The Lancer Evolution series, known for its raw power and impressive engineering, has left an indelible mark on the automotive culture. At its heart is the performance-driven 4G63 and the innovative 4B11T engine. These engines not only symbolize Mitsubishi’s engineering prowess but also reflect the evolution of motorsport technology. This article delves into the intricacies of these engines, their transformation over generations, the concept of electrification in future models, and their profound influence on car modification culture. By understanding the legacy and future of the Lancer Evolution motors, business owners can gain insights into an ever-evolving industry.

Lancer Evolution Motor: 从铁心到铝翼的传承与革新

外部参考资源为进一步阅读提供了另一层次的维度。有关 4G63T 的详细背景、工程设计理念以及在改装文化中的地位,可以通过权威媒体的专题报道获得更系统的理解。外部链接如下,读者可以在需要时进行查阅。外部资源: https://www.motor1.com/news/287654/4g63t-legendary-mitsubishi-engine/

Lancer Evolution Motor: The 4B11T Dawn—A Lightweight Aluminum Era for a Rally Legend

The Lancer Evolution’s engine lineage reads like a map of performance ambition. For generations, the series leaned on a rugged iron-heart that could endure punishing boost and brutal rally conditions. The shift to a modern, lightweight era did more than shave weight; it redefined how the car behaved at the edge of grip, how quickly it responded to a driver’s input, and how reliably it would sustain high-power engagement over the long haul. This chapter follows the turning point when Mitsubishi embraced an all-aluminum approach, ushering in a new epoch that European tuners and Japanese engineers alike would parse as the critical bridge between raw, iron-willed torque and a more sophisticated, electronically coordinated performance. It is a story of balance: not simply less mass, but smarter mass, not merely faster acceleration, but a more controllable, confident surge through the mid-range and into the upper reaches of the rev band.

The heart of this transformation lies in the engine that powered the tenth-generation Evolution. In broad strokes, the new powerplant was a 2.0-liter inline-four that retained the turbocharged character of its forebears but adopted an all-aluminum block. The result was a substantial reduction in overall engine mass—roughly one-fifth lighter for the entire assembly—without sacrificing the reinforced stiffness and durability required by high-boost operation. The aluminum block did not stand alone as a lightweight trophy; it was paired with a robust design that kept the essential strength where it mattered most. An important note in this lineage is the coexistence of lightweight architecture with engineered durability: the block used durable cylinder sleeves, which provided a reliable foundation for high compression and high boost while preserving a safer, more predictable wear profile under aggressive, track-oriented duty cycles. Such an approach illustrates how the engineers balanced the competing demands of lightness, heat management, and long-term reliability, a trifecta that had to be navigated with care as turbocharged output rose and the chassis demanded more from the drivetrain.

From a performance perspective, this engine family marked a clear departure from the earlier iron-centric approach. The modern aluminum block helped reduce unsprung weight and rotating mass, contributing to crisper throttle response and more immediate engine-to-wheel communication. Power figures settled in a range around the upper 290s to just over 300 horsepower, while torque figures climbed into the mid-to-high three hundreds of newton-meters. These numbers, while impressive on paper, translate in the real world to a cadence of acceleration that feels immediate and involving. The chassis could be coaxed into a responsive, predictable surge that allowed a skilled driver to place the car with greater precision on a corner exit, then dial the throttle to balance understeer and oversteer with a level of patient control that was harder to achieve with a heavier block. The four-wheel-drive system—fully integrated with the engine’s timing and the drivetrain’s torque vectoring logic—worked in harmony with the lighter architecture to deliver a sense of unity between man and machine, a resonance that enthusiasts often describe as the car “singing” at the limit rather than fighting for traction.

A crucial mechanical detail worth noting is how the 4B11T-era engine managed turbo loading under continuous high-demand conditions. The design employed a semi-open waterway layout and a robust set of cylinder sleeves to temper heat and maintain structural integrity when boost levels rose and the RPM band widened. This combination of lightness and reliability helped the engine tolerate repeated, high-boost bursts during aggressive cornering and rapid direction changes, a hallmark of the rally-bred heritage. For readers focused on the practical underpinnings, the progression from a stubborn, iron-centric backbone to a more elegant all-aluminum architecture signals more than improved fuel economy or raw weight savings. It implies better overall balance, especially in the car’s mid-range, where responsible throttle modulation matters as much as outright peak power.

The character of this era’s powerplant is perhaps most apparent in how it redefined throttle responsiveness. Turbine compliance—how quickly the turbo spools and responds to pedal input—became sharper as a result of both reduced mass and refined flow paths. Titanium turbine blades, while a high-end feature in many turbocharged engines, exemplify the direction the engineers pursued: reduced inertia in the rotating assembly translates to a more immediate boost onset. The driver feels this as a more willing, eager response to mid-throttle requests, which in turn encourages a more nuanced, less binary driving style. In practical terms, the body communicates with the right amount of information at the right moment, enabling precise throttle modulation through tight corners and whoops where a fraction of a second can be the difference between ideal line and suboptimal exit. This sensorial clarity is the core reason the aluminum-era engine is often described as a turning point—a moment when the car began to reward not just the strongest or the bravest, but the most deliberate and technically attuned driver.

