For business owners, understanding the technology and capabilities behind the Mitsubishi Lancer engines is essential. The Mitsubishi Lancer, renowned for its robust performance and reliability, showcases a spectrum of engines that cater to various needs—from efficient urban mobility to high-performance driving. This article will unpack the MIVEC technology that underscores its capabilities, delve into different engine options, examine potential performance upgrades, trace the evolution of its engines, and provide insight into the specifications and efficiency ratings that make this vehicle an attractive choice for businesses seeking both utility and performance.

Valve-Tuned Precision: How MIVEC Shapes the Mitsubishi Lancer’s Engine Story

The Mitsubishi Lancer’s engine narrative is not a single note but a layered symphony of timing, aspiration, and pragmatic engineering. At its heart lies MIVEC, Mitsubishi’s signature approach to variable valve timing. This technology isn’t merely a feature on a spec sheet; it is a guiding principle that lets the Lancer bridge two often conflicting driving worlds. In city traffic, with stop-and-go shifts and the need for smooth, predictable response, and on winding back roads or a highway sprint, when throttle input demands both immediacy and control. MIVEC works behind the scenes, modulating the timing of the intake valves across the rev range so the engine breathes more efficiently at low speeds and delivers better power when the throttle is opened wider. The result is a car that feels livelier than its displacement might suggest, without the buyer needing to choose between economy and performance at the showroom floor. The engineering logic is straightforward in concept: adjust when the valves open and close to shape the combustion process in real time, guided by an ECU that reads RPM, air intake, throttle position, and coolant temperature. In practice, this translates to smoother throttle response, more linear power delivery, and a broader usable torque curve. The Lancer’s MIVEC-equipped engines are testament to a philosophy that performance and efficiency are not mutually exclusive, but rather complementary outcomes of intelligent valve timing and precise calibration across the engine map.

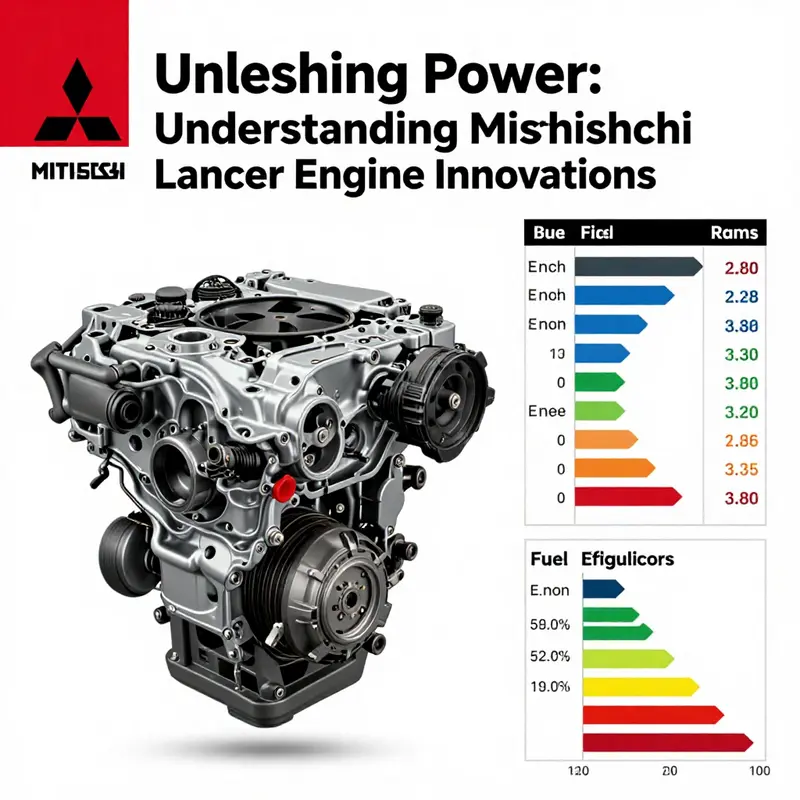

The lineup illustrates how MIVEC can scale from practical daily driving to sportier applications while maintaining a cohesive identity. The 1.6-liter 4B11 MIVEC is a compact, efficient workhorse designed for urban mobility. It emphasizes low-end torque and steady, predictable performance that makes city commutes less taxing and maintenance costs easier to manage. In numbers, it typically produces around 110 to 120 horsepower, with combined fuel economy hovering in the neighborhood of 30 to 35 miles per gallon. This combination of modest power and excellent efficiency makes it a sensible choice for those who prioritize running costs and reliability. Yet, the same MIVEC logic that tallies up the miles per gallon also supports a surprisingly responsive character when the accelerator is pressed more decisively. The engine’s valve timing adjustments help mitigate the traditional trade-off between efficiency and power, allowing the Lancer to feel more confident in everyday acceleration without demanding excessive fuel at the pump.

