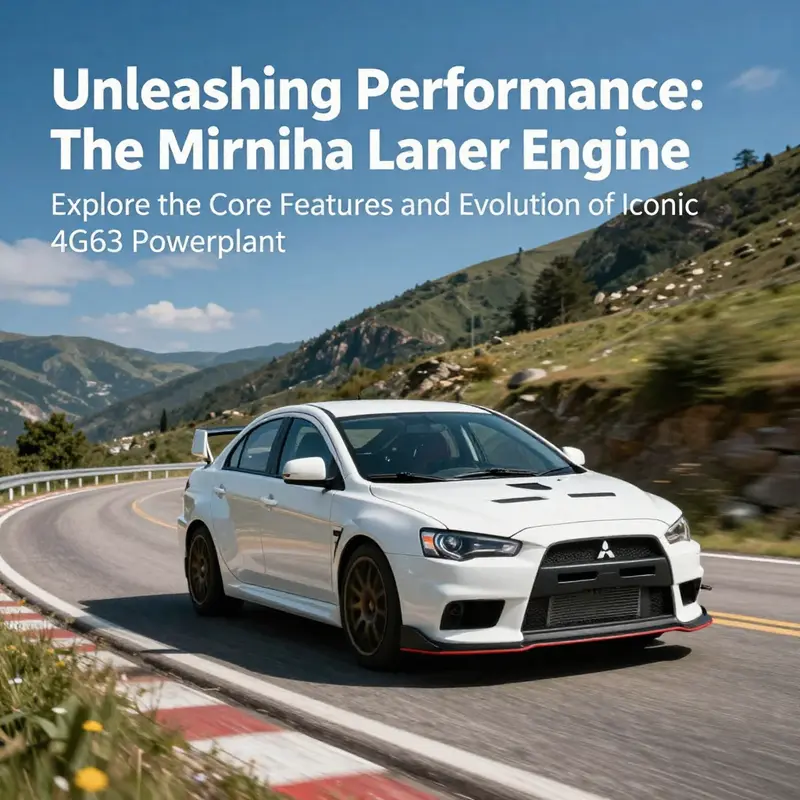

The Mitsubishi Lancer Evolution, revered in both motorsports and automotive circles, owes much of its legendary status to its robust 4G63 engine. Launched in the early 1990s, this engine has undergone extensive development, adapting to the rising demands of high-performance driving. Each generation of the Lancer Evo has seen innovations that not only elevate power and handling but also solidify its place in car culture. Understanding the core features of the 4G63, its performance upgrades over the years, turbocharging enhancements, and aftermarket modification potential will provide business owners insight into its enduring appeal and profitability within the performance market.

Turbocharged Heritage: Core Features and the Engine Evolution Behind the Mitsubishi Lancer Evo

The Mitsubishi Lancer Evolution line is inseparably tied to a single, stubborn belief about how a compact four‑door can conquer both road and rally: power has to be delivered with endurance, precision, and a readiness to push beyond conventional limits. At the core of that belief sits the 4G63T engine, a turbocharged inline‑four that began its most influential journey in the early days of the Evolution and grew into a symbol of engineering resilience and tuning potential. This chapter traces not just the factual arc of horsepower and torque, but the way the engine’s architecture and its evolving technologies threaded through the Evo’s design philosophy. It is a story of how a robust, iron‑block heart could be adapted to meet the demands of increasingly aggressive boost, better breathing, and a broader rev range, all while preserving the reliability necessary for everyday performance and the relentless rigor of rallying where the car’s tempo never settles.

From its base configuration, the 4G63T is a study in durability married to adaptability. The cast‑iron block forms a rugged foundation, while an aluminum head introduces lighter, more responsive flow characteristics at higher speeds. This combination is a cornerstone of the engine’s enduring appeal: it resists the fatigue of sustained high boost pressures, and it remains amenable to modifications that push power figures well beyond the stock numbers. The turbocharging strategy itself tells a parallel tale. Early iterations relied on a single‑scroll design that delivered a robust surge, then evolved into a dual‑scroll configuration later in the lineage. The scientific logic behind that shift is straightforward: dual‑scroll turbos improve flow distribution and spool characteristics, reducing lag and widening the usable torque band. In the Evo’s broader pursuit of improved drivability, these turbocharger refinements were coupled with refinements to intake and exhaust paths, cam profiles, and fuel delivery, all aimed at extracting more thrust without destabilizing the engine’s reliability envelope.

