the chosen part will harmonize with the car’s ADAS configuration, paint, and overall silhouette. External references ground this discussion in real-world industry practice. For a broader view of OEM replacement options and the broader market for new front bumper components, refer to the external resource linked at the end of this chapter. The interplay of materials, geometry, and integration remains the core story of Outlander bumpers: a narrative of how a seemingly simple component embodies the vehicle’s safety philosophy, its engineering discipline, and its evolving capability to tackle both the daily commute and the unexpected challenge of the road with equal poise. External resource: https://www.alibaba.com/product-detail/Mitsubishi-Outlander-Front-Bumper-New-Design-2023_1600587259893.html

Front-Line Engineering: How OEM and Aftermarket Bumper Materials Shape the Outlander’s Safety, Fit, and Performance

Bumpers are often taken for granted until a collision tests them. Yet in a vehicle like the Outlander, the bumper assembly is a carefully engineered system that blends protection, aerodynamics, and sensors with styling. The materials chosen for the bumper cover, the energy absorber behind it, and the underlying reinforcement all work together to manage impact energy, preserve critical components, and maintain a confident road presence. When we speak about the Mitsubishi Outlander, we’re really discussing a family of assemblies that evolve with generations, model-year refinements, and the shifting demands of safety regulations, weather exposure, and consumer preferences. The decision between OEM and aftermarket bumpers is not simply about price. It is about a chain of design intents that begin with safety margins and end with fit, function, and long-term ownership costs. In this chapter, we explore the materials that make up these bumpers, the trade-offs between factory and third-party options, and how those choices ripple through handling, protection, and even the vehicle’s warranty and sensor systems. The aim is not to persuade one path universally but to illuminate how material science and engineering choices translate into real-world consequences for Outlander drivers.

The OEM approach to bumper construction centers on precision, compatibility, and a defined, repeatable performance envelope. The outer cover of an OEM bumper for the Outlander is typically molded from high-grade ABS plastic, often blended with polypropylene and polyurethane. This blend is not arbitrary. ABS provides a balanced mix of impact resistance, elasticity, and the ability to recover its shape after minor blows—a property that minimizes repair costs by reducing the likelihood of permanent deformation after low-speed bumps or nudges. The plastic’s surface can be finished to match the vehicle’s paint and weather-seal requirements, offering a seamless transition from the bumper to the rest of the fascia. Behind this cover sits the front energy absorber, a crumple-zone-like component designed to absorb and dissipate energy before it reaches the vehicle’s core structure. In the OEM stack, this energy absorber is frequently constructed from high-strength steel or lightweight aluminum. The choice between steel and aluminum is more than a weight question; it’s about how the absorber behaves under repeated low-speed impacts, the ease of replacement, and the integration with other safety features. Steel provides robust energy containment and proven durability, while aluminum reduces weight, improves corrosion resistance, and can contribute to better fuel economy and handling. However, aluminum often necessitates specialized installation tools and processes, which can raise service costs after a collision and make field repairs more complex than with traditional steel reinforcements.

From the front to the flange, the OEM approach emphasizes precision and corrosion resistance as critical performance aids. Corrosion-resistant metal components, tightly controlled tolerances, and alignment with integrated sensors and fog lights are not afterthoughts—they are built into the design brief. When the bumper is designed for the Outlander, technicians ensure that the two or more generations of sensors facing the bumper, including soft routers for parking and forward collision systems, align perfectly with the mounting points. The consequence of misalignment can be not only cosmetic gaps but sensor drift, lighting misalignment, or calibration issues after a minor bump. OEM parts come with the assurance that they have been tested for thermal stability and mechanical stress across a range of temperatures and conditions. While they may carry a higher upfront cost, the predictability of performance, the assurance of warranty compatibility, and the certainty of fit can be decisive for owners who rely on the vehicle’s safety systems and want to avoid downtime or rework.

The material science behind OEM bumpers also speaks to a broader industrial shift toward lightweight yet strong constructions. Aluminum is increasingly used in modern automotive design, including many front-energy-absorber systems, because of its favorable strength-to-weight ratio and resistance to corrosion. The lighter weight reduces the unsprung mass, which helps with overall handling and steering response. It can also contribute to slightly improved fuel efficiency, an ongoing priority for many owners. Yet aluminum is not a universal remedy. For some Outlander configurations, the added cost of aluminum and the need for specialized repair procedures can make aluminum-integrated OEM bumpers more expensive to replace or repair than steel-reinforced options. The decision to favor steel or aluminum in a given bumper often reflects a balance among weight, cost, serviceability, and the expected life cycle of the vehicle in its market.