Moving up to the 2.0-liter family, the naturally aspirated 2.0L 4B11 MIVEC embodies a different balance. In this variant, the emphasis shifts toward mid-range power delivery and refinement, with output in the approximate range of 148 to 160 horsepower and a broader, more usable torque band. Real-world driving benefits include confident highway merging, smoother passes, and a sense of steadiness when carrying a payload or cruising at steady speeds. The fuel economy numbers, often in the 27 to 32 miles per gallon range in mixed conditions, reflect a design that aims to minimize penalties across varied driving scenarios rather than optimizing for overt efficiency in a single use case. Here, MIVEC’s valve timing modulation contributes to a more linear throttle response, so the driver experiences consistent شي progressive acceleration rather than a sudden surge that can catch the unprepared by surprise. The appeal lies in the versatility—the output that makes daily commutes feel effortless while still offering a surprisingly capable platform for longer trips.

The pinnacle of the MIVEC story in the Lancer is the turbocharged 2.0L MIVEC, the powerplant that underpins the Evolution and Ralliart variants. Here the same valve-timing intelligence is married to a forced induction system, creating a symphony of rapid boost onset and controlled, predictable fuel management. The turbocharged configuration pushes far more aggressive power, delivering rally-inspired responsiveness that delights enthusiasts who crave speed with a chassis that can handle the cadence. MIVEC’s dual role—timing optimization on the intake side and the turbo’s capacity to increase air mass—produces a combination of strong peak power, a broad usable range, and a throttle feel that remains approachable rather than abrupt. The overall experience is one of confidence: you can tip in at highway speeds and feel the engine respond with vigor, yet the system still retains the civility required for daily driving, letting the car glide through city streets without demanding excessive attention from the driver.

Beyond these core options, the Lancer has had other engine options that informed the broader engineering philosophy of the line. The 1.8-liter 4G93 engine, found in older or region-specific models, offered a balance of power around the 138 horsepower mark with respectable fuel economy. Its performance was notably stronger than the earliest small-displacement engines and signaled Mitsubishi’s willingness to push for more capability without sacrificing everyday usability. In earlier generations, smaller displacements such as a 1.5-liter engine appeared in certain markets, providing quicker acceleration than the tiniest engines on offer but stepping back in absolute power compared with the more mature 2.0-liter variants. These options contributed to a broader fleet where the Lancer could be configured to emphasize economy, reliability, or performance, depending on the market and the intended customer base.

In discussions of performance, the physical relations of the engine to the rest of the car are as important as the raw numbers. The choice of engine mounts, for example, has a tangible impact on the driving experience that often goes unappreciated. Hydraulic mounts, with their fluid-filled chambers, excel at isolating vibrations and noise, delivering a quiet, comfortable ride that suits daily commuting and family use. Solid rubber mounts, by contrast, reduce flex and reduce manufacturing costs, offering durability and a stiffer feel that appeals to budget-conscious owners and those who prefer a more connected sense of the engine’s presence. Polyurethane mounts exist as a middle ground, delivering improved engine control and responsiveness without sacrificing too much vibration damping. The choice of mount is a subtle but meaningful way to tailor the Lancer’s personality to the owner’s priorities, and it reveals a broader design ethos: the Lancer is built to adapt, not just to perform.

Performance-minded enthusiasts often look beyond alignment to the intake and exhaust paths that feed the breathing of the engine. Upgrades and refinements can include an OEM-tuned throttle body swap or refinements that improve airflow through the intake system. When executed with care, these changes can yield noticeable benefits, such as improved throttle response and a modest uplift in efficiency, with reported gains in the vicinity of up to 15 percent in power and fuel economy relative to stock configurations. The essence of these upgrades is not to create a race engine out of the Lancer, but to refine the engine’s ability to draw in air signal and deliver it with precision across operating ranges. This aligns with the MIVEC philosophy: optimize the intake path and the timing in concert to extract more usable energy from every combustion cycle.

For those with a taste for hands-on improvement, the Lancer’s platform presents a pathway to enhancement that respects the car’s original intent. The option to explore components that strengthen the engine’s underlying foundations—such as a billet-block approach for the 4B11 family—illustrates the ongoing interest in making the engine hardware more robust while preserving the characteristics that define the Lancer’s identity. Enthusiasts have pursued such paths to increase stiffness and reliability under higher power demands, which can be especially relevant for turbocharged variants that push the engine toward track-ready levels of performance. The idea here is not to reinvent the wheel, but to give the engine a sturdier home in which MIVEC can operate at its most effective. The practical takeaway is that the Lancer’s engine family supports an incremental, thoughtful upgrading path that respects the vehicle’s heritage while addressing the demands of modern performance expectations. To explore this kind of upgrade, one can reference dedicated resources that detail the compatibility and considerations involved in a billet-block approach for the 4B11 family.