A pivotal turning point in the engine’s evolution came with the introduction of MIVEC technology, Mitsubishi’s variable valve timing electronic control, which first became a defining feature in the later stages of the Evo VII and found further refinement in the Evo VIII. With MIVEC, the engine could alter valve timing in response to engine speed and load, smoothing the transition from low-end response to high-rpm power. The practical effect was a broader, more usable torque curve and improved efficiency at a time when turbocharged engines often sacrificed low-end torque for peak horsepower. The result was not merely an increase in peak figures but a more coherent performance profile: quicker throttle response, more linear power delivery, and a sense that the engine was actively balancing competing demands to keep the Evo responsive and controllable on a twisty road or a demanding rally stage.

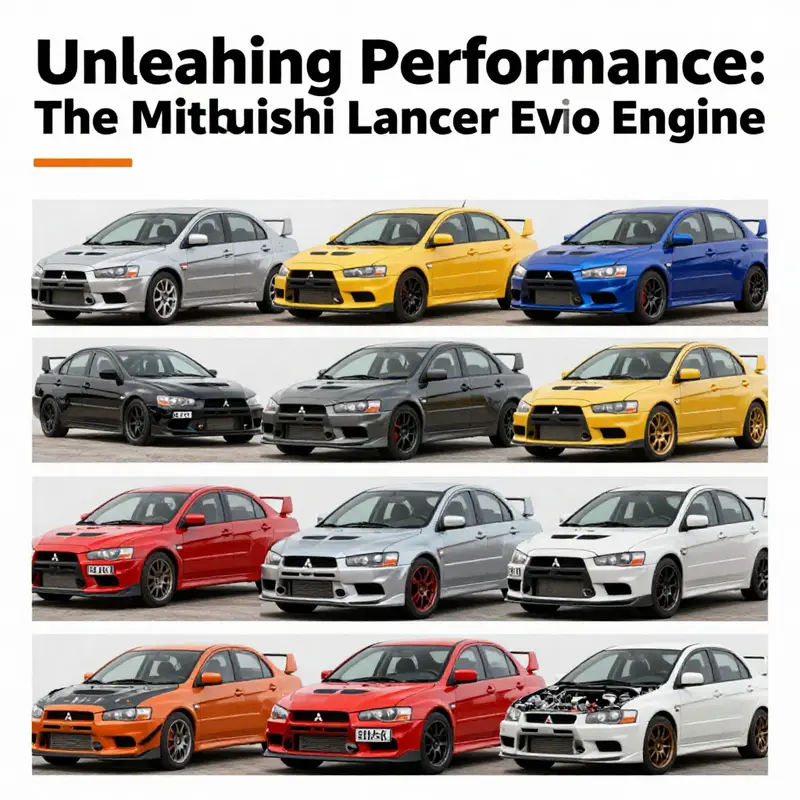

To understand the core features as they unfolded across generations is to see a disciplined trajectory toward both more power and better delivery. The EVO II marked a significant step up from the early model’s baseline, lifting output to about 260 horsepower through a combination of better exhaust efficiency, increased valve lift from 9.0 mm to 9.5 mm, and a higher-capacity fuel pump. This set a new performance bar while preserving the engine’s fundamental durability. The change was not just about a higher number on a spec sheet; it was about a more responsive engine character that could sustain aggressive operation without betraying the chassis’ intent or the car’s rally-grounded temperament. The stage was now set for a more radical rethinking of packaging and breathing, a theme that would carry through the Evo IV’s era in particular. The Evo IV is where the engine narrative takes a surgical turn, almost literally. The Evo IV introduced a redesigned engine orientation within the chassis—rotated 180 degrees relative to the body’s initial orientation—to improve weight distribution and reduce torque steer. This reconfiguration was not merely cosmetic; it was an engineering choice intended to balance the car’s dynamic tendencies under high-power, front-wheel-drive conditions. The introduction of a dual-scroll turbocharger, together with high-angle camshafts and a revamped intake and exhaust system, translated into a substantial leap in power, with a peak around 280 horsepower arriving at 6500 rpm. This model’s engineers also focused on reliability under boost, recognizing that the Evo’s role on track and rally requires a powertrain that can tolerate repeated, brutal loads. The narrative here is less about isolated gains and more about orchestration: turbo efficiency, breathing, heat management, and mechanical strength all moving in concert to create an engine that felt both fast and sure when pressed hard. Torque, in particular, became a central thread in the Evo V’s refinements. Although the horsepower figure remained at around 280 horsepower, torque rose to about 38.0 kgm at 3000 rpm, delivering a stronger mid-range pull that helped the car accelerate more briskly from lower speeds and respond to driver inputs with a more immediate sense of momentum. The cooling system received updates as well, recognizing that more aggressive boost and retained high-rpm operation demand better thermal management. In this era, the Evo was not simply a straight-line performer; it was the kind of car that rewarded deliberate, precise throttle control and a mindset that valued consistent traction and engine response through corners and straightaways alike. The chassis, the brake package, and the transmission dialogue all benefited from the engine’s willingness to deliver strength across the rev range, reinforcing the Evo’s identity as a balanced performance machine rather than a one-note sprint car. As the years moved toward the late 1990s and early 2000s, the engine’s evolution matured into a more complete package. The EVO VI through VIII generations consolidated the use of MIVEC, elevating the engineering standard and expanding the range over which the engine could stay productive and predictable. By the EVO VIII, the 4G63T had reached a new apex in factory tuning, producing roughly 300 