In contrast, aftermarket bumper options present a broader set of material choices, driven by consumer priorities such as cost, aesthetics, and sometimes enhanced protection. The aftermarket landscape includes ABS plastics in various grades, rubberized or flexible protective films, and metal guards built from stainless steel. Each material brings its own set of advantages and trade-offs. ABS remains a popular choice for aftermarket bumpers because it mimics the look and feel of the OEM cover at a lower price point while preserving basic impact resistance and weather resistance. The flexibility of ABS also allows aftermarket designers to mimic the contours of the Outlander’s face, achieving a close visual match that appeals to owners seeking a refreshed appearance without the full OEM cost.

Stainless steel guards enter the picture as a form of high-durability protection. They offer notable resistance to severe impacts and wear, and their corrosion-resistance can be an asset in harsh climates or salty environments. The trade-off, however, is increased weight. Heavier bumpers can alter the vehicle’s aerodynamics and, to a degree, its fuel economy and suspension dynamics. For daily driving and mild off-road use, a stainless steel guard can deliver a robust sense of protection and rugged appeal—but it can also restrict airflow and add wind noise if not meticulously engineered for the Outlander’s cold-start and climate-specific operating envelopes.

Rubberized films and flexible plastic guards are another category you’ll encounter in the aftermarket. They prioritize energy absorption and the ability to deform without transferring a heavy load to the underlying structure. This characteristic can be appealing for drivers who want to reduce cosmetic damage from parking lot incidents or light impacts. The downside is that these materials may not offer the same level of structural reinforcement or sensor compatibility as OEM parts. They may also require more attention to installation alignment, as gaps and misfits can affect not only appearance but the operation of nearby lighting or proximity sensors. The variability among aftermarket products is greater here. Without the same level of centralized testing and quality control, some claims of “OEM-matched” performance may not translate into identical real-world results. Yet for some buyers, the price-to-performance ratio remains attractive, particularly when parts are intended for occasional use, or when budget constraints make a full OEM replacement less feasible.

The debate between OEM and aftermarket bumpers is not simply about material strength. It is also about how those materials interact with the bumper’s integration points and with the vehicle’s broader safety architecture. The Outlander’s bumper system is designed to align with a sequence of connectors for sensors and lights, with precise mental mappings of bolt patterns, mounting brackets, and energy-absorbing layers. If an aftermarket part deviates in any dimension—whether in the bumper cover’s thickness, the energy absorber’s geometry, or the reinforcement profile—the risk of misalignment increases. Even small deviations can accumulate into gaps that become wind routes, create noise, or complicate sensor calibration. When drivers discuss OEM suitability for safety, the conversation is rarely about aesthetics alone. It is about preserving the integrity of the intended energy dissipation pathway and ensuring sensor data remains reliable for driver assistance systems. In this sense, OEM bumpers are designed with a factory-first philosophy that prioritizes consistent performance across a vehicle’s life cycle, even as the fixed costs of replacement are weighed against the potential risks of aftermarket misfit.

The practical implications of these material choices show up in everyday scenarios. In a low-speed collision, the bumper cover and its energy absorber must work together to dissipate the impact energy before it reaches the chassis. A well-maired absorber behind an OEM cover can compress and shear energy effectively, protecting the frame rails and preserving alignment of critical systems such as airbags, radar, and camera sensors. The material used for the bumper cover matters here not only for its immediate deformation characteristics but for its ability to rebound to a near-original shape. A stiff, brittle outer layer or a cover with insufficient flex can lead to pigment cracking, warping, or a poor fit with the hood and fenders. Those outcomes can complicate subsequent repairs and potentially impact long-term resale value. Conversely, an aftermarket bumper with a mismatch in energy-absorbing density or a misaligned bracket system may offer adequate cosmetic protection but could underperform in real-world energy management, especially in varied climate conditions where temperature swings alter polymer behavior.

From a maintenance perspective, the repair path after a collision is telling. OEM bumpers, by virtue of their exact fit and the validated performance envelope, typically enable a more straightforward repair plan. The alignment with safety sensors, the certainty of bracket attach points, and the predictable repainting process are attributes that reduce the risk of follow-on issues after the repair is completed. Aftermarket bumpers, particularly those with multiple material layers or non-standard reinforcement shapes, may require custom fitting and recalibration. The technician must verify sensor calibration and ensure light assemblies and fog lights line up properly with the new cover. The cost calculus then becomes not only the price of the part but the sum of labor, potential re-calibration, and the risk of rework if any misfit is discovered after installation.