The thread that runs through all these considerations is a core principle: MIVEC provides a dynamic, adaptive approach to valve timing that allows the Lancer to perform across a spectrum of use cases. From the quiet, efficient commute to the exhilarating feel of a turbocharged rush, the engine’s timing, air intake, and fuel management cooperate to deliver power where it is needed, when it is needed, and in a form that remains controllable and predictable. The Lancer’s engine story is not simply about horsepower figures; it is about a holistic calibration that respects efficiency, drivability, and durability. The MIVEC-enabled lineup demonstrates how a manufacturer can offer a broad range of choices without fragmenting the underlying engineering philosophy. The result is a family that feels coherent—different in specification, yet unified in approach—ensuring that every driver can find a Lancer that matches their priorities, whether that priority is daily reliability, refined cruising, or spirited performance. For readers who want to delve deeper into the technical specifics, concise overviews are available that describe how the ECU-driven valve timing interacts with each variant’s displacement and turbocharging strategy, underscoring a single, unifying idea: intelligent timing is the key that unlocks the Lancer’s flexible engine character.

For those who want a quick navigation point within the broader ecosystem of Lancer engine discussions, one practical reference worth exploring is a dedicated technical page that covers components relevant to the 4B11 family and its performance tuning options. This resource offers a compact overview of the hardware and upgrades that can complement MIVEC in the modern Lancer, providing a useful bridge between pure theory and hands-on modification. 4b11t billet block provides a starting point for understanding how stronger foundations can support higher power delivery while maintaining reliability. This chapter, however, remains focused on the intelligence of timing and the broad spectrum of engine variants that make the Lancer a versatile platform rather than a device designed for a single purpose. The ongoing narrative is that MIVEC is not a single feature but a systemic approach to engineering that shapes how the Lancer feels in every mile.

In sum, the Mitsubishi Lancer’s engine lineup reflects a robust philosophy: adapt the engine to the driver and the road, not the other way around. MIVEC makes that adaptability tangible, widening the performance envelope without abandoning daily practicality. The 1.6-liter, the 2.0-liter naturally aspirated, and the turbocharged 2.0-liter each offer a distinct flavor, yet they share a common thread—the capacity to optimize combustion through smart valve timing. The hardware options—engines, mounts, and selective upgrades—work together to present a cohesive, flexible package. It is a story of how clever engineering can deliver both efficiency and emotion, ensuring the Lancer remains relevant across generations and driving styles. As the chapter on engine technology closes, the broader arc remains clear: the Lancer’s engine family is a living interface between innovation and everyday usability, a testament to how engineering can empower a car to travel beyond its wheelbase and propel its journey with purpose.

From Economy to Rally Power: The Engine Options That Shaped the Mitsubishi Lancer

The Mitsubishi Lancer’s engine lineup reads like a map of the model’s personality over decades of refinement and competition. At its core lies a philosophy that values efficiency without sacrificing the thrill of responsive power when the moment demands it. This balance is embodied in Mitsubishi’s MIVEC technology, a system that tames the harsh extremes of power delivery by actively timing the intake and exhaust valves. The result is a family of engines that can glide through city streets with admirable fuel economy and then spring to life when a driver asks for confident acceleration or a surge of turbocharged excitement. Across generations and markets, the Lancer has offered engines that meet different needs—compact and thrifty for daily errands, robust and smooth for family use, and fiercely tuned for rally-inspired performance. The narrative of these engines is not simply a catalog of displacements and power ratings; it is a story of how engineering choices respond to shifting demands, regulatory environments, and the evolving expectations of drivers who want a practical car that can still light up a twisty road when the mood strikes.

In the early chapters of the Lancer’s engine saga, the emphasis often leaned toward efficiency and broad usability. The 1.6L 4B11 MIVEC, for example, is a compact, efficient double overhead cam unit designed with urban commuting in mind. It delivers dependable performance with modest horsepower and excellent low-RPM responsiveness, paired with fuel-saving potential that suits city dwellers and budget-conscious buyers alike. Its limitations are clear, however: power output sits in the range of roughly 110–120 horsepower, and the platform offers limited headroom for high-performance tuning. This is the Lancer’s bread-and-butter engine for many users, a mill that makes daily life comfortable while keeping running costs in check. Alongside it, the older but still relevant 1.8L 4G93 powerplant found life in base models in several markets. It produced roughly 138 horsepower in many configurations, a respectable step up from smaller displacements while retaining the reliability and efficiency that families and commuters value. And in some regions and generations, smaller early-displacement options—such as a 1.5L engine—were deployed to prioritize lighter weight and nimble city driving, reminding buyers that there was a time when the Lancer’s approach to mobility was simply about getting from point A to point B with sensible economy.