Beyond the baseline performance metrics, the Evolution’s transformation into an aluminum-focused power unit opened the door to broader engineering exploration. The lightened mass made the vehicle more forgiving at the limits, which, counterintuitively, also allowed for more aggressive suspension tuning and steering calibration. With each pound shed from the engine bay, the front-to-rear weight distribution could be managed with greater confidence, letting engineers tune the suspension to exploit the available mechanical grip without inviting abrupt snap responses. In other words, the chassis learned to ask slightly more of the tires, and the tires responded with steadier, more linear grip. The overall effect was a vehicle that felt more predictable at the apex and quicker in the transition between apexes—a quality that transformed the way the Lancer Evolution was piloted on mixed tarmac or gravel courses.

The lineage link to this era’s heritage remains a touchstone for enthusiasts who value mechanical honesty. The engine’s aluminum heart did not erase the rally-bred soul; rather, it refined it. This refined essence was reinforced by a practical engineering ethos: emphasize controllability and repeatability under heavy use, and the car will reward the driver with consistent, repeatable performance across a wide range of conditions. The result is a powertrain that communicates not just numbers, but intent. A driver who understands the car’s capacity can exploit its mid-range torque, use the turbo’s wind-up as a precision tool, and ride the balance between front-end grip and rear-end rotation with the kind of finesse that makes a machine feel almost telepathic.

One experimental thread in the broader conversation about Evolution’s future concerns electrification—a topic that had already begun to flicker on the company’s radar in the mid-2000s. Though a production electrified Evolution did not materialize in that era, the concept of hybrid or electric propulsion surfaced in concept studies. The 2005 Lancer Evolution MIEV concept famously explored wheel-on motors and other electric-drive concepts, signaling a willingness to push beyond conventional internal combustion while preserving the core dynamics that defined the lineage. The discussions never settled into mass production, but they underscored a philosophy: performance engineering should evolve to harness power in more versatile, efficiency-minded ways without surrendering the driver’s relationship with the car. The broader message was clear—performance and sustainability would not be mutually exclusive; they would be integrated as technology matured.

More recently, the conversation about a potential new Evolution has resurfaced in industry chatter and measured commentary. At the 2025 Japanese mobility showcase, a Mitsubishi engineer hinted that the company still holds a reserve of advanced technologies suitable for a hypothetical next-generation Evolution. The remarks, reported in professional circles and picked up by automotive observers, suggested that a fresh interpretation—whether plug-in hybrid, pure electric, or some hybridized architecture—could build on the 4B11T-era principles while embracing electrification’s benefits. Analysts interpret this as an acknowledgment that the Evolution’s spirit—compact dimensions, precise handling, and a willingness to push the performance envelope—remains a central tenet of Mitsubishi’s performance strategy. The precise form of any future Evolution remains to be seen, but the underlying narrative is unmistakable: the lineage is not merely a museum piece; it is a living framework, capable of absorbing new propulsion concepts and translating them into a driving experience that stays true to the car’s ethos.

In the meantime, the 4B11T chapter remains a reference point for engineers and drivers who value a balanced, thoughtful approach to performance. The shift to an aluminum block did more than save weight; it reshaped the way a turbocharged engine interacts with the chassis and the road. The drivetrain’s capacity to deliver consistent, high-quality power while maintaining manageable heat and wear characteristics created a platform on which drivers could develop nuanced car control. The synergy among the engine, turbocharging, cooling, and suspension became a template for how to design a high-performance car that remains tractable, even when driven at the edge. The result is a vehicle that, while it may not be the most extreme machine in its era, offers a compelling combination of immediacy, feedback, and confidence.

As the chapter closes on the 4B11T era, the car’s story does not end with a straight line to the next technology—it points toward a broader arc. The lightweight aluminum era proved that performance engineering could be both aggressive and disciplined, capable of delivering quick, responsive dynamics without sacrificing durability. It suggested a philosophy that would continue to inform Mitsubishi’s approach to engineering, a philosophy that will hopefully reflect in the next generation of the Lancer Evolution if and when a revival arrives. The chassis, the drivetrain, and the electronic controls all moved toward a more integrated, responsive relationship with the driver, an ideal that remains central to any future interpretation of the Evolution’s motor. The legend endures not because it remained the strongest or loudest in its class, but because it evolved with intention, kept faith with its roots, and demonstrated that innovation can be as respectful of a legacy as it is excited for the unknowns ahead.

