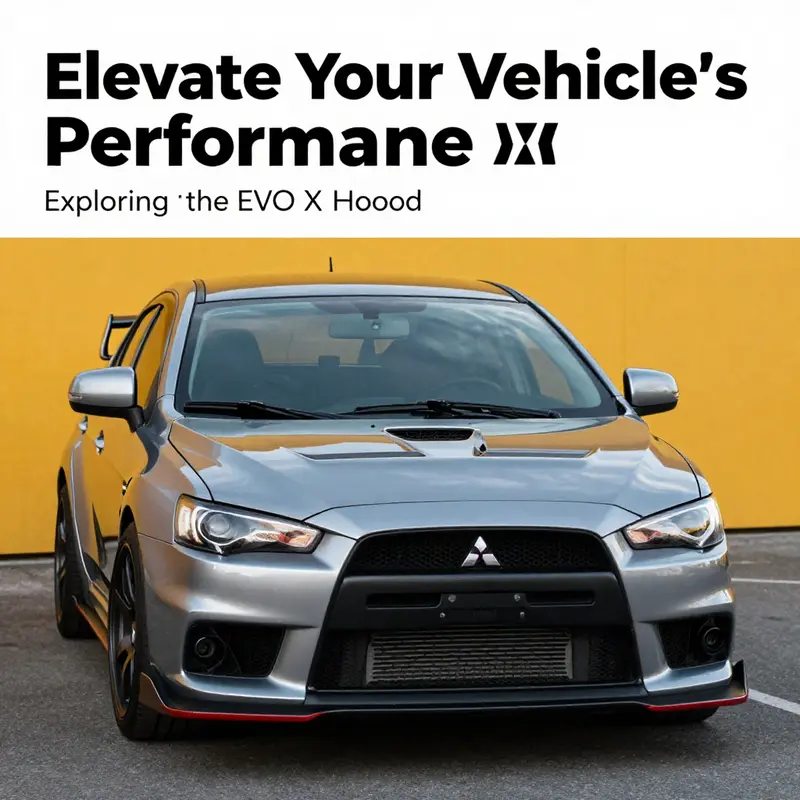

The hood of the Mitsubishi EVO X is not just a covering for the engine; it is a crucial component that combines functionality with aesthetic appeal. For business owners in the automotive industry, understanding the options available is paramount. This overview will delve into the original and aftermarket hood options, highlighting their functional benefits, design versatility, and compatibility with the EVO X. Each chapter will equip you with knowledge to make informed decisions and enhance vehicle performance through effective hood modifications.

Engine Bay Edge: OEM Roots and Aftermarket Evolution for the Evo X Hood

The hood is more than a cover for the engine bay. On the Evo X, it is the primary interface between the powertrain and the air that feeds it, the thermal management system that keeps vital components in their optimal range, and a visible statement of intent about how the car will be driven. When we start from the factory, the hood is designed to balance strength, weight, and aerodynamics. It safeguards the engine bay from road debris and weather, supports a predictable air intake path, and shapes the front end’s silhouette in a way that respects the car’s engineering heritage. The stock hood, typically metal or a durable composite, is engineered to pair with the stock ventilation strategy, channeling air in a way that reduces drag while aiding cooling under normal driving conditions. This is the baseline—the point of reference from which all performance-oriented ambitions emerge. The decision to leave the hood as is or to swap in an aftermarket alternative is rarely about a single factor. It is about how much of the car’s character you want to alter, how hard you drive, and how deep you want to go into weight management, heat dissipation, and aesthetic storytelling.