The 1999 model year stands out as a watershed moment for the Lancer’s performance narrative. Base models commonly carried the 1.8L 4G93 engine, a naturally aspirated unit designed for reliability and everyday driving duties. Yet for buyers who craved a more dynamic experience, the GT and GSR variants were powered by the legendary 2.0L turbocharged 4G63 engine. This turbocharged heart, known among enthusiasts for its durability and tunability, laid a foundation for the Lancer’s reputation in the rally and performance communities. The turbocharged 4G63 could be coaxed toward impressive outputs with targeted upgrades—turbochargers, intercoolers, and engine control tuning—all while maintaining a robust, road-ready feel. It was a period where Mitsubishi demonstrated that the Lancer’s chassis could hold a performance-oriented engine without losing the everyday usability that made the model popular with a broad audience. The turbo option also served as an introduction to the broader performance ecosystem that would develop around the Lancer line in the years to come.

As the lineup matured into the late 2000s and beyond, the engine strategy shifted toward standardization and modernization, especially in non-performance models. The 2008–2017 era saw a move toward the 2.0L 4B11 naturally aspirated inline-four as a widely used baseline, paired with the larger 2.4L 4B12 in higher trims and certain markets. The 4B11 family introduced a modern balance of power and efficiency, with horsepower typically in the neighborhood of the mid-to-high teens in kilowatts, translating to roughly 140–160 horsepower depending on tuning and market. This generation benefited from Mitsubishi’s MIVEC technology, which helped optimize valve timing across a broad RPM range. The result was a drivetrain that could deliver smooth and linear throttle response for daily driving while still offering a lively mid-range punch when required. The 2.4L 4B12 variant added refinement and quicker acceleration, especially when paired with the right transmission and gearing, contributing to a more confident highway drive and a more engaging overall driving experience in higher-trim configurations.

For performance-focused buyers, the Lancer’s high-output story persisted in the 2.0L 4B11 Turbo MIVEC offerings found in Evolution and Ralliart models. This turbocharged engine carried the rally-bred DNA that defined Mitsubishi’s racing heritage, delivering aggressive power and responsive throttle behavior ideal for enthusiasts chasing track-ready performance. The Turbo variant is not just about raw numbers; it’s a package that marries turbocharged acceleration with the MIVEC’s valve-timing optimization to keep power delivery manageable and predictable at different RPMs. Across these generations, the turbocharged option stood as a flagship, exemplifying how the Lancer could transition from a practical daily driver to a capable performance machine with the right engineering and a tuned powertrain.

Beyond the MIVEC-equipped mainstays, the Lancer’s engine family included other configurations that reflected regional preferences and product positioning. The 1.3L and 1.6L engines were part of earlier or more niche iterations that prioritized lighter weight and agility, elements highly valued in certain markets and during particular model years. These engines underscored a core lesson about the Lancer: its powertrain options were not a one-size-fits-all solution, but rather a spectrum designed to meet a spectrum of needs. The engine mounts used in these cars further shaped the driving experience. Hydraulic mounts offered excellent vibration and noise isolation, enhancing comfort for daily commuting. Solid rubber mounts provided rigidity and durability at a lower cost, appealing to budget-conscious buyers and those replacing aging components. A polyurethane upgrade could strike a middle ground, delivering firmer control over the engine while still absorbing substantial vibration—an appealing option for drivers seeking a more connected feel without sacrificing everyday usability.

Engine upgrades have always been part of the Lancer’s ongoing narrative, and a practical example of this mindset is the potential upgrade to the intake system. A direct OEM-type throttle body upgrade—broadly speaking, an enhanced flow component designed for the 1996–2014 generation window—could yield improvements in airflow that translate to more responsive throttle behavior and, in some cases, power and efficiency benefits. This kind of modification embodies the Lancer’s spirit: small, well-chosen enhancements can unlock measurable gains without requiring a wholesale change in drivetrain architecture. For enthusiasts who enjoy hands-on tuning, the prospect of matching a refined intake component with a compliant exhaust and a calibrated ECU continues to be an appealing path to extract additional performance while preserving reliability and drivability.