For drivers weighing the decision, the priorities often come down to three axes: safety and warranty, cost and accessibility, and aesthetics or performance preferences. Those who prioritize safety and warranty integrity tend to favor OEM parts precisely because they are engineered to the original specifications. They provide assurance that the alignment with sensors and safety systems remains intact and that the bumper’s performance will be consistent across the vehicle’s service life. Those who need a more budget-conscious option may accept aftermarket bumpers with an understanding of possible trade-offs. They might prioritize visual changes—such as a more aggressive look or a different texture—while accepting the potential for minor compromises in fit or the need for additional adjustments during installation. A third path favors a hybrid approach: OEM-inspired aftermarket components that aim to reproduce critical geometry and finish while offering a more affordable price tag. Yet even this hybrid approach requires careful vetting, including questions about the absorber’s material density, the reinforcement’s geometry, and whether sensor mounting points are retained intact.

It is also important to consider the Outlander’s broader design language and how bumper materials interact with it. The front fascia, headlights, and grille contribute to the vehicle’s aero profile, and the bumper plays a central role in channeling air for optimal cooling and drag reduction. The choice of bumper material can influence airflow, with some designs incorporating vents, slotted openings, or lip geometries that are math-charged for aerodynamic efficiency. In this sense, the bumper is not merely a safety device but a functional component that communicates the vehicle’s intended performance character. If a chosen bumper disrupts airflow in unintended ways, it can alter cooling efficiency, contribute to engine under-hood heat buildup, or create unexpected wind noise—issues that drivers notice in daily commutes or highway drives rather than in a showroom.

The decision matrix also hinges on regional conditions. In climates with salt exposure, corrosion resistance becomes a major factor. In metropolitan areas with heavy traffic, the bumper’s ability to absorb energy without deforming too easily matters for the integrity of the body structure and the timing of repairs. In markets with demanding warranty coverage, OEM components may offer more predictable coverage of related safety features after a collision. Conversely, in markets where consumers demand rapid availability of parts at a lower initial cost, aftermarket options can serve as a practical stopgap, provided the installation adheres to precise guidelines and the part includes compatible mounting hardware.

For readers who want a concrete sense of how a representative option fits into the Outlander’s world, consider this practical touchpoint. The bumper assembly is a linked system, and a properly matched front bumper for this model year will usually share a mounting framework with unaffected portions of the fascia, ensuring consistent line length and a clean seam where panels meet. It will align with the hood edge, the fender lips, and the headlights. The internal geometry of the energy absorber behind the cover must be designed to compress in a controlled manner, preserving the integrity of the vehicle’s frame rails and providing predictable crash performance. The sensors that monitor proximity and forward crash events assume a certain mechanical relationship to the bumper. Any deviation from those relationships can compromise the sensors’ calibration and the performance of driver-assistance features.

The conversation, then, is not solely about materials but about a systems-thinking approach to bumper engineering. The Outlander’s bumpers embody an integrated strategy: a cover that tolerates weather, a front absorber that handles energy, and a reinforcement that anchors the structure. The layers must maintain their relationship through temperature extremes, humidity, and road exposure. In an OEM system, those relationships are tested across a wide range of real-world conditions, which is why many drivers pursue OEM replacements after an impact. In aftermarket scenarios, the same relationships must be re-created through precise measurement, careful installation, and, ideally, professional calibration of adjacent systems. The value of a thoughtful choice becomes clear when considering not just the initial purchase price but the downstream effects on repairability, sensor accuracy, and overall vehicle reliability.

To ground this discussion in a practical reference, one can explore how compatibility and fit are described in the broader automotive parts ecosystem. For those curious about the spectrum of bumper-related parts and their alignment with model-year changes, an example within the broader parts landscape can be found at the front bumper for Outlander-19, which illustrates how outward appearance and internal geometry align in a factory context. See the reference at front-bumper-mitsubishi-outlander-19.