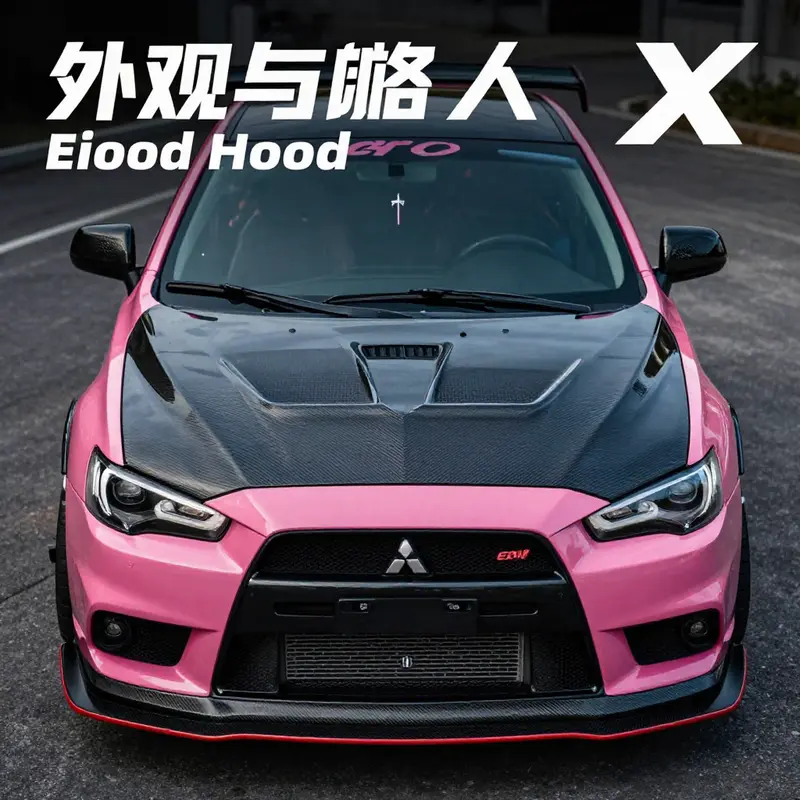

The aftermarket options introduce a spectrum of trade-offs that can redefine the Evo X’s dynamics both on the street and at the track. Carbon fiber hoods, for example, are celebrated for their lightness. Reducing the weight at the very front of the car changes the front axle load distribution, which can sharpen steering response and reduce the yaw inertia that makes a nose-heavy car feel sluggish in quick direction changes. The reduction in unsprung weight at the leading edge is not just about speed. It translates to more precise feedback through the steering wheel and a more predictable chassis response, especially when you are balancing grip, aero demand, and brake heat under high-load conditions. In many setups, the light hood also contributes to better fuel economy marginally, because the engine can work a little less to attain the same performance envelope, though this is often a secondary benefit compared to heat management and handling.

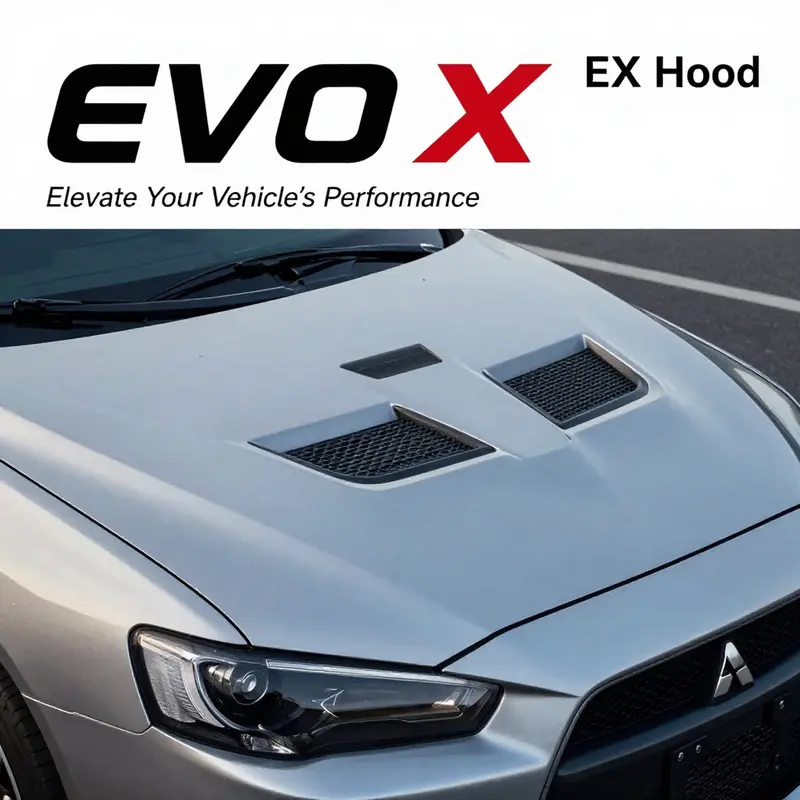

Beyond weight, heat management remains a central pillar of any hood discussion. The Evo X’s four-cylinder turbocharged layout generates substantial heat under heavy load. An aftermarket hood that integrates vented channels or a functional scoop can influence how air moves through the engine bay. A vented design, when executed properly, does more than simply vent hot air to the sky. It changes the flow pattern across the engine bay, pulling cooler air toward the intake or turbo area and facilitating faster heat exchange with ambient air. This can lower intake air temperatures, which is a direct lever in improving turbo efficiency and the reliability of critical components during sustained periods of performance driving. It is also why some builders pair a carbon fiber hood with a carefully engineered ventilation strategy that avoids creating turbulent recirculation or exhaust-like pockets of hot air around the engine. The goal is a harmonized system where the hood contributes to breathability rather than simply looking aggressive.