The engine story in the Lancer isn’t simply a sequence of displacements and horsepower figures. It’s a narrative about markets, engineering priorities, and a design language that wants to be both practical and engaging. The late-2000s and early-2010s period, in particular, shows how Mitsubishi integrated MIVEC across a broader range of engines, delivering better fuel economy and refined emission characteristics while maintaining strong mid-range torque. In stark contrast, the performance-oriented models retained the legacy of turbocharged power and responsive throttle response that has long attracted a dedicated fan base. This balance—efficiency for daily use, and a path to higher performance for those who want it—illustrates why the Lancer has remained a versatile platform for a wide spectrum of drivers. The platform’s adaptability to different engine configurations, a robust network of parts, and a willingness to refine the valve-timing approach demonstrate how Mitsubishi leveraged technology to evolve with changing consumer expectations.

For readers who want a closer look at a particular high-performance path within this broad family, a dedicated reference to the turbocharged route can be insightful. The 4B11T billet-block option, a targeted upgrade discussed within community and aftermarket resources, offers a tangible example of how power-focused builds are approached within the Lancer’s engine ecosystem. This sort of upgrade shows how the lineage continues to inspire enthusiasts to explore engine reliability and performance enhancements within a framework that remains true to the car’s original balance of daily practicality and track-ready potential.

In sum, the Mitsubishi Lancer’s engine options tell a story of evolution rather than revolution. The lineup moved from compact, economical powerplants to more sophisticated, MIVEC-assisted units that deliver a refined blend of power, efficiency, and emissions compliance. Through the years, the Lancer has maintained its core identity while inviting a broad audience to experience its dynamic driving feel—whether in everyday commuting, family-focused use, or spirited weekend driving. The journey from the 1.6L and 1.8L entries to the modern 2.0L and 2.4L variants, with the celebrated turbocharged high-performance options, reflects a deliberate engineering philosophy: to offer a model that satisfies a wide array of drivers without losing the essential Lancer character. For those curious about the deeper technical specifics or the practical paths available to modify and tune, the route through the Lancer’s engine family remains a compelling and enduring aspect of this iconic automobile.

Internal link reference: For readers interested in a specific high-performance component used in some turbo builds, see the 4B11T billet block resource here: 4B11T billet block.

External resource: https://www.mitsubishicars.com/vehicles/lancer.html

Breathing Fire: Integrated Performance Upgrades for Mitsubishi Lancer Engines

The Mitsubishi Lancer has a broad engine family designed for everyday practicality and rally-inspired performance. Upgrading these engines is not about simply bolting on bigger parts but building a cohesive package that respects the engine’s architecture while improving breath, responsiveness, and durability. MIVEC variable valve timing provides flexible flow control across a wide rpm range, enhancing low‑rpm torque and preserving strong top‑end power. A thoughtful upgrade plan therefore treats the car as a system: durability, breathing, cooling, and intelligent engine management all coordinated with chassis refinements to keep the car predictable at the limit.

Forged pistons form the first pillar of strength in a tuned Lancer. They resist higher pressures and heat, enabling higher compression and improved long‑term durability under boost. Paired with an appropriate cam profile, hardened valve seats, and tuned springs, the engine gains a broader, more useful torque curve while keeping idle characteristics pleasant and throttle response crisp. The goal is a responsive engine that behaves predictably under cornering, braking, and wheel slip, especially when turbocharged variants are driven hard.

Valve springs matter when a cam is allowed more lift or more aggressive timing. Upgraded springs reduce valve float at high rpm, preserving accurate closing events. Downstream components matter too: a high‑flow intake manifold reduces throttle losses and helps the engine respond quickly to pedal input. When matched with a complementary exhaust and turbocharger, the intake and exhaust paths work together rather than fighting for the same airflow.

Intercoolers are a pivotal link for turbocharged Lancers. A robust intercooler lowers intake air temperatures, stabilizes density, and helps prevent timing shifts or knock tendencies. A well‑designed intercooler system with a capable core and quality piping can shave charge temperatures by a meaningful margin, translating into more consistent power at the wheels. ECU tuning then becomes the keystone, guiding fueling and spark to maximize breathing improvements while staying within safe limits. The best outcomes come from dyno‑based calibration that respects emissions and reliability for road use.

Beyond core breathing and boosting, lighter upgrades support the whole package. A high‑flow intake paired with a proper air filter and piping improves mass airflow and combustion efficiency, while a properly sized exhaust reduces backpressure and keeps exhaust gas velocity high through the rpm band. The combined effect is a more linear, usable power band and crisper throttle response, especially when the turbo is working with the upgraded intake and exhaust.