For readers who want to explore a specific technical facet of the aluminum-block approach, a deeper look at the dedicated block component offers tangible insight. One engineering detail signals this shift: the use of an all-aluminum block paired with durable cylinder sleeves, a configuration that balances lightness with longevity. A dedicated resource on this topic is available here: https://mitsubishiautopartsshop.com/4b11t-billet-block/

As a closing reflection, the 4B11T epoch represents more than a change in materials. It marks a deliberate reimagining of how weight, heat, dynamics, and driver feedback cohere in a high-performance compact car. The era’s practical achievements—mass reduction, responsive turbo dynamics, and reliable high-load operation—are not simply historical footnotes. They are a blueprint for approaching future mechanical challenges and a reminder that performance can be redefined without discarding the core identity that gave the Evolution its enduring appeal.

External resource: https://www.mitsubishi-motors.com/en/vehicle/lancer-evolution-x/specifications.html

Lancer Evolution Motor: From Iron Heart to Electric Horizon—Paths Toward a Modern Evo Revival

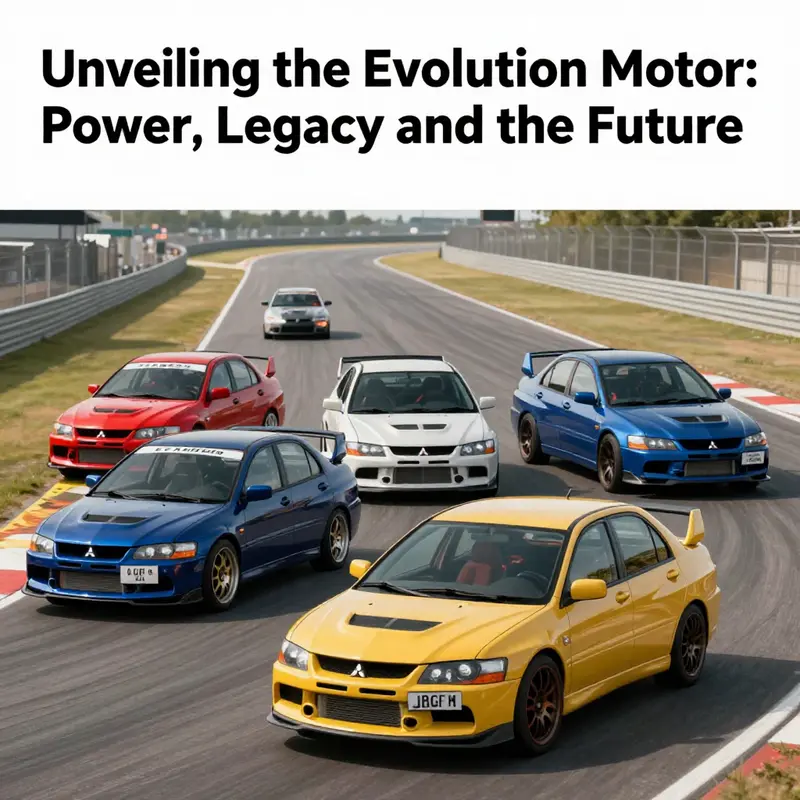

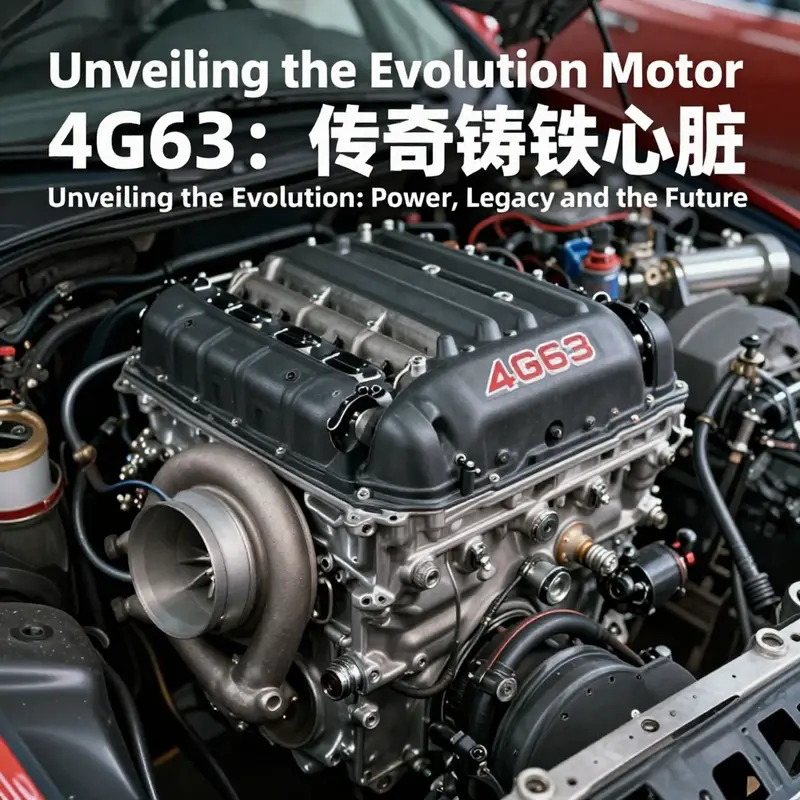

The engine of the Lancer Evolution has always been more than a collection of pistons and gears. It has been a compact manifesto of engineering courage, a tale told in metal that ties the thrill of rallying with the precision of modern science. From EVO I through EVO IX, the 4G63 iron block stood as the pulse of the lineage, a 2.0-liter inline-four that could be pressed into shapes of power by boost and tuning yet stubbornly durable under the unforgiving demands of high-traction, high-heat competition. Its frame was not merely a cage for combustion but a statement: in rally, the heart holds and the chassis forgives. When enthusiasts speak of the 4G63 as the “legendary iron heart,” they are naming a threshold in performance culture. Early iterations delivered around 195 horsepower, enough to carve corners with a surging torque curve that made the Evo feel almost alive at the edge of grip. Over the years, the power curve climbed toward the three-hundred-horsepower neighborhood, and with the right turbo and manifold, the engine could respond with a precision that kept the driver in control even as boost rose and the turbo whistled a warning to the tires that the road ahead would demand every ounce of grip. The 4G63 earned reverence not merely because it produced numbers but because it taught a generation how to extract reliability from aggression. In models that became symbols of the era—the EVO III and the Tommi Mäkinen Edition among them—the engine and the car formed a symbiosis. It was a time when the winner’s circle preferred a red profile and a growl that could travel through the canyon like a shout from a rally stage, a sound that still stirs even as the chapters of the line move forward and away from the factory floor.