horsepower in stock form and continuing to demonstrate that a turbocharged inline-four, when paired with thoughtful intake, exhaust, cam timing, and cooling improvements, could maintain a robust performance envelope without compromising reliability. The Evo VII’s claimed 0–100 km/h sprint time around 4.7 seconds underscored how the engine’s torque delivery and turbo response translated into real-world performance that excited drivers and impressed track observers. The story of the 4G63T’s enhancement across these generations is one of steady, disciplined refinement that respected the engine’s roots while embracing the technologies that would unlock higher performance without surrendering the reliability demanded by rally and daily use alike. What remains compelling about the 4G63T, even beyond the official horsepower numbers, is its formidable potential for modification. Its thick iron block and proven bottom end offer a generous safety margin for boost, and the head’s aluminum construction continues to respond well to improved air intake and exhaust flow. Enthusiasts quickly discovered that, after removing factory ECU restrictions and refining the ignition and fuel delivery, the engine could sustain substantially more boost and air flow than the stock setup had ever intended. In the broader culture of Japanese performance tuning, this engine is celebrated as a robust platform for development, inviting projects that push well beyond the factory ceiling while still preserving the fundamental architecture that makes the Evo a coherent, drivable performance car. The core idea is not reckless escalation, but a sustained, thoughtful pursuit of more power that remains manageable for a skilled driver and reliable enough for weekend track days and daily driving alike. In this spirit, the engine’s intrinsic strength—its cast-iron block, its adaptable head, its turbocharged heart—continues to be the foundation of a modern legend, even as new generations and new platforms push performance boundaries in other directions. An enduring example of how this engine’s legacy is preserved in the modern automotive landscape can be seen in the ongoing interest in genuine, period-correct configurations. Enthusiasts seeking authenticity still pursue well-preserved examples or meticulously rebuilt units that reflect the Evo’s original ethos—durable, tunable, and capable of delivering a balanced, exhilarating driving experience. For readers who want a tangible touchstone to explore a 4G63T’s original configuration or its near-period variants, the genuine, low-mileage representations of the 4G63T engine from the mid-to-late 1990s provide a compelling reference point. See the following listing that highlights a 4G63T unit from that era, including details about boost-ready hardware and compatible transmission and ECU configurations: genuine-jdm-low-mileage-1995-1999-jdm-mitsubishi-4g63t-2-0l-dohc-turbo-engine-evo-7-bolt-eclipse-talon-awd-automatic-transmission-and-ecu-attached. This link is a reminder that the engine’s viability as a tuning platform rests on a well-built core and a willingness to honor the engineering choices that have shaped its history. The evolution of the 4G63T in the Lancer Evolution lineage, from its rugged cast-iron heart to its refined, variable-timing sophistication, illustrates a broader automotive truth: performance engineering advances not just through bigger numbers, but through smarter flow, better control, and more deliberate integration with the entire vehicle architecture. The engine’s journey—from the early efficiency of a single-scroll turbo, through cam timing and cooling upgrades, to the MIVEC-enabled era that broadened the torque curve—exemplifies how a compact powerplant can remain relevant across changing regulations, competition formats, and driver expectations. The Evo’s legacy, stitched together by this engine, is not only a catalog of horsepower milestones; it is a narrative about engineering prudence meeting performance, a narrative that continues to resonate with enthusiasts who value both speed and the art of driving. External resource: https://en.wikipedia.org/wiki/MitsubishiLancerEvolution

From the 4G63 Legend to Hybrid Power: The Generational Odyssey of the Lancer Evolution Engine