The choice between OEM and aftermarket is not binary but continuous. An OEM hood provides a predictable fit, proven seal integrity, and a straightforward maintenance path. It preserves the car’s original weight distribution, its acoustic character, and its compliance with the factory’s aerodynamics program. For a driver who values durability, factory compatibility, and ease of ownership, an OEM hood remains a sensible baseline. On the other hand, a high-performance carbon fiber hood with venting or a central scoop represents a deliberate shift. It signals a willingness to accept the cost and upkeep that comes with exotic materials and more complex cooling pathways in exchange for reduced weight and a more aggressive stance on the street. The carbon fiber’s visual texture and the hood’s geometry together embody a philosophy: performance is a conversation between lightness, airflow, and the engine’s breathing room. In this conversation, some hoods prioritize cooling efficiency, while others emphasize raw weight savings or bold styling cues. There are also aluminum options that strike a middle ground, offering improved stiffness and corrosion resistance with a weight penalty less dramatic than carbon fiber. These choices reflect personal goals—whether you prioritize track readiness, street presence, or a balanced blend of both.

The street to track continuum influences how people appraise feed-forward performance through the hood. A functional central scoop, for instance, is not just a spectacle; it can act as a precise conduit for cooler ambient air into the intake tract or turbocharger system. The hood’s venting strategy, if well integrated with the car’s intercooling and exhaust routing, helps stabilize charge temperatures during laps where heat soak would otherwise erode power. In practice, this means less throttle lag, more consistent boost, and the sense of a more liberated engine at high rpm. It also means a more stable braking window. Heat after repeated hard braking can soften brake pads and rotors; a hood that contributes to cooler engine bay temperatures indirectly supports the whole braking performance envelope by preserving the integrity of brake heat management systems.

As with any substantial modification, compatibility and fitment are essential. The Evo X’s CZ4A chassis line is well understood in aftermarket communities, which helps ensure aftermarket hoods align with the original geometry, mounting points, hood latch mechanisms, and seal lines. A quality hood is not simply a skin over the engine bay; it is a part of a larger system that includes hinges, damping, weather sealing, and alignment with the fenders and front bumper. When installing an aftermarket hood, many owners choose to invest in professional fitment to protect against misalignment that can cause wind noise, hood flutter at speed, or improper sealing that invites water ingress. The practical takeaway is simple: a hood can be a straightforward swap or a gateway to a broader set of performance-oriented upgrades, but it should be treated as a carefully integrated component rather than a stand-alone ornament.

The aesthetics of a hood in this context deserve attention as well. Carbon fiber is prized not only for weight but for its distinctive weave and the way it catches light. When combined with vent channels or a functional scoop, the hood conveys a racing lineage that resonates with enthusiasts who like to express their performance intent through the car’s silhouette. The look can be as aggressive as the drive feel, capturing the eye of passersby and the respect of fellow drivers on the pit lane. Yet beauty in engineering terms is more than skin deep. The choice of finish—whether bare carbon, clear-coated, or painted to match the car’s body color—can influence how the hood ages in the sun, how it wears in road grime, and how it responds to stone chips that could compromise the surface integrity of delicate carbon fiber.

In this broader context, a chapter like this does not exist in isolation. It connects back to the car’s entire performance architecture and to a philosophy of modification that weighs cost, risk, and reward. The material properties of carbon fiber—high stiffness-to-weight ratio, corrosion resistance, and thermal stability—offer clear advantages when matched with airflow enhancements. But these advantages come with trade-offs: higher price, potential repair costs, and concerns about impact resistance in certain settings. Aluminum, by contrast, can offer a cost-effective path to lightening the front end while delivering more forgiving repair options. For some owners, a hybrid approach might even emerge, using a light hood with a focused venting plan designed to address the specific heat paths of their typical driving regime.

The research that anchors these observations underscores how modern hoods contribute to mechanical performance in subtle, but measurable, ways. A recent technical overview delves into standards, grades, and mechanical outcomes for Evo X carbon hoods, emphasizing how airflow, heat dissipation, and structural integrity interrelate under load. It makes the case that the hood is not just a one-trick improvement but a complex component whose influence extends to intake efficiency, engine breathing, and overall reliability during sustained performance driving. This framework helps drivers and builders navigate the practical realities of choosing between stock and aftermarket options, clarifying how to evaluate a hood not just by weight savings or appearance, but by the predicted impact on temperature management and power delivery across different driving scenarios.

To anchor these ideas in practical terms, consider the installation and maintenance realities. OEM replacement hoods offer the simplest path to return-to-stock reliability, especially for daily-driven Evo Xs or cars used in environments where compliance with stock specifications matters. Aftermarket carbon fiber hoods, while demanding careful handling and professional alignment, can be a gateway to more aggressive aero tuning and enhanced cooling strategies. The squared decision matrix tends to revolve around how much front-end weight you want to shave, how aggressive you want the visual language to be, and how much you value heat management under stress. Car care routines also shift with these choices. Carbon fiber requires attention to UV protection and chip repair, while aluminum or composite counterparts may demand different paint and sealing considerations. The essential practice remains: ensure that whatever choice you make, it aligns with your driving needs, your maintenance plan, and your long-term ownership goals.