Yet alongside the iron heart stood a second, contrasting thread in the Evo story—the lighter, more agile, aluminum-focused chapter that began in the later generations and culminated in the Evolution X era with the 4B11T. This engine marks a transition into a new era of balance: a 2.0-liter inline-four turbo with an all-aluminum block, crafted to shed every possible gram without compromising the structure needed to live through brutal high-output cycles. The project was straightforward in ambition but complex in execution: keep the revs responsive, but add the torque that makes four-wheel drive feel as if it were carved from a single slab of momentum. The result was a factory specification that began with roughly 295 horsepower and 366 Newton-meters of torque, a stance that made the Evo X feel lighter on its feet than its predecessors while preserving that characteristic, surgical throttle response. Titanium turbine blades framed the turbocharger, shaving lag and increasing peak efficiency, a choice that reflected a broader engineering philosophy: performance must arrive quickly, and it must be controllable. It is not merely about raw power; it is about the feel of power at the driver’s left leg and the ability to translate intent into speed with minimal delay. In the hands of enthusiasts and tuners, the 4B11T became a canvas for further refinement. Some of the most dramatic demonstrations of its potential happened in specialized variants like the EVO X FQ-440 MR, where the factory recipe met deep tuner knowledge, and the output crept beyond the four-figure mark for street-legal performance. In that space, the combination of lighter weight and strong combustion geometry allowed rapid acceleration and precise throttle modulation to keep the car balanced through rapid transitions—a hallmark of what a modern turbocharged four-wheel-drive should feel like.

But the Evo story is not only about what was; it is also about what could be. The thread of possibility threads through the company’s mid-2000s concept projects, the discussions in boardrooms about electrification, and the quoted optimism that returns in whispers at major shows. The Lancer Evolution MIEV concept in 2005 offered a bold glimpse: wheel-hub motors and a drive philosophy aimed at eliminating response delays and redistributing energy where it could most improve dynamics. The concept was ahead of its time in the way it treated heat, weight, and the potential for modular torque delivery, yet it faced the plain physics of real-world production: thermal management, packaging, and the economics of high-performance electrification. The concept proved instructive, not just aspirational, because it laid out the kinds of questions a modern Evo would need to answer if it were to reappear at the pinnacle of performance in a world already moving toward electrification.

In the years that followed, the narrative drifted toward a more explicit electrified horizon. Interviews and industry analysis from the 2025 Tokyo mobility showcase era suggest that a revival remains possible, but not as a simple rehash of the old formula. The engineering voice guiding the conversation emphasized a future where electricity is not merely an option but an enabling force for handling and speed. The idea is not to abandon the pedigree but to extend it—a chassis that can exploit instantaneous electric torque, a drivetrain architecture capable of four-motor precision, and a control system so refined that it can distribute power to each wheel in real time with the kind of fidelity that the old all-wheel-drive layout could only dream of achieving with mechanical torque vectoring. The hope, as articulated by engineers and observers alike, is to combine the Evo’s storied handling with a new energy architecture that aligns with global emissions goals without surrendering the sense of immediacy that defined the original machines.