The Mitsubishi Lancer Evolution lineage has always been defined by a single creed: power delivered with precision, under control, and in a package that invites circuit and rally action. At the heart of that creed lies an engine family that began as a compact 2.0 liter turbocharged four and, generation by generation, learned to breathe harder, stay cooler, and respond faster to the driver’s intent. What began as a homologation engine for a World Rally program evolved into a torque-rich, high revving benchmark for thrust and handling. Across generations, the EVO engine line demonstrates a continuous negotiation between raw performance and practical reliability, a balance that allowed Mitsubishi to push the limits without sacrificing daily usability. When we trace this journey from the early 1990s to the present, we see not merely a tale of horsepower figures but a story about how engineers refined airflow, improved cooling, and hardened internals to meet demands from the track to the road. In that sense, the EVO engine is less a single powerplant than a lineage of interconnected improvements that collectively defined how all wheel drive performance could be harnessed with surgical precision.\n\nThe journey begins with the 4G63 family, a robust and versatile 2.0 L turbocharged inline four that earned a reputation for durability as much as for its capacity to be tuned. In the first Evolution, the engine emerged as a WRC homologation solution that delivered a strong punch right from the box. Despite its relatively modest displacement, the turbocharged four delivered the spark that would ignite an entire culture around high performance Mitsubishis. The early power figure—roughly 195 horsepower—set a baseline that would be challenged and expanded in subsequent generations. The objective was not only to increase peak numbers but to improve the character of the engine on the street and, more crucially, on the rally stage where friction between boost, fueling, temperature, and response could quickly turn into a performance deficit if not carefully managed.\n\nEvolution II built on that foundation by pushing output higher and refining the way the engine filled the cylinders. The engineering team focused on altering the cam profiles to increase valve lift from 9.0 mm to 9.5 mm, a change that improved cylinder filling and translated into stronger midrange and better high end flow. A higher capacity fuel pump supported the increased fuel demand, ensuring the air fuel mixture could be maintained even as boost rose. The result was not just a raw horsepower gain but a more usable, linear delivery of power across the rev range. The car could pull more confidently through corners, with throttle modulation translating to precise responses rather than sudden surges. This was the era when the EVO chassis started to feel like a hardware extension of the driver’s intent, where turbo response, exhaust tone, and turbocharger whine created an almost ritualized engagement with the car as a whole.\n\nThe Evolution III era represented a significant leap in peak performance and cooling strategy. The 4G63 gained a larger turbocharger, the TD05H-16G6-7, and moved to a compression ratio of 9.0:1. The changes produced a marked uptick in peak horsepower to around 270 hp, but the more meaningful improvement lay in the engine’s ability to sustain high-boost operation without succumbing to heat soak. A more efficient intercooling system and upgraded intake paths helped manage the higher charge temperatures that come with bigger boosts. The EVO III era signaled a turning point where the engine’s performance characteristics were tightly coupled with the vehicle’s aerodynamic and cooling architecture. Evolution IV built on that foundation, incorporating further refinements in the turbo system, electronics, and engine management strategies to deliver improved throttle response and reliability under the stress of aggressive driving and endurance level use.\n\nAs the lineup matured into the mid to late 1990s, the EVO’s power curve shifted toward refined, track ready performance with an emphasis on durability. The Evolution VII, in particular, aspired to a peak state for the 4G63 family that would come to define the engine’s reputation in enthusiast circles. With a maximum power figure nudging toward 280 horsepower and a peak torque in the high 30s of kilogram meters, the engine felt both potent and controllable. The availability of a higher spec turbo configuration, such as the TD05HR-16G6-9.8T, contributed to a broad, usable torque band. The tuning philosophy during this era leaned into efficient heat management, sophisticated boost control, and refined electronic management that could make high power operation more legible to the driver. In practical terms, this meant quicker, more predictable acceleration and a chassis that could exploit that power with confidence. The EVO VII’s drivetrain architecture and its turbocharging strategy became a reference point for the balance between aggression and reliability that the EVO name would carry forward.\n\nYet power alone was never the sole story. The Evolution IX and X mark a deliberate pivot in engineering thinking as the platform moved to a new engine family starting with the 4B11T. The shift was not merely a change of badges or a fresh coat of electronics; it embodied a strategic move toward a new balance of weight, strength, and efficiency. The 4B11T, a 2.0 L turbocharged inline-four designed with forged crank and strengthened internals, delivered roughly 280 horsepower in the late EVO IX period while offering improvements in high rev reliability, fuel efficiency, and durability under the rigors of competitive use. In parallel, the platform transition itself brought a reimagined chassis architecture and a more refined all wheel drive system. This was not simply an engine swap but a redefinition of how the EVO concept translates into real world performance. The engine’s role shifted toward maximizing tractable grip and precision steering through an intelligent integration with the chassis, rather than relying solely on raw appetite for boost.