Airflow management also benefits from upgraded intercooler piping and a larger core. Lower charge temperatures and reduced pressure drop enable more repeatable power during long stints at elevated boost, while preserving turbo life and response. With the right fueling and timing strategy, the gains can be felt as a smoother torque curve and more usable horsepower across the range.

Of course, increasing performance demands more capable handling and stopping power. Upgraded brake components, sport suspension, and carefully chosen engine mounts help the car stay controllable as power increases. The goal is not simply to accelerate faster, but to carry speed through corners with confidence and maintain comfort on public roads.

Finally, plan your upgrade around how you intend to use the car. Daily driving with a dash of spirited fun can be achieved with targeted internal upgrades, a calibrated ECU, and a balanced intake–exhaust pairing. For track‑oriented builds, you’ll want a broader toolkit and more aggressive calibration, always with a priority on reliability and emissions compliance.

External resources can help you map a staged upgrade path, from internal components to ECU strategies, while keeping the car in a usable form. The overall philosophy remains the same: treat the engine and drivetrain as a system, not a collection of parts, and tune them to work together in harmony for a satisfying and repeatable driving experience.

Fuel, Force, and Frequency: Tracing the Engine Evolution of the Mitsubishi Lancer from 4G63 Roots to Modern Turbo Performance

The Mitsubishi Lancer’s engine narrative is a line that travels from economical efficiency to rally-bred power, tracing a path that mirrors the car’s broader transformation across generations. In the early years, the Lancer leaned on compact, practical powertrains designed for everyday use, but beneath those humble façades lay a lineage that would become legendary among enthusiasts. The centerpiece of that legend is the 4G63 turbocharged engine, a powerplant whose evolution through the Evolution line became a textbook in turbocharged performance. From the road-legal prototype that set the stage for WRC competition to the high-strung, track-ready machines of the late 1990s, the 4G63 family demonstrated how a single engine architecture could be refined, tuned, and reimagined to punch above its weight. The story then expanded with a broader engine strategy in the Lancer lineup, introducing MIVEC timing and modernized displacement options, and it culminated in a transition toward more modern, efficiency-focused turbocharged designs that could meet evolving emissions standards without sacrificing the core sense of sprint and grip that defines the Lancer’s spirit.

Evolution I, introduced in 1992, marked the world’s first serious road-going expression of a turbocharged 2.0-liter in the Lancer. The 4G63, a double overhead camshaft, 16-valve twin-cam unit, pumped out 247 horsepower at a lofty 6000 rpm. It wasn’t merely about peak numbers; the car was a proof of concept that a turbocharged four could deliver a broad usable tempo, one capable of translating rally-derived momentum into accessible, real-world performance. The road-based character of Evolution I leaned on a balance between tractable mid-range delivery and a willingness to surge when the driver asked for it, a theme that would echo through the subsequent evolutions. By Evolution II in 1994, Mitsubishi refined exhaust pressure management and nudged valve lift from 9.0 to 9.5 millimeters, a somewhat subtle adjustment that widened the engine’s breathing window and allowed for stronger top-end performance. The result, a bump to 260 horsepower, reinforced the sense that every fraction of a millimeter of valve movement, every pascal of exhaust pressure, could meaningfully alter the car’s personality. The update also brought a mechanical LSD into the drivetrain—a 1.5-way unit—that improved traction during aggressive exits and helped translate the turbo’s power into real grip around corners.

Evolution III, arriving in 1995, nudged power higher still and underscored a shift toward more aggressive turbo pairing. A larger TD05H-16G6-7 turbocharger joined the mix, and Mitsubishi widened the compression ratio to 9.0:1 to sustain higher boost levels without sacrificing reliability. Power climbed to 270 horsepower, a figure that signaled the Lancer’s emergence as a credible performance machine rather than a mere sporty family sedan. With each passing year, the engine’s internals grew more sophisticated, and the chassis had to keep pace—stability, control, and predictable response becoming as important as raw horsepower. Evolution IV and the mid-to-late 1990s era continued refining the package, but it was Evolution VI, debuting in 1999, that introduced a confluence of modernity and technique that many regard as the era’s apex. At approximately 280 horsepower at 6500 rpm, and a torque figure of 38.0 kgm at 3000 rpm, the engine achieved a level of operational stability that allowed the car to deliver sprinting capability from low-to-mid revs while maintaining tractable street manners. Piston design was enhanced with oil-cooling channels to boost thermal resistance, an area that showed Mitsubishi’s attention to long-run performance under heavy load. The air-cooled oil cooler became larger, and the oil pan received an upgrade to manage higher temperatures and the associated stamina demands of high-speed running. The RS variant even used a titanium-aluminum alloy turbocharger, cutting rotational inertia and sharpening throttle response. These changes didn’t merely raise numbers; they altered the feel of the car, translating turbo surge into clean, linear acceleration while still preserving reliability in demanding rally-styled driving conditions.