This vision does not exist in a vacuum. Several strategic challenges must be overcome. First, the base Lancer line has long since ceased production, which means any new Evolution would need to be built from a clean slate, then tested against the high heat, high-load realities of competitive performance. Second, the question of collaboration remains a live issue. The conventional path of platform sharing and alliance partnerships is not guaranteed to produce a direct resource advantage, especially when the brand’s current focus is on lean profitability and on strengthening other performance lines. Even the perception of revival has to contend with the risk of creating anticipation without a clear, deliverable product road map. Third, there is the question of the market’s appetite for a new high-end Evo that can justify the investment required for fresh platforms, powertrains, and manufacturing lines. The revival would likely hinge on a combination of performance, efficiency, and an ability to persuade new buyers that the Evo’s core appeal—its balance of grip, torque, and control—can transcend a generation that has grown up with electrification as the default expectation.

Yet the strategic logic of electrification offers a compelling answer to the core demand: how to deliver true, controllable performance in a world where emissions rules, fuel economy expectations, and urban driving patterns constrain traditional powertrains. The proposed architecture sketches range from a plug-in hybrid concept inspired by a proven, compact gasoline engine paired with front and rear electric motors to a full BEV that uses four independently controlled motors to realize torque vectoring and yaw control at a level of precision previously associated with mechanical systems only in theoretical design rounds. In the more optimistic scenario, a hybridized Evo would preserve the essence of the traditional turbocharged four with a modern energy system integrated to reduce unsprung mass and improve thermal stability, letting the car breathe under load as electricity does the heavy lifting of instant torque and torque distribution.

In the broader cultural sense, electrification promises something more than speed; it promises a way to sustain the Evo’s identity while honoring the community that has built up around it—tinkers who understand the art of tuning an engine, rally fans who can hear a rumble and recognize a lineage, and drivers who measure a car’s worth not just by top speed but by how smoothly it can be coaxed through the corner at the limit. The memory of the 4G63’s iron heart and the 4B11T’s aluminum lightness is not simply nostalgia; it is a study in materials and architecture—the way a machine learns to leverage strength and lightness as a continuous spectrum, not as a fixed binary. The move toward electrification does not erase the past; it invites the past to evolve, to inform, and to refine the dynamic equations that govern grip, balance, and instantaneous response.

For enthusiasts who want a tangible sense of the technical thread linking past to possible, revisiting the mechanical lineage—especially the durability and rigidity of the turbocharged core—remains instructive. A concrete touchpoint is the exploration of high-strength, lightweight components that can endure the repeated stresses of spirited driving without adding unacceptable mass. In that spirit, a closer look at the attainable milestones within the 4B11T lineage—along with their potential for further refinement—offers a practical map of how a modern Evo could retain its core driving charisma while embracing new propulsion technologies. See the detailed discussion on lightweight, high-strength options here: 4B11T billet block.

As the industry moves toward configurations that can combine electric torque with a refined, emotive driving experience, the Evo’s myth remains a powerful lens for development. Electrification, if executed with sensitivity to the Evo’s handling philosophy, could unlock a level of control and throttle responsiveness that makes the old turbo lag feel archaic by comparison. The Electrified Evo would likely not replicate the past’s exact powerband but would instead offer a different, perhaps more intuitive, expression of power—instant and controllable, capable of being dialed in with the precision a rally stage demands. From a design and engineering standpoint, the challenge is not merely to replicate the sensation of turbocharged speed but to craft a dynamic under the constraints of modern safety, efficiency, and consumer expectations. The reward, if achieved, would be a new kind of driving experience—the same shredded-tire, corner-carving exhilaration that defined the Evo while tempered by the calm certainty of electric torque management and advanced all-wheel control.

For readers seeking a broader context on performance electrification trends beyond the Evo story, industry analyses and test drives from established automotive media offer useful perspectives on how four-miber motors and multi-motor torque vectoring reshape the balance between speed, precision, and energy use. External resources can illuminate how manufacturers are integrating multi-motor architectures with sophisticated energy recovery, thermal management, and drive mode systems to deliver consistent performance under varied conditions. As the chapter closes on this chapter of Evo’s motor saga, the dialogue itself shifts from a singular power plant to a holistic approach to performance and sustainability, a conversation that continues to unfold as engineers weigh the legacy with the leap forward. For readers who want to explore these broader trends in greater depth, see the external resource linked here: https://www.caranddriver.com.