In sum, the Evo X hood landscape is a spectrum rather than a single path. You begin with the OEM hood as a baseline that honors the engineering intent and the car’s balance. You explore aftermarket options that add weight savings, airflow enhancements, and a visual language that communicates performance commitment. You evaluate the practical implications of vented versus non-vented designs, the durability of carbon fiber in everyday use versus track-focused applications, and the compatibility of any chosen hood with the car’s other systems. The resulting decision is a personal negotiation between speed and serenity: how fast do you want to go, and how calmly can you maintain the car when you get there? For readers who want a technical, evidence-backed perspective, an authoritative overview of Evo X carbon hoods underlines the connection between breathing efficiency and mechanical performance, while a practical, hands-on approach to selection keeps the journey grounded in the realities of real-world driving. See the external resource at the end for a deeper dive into standards and performance grading. And if you’d like to glimpse a real-world example of a carbon fiber hood option that closely mirrors the themes discussed here, you can explore a product page like the one linked here: brand-new-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x.

The hood, in short, is a microcosm of the Evo X’s broader performance philosophy: it is about weight, heat, and the way air moves over and through the car. It invites you to think not just about how the car looks, but about how it breathes, how it cools, and how the front end communicates your intent to the road. As you weigh OEM calm against aftermarket edge, let the numbers, the tactile feel of the hood’s weight in your hands, and the data from your own driving experiences guide you. The Evo X hood is one piece of a larger puzzle that, when assembled thoughtfully, yields a vehicle that feels faster, more responsive, and visually unmistakable on every street corner and every racetrack straight.