When Evolution X arrived in 2008, the engine story took a decisive turn. In some markets, the aging 4G63 found itself retired in favor of a new 2.0-liter turbocharged 4B11T, a powertrain designed with greater efficiency and tighter emissions control in mind. This transition marked the end of the 4G63 era as the vanguard of the Lancer’s performance identity, but the philosophy of engine development—balancing response, torque, and reliability with the ability to deliver track-ready power—remained the guiding principle. The 4B11 family, with its MIVEC timing, represented Mitsubishi’s response to a world that demanded cleaner burn with robust, usable power. This shift didn’t erase the legacy of the 4G63; it reframed it. The Lancer’s engine lineage broadened to include variable valve timing and modern direct- or sequential-injection strategies aimed at smoothing delivery across RPM and improving fuel economy without sacrificing the sense of propulsion that has defined the model for decades.

Beyond the rally-tuned heart of the Evolution line, the standard Lancer engine roster offered a spectrum of choices that framed the driving experience for a broad range of owners. The MIVEC-equipped 1.6-liter 4B11 is a compact, efficient unit well-suited to urban commuting, delivering solid real-world efficiency in the 30–35 MPG range while maintaining a responsive everyday character. Its main limitations sit in relatively modest power output and limited potential for high-performance tuning, yet this is the engine that anchors efficiency without denying the Lancer’s identity as a practical, well-rounded compact. The 2.0-liter 4B11 naturally aspirated variant, often rated around 148–160 horsepower, strikes a balance between performance and economy. With a predicted 27–32 MPG in mixed driving, it remains the most versatile option for general driving and family use, offering smooth throttle response and availability across many trims. When turbocharged, the 2.0-liter 4B11 becomes a different animal altogether: the 4B11T harnesses turbocharging in a way that suits both track sessions and spirited daily driving, with the MIVEC timing optimizing valve events across RPM to preserve power delivery and efficiency.

To complete the lineup, there are still other legacy engines that have lived on in the Lancer’s broader family tree. The 1.8-liter 4G93 provides a different blend of performance, offering a robust power curve and competitive efficiency for regional variants and older generations. Earlier Australian and other regional models sometimes employed smaller 1.5-liter engines, which, while lighter and more economical, offered less ultimate horsepower than later 2.0L variants. Across these options, the engine mounts and accompanying hardware shaped the character as much as the displacement or turbo size. Hydraulic mounts deliver quiet, smooth operation that suits daily commuting, while solid rubber and polyurethane variants can improve engine control and throttle response for those who chase a more aggressive feel or a budget-friendly upgrade path. The practicalities of mount choice—noise, vibration, and stability—interact with the engine’s torque delivery and the chassis’ dynamic balance to produce the overall sensation of performance. In the same vein, performance upgrades such as swapping in an OEM throttle body—an example being the MR560120—can yield meaningful gains, sharpening airflow and, in some configurations, delivering up to about a 15 percent improvement in power and efficiency relative to stock parts. These upgrades are compatible with Lancer models spanning 1996 to 2014, reflecting a continuity of investment in the engine bay as the chassis evolved.

All of these threads—the turbocharged 4G63 family, the advent of MIVEC with the 4B11/4B11T family, and the wider ecosystem of mounts and intake components—reveal a coherent philosophy. Mitsubishi pursued a rhythm of refinement and bold leaps, advancing reliability and drivability while preserving the core thrill that defines the Lancer’s performance identity. The Evolution line, in particular, embodies this tension between the road-legal and the rally-bred, between high-end engineering and practical use. The engine’s evolution is not just about peak horsepower figures; it is about how power translates into usable, repeatable performance in a car that could be driven daily and then pushed to the edge on a weekend track or a winding mountain road. This philosophy persists in a modern context, where new engines blend turbochargers, sophisticated valve timing, and careful thermal management to deliver consistent propulsion without compromising efficiency.

For readers curious about the deeper technical spine behind the turbo era and the way earlier generations laid the groundwork for later technologies, the journey across Evolution I through Evolution X offers a case study in automotive engineering that is still relevant today. While the specifics of turbo sizing, compression, and cooling strategies evolved, the underlying pursuit remained constant: to convert exhaust energy into controlled, immediate thrust, to keep the engine within its optimal thermal envelope, and to ensure that the driver’s inputs translate into decisive, tractable acceleration. The engine’s story, in this sense, is the story of the Lancer itself—a compact performance sedan that learned how to move with greater force, greater control, and greater efficiency, generation after generation.