跃动的心脏:从 EVO I 到 EVO X 的 Lancer Evolution 动力演化

Lancer Evolution 自1990年代初问世以来,便以“车轮上的极限挑战”著称。它不仅是一系列高性能车型的集合,更是一部关于动力系统如何在极端条件下被持续推升的活教材。核心在于发动机与传动系统的协同进化,以及随之而来的一系列轻量化、扭矩管理与扭矩分配技术的突破。在这一段长达近二十年的旅程中,4G63 作为铁心脏的时代,逐步为后来的轻量化、电子化和更高效的调校奠定了基石;而进入 EVO X,4B11T 的出现则象征着三菱在动力技术上的全新纪元。通过对这两代核心引擎及其随同系统的演变进行梳理,可以看到一个品牌在赛车血统驱动下,如何把“速度的可控性”和“耐久性”并行推进,最终形成一套以四驱、扭矩分配和底盘响应为核心的完整性能哲学。

在早期的 EVO I-EVO IX 时代,4G63 成为无可替代的发动机符号。2.0 升直列四缸涡轮增压、铸铁缸体的组合,赋予了这台发动机极强的抗压能力与耐久性。铸铁缸体的刚性,使得高应力工况下的可靠性成为改装者的信任底座,也成为勒紧涡轮、追求高马力改装时最稳妥的选择。初代 EVO I 的官方输出约为 195 匹马力,一直是拉力与街道之间的桥梁。当后续代际不断在气门驱动、排气效率和可控性方面实现微调时,4G63 的潜力像被慢慢挖掘出来:从气门扬程的改进,到更高容量喷油嘴的应用,再到采用更轻量的涡轮叶扇,车辆的响应与推重比逐代提升。到了 EVO VI 时,尽管最大马力仍被尺子上的数字锁定在约 280 匹,但峰值扭矩的显著提升和扭矩带来的爆发力让这台发动机在赛道与改装界的地位更加稳固。

到了 EVO IX,4G63 达到了它在耐用性和性能之间的极致平衡。该代不仅在扭矩曲线与低速响应方面做出改进,还首次对气门正时系统进行了实质性升级——可变气门正时技术(MIVIC)的引入,让发动机在不同工况下拥有更佳的进排气效率与持续输出能力。这一代的综合调校使 EVO IX 成为许多车迷心中的“红头”之心,既能在弯道中提供明确的指向性,也能在直线加速中维持稳定的动力输出。与此同时,传动系统的进化同样不可忽视。早期的密齿比五速手动变速箱搭配黏性耦合式中央差速器(VCU)在当时已经具有极强的可用性,但随着高性能需求的提高,AYC(主动舵角控制系统)在第四代 EVO IV 的出现成为一大突破。它通过对后轴左右车轮的扭矩分配进行主动控制,使得转向响应与循迹性在复杂路况下得到显著提升。

进入 EVO VII 时,ACD(主动中央差速器)首次使前后轮扭矩分配更加智能化,提升了脱困能力与高速稳定性。这一代的探索还包含了全球独一无二的自动变速箱版本 GT-A,为了在传统手动与潜在自动之间寻找平衡,尽管最终未能大规模落地,但它的试验精神体现了三菱在传动系统上的多维尝试。到了 EVO VIII 与之后的 MR 版在美国市场的落地,螺旋式限滑差速器开始被采用,以更直接的扭矩传递和更快的响应来应对高强度的赛道压力。

与4G63 的历史脉络并行推进的是 4B11T 的诞生与应用。 EVO X 的到来,标志着次世代动力系统的正式启用。全新 2.0 升直列四缸涡轮增压发动机采用铝合金缸体,明显减轻了发动机整体重量,提升了操控性与操控中的反馈速度。该代的官方输出为约 295 匹马力、366 牛·米的峰值扭矩,较前代在重量与响应方面实现了更优的综合表现。涡轮方面,采用钛合金涡轮叶扇,使油门响应更迅猛,热管理也得到了显著改进。与之匹配的,是全新的双离合器六速半自动变速箱(TC-SST),带来更顺滑且更迅速的换挡体验,这在传统的街道与赛道双重使用场景下,显著拉低了换挡时的动力断续,提升了线性输出的持续性。

EVO X 的外观也承载着对未来的勇敢设想。极具攻击性的前脸与尖锐的灯组设计不仅在视觉上传达出强烈的性能暗示,也在空气动力学层面体现了高度的考虑。与此同时,品牌对轻量化的坚持并未止步于发动机本体的改良。资料显示,第六代的TME 版等高规格版本采用了钛铝合金涡轮叶、对旋转质量的优化,都是围绕着“在不牺牲强度与耐久性的前提下,减轻整体质量”的核心目标来执行的。

尽管 EVO X 是这一传奇系列的终章,但关于未来的传言却没有真正停摆。自动化与电气化的复兴在全球汽车界持续发酵,三菱对性能极致的渴望并未熄灭。早在 2005 年,Lancer Evolution MIEV 概念车就已经提出轮上电机(In-Wheel Motor)的纯电驱动设想。虽然因散热与能量管理难题未能实现量产,但这一尝试体现了品牌对性能边界的持续逼近。更令人关注的是,2025 年日本移动出行展上,工程师关于“未来新一代 Evolution 的技术储备”的发言被广泛解读为一个信号:新一代车型或将结合插电式混合系统,甚至是纯电方案,力图在保持四驱精准与动态响应的同时,迎接电动化带来的新维度控制。