External resource for further reading: https://example.com/evox-carbon-hood

轻量化与气流管理的协奏曲:Evo X 碳纤维引擎盖的性能革命

当谈论 Evo X 的改装引擎盖时,许多人把焦点放在视觉冲击力上,仿佛这只是前脸的一道装饰线。然而,真正的潜力藏在它与整车动力系统的协同作用中。功能性碳纤维盖并非单纯的轻量外壳,而是一项系统性升级,旨在通过材料、空气动力学和热管理三重维度,重新塑造前部的动力学行为与稳定性。在高转速、长时间高负荷的驾驶情境中,这种盖子的作用尤为突出,它能让车辆在弯道中的响应更干脆,直线段的持续动能也更稳定。就像其他高性能平台一样,Evo X 的性能提升不是单点的提升,而是一系列微调的综合结果,其中重量的下降、气流的导向以及热管理的优化相互作用,共同决定了单位时间内的能量如何被更高效地转化为可用动力。研究表明,改装碳纤维引擎盖的直接效益之一是重量显著下降,通常可以实现 40% 至 60% 的减重。这种幅度的前部重量减轻,直接降低了前轮的负担和整车的前倾惯性。这在过弯时尤其明显,前轮更灵活,转向输入的线性响应更易被驾驭者感知。更重要的是,减轻的前部重量带来的是“重心微移”的积极效应,轻微的前段下降会让悬挂系统在进入急弯时不再被前端的重量压垮,车身在转向中的前倾被抑制,从而提升转弯稳定性与纵向加速的连续性。这个过程并非纯粹的重量数字所能完整揭示的,它需要驾驶者在赛道日或激烈公路驾驶中去体会:转向的初始抵抗变小,方向盘的回中速度提升,车头在节拍更紧凑的节奏中对路面纹理的反馈也更为清晰。碳纤维的刚性与轻量特性使盖面在高速行驶时更易维持刚性与形状稳定,避免因材料柔软而带来的震动放大,进而降低了前部结构在纹理路面上的能量损失。这种综合的改善,最终指向一个目标:让车辆在高负荷状态下保持持续的动力输出与稳定的操控表现,而不是在某一瞬间爆发后迅速消散的性能差距。除了重量的直接收益,功能性碳纤维盖还承担着空气动力学设计的核心职责。许多高性能盖设计中,集成的导流槽或中央进气口并非“装饰性孔洞”,它们被用来引导冷空气进入发动机舱及相关进气系统,以提高涡轮增压系统的进气密度与温度控制效率。一个常见的设计概念是将冷空气引导至散热更高效的区域,或者直接送入中冷器与进气系统的关键节点。通过中心风道,冷空气能更直观地触达热积累最集中的区域,降低进气温度,提升空气密度,从而在高负荷驾驶下提升功率输出的稳定性。这种设计的物理效果,是在现场驾驶中逐步显现的:涡轮增压系统在高转速区间的响应更迅捷,输出波动被压制,油温和进气温度的上升曲线变得更平缓。热管理的提升同样来自于盖面与机舱内部的协同设计。开放式通风孔与导风结构构成的“烟囱效应”有助于将热空气从发动机舱快速排出,尤其在连续高负荷运行时,能显著减缓热衰减带来的动力下降。这不仅关系到发动机本身的可靠性,也影响到电子元件的长期稳定性。高温态下,电子元件的热漂移可能引发微弱的性能波动,改装盖的高效排热能力则有助于保持系统在稳定的温度区间运行。这一系列热力学与空气动力学交织的效应,最终指向一个整体:功能性碳纤维盖使 Evo X 在高强度场景中的呼吸更加顺畅,空气进入发动机舱的温度压力波动被更好地控制,推动动力系统以更高的阶梯保持输出,同时降低在极端条件下的热疲劳风险。站在安全性与密封性的角度看,改装盖通常以原厂替换件的形式提供,设计时已考虑与原车线条的完美贴合与密封性保持。专业技师的安装不仅确保了外观与前脸比例的和谐,也确保了盖面与密封垫之间的连续性,避免因密封不严导致的进水、灰尘侵袭或风噪增大。这些看似细微的环节,在高性能驾驶中却可能成为影响整车体验的关键因素。因此,选择合适的盖面材料、合适的导风设计、以及专业的安装工艺,都是实现上述性能收益不可或缺的前提。除了力学与热力学层面的考量,碳纤维盖的视觉与风格属性也不可被忽视。碳纤维材料本身的纹理会在前脸提供一种赛车化的质感,与通风口的存在共同构建一种“街头霸王”的视觉气质。这种视觉冲击力不仅提升了外观的吸引力,也在品牌叙事中加强了改装的主题——通过高科技材料与工程设计的结合,展现对极致性能的坚持。对于车主来说,个性化的选择同样重要。市场上能够提供的改装盖样式多样,从纯碳纤维到带有涂装的版本,从风格化的开口到更为简约的设计,每一种都对应着不同的审美与使用场景。然而,所有的选择都应以工程效果为基础,确保形态设计不会削弱机芯的散热与密封性,也不会在雨雪等天气条件下造成潜在的维护挑战。总的来说,Evo X 的功能性碳纤维引擎盖并非单一的改装件,而是一个综合性工程优化的结果。通过显著的重量减轻、优化的气流导向与热管理能力,它让前部系统更好地“呼吸”,使发动机在高负荷情境中的动力输出更加稳定、持续,操控性也随之提升。这种升级方式强调的是工程美学与性能的统一——材料的选择、几何形态的设计、气流路径的布置、以及安装工艺的严谨性,都是影响最终驾驶体验的关键要素。对于渴望在城市街头与赛道日之间保持一致性能的 Evo X 车主而言,功能性碳纤维盖提供了一条清晰的升级路径:在不牺牲密封性与耐用性的前提下,实现重量的显著下降、热管理的显著改善、以及空气动力学的实质提升。这些元素共同构成了一个“协奏曲”,让前部成为驱动整车性能优化的重要环节,而不仅仅是一个视觉焦点。外部观察也好,实际驾驶感受也罢,盖子的存在正在把手工制造的边界拉向更高的工程标准。只有当材料科学、热力学原理与空气动力学设计在同一条线上协同时,Evo X 的满载潜力才会真正被释放。> 相关权威信息来源的核心结论在于:功能性碳纤维发动机盖通过“增强引擎呼吸效率”和“降低进气温度”来提升性能,并且兼容冷空气进气系统,这些要素是实现高效设计的关键要素。若要进一步了解这一领域的技术标准与等级划分,读者可以参阅专门的综合评述性文章,获取对比分析与机械性能数据的全面视角。 brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x 外部参考资源:https://www.caranddriver.com/features/a33467867/carbon-fiber-hoods/

Carved Attitude: Personalizing the Evo X Hood as a Statement of Speed and Style

The Evo X hood is more than a cover for what lies beneath; it is a canvas where performance meets personality, shaping the car’s face before the engine speaks. Its characteristic three vents anchor a front-end identity that signals intent to the street and the track alike. Those vents are functional as well as stylistic, guiding heat and airflow from the engine bay toward the outside world with a purpose obvious to drivers who chase efficiency and speed.

Understanding the spectrum from preservation to experimentation helps frame the decision. The OEM hood emphasizes reliability, precise fit, and a factory rhythm that stays faithful to the design language. A repaint or a mild, factory-look enhancement can refresh the face without stepping away from original intent, preserving balance between form and function.