External resource: https://www.alibaba.com/product-detail/Mitsubishi-Outlander-Front-Bumper-Parts_1600747516145.html

From OEM Fortitude to Trail-Ready Flair: A Deep Dive into Mitsubishi Outlander Bumpers for Safety, Style, and Performance

The bumper is often the first touchpoint a driver has with a vehicle when imagining its character on the road. On the Mitsubishi Outlander, this component does more than greet pedestrians with a painted face; it acts as a shield, a guide for airflow, and, in many trims, a canvas for lighting and sensors that keep the road safer and the drive more convenient. The evolution of Outlander bumpers illustrates a broader shift in compact-SUV design: a constant negotiation between the needs of aerodynamics, energy absorption in low-speed crashes, and the appetite for personal style that can be translated into a more confident street presence or a more capable off-road stance. The discussion that follows threads together the core ideas behind bumper design, material choices, safety implications, and the spectrum of customization that ownership often pursues, all while keeping a clear eye on what matters most to drivers: reliability, compatibility, and value over time.

At the heart of any bumper is a simple, stubborn truth: it is a safety device first and a visual element second only in the eyes of most owners. The OEM approach to Outlander bumpers highlights a precise, model-year–matched fit, designed to seal gaps and integrate with the vehicle’s front-end geometry. This precise fit is not merely cosmetic; gaps matter for aerodynamics, under-hood cooling, and sensor alignment. A bumper that fits like a tailor-made coat does more than look right. It positions fog lamps, camera fields, radar modules, and daytime running lights so they work together rather than conflict with one another. The inner structure—often a reinforced framework of steel or aluminum—works in concert with a plastic or composite outer cover that acts as the primary energy absorber during a collision. The weight distribution rooted in this assembly affects handling, braking response, and even fuel efficiency. In the Outlander’s context, aluminum has grown in popularity for its favorable strength-to-weight ratio and corrosion resistance, which translates into better efficiency and nimble handling. Yet the tradeoff is clear: lighter materials can require specialized repair procedures and sometimes higher replacement costs. The practical implication for owners who are not merely chasing appearance is straightforward: if you crave factory precision and warranty coverage, OEM bumpers offer the cleanest path to maintaining the vehicle’s integrity and its sensor calibration, ensuring that the car’s advanced safety features remain unimpaired after a minor accident or curb encounter.

But the market’s appetite for upgrades is not content to rest on factory laurels. Aesthetic enhancements have become a substantial part of the Outlander’s customization landscape. A notable development in recent years is the emergence of a newer front bumper design that aims to elevate the vehicle’s visual appeal while delivering functional gains. The updated front-end design tightens the lines with the hood and fender contours, improving aerodynamics and enabling a more integrated look with LED lighting elements. For city driving and show-ready builds, this kind of redesign can sharpen the Outlander’s street presence, giving it a more contemporary face that still respects the vehicle’s original proportions. The emphasis here is not merely on adding bling; it is about refining airflow, reducing drag where possible, and facilitating a more cohesive aesthetic with other modern engine-vent and lighting packages. The practical upshot is that a well-conceived cosmetic update can deliver a modest if noticeable improvement in efficiency and a more polished, cohesive appearance that echoes the updated lines of the rest of the vehicle.

A second pillar in the bumper’s ongoing evolution concerns performance-oriented upgrades that speak directly to durability and capability off the beaten path. For drivers who view the Outlander as a versatile companion for adventures, specialized off-road bumpers have become a meaningful way to expand the vehicle’s utility. These bumpers prioritize robust construction, often using reinforced steel or high-strength composite materials to withstand impacts with rocks, branches, and uneven terrain. They frequently incorporate features that extend the vehicle’s reach beyond pavement: winch mounts that provide traction when stuck in mud or sand, protected housing for fog lights that remain accessible even after brush contact, and increased ground clearance that helps the vehicle slide over obstacles rather than get hung up on them. The logic here is straightforward: if you routinely confront rugged environments, the bumper becomes a platform for capability rather than merely a safeguard. In such configurations, engineers and installers plan for a balance between protection and approach angle, ensuring that the bumper’s geometry does not obstruct the vehicle’s departure angle or throttle response while providing the reinforcing structure necessary to support a winch or additional recovery gear.

The broad spectrum of bumper upgrades also embraces customization options aimed at personal expression and personalized function. Aftermarket body kits have gained traction among Outlander owners who want a more aggressive stance or a streamlined, modern silhouette that signals intent and performance from curbside. Front bumper lips, chromed or painted rear lip extensions, and side skirts are common components of these kits, designed to align precisely with existing mounting points and to preserve, if not enhance, the bumper’s integrated sensors and lighting provisions. The appeal lies in achieving a cohesive, sportier profile without compromising the integrity of the vehicle’s architecture. For some drivers, the goal is to create a visually lower and sleeker silhouette that suggests enhanced aerodynamics and a more dynamic highway presence. For others, it is about a personalization that makes the Outlander feel uniquely theirs while maintaining the core protection and alignment required by the rest of the vehicle’s safety systems. It is important to recognize that good-fit aftermarket pieces should be selected with care; a mismatch in mounting points or a failure to accommodate sensor housings can undermine safety features or lead to alignment issues that are expensive to correct later.