从历史角度看,4G63 的铸铁心脏承载着极限耐久与高强度改装的基因,而 4B11T 的铝合金心脏则承载着“轻量化、快速响应、复杂动力系统协同”的现代性能哲学。两者之间,是一个品牌在发动机材料、热管理、涡轮工艺、变速箱技术、以及驱动系统智能化方面不断拉伸边界的连续线。正是这种连续性,使 EVO 系列成为全球车迷心中的象征:它不仅代表一个时代的竞速标准,更呈现出一个品牌在技术、工程与驾驶乐趣之间寻求平衡的坚持。

最后,EVO X 的停产不仅是技术迭代的自然结果,也是汽车产业向混合与电动化转型的大趋势的缩影。它的故事,仍在被车厂与改装圈共同讲述;它的心脏——无论是 4G63 的铸铁肌肉,还是 4B11T 的铝合金心脏——都以不同的方式,持续推动着“驾控的极限”这一主题向前展开。对于未来的我们而言,Lancer Evolution 的动力演化不仅是历史的回顾,更是对工程师在复杂约束条件下追求极致性能的致敬。

若需更深入了解 4B11T 的铝合金结构及其在热管理和轻量化方面的实际应用细节,可参考以下内部资源:4B11T billet block。

外部参考与扩展阅读:

- https://en.wikipedia.org/wiki/MitsubishiLancerEvolution

内部链接:

- 4B11T billet block

Lancer Evolution Motor与汽车改装文化的深远影响

The Lancer Evolution has always stood at the crossroads of engineering audacity and a shared passion for speed. Its motors are not merely powerplants; they are narratives that tell us how people translate a car’s potential into a living culture. From the earliest generations to the final bows, the Evolution’s engines did more than move a car forward. They invited a global community to learn, to experiment, and to express itself through performance. The essence of the EVO lies in the way its core powertrains shape both the driving experience and the social ritual that grows around it. In that sense, the Evolution is as much a social artifact as a technical achievement, a symbol of how a machine can become a language for a community that cherishes speed, control, and a shared appetite for progress.

The 4G63 engine, a 2.0-liter inline-four with a cast-iron block, became the enduring heart of EVO I through EVO IX. Its rugged architecture offered a robustness that allowed enthusiasts to push the limits of boost and airflow with a level of reliability that few competitors could match. This durability transformed tinkering from a risky hobby into a practical pursuit; builders could chase four-figure horsepower targets with a sense of security that the engine would not crumble under the pressure. In rally and street, the 4G63 enabled a kind of alchemy: ordinary parts could be stressed into extraordinary outputs, and the chassis—seasoned with a torque-rich surge and a cockpit that rewarded precise input—turned raw numbers into confident handling. The engine’s life-lofting trait—the ability to absorb endurance and punishment—made it the “foundry” for a culture that valued repeatable results and the joy of incremental improvement.

As generations evolved, Mitsubishi shifted gears with the 4B11T that powered the Evolution X. The new era leaned on aluminum for reduced weight, pushing the entire dynamic package toward quicker responses and sharper steering feel. The factory tune delivered a notable punch—nearly 300 horsepower and a robust torque curve—but the real story was the lighter, more agile chassis that could harness that power with greater finesse. A modern turbo setup, paired with lighter rotating assemblies and refined electronics, translated into acceleration that felt less like a cliff and more like a precise, surging arc. This was not simply more horsepower; it was a different kind of performance—one that rewarded throttle finesse, mid-corner pace, and mechanical grip in a way that allowed drivers to probe the car’s limits with a clear sense of boundary and control. The 4B11T era broadened what people believed was possible on both road and track, and it encouraged a shift in the culture from raw power to a more sophisticated, well-balanced performance philosophy.

The coexistence of iron-block durability and aluminum-block lightness forged a unique dual lineage in the Evolution’s cultural DNA. On one hand, the 4G63’s legendary strength taught a generation to respect the engineering and to trust the engine as a platform capable of handling ambitious power at relatively accessible costs. On the other hand, the 4B11T’s lighter skeleton opened doors to more intricate chassis work, stiffer suspensions, and aero refinement. Enthusiasts began to see tuning as a holistic discipline—engine performance, driveline behavior, suspension tuning, aerodynamics, and heat management all intertwined to deliver a complete driving experience. This holistic mindset helped foster an ecosystem where people asked how a car could stay balanced with more grip, rather than simply how fast it could accelerate. It was the difference between chasing peak horsepower and chasing a precise, repeatable cadence on the road and on the track.

The Evolution’s rally heritage cemented its position as a cultural touchstone. The car’s WRC lineage gave it credibility as a platform where performance was not only possible, but expected under demanding conditions. This rally pedigree seeded a narrative of perseverance and technical curiosity that traveled far beyond the stages. In the garages and on the forums that sprang up around the EVO, owners discussed everything from boost control strategies to heat management during long sessions, from gear ratios to drivetrain tune for sub-second transitions. This environment nurtured a culture where modification was not a departure from reliability but a careful extension of it. The EVO’s engineering language—rapid mid-range response, a chassis that invites aggressive but controlled cornering, and an engine that rewards deliberate, data-driven tuning—became a blueprint for countless projects that followed.