By contrast, aftermarket options bring a broader toolbox. Lightweight materials—carbon fiber, FRP, and sometimes aluminum—lower mass for a more responsive front end and a livelier feel when the throttle is pressed. Carbon fiber speaks to both eye and hand, offering rigidity and a premium look, while FRP can be shaped to follow the lines with a contemporary edge. Aluminum sits between these extremes, delivering mid-weight performance with a different stiffness profile. Across options, the goal is to maintain strength and durability while unlocking weight savings and improved heat management.

High-performance, function-first designs treat the hood as a system rather than a skin. Larger vents, raised contours, and carefully engineered channels work to pull heat away from the engine, stabilize temperatures on long drives or track sessions, and prevent heat soak from eroding performance. The challenge is balancing open area with stiffness and ensuring weather seals and latches remain trustworthy at speed.

Material choice drives much of this balance. Carbon fiber offers top-tier weight savings and a glossy, high-tech look; FRP reduces weight while remaining forgiving on installation and cost; aluminum provides a middle ground with a bright finish and predictable rigidity. Each option changes the hood’s feel, balance, and interaction with the rest of the body, influencing responses in corners and the car’s stance at idle.

Beyond materials, design geometry matters. Some builders preserve an open-heart vibe, others push venting toward aggressive silhouettes, and a few explore a central raised scoop or vent pairs aligned with the engine bay. The goal is a cohesive message: performance through airflow, a clear sense of purpose, and a look that matches the owner’s taste—from restrained to bold.

Color, finish, and treatment complete the statement. A matched or contrasted hood can sharpen the Evo X’s lines, while finishes from gloss to satin to matte alter how light plays across the surface. Wrapping or painting, subtle patterns or color blocking, all contribute to a unique identity without compromising function.

Installation and fitment are not afterthoughts. The hood must align precisely with fenders, seal cleanly against weather, and tolerate the stresses of daily driving and occasional track work. Professional fitment ensures the chosen venting or scoop stays true to design while preserving chassis integrity, ride quality, and long-term durability.

In the end, hood personalization becomes a language: a way to communicate restraint, audacity, or a racing-inspired edge. It blends aesthetics with airflow engineering, tying the driver’s goals to the car’s presence on street corners, roadside meets, and open-road cruises. The Evo X hood thus becomes a visible sign of the owner’s commitment to performance, style, and the craft of making a factory front end uniquely theirs.

Fit, Function, and Trust: Navigating Evo X Hood Compatibility and Installation

When you set out to upgrade the hood on a Mitsubishi Lancer Evolution X, you’re choosing more than a new face for the car. You’re deciding how the engine breathes, how the front end seals against weather, and how the entire chassis behaves at speed. The hood is a front-line piece in a system that blends heat management, aerodynamics, and structural integrity. In practice, Evo X owners encounter three broad categories of hoods: OEM replacement hoods that preserve the factory geometry, functional hoods engineered to improve cooling with vents or ducts, and aerodynamic upgrades designed to influence downforce and air flow at higher speeds. Each category has its own set of advantages and constraints, and the best choice hinges on how you use the car, how much you value weight savings, and how deeply you’re willing to tailor surrounding components to maintain reliability and street usability. From a practical standpoint, compatibility boils down to three core dimensions: fitment, structural resilience, and sealing. If any of these falter, the promise of cooler intake air or cleaner under-hood temperatures can be compromised by rattles, misalignment, or unwanted water ingress. For a driver who expects the Evo X to perform under stress, the hood is more than styling; it is a conduit for controlled heat, a determinant of front-end balance, and a potential source of noise if not paired with proper hardware and finishing details.

In the realm of fitment, OEM replacement hoods are designed to align with the car’s original bolt pattern, hinge geometry, latch position, and the subtle sculpting of the fender line. The advantage is straightforward: you pop off the stock piece and substitute the new panel with a minimal chance of misalignment. This is the route many owners choose when they prioritize reliability, documented fit, and a seamless look that echoes factory quality. The downside is that this path offers limited weight reduction, modest aesthetic differentiation, and little opportunity to alter thermal management through venting. Yet for daily drivers or track enthusiasts who want predictable service intervals and a conservative approach to maintenance, OEM-replacement hoods present a tidy, compatible baseline that preserves safety margins and standard sealing interfaces.

By contrast, functional hoods introduce changes in the engine bay’s breathing and heat management. Think of a hood that incorporates venting channels or heat extraction perforations designed to purge the plenums and valve covers of high-temperature air generated by turbocharged operation. In high-load situations—say, sustained strip runs or spirited mountain passes—the engine’s intake air temperature can rise quickly if the cooling path is hindered. A hood with venting vents hot air out and can direct cooler air toward the air intake or intercooler ducts, reducing heat soak and lessening the risk of heat-induced detonation. These hoods often use lighter materials such as carbon fiber or advanced composite blends. The trade-off, however, is that any structural compromise must be addressed. The hood’s stiffness, the integrity of the edge radii at the cowl, and the anchoring around the latch and hinges all influence how well the hood stays sealed at speed and how it behaves in sharp corners or over bumps. If the material is not engineered with sufficient resin saturation, or if the vent openings create unanticipated flex, you can end up with squeaks, misalignment, or even premature wear on the hood’s mounting points.