The topic of compatibility runs through every layer of bumper choice. OEM parts offer the cleanest guarantee of a problem-free rebuild after an impact. They are designed with the same tolerances as the rest of the vehicle, ensuring an undisturbed relationship with the air intakes, the hood, and the bumper cover. This alignment is crucial for preserving the sensors that keep adaptive cruise control, lane-keeping assist, and collision warning functioning as intended. On the other hand, aftermarket options, especially external aesthetic upgrades and off-road bumpers, demand careful attention to fitment and calibration. Off-road variants may demand recalibration of parking sensors or replacement of light housings to maintain proper illumination angles. In some scenarios, installation requires more than a simple bolt-on procedure: it can involve re-wiring, minor trimming, or adjustments to the splash guards to ensure smooth airflow and to prevent rubbing during suspension travel. The overarching idea is not to romanticize the ease of “bolt-on” parts but to approach upgrades with a methodical plan that includes fit, finish, and function. In this sense, the bumper becomes not merely a protective panel but a modular node in the vehicle’s safety and performance system.

In balancing aesthetics and performance, the material conversation remains central. Plastic or composite outer covers paired with a reinforced inner structure provide a combination that is affordable, weather-resistant, and capable of absorbing low-speed impacts effectively. Plastic materials resist weathering, resist UV damage reasonably well, and can be molded into intricate shapes that support aerodynamics and integrated light housings. This is especially valuable when the goal is to sculpt a bumper that looks modern while still performing its protective role. Adjacent to this is the inner skeleton, which can be steel or aluminum. Steel has long offered exceptional strength and impact resistance, a dependable choice for heavy-duty applications, particularly in off-road builds where the bumper must endure repeated contact with rough terrain. Aluminum, increasingly favored in contemporary designs, offers a compelling mix of light weight and corrosion resistance, which helps with fuel efficiency and handling while reducing the penalties of unsprung weight. The costs, however, rise with aluminum because repair operations and parts can require specialized tools and processes. The choice of material therefore becomes a strategic decision: do you aim for a go-anywhere capability with a heavier, more rugged bumper, or do you favor lower weight with a possibility of higher maintenance costs and specialized service needs? This decision is not merely about dollars; it is about how you plan to use the vehicle, what you expect from ownership, and how you wish to balance daily practicality with occasional adventure.

The discussion would be incomplete without addressing the broader ecosystem of design and sourcing that supports these choices. In recent times, the visibility of new bumper designs has grown as manufacturers pursue greater integration with modern lighting systems and driver-assistance sensors. A forward-looking bumper design can facilitate better integration with LED lighting arrays and assist systems by aligning the sensor fields within the bumper’s plane, reducing the chance of shadowing or misalignment that could degrade performance. For urban motorists, a design that improves frontal aerodynamics can contribute to smoother airflow across the hood, reducing drag marginally and producing a more refined feel at highway speeds. For the same reason, a bumper that respects refresh rates and sensor calibrations is less likely to trigger nuisance messages and requires fewer trips to service centers after a fender bender. In the real world, this means choosing an approach that acknowledges both appearance and the complex web of electronics that modern vehicles rely on for safety and convenience.

For readers who are curious about practical procurement paths that emphasize both design and deliverables, there is a spectrum of options worth considering. Aesthetic upgrades, such as a refreshed front bumper design released for a newer model year, can provide a refined look that pairs well with updated lighting and a sharper grille context. This kind of update can be particularly appealing for owners who want to refresh their vehicle’s appearance while keeping the underlying architecture intact. When exploring off-road-focused options, the emphasis shifts toward structural robustness, mounting versatility, and protection for wheel arches and lower body surfaces that are particularly vulnerable on rough terrain. In this arena, a bumper is less a statement-of-style and more a statement-of-capability, a physical extension of the vehicle’s ability to take on harsh environments without compromising occupant safety or the car’s essential systems.