\n\nIn the Evolution X era, that integration deepened. The 4B11T was fine tuned to offer a more sophisticated response profile, and the electronics package—centered around the Super All Wheel Control system—made the car steadier at the limit and more forgiving in everyday driving. The result was a car that could feel more composed at speed while still delivering the thrilling push needed on a track or a twisty mountain road. The horsepower figure remained impressively competitive for its class, but the real gains were in the way the power was deployed: smoother torque delivery, more linear acceleration, and a chassis that could translate that power into cornering grip with exceptional clarity. This era underscored a shift toward engineering that valued the synergy between engine, drivetrain, and suspension as much as the raw numbers on a dyno chart.\n\nThe most striking arc in the EVO engine saga is perhaps the most recent. The 2026 model year introduces a substantial philosophical departure: a plug in hybrid powertrain that blends a 2.0 L turbocharged gas engine with an electric motor for a combined output of about 250 horsepower. The new package is designed to eliminate turbo lag, deliver instant torque from the electric motor, and extend urban usability with an estimated all electric range. In a sense, this marks a culmination of the EVO engine’s long running mission to balance performance with controllability and efficiency. The car retains its iconic four wheel drive character and its dynamic disposition, but the power delivery now arrives through a more cohesive, multi source system that emphasizes sustainability alongside speed. The EVO story ends not with a single pinnacle of horsepower but with a reimagined powertrain that leaves room for future refinements in hybrid engineering while preserving the driving DNA that made the EVO a benchmark in the first place.\n\nWhat ties these generations together is a relentless focus on fundamentals: airflow, cooling, and control. Across the early 4G63 era, the quest was to feed the turbocharger with enough air and fuel while keeping temperatures in check. That meant larger turbos, refined intercooling, and careful calibration of the engine’s breathing. As boost levels rose, so did the importance of robust cooling paths and durable internals. The mid era around Evolution III and IV reveals a transition from basic upgrades to an integrated approach that combined engine hardware with chassis and electronic control to achieve a more manageable, race informed drive character. When the platform evolved to the 4B11T in Evolution IX and X, the engineering focus broadened. It was no longer enough to chase horsepower; the package needed to deliver tractable performance day in and day out, a tall order when the car would be driven hard on street, track, and rally stages alike. The adoption of a sophisticated AWD control system complemented the engine’s repertoire, turning raw power into confident, repeatable cornering and braking performance. The later shift to a PHEV configuration is the natural culmination of that philosophy: a drive that preserves the Evo’s spirit while aligning with contemporary needs for efficiency and emissions considerations. In every generation, the engine’s evolution has been as much about refining heat management and air flow as it has about chasing peak numbers.\n\nThis progression has also fed a vibrant tuning culture around the EVO’s core. The 4G63’s reputation as a sturdy, forgiving block made it a favorite in the Japanese domestic market and beyond. Aftermarket modifications stretched from exhaust and intake improvements to fuel delivery and ignition system upgrades, all aimed at smoothing throttle response and raising the power ceiling. With the ECU increasingly capable of handling higher boost and altered fueling strategies, ambitious builders discovered that a well tuned 4G63 could surpass 300 horsepower without overburdening the engine’s fundamental strength. For many, the pinnacle of that era involved combinations of boosted charge, refined cam timing, and, in some cases, nitrous assistance. The result is a heritage of cars that were simultaneously exhilarating on a track and reliable enough for weekend track days or spirited street drives.\n\nWhen these engines reached the later EVO generations, the conversation about power shifted toward a broader question of balance. The 4B11T, while delivering impressive numbers, introduced a new dynamic: an engine that could operate with greater efficiency, and an AWD system that could exploit refined throttle maps and electronic control to maintain grip without sacrificing drama. In this sense, the engine’s evolution mirrors a broader automotive shift—a movement away from mere peak horsepower toward an integrated, driver focused performance envelope. The EVO’s powertrain became a holistic system in which turbo lag was minimized, fuel delivery was carefully matched to the air charge, and the cooling system was designed to sustain high-output operation over longer periods. The result was a car that could deliver the same white-knuckle excitement at the limit while remaining more adaptable for daily use and repeated sessions on a race weekend.\n\nIf we look back at the career arc of the EVO engine, a single thread stands out: the engine’s ability to adapt without surrendering its fundamental identity. The 4G63 family, with its iron block and long-stroke geometry, offered a base that invited modification and resilience. The later generations, with 4B11T and then the hybrid configuration, demonstrated a willingness to evolve the core architecture in ways that did not dilute the driving experience but rather enhanced it. That evolution is not merely about chasing higher numbers; it is about rethinking how power is generated, cooled, managed, and delivered to the driver. The result is a family of engines that, while each generation carries its own character, remains unmistakably EVO in its pursuit of precision, balance, and a sense of immediacy that makes the car feel like an extension of the driver’s intent.\n\nFor enthusiasts, the story of the EVO engine is a narrative about taste as much as engineering. It is about embracing a tradition of reliability while pushing the boundaries of what a compact turbo four can accomplish. It is about recognizing that performance is a system quality, not a solo attribute. The engine is the loud, honest heart of a car that thrives on pushing boundaries, yet it exists within a chassis, a boost strategy, and an electronic control ecosystem that turns bold numbers into controlled speed. The chapter ends not with a final tally of horsepower but with a sense of the EVO as a living lineage—one that has transformed from a turbocharged icon into a modern, efficient performance machine that preserves the exhilaration of its origins while speaking to a future where efficiency and electrified powertrains share the stage with the roar of a well-tuned turbo.