Aerodynamic upgrade hoods push the envelope further. These panels often incorporate sculpted channels or even controlled airflow fasteners intended to manage pressure gradients across the car’s nose at high velocity. In practice, their purpose is to balance the front-end lift that naturally occurs at speed, extending stability on the highway and in the corridor between aero and mechanical grip. On a street-driven Evo X, the gains can be subtle but real: sharper turn-in feel, reduced front-end lift in cornering, and a more planted front fascia when negotiating road irregularities at speed. The potential downside is wind noise and a slightly altered cabin feel at highway speeds, along with the possibility that the hood’s geometry clashes with nearby components—windshield washer lines, hood dampers, or the cowl’s attachment points—if the install is not precisely coordinated with the rest of the front-end assembly. When weighed against daily usability and long-term reliability, many drivers opt for a compromise: a hood that delivers meaningful heat or aero benefits without introducing compounding, hard-to-diagnose issues in everyday driving.

Whichever path you choose, installation quality is the hinge on which all benefits turn into predictable performance. The process begins with a careful prep: confirming that the car is in a stable state, the engine is cool, and the mounting hardware is intact. Even the most straightforward replacement hood requires attention to torque specs, proper gasket seating, and clean mating surfaces to ensure a uniform seal. The installation sequence, while seemingly mechanical, is best approached as a choreography rather than a checklist. Begin by safely supporting the hood and the latch mechanism, then remove the stock unit with steady, even pressure to minimize twisting the hinge pins. When the new panel is brought into place, align it with the vehicle’s reference points and locate the hinges using the original mounting holes. A key step in this process is incremental tightening: working from the center outward and tightening each fastener just enough to hold the hood in alignment, then stepping through the rest of the mounting points with a calibrated torque wrench. In the Evo X, the recommended torque range for hood-mounted fasteners is modest, typically in the low tens of Newton-meters, with a focus on avoiding over-torquing that could buckling or pull out threads in the hinge mounts. This is not a ritual to be rushed; the hood must sit evenly across the fenders, with consistent gaps from the top of the fender line to the body seam across the entire length of the edge.

A functional or vented hood adds another dimension to the install. The venting needs to align with the passages under the hood to prevent exhaust gas recirculation or unwanted humidity trapped in a poorly sealed cavity. In the heat of a high-rev session, a poorly aligned vent can act like a mini wind tunnel, generating flutter or even lifting at the front edge. To mitigate these concerns, many builders choose a hood design that provides a clearly defined intake channel to deliver cold air into the engine bay or intercooler ducting. The central scoop, a common feature on many performance hoods, must be calibrated so it feeds air where it is most effective, not where it is simply visible from the street. In addition to vent alignment, attention to the hood’s edge sealing matters as much as the seal around the engine bay. If the hood is designed to close against a gasket, ensure the gasket remains intact and that the edge of the hood seats evenly against the bodywork. If the installation uses a carbon fiber hood with a clear coat, its rigidity adds a dense feel when opening and closing, but it also requires UV protection and a restorative regimen to prevent chalking and micro-scratches that diminish gloss and surface clarity over time. A simple tip here is to keep the hood surface clean and to avoid abrasive cleaners that could erode the resin matrix or glazing layer; instead, use mild detergents and soft cloths to preserve the finish.

For those who seek weight reduction as part of the goal, the physics of the hood becomes a balancing act. The lighter a hood, the more the weight savings contribute to unsprung mass reduction and potentially improved suspension behavior. However, if the hood is significantly lighter than the original and relies on an unsupported edge, the added flex can alter front-end geometry under load, changing the alignment of fender gaps and hood-to-cowl seals during hard cornering. This is where a professional installation comes into play. A trained technician who can verify fitment with the hood closed and keyed into the latch, ensure uniform gaps around the entire perimeter, and check the paint line continuity at the hinge areas can prevent long-term misalignment that might otherwise appear as a stubborn, slow-developing panel gap.