The path from OEM reliability to aftermarket adaptability is not simply a line of products but a narrative about the relationship between a vehicle and its driver. Owners who prioritize safety and factory warranty protection tend to favor OEM parts because they preserve alignment with sensors and the vehicle’s structural integrity after a mishap. Those who crave a more aggressive appearance or enhanced off-road readiness may opt for aftermarket body kits or bumper systems that are engineered to fit with careful attention to mounting points and overall geometry. In either case, the principle remains constant: an effective bumper is one that works in concert with the rest of the vehicle. It should not require heroic gymnastics to install, recalibrate, or maintain. It should protect occupants, support the vehicle’s systems, and extend the vehicle’s life by absorbing the energy of collisions at low to moderate speeds, while also reflecting the driver’s values—whether they lean toward urban sophistication or rugged adventure.

In this light, the Outlander bumper becomes more than a single part in a catalog. It is a gateway to a broader philosophy of ownership that respects engineering precision, values safety, and invites personalization without compromising the core strengths of the vehicle. The balance between aesthetics and function is a continual negotiation, a reminder that design decisions made in the bumper’s factory can resonate through the car’s entire lifecycle. The right choice will depend on how the vehicle is used, where it lives, and what the owner hopes to extract from it in terms of reliability, efficiency, and curb appeal. For readers seeking a practical path through this landscape, the takeaway is straightforward: evaluate fitment and warranty implications first, then weigh the relative merits of materials and design for your specific use case. If your aim is to preserve the factory feel and safety edge while occasionally stepping onto rougher terrain, a measured approach that leans toward OEM compatibility with selective upgrades is prudent. If you aim for a bold, purpose-built look and a higher tolerance for ongoing maintenance, an aftermarket solution that emphasizes rugged protection and flexible mounting points may be the better route. Either way, the bumper’s role is central to the Outlander’s ongoing story as a compact SUV that can serve as a pragmatic commuter, a capable family transporter, or a faithful companion for weekend explorations.

For enthusiasts who want to explore customization options, one practical path is to consider how a bumper update aligns with lighting and sensor integration. A new aesthetic design might offer a more cohesive look with upgraded LED accents, while preserving or improving the layout that accommodates essential sensors and cameras. If wiring and calibration are properly managed, this can yield a more sophisticated, modern expression of the Outlander identity without undermining the safety features that define the vehicle’s value proposition. A practical reminder accompanies every upgrade: keep the installation as straightforward as possible, ensure that mechanical and electronic interfaces remain undisturbed, and verify that any new components are compatible with your vehicle’s overall electrical system. The last thing a driver wants is a system-wide recalibration headache after a charming new bumper has already added personality to the vehicle. With thoughtful planning, however, the bumper becomes a reliable ally—one that protects during everyday encounters, supports efficiency on the highway, and contributes to a personal statement that reflects the owner’s expectations for safety, durability, and style.

As this chapter closes its loop on the many pathways for Outlander bumper enhancement, it is useful to anchor the discussion with a concrete, real-world touchstone: the availability of a newer front bumper design that integrates with modern lighting and aerodynamic considerations while offering a fresh visual cadence. For readers who want to explore a concrete example of the kind of design update that can elevate a vehicle’s appearance and performance, a recent front bumper release provides a glimpse into what thoughtful engineering can achieve. It is not a universal recommendation, but it serves as a useful illustration of how a well-executed bumper update can align with the broader goals of safety, efficiency, and contemporary styling. For those who want to see more about this kind of evolution, the linked resource offers a glimpse into the design thinking behind such updates and how they fit into the wider ecosystem of Outlander maintenance and customization. front bumper mitsubishi-outlander-19

In closing, the conversation about Mitsubishi Outlander bumpers—OEM versus aftermarket, aesthetic refreshes versus rugged protective realisms, and the nuanced balance of materials and design—reflects a broader truth about owning a versatile crossover. The bumper is where form and function meet, where safety protocol intersects with personal expression, and where the vehicle’s story continues to unfold with every mile. It is a component that invites ongoing attention, not only for the immediate protection it offers but for the long arc of how it supports the Outlander’s evolving role in a driver’s life. And as regulations and safety expectations continue to evolve, the bumper’s importance remains undiminished: a prudent choice today can translate into enduring peace of mind tomorrow, with the right balance of innovation, quality, and informed judgment guiding every upgrade.

External reference: https://www.alibaba.com/product-detail/Mitsubishi-Outlander-Front-Bumper-New-Design-2023_1600569436819.html

Final thoughts

In summary, the Mitsubishi Outlander bumpers represent a vital component with impressive design, material choices, and the potential for customized enhancements. Business owners benefit significantly from understanding these aspects, as they directly influence the vehicle’s safety profile, aesthetics, and overall market value. Whether opting for OEM for safety compliance or aftermarket parts for performance, informed decisions can lead to better fleet management and customer satisfaction.