Beyond the engine bays, the Evolution’s influence radiated through the broader automotive environment. The car’s popularity catalyzed a vibrant aftermarket ecosystem that included aero parts, suspension components, brake systems, and interior refinements. Aesthetics and performance converged in the yearly rituals of upgrading bodywork, lightening weight where it mattered, and tuning the cockpit for better feedback and usability. The carbon-fiber bonnet hood, in particular, became a visible symbol of the practical and aspirational side of the culture: a lighter, stiffer front end that reduces lift and enhances steering feel, while signaling a craft-minded commitment to performance. This particular improvement—embodied in the simple act of swapping a bonnet—advised a broader truth: the EVO’s magic lay not in any single element, but in how a community stitched together many small, deliberate choices into a coherent performance philosophy. And the linked piece carbon fiber bonnet hood for Mitsubishi Lancer Evo X epitomizes how a technically focused upgrade can resonate culturally, turning a functional modification into a shared story of weight reduction and improved handling.

Culturally, the EVO helped crystallize a distinctive JDM identity—a fusion of speed, precision, and a relentless pursuit of improvement. Its fans internalized a philosophy that speed alone was insufficient without control, and that the car’s personality was revealed through how well a driver could balance courage with finesse. That ethos spread through gatherings, guides, and the countless hands-on exchanges that define how modern automotive culture learns. The EVO’s influence also manifested in how communities organized themselves around tuning projects. Enthusiasts built networks that crossed continents, sharing data on boost curves, fuel mixtures, and cooling strategies. The car served as a common language for people who spoke in engine maps and suspension sag, translating technical curiosity into a shared sense of accomplishment when a build finally ran with the precision and predictability that the driver had envisioned.

This culture did not exist in isolation. It was shaped by the car’s continuous dialogue with performance, durability, and design. The Evolution’s chassis, with its four-wheel-drive confidence and a cockpit that encouraged aggressive yet controlled inputs, became a canvas for experimentation. The car offered an accessible gateway into the broader world of performance engineering: a place where a determined owner could replace a single component, observe the effect, and then refine further. The result was a community that valued iterative learning and the slow, satisfying arc of improvement—a process that transcended mere speed and echoed a philosophy of disciplined, craft-driven engineering.

Looking ahead, the future of Lancer Evolution is being framed not by nostalgia alone but by a conversation about electrification and intelligent drive. In the mid-2000s Mitsubishi explored wheel-driven electric concepts that hinted at new approaches to torque delivery and vehicle dynamics. Although those concepts did not reach mass production at the time, they demonstrated a willingness to rethink the fundamental relationship between power, weight, and control. In recent years, sources from the engineering community have suggested that a new Evolution is still on the table, potentially as a plug-in hybrid or even a BEV, depending on regulatory and market forces. The idea of a multi-motor arrangement—four motors with coordinated torque vectoring—appeals because it promises the same sense of immediacy that defined the earlier generations, but with a new capability to manage traction, steering feel, and heat under electric propulsion. The challenge remains substantial: how to maintain the driver’s intimate connection with the road while ensuring reliability across a broader performance envelope. Cooling, thermal management, and the integration of sophisticated control software will be central to any revival. Yet the spirit of the EVO endures in that very possibility—the belief that performance cars can evolve without surrendering their core identity.

The Lancer Evolution’s motors—whether the stalwart 4G63 or the leaner 4B11T—are more than mechanical devices. They are living threads in a global tapestry that ties together racing heritage, garage tinkering, and a culture of collective learning. The Evolution’s engine stories teach us that performance is not a solitary pursuit but a shared practice, a way of crafting skill, taste, and courage through the continuous act of adjusting, measuring, and refining. The chassis stays as a responsive partner; the engine remains a symbol of resilience; and the community persists as the engine’s most enduring artifact. In that balance—between power and control, between the individual and the collective—the Lancer Evolution’s motor narrative continues to influence how enthusiasts approach every challenge on the road, on the track, and in the imagination.

External reference: https://en.wikipedia.org/wiki/MitsubishiLancerEvolution

Final thoughts

The legacy of the Lancer Evolution motors, particularly the 4G63 and 4B11T, is a testament to Mitsubishi’s commitment to performance and innovation. From their ferocious power outputs to their contributions to automotive culture, these engines have not only defined a generation of vehicles but have also shaped aftermarket tuning and motorsport engagement. With electrification on the horizon, the future of the Evolution series promises to blend traditional performance with cutting-edge technology, maintaining its reverence in the automotive community. As we anticipate the next chapter in this iconic series, businesses involved in the automotive industry could leverage these insights to foster growth and innovation in their endeavors.