A practical note for those who are still evaluating their options is to examine how the hood integrates with the rest of the front-end components. If you are running a turbocharged engine with a high-pressure intake or a turbocharger-mounted intercooler, you must consider the hood’s vent placement relative to those components. A vent that is too close to the turbocharger can pull hot intake air back into the system or complicate the route of intercooler piping. Conversely, a vent that channels air toward the radiator or oil cooler can help mitigate heat soak in sustained high-load conditions. The goal is to create a holistic air-path that does not rely on a single component to solve cooling; it is the sum of the parts—the hood, the ducting, the radiator, and the intercooler—that yields consistent performance under demanding use. That is why the compatibility conversation is never finished with a single purchase. It continues through the vehicle’s life as you add or modify components, ensuring that the hood remains a coherent part of the system rather than a standalone cosmetic upgrade.

If you are curious about a concrete example of a carbon fiber hood with a functional venting design, you can explore one of the options in the aftermarket catalog that emphasizes both weight savings and heat management. This option demonstrates how vent placement, hatch-style louvered vents, and a carefully engineered intake ductwork can reduce thermal load while preserving the hood’s structural stiffness. The design philosophy behind this kind of hood is to preserve the original vehicle’s facial proportions while delivering a measurable improvement in how heat moves away from the engine bay and how air is distributed across the front end. It is not merely about decreasing temperature; it is about maintaining consistent engine performance and avoiding heat-related degradation of electronic components during aggressive driving. That said, the decision to opt for such a hood should be paired with checks on the front-end components’ compatibility with the new profile. Hood-to-bumper clearance, headlight mounting, and the hood’s interaction with the windshield washer reservoir and other under-hood devices are all considerations that demand careful verification prior to final installation.

In the broader picture, the process of choosing and installing an Evo X hood should be treated as a systems decision, not a standalone upgrade. A correct hood improves heat management, reinforces the sense of a performance-oriented persona, and can harmonize with other upgrades to present a coherent, street-credible, and track-capable machine. The discussion of compatibility, therefore, cannot ignore the realities of weather, road conditions, and daily routine that define most owners’ use-case. A hood chosen for bright, sunny climates that sees little rain and long highway cruises may favor a vented carbon fiber approach that minimizes weight while providing a clear path for heat egress. In rain-prone regions, you might prioritize weather-sealing measures and water-management features that minimize moisture intrusion through the vents. The words on the page can only hint at those realities; the true test is in the hands of the mechanic who installs the hood and the owner who observes the car’s behavior in real-world conditions after the change.

For readers who want a tangible example of how one can approach this decision with practical guidance, consider a well-documented installation guide that walks through compatibility charts, torque specifications, and safety precautions based on real-world testing. This resource offers a structured path to ensure that the hood you choose not only fits but also preserves the reliability and safety features of the Evo X. To explore a concrete option for a carbon fiber bonnet that aligns with these considerations, you can view brand-new original carbon fiber bonnet hood for Mitsubishi Lancer Evo X.

While the primary focus lies on compatibility and install procedure, it is also worth noting where to turn for detailed, model-specific guidance. The Evo X hood installation guide published by an authoritative aftermarket resource offers step-by-step instructions that align with the torque ranges and sequencing described here. This external reference can help you confirm your process against tested best practices and ensure you avoid the common missteps that arise when new panels are introduced to an aging mounting system. The guide covers compatibility considerations, the order in which fasteners should be torqued, and how to verify a clean latch engagement after the hood is fully closed. It also highlights the importance of ensuring that the sealing surfaces are free of debris and properly aligned to prevent air leaks and water ingress. If you are pursuing a more performance-focused build, this source becomes even more valuable, since it contextualizes how an upgraded hood interacts with turbocharger plumbing and intercooler routing, as well as how to approach heat management holistically rather than in isolation. External references like this one provide a broader framework for making informed decisions about aftermarket components without losing sight of safety and daily usability.

In closing, the compatibility of Evo X hoods is a layered matter. The right choice balances fit, material resilience, and sealing with the driver’s intent and the car’s long-term maintenance plan. Installation is not a one-size-fits-all procedure; it demands meticulous alignment, careful torqueing, and an appreciation for how venting or aerodynamics affect the whole vehicle. When executed with care, the hood upgrade can deliver tangible benefits in heat management, handling, and aesthetics, all while maintaining the creature comforts and safety features that make the Evo X a versatile performance machine. For readers who want a concrete path forward, aligning with resources that detail installation and compatibility ensures that the upgrade remains a source of pride rather than a source of ongoing concerns. And as always, the goal is to keep the car’s performance coherent with its everyday use, so the hood becomes a trusted ally on both the road and the track.

External resource: https://www.evoxperformance.com/hood-installation-guide

Final thoughts

The Mitsubishi EVO X hood offers a blend of functionality, style, and customization that is appealing to automotive enthusiasts and business owners alike. Understanding the differences between the OEM and aftermarket options helps ensure that you can make choices that enhance not just the vehicle’s performance but also its aesthetics. Embracing these hood modifications can ultimately lead to improved efficiency and an impactful presence on the road, making the EVO X not just a car but a statement.