Turbocharging the Lancer Evo: The Art and Science of Boost Across a Legend

The Mitsubishi Lancer Evolution has long stood as a testament to how turbocharged engineering can fuse rally heritage with the precision and discipline of Japanese performance tuning. At the core of this legend lies a narrative about how air, fuel, and controlled pressure converge to turn a modest 2.0-liter four into a dynamic, motorsport-ready powerplant. Turbocharging is not merely a feature of the Evo; it is the lifeblood that defines its character across generations. From the early, sturdy architectures that rewarded builders with a platform capable of impressive gains, to more modern configurations that balance high output with refined torque delivery, turbocharging in the Evo tells a continuous story of evolution, adaptation, and relentless pursuit of speed. What follows weaves a cohesive arc through that history, highlighting how turbocharging techniques, airflow management, and engine architecture interplay to shape what the Evo can become on a track, a rally stage, or a mere twist of asphalt on a midnight street run. It is as much about the tempering of boost as it is about the raw numbers on a dyno sheet, because the art lies in the balance between air, fuel, and heat — the three pillars that decide whether power is a thrill or a danger that can outpace reliability.

From the outset, the Evo’s turbocharged heart rested on a simple premise: more air and more fuel, precisely managed, would yield more power. But that premise only made sense when paired with a robust, enduring foundation. The early iterations leaned on a turbocharged, iron-block inline-four that produced strong low- and mid-range torque, a formidable trait for rallying where immediate response matters as much as peak figures. This combination of a hard-wearing block with a turbocharger that spooled with a gratifying immediacy gave the Evo its characteristic shove. It wasn’t just about peak horsepower; it was about the way that torque arrived. In competition, where stage times hinge on predictable, usable power, the engine’s delivery mattered as much as its raw potential. The design philosophy emphasized durability, ease of tuning, and a chassis that could exploit the engine’s boosted character without inviting catastrophic failures under sustained boost.

As the generations progressed, the turbocharging strategy became a lattice of incremental improvements rather than a single seismic shift. The base models of the early 1990s and 2000s relied on a turbo system that could be tuned to push power from roughly two hundred horsepower in stock form to well above two hundred with careful modifications. The evolution that followed—spanning multiple generations—refined how air navigates through the intake, how exhaust exits, and how the engine breathes in the critical seconds after ignition. One of the core tasks in this evolution was to increase air flow while preserving engine reliability. A larger turbine and a redesigned compressor, paired with refined charge-air cooling, enabled higher boost pressures to be sustained without detonation or runaway heat. The result was not a single leap but a series of carefully choreographed steps: improving exhaust efficiency, increasing valve lift, and optimizing fuel delivery to match the upgraded airflow. These changes culminated in a progression where horsepower rose from a base around two hundred forty horses to the mid-two-hundreds in later Evo II through Evo VII, with peak figures continuing to climb as further turbocharger refinements landed in subsequent generations.

Among the decisive mechanical shifts that shaped the turbocharging trajectory was the move from simpler, smaller turbochargers to larger, more capable units that could sustain higher boost pressures and deliver power more cleanly at higher engine speeds. In the mid-Evolution timeline, the adoption of more robust turbocharging hardware enabled a shift from torque-dominated pull at lower RPMs to a broader, more controllable power curve at higher RPMs. The benefit of this approach is not merely higher peak numbers; it is the ability to maintain power across a wider rev range, which translates into more decisive acceleration on straights and more confident drive through corners at the limit. The chassis and drivetrain endured these changes through refined engine management and cooling strategies, underscoring that turbocharging is as much about thermal management and ignition control as it is about the turbo itself.

With the Evo X, a more modern architectural approach entered the picture. The 4B11T engine, a next-generation turbocharged, DOHC inline-four with a higher valve count and more advanced airflow management, represented a shift toward smoother power delivery and improved high-RPM performance. The 4B11T’s design emphasized efficiency and repeatability under boost, qualities that are crucial on long rally stages and varied road courses. In this era, Mitsubishi and the Evo’s engineering community pursued a more balanced equation: higher peak power without sacrificing drivability, a broader torque band, and better response across the rev range. The engine’s architecture and turbocharging strategy aligned with a broader trend in performance engineering—pushing more air into the cylinder in a controlled fashion, then marrying that air with precisely metered fuel and dependable ignition. The end result was a platform that tolerated more aggressive tuning, enabling enthusiasts to chase power while maintaining driveability, a fusion that remains a hallmark of the Evo’s identity.

The turbocharger itself became a focal point for performance gains. In the Evo X era, the turbo system was designed to cope with higher boost pressures and a greater volume of intake air. A modern turbocharger designed for this configuration could deliver substantially more air mass into the combustion chamber, unlocking significant horsepower increases when paired with supportive upgrades. At the same time, the importance of the entire charge-air system could not be overstated. The intercooling stage, typically a top-mounted intercooler in many Evo configurations, played a central role in reducing intake air temperature before it enters the combustion chamber. Cooler air is denser, allowing more oxygen per unit volume and reducing the propensity for detonation, particularly under sustained boost. The intercooler thus serves as a critical throttle ladder, enabling the boost to translate into reliable, repeatable power rather than heat-induced performance constraints.

The relationship between turbocharger size, boost control, and fuel delivery is a nuanced negotiation. When you increase turbo size or boost pressure, you must also adapt the fuel system and the engine’s computer mapping to maintain a healthy air-fuel ratio across all operating conditions. If you push air in without providing enough fuel or if the mixture detonates due to heat, the engine’s integrity is at risk. The Evo’s engine management ecosystem—carefully calibrated electronic control units, flexible fuel delivery, and reliable ignition timing—has to mature in concert with turbo hardware. This synergy is what allows the Evo to produce meaningful performance figures without sacrificing reliability. In practice, the path from a factory boost to a more aggressive tune includes a series of well-coordinated steps: upgrading fuel pumps to maintain fuel pressure at high flows, dialing in cam profiles and valve timing for the altered air dynamics, and ensuring the cooling system can shed the extra heat generated by higher cylinder pressure and furnace-like exhaust gas temperatures. Each modification requires thoughtful integration with the others; otherwise, improvements in one area may be nullified by bottlenecks elsewhere.

The practical outcome of these turbocharging refinements is a power envelope that, when managed with care, yields extraordinary performance without compromising the Evo’s rally-bred behavior. For enthusiasts, this means the ability to extract more usable horsepower from the engine at realistic, repeatable conditions. The power delivery can be tuned to maintain strong midrange torque for quick gains on twisty segments while preserving a high-rev, linear response that makes the car feel predictably strong on long, flowing sections. The result is a car that remains manageable at the limit, a key trait for a machine that once sprinted from stage to stage in tight forest roads and quickly adapted to asphalt rallying in modern transitions.

As the turbocharged journey progressed, so did the philosophy around optimization kits and customizations. The Evo platform became a canvas for the tuning community, a space where enthusiasts could experiment with turbo configurations, fuel strategies, and exhaust designs to realize ambitious horsepower targets. The culture around these modifications—carefully staged boosts, meticulous fuel tuning, and cooling upgrades—became a central element of the Evo’s enduring appeal. It’s not simply about a higher number on a dyno; it’s about how a driver experiences momentum, throttle response, and the precise, engineered feel of the boost coming on with confidence. The best setups are those that deliver a connected sensation: you press the pedal, and the car responds with a surge that is both immediate and controllable, leaving you with a sense of control even as the engine breathes through compressed air.

Within this broader narrative, a simple, yet powerful truth emerges: turbocharging is as much about thermal and mechanical discipline as it is about clever engineering. The intercooler’s ability to reduce intake temperatures, the exhaust path’s efficiency, and the turbocharger’s response all shape this discipline. The top-mounted intercooler’s cooling capacity translates directly into longer, more stable boost periods, enabling more aggressive maps and more consistent lap times. When the engine carries a cooler charge, the risk of detonation falls, the timing can be more aggressive, and the engine can sustain high performance for longer. These are not merely academic considerations; they define the practical limits of how far turbocharging can push a street-legal Evolution before the underlying hardware starts to protest. In this sense, every horsepower gained through boosting is accompanied by a balancing act: you must gain cooling, refine fueling, and maintain the structural rigidity of the block and head to support higher pressures.

The modern Evo’s turbocharger history also reflects a broader, almost architectural shift in performance engineering. Where early boost strategies emphasized immediacy and robustness, later approaches pursued smoother, more accessible power across a broad RPM band. This evolution suited a diverse range of driving contexts—from the precision demands of circuit racing to the versatile realities of street performance. The driver’s experience becomes a function of not only peak output but, crucially, the predictability of that output as the engine spins through the revs. The result is a car that can exploit its turbocharged heart in a disciplined, repeatable fashion, delivering thrills without the disorienting jolt or abrupt surge that can challenge a driver on high-speed corners.

For enthusiasts who want to push beyond the factory envelope, the turbocharging path offers a well-trodden blueprint: upgrade the turbo and intercooler, improve the exhaust flow, and tune the fueling and ignition to suit the new air mass and temperature profile. It is a journey that invites a careful balance of risk and reward, where the aim is to extract meaningful power while preserving the Evo’s well-known dynamic balance. In this landscape, the chapter of turbocharging is as much about the craft of integration as it is about the charisma of horsepower. The Evo’s turbocharged heritage demonstrates that when airways, fuel avenues, and cooling channels are aligned with the chassis’ latent capabilities, the result is more than a number—it’s a coherent driving experience that remains faithful to the car’s rally-born identity while embracing the modern demands of speed and precision.

For readers who want to explore a deeper engineering angle or consider future projects, a closer look at how cooling and airflow management underpin high-boost performance can be instructive. The high-performance pathway often involves not only larger turbos or higher boost but also enhanced intercooling capacity, upgraded piping for reduced pressure drops, and more robust fuel systems to handle sustained pressures. The synergy of these components defines not just peak numbers, but the ability to maintain repeatable performance on a race circuit or a demanding road course. In that sense, the Evo’s turbocharged evolution exemplifies how modern performance tuning is a holistic enterprise—one that respects the engine’s root architecture while embracing the creative latitude that enthusiasts bring to the table.

Internal link for deeper exploration of a common upgrade path:

4b11t-billet-block

External resource:

https://www.mitsubishiparts.com/49378-01642

Beyond the Badge: Unlocking the Aftermarket Potential of the Mitsubishi Lancer Evolution’s 4G63 Engine

The Mitsubishi Lancer Evolution’s 4G63T engine has earned a reputation for durability and tuneability. Its cast iron block and strong bottom end provide a reliable platform for boosted power, while a relatively simple, compact four cylinder layout eases the path to bigger numbers. In the aftermarket, the main gains come from reinforcing internals, upgrading the fuel system, and selecting a correctly matched turbo and intercooler to preserve efficiency and reliability. A well-planned upgrade path emphasizes steady power growth and fuel control, rather than chasing a single peak number. Forged pistons, rods, and a robust crank can support sustained high boost when paired with oiling and cooling improvements. A modern ECU tune ties it all together, optimizing ignition timing and fuel delivery for daily driving and track sessions alike. The ecosystem of compatible parts from multiple suppliers helps builders assemble balanced packages with repeatable results, so performance upgrades remain accessible rather than bespoke. While chassis and brakes should scale with horsepower, the engine remains the heart of a well-rounded Evo build, delivering meaningful, usable gains without sacrificing reliability.

Final thoughts

The Mitsubishi Lancer Evolution 4G63 engine remains a benchmark in the high-performance car realm. Its articulation of power, durability, and the potential for aftermarket enhancements make it an appealing option for both enthusiasts and business investors alike. As automotive technology evolves, the Lancer Evo’s legacy as an engineering marvel continues to attract attention, promising lucrative opportunities for business owners in the automotive aftermarket. Understanding this engine’s historical significance and performance capabilities paves the way for future investments and innovations in the automotive industry.