Breathing Life into the Lancer: Engine Specifications, Efficiency, and the Evolution Toward Balance

The Mitsubishi Lancer earned its reputation not merely from its lines and rally heritage but from the way its engines translated ambition into everyday mobility. Across generations, the Lancer’s powerplants have been knit together by a single thread: an enduring commitment to balance. The engines that power modern Lancers—primarily the four-cylinder family built around Mitsubishi’s MIVEC technology—demonstrate how a compact displacement can yield a surprising breadth of character. MIVEC, Mitsubishi’s valve timing electronic control system, is the quiet engine room of this strategy. It modulates which valves open and when, optimizing flow at different RPMs to lift torque in the midrange, sharpen throttle response at low revs, and improve fuel economy during routine cruising. This tuning philosophy matters more than peak figures because it shapes the everyday feel of a Lancer, the confidence you experience when pulling away from a stop, the smoothness of a long highway glide, and the steadiness of a steady climb on a canyon road. In practice, the Lancer’s engine lineup has been about giving drivers choices that align with how they actually drive: urban errands, family road trips, or the occasional foray onto a back road where refinement and responsiveness must coexist with efficiency.

A clear center of gravity for the contemporary Lancer engine family is the 4B1 series paired with the 4A series. These families share the common thread of MIVEC, yet they carve distinct paths through displacement, breathing, and tuning. The 4B1 family brings a compact breadth to the lineup, emphasizing lightness and efficiency without surrendering usable power. Among them, the 1.5-liter 4B10 appears as a configuration designed for city duties, where light weight and easy response are valued as much as economy. The aluminum block and head reinforce this by reducing mass, which helps with city maneuvering, stop-and-go rhythms, and lower overall operating costs. Its power output sits modest by modern sport-sedan standards, but the experience is not about chasing number one on a dyno; it’s about theability to feel nimble and predictable every time you reach for the accelerator. The synergy of low-end response with clean, quiet operation makes daily driving markedly more comfortable, and the economics of maintenance and fuel use align with urban living. In a practical sense, this engine is the portrait of a practical Lancer—reliable, frugal, and easy to live with.

Moving up in displacement and ambition, the 1.8-liter 4B11 becomes the centerpiece for a broad spectrum of roles. In its naturally aspirated form, the 4B11 delivers around 148 to 160 horsepower and roughly 175 to 185 Newton-meters of torque. What matters more than the headline figure is how that mid-range torque translates into real-world acceleration and highway efficiency. The 4B11 NA is praised for a smooth throttle response, steady power delivery, and a favorable balance of fuel economy in mixed driving conditions. It feels composed on the highway, with enough torque to merge cleanly and sustain comfortable touring speeds, yet it remains efficient enough for daily commuters. For enthusiasts seeking additional zest, the turbocharged variant of the same family—often referred to in the context of the Lancer Evolution lineage—opens a different door entirely. The turbo adds a surge of power and a rally-bred immediacy that makes even a routine drive feel purposeful. However, the turbo configuration brings a steeper appetite for fuel and more complex maintenance dynamics, underscoring how the Lancer engine family calibrates performance to driver intention. This duality—NA for balance, turbo for thrill—illustrates the Lancer’s engineering flexibility, where the same architecture can be tuned to match distinct personalities without abandoning the core ethos of efficiency.

Beyond the 4B1 family, Mitsubishi has also stretched the envelope with the 4A-series, which centers on economical entry points without sacrificing the essential MIVEC advantage. The 4A11, a 1.8-liter engine, embodies this philosophy with approximately 120 to 130 horsepower and torque around 160 Newton-meters. Efficiency remains a priority, with combined fuel economy typically reported in the 6.8 to 7.3 L/100 km range. These numbers translate to a calm, predictable drive—easy on fuel bills and simple to own—while still offering respectable acceleration for everyday motoring. The 4A11’s role in the Lancer lineup underscores a strategic emphasis on low operating costs, dependable performance across varied road conditions, and a broad appeal to buyers who want a compact sedan that handles both city commutes and weekend getaways without demanding premium fuel or premium maintenance. In many markets, these engines have earned a reputation for longevity, a testament to their engineering discipline, the simplicity of their design, and the efficiency of their combustion and timing strategies.

The engine family’s evolution is not merely about displacement or peak horsepower. It’s about how the engine breathes, how the intake and exhaust work in concert with variable valve timing, and how the drivability translates into a confident ownership experience. The natural progression—from lighter, city-focused powerplants to more capable mid-range units, up to high-performance variants—maps onto the way drivers use their Lancers. The Lancer’s engine strategy also reflects a recognition that efficiency matters as much as outright power. The modern combined numbers for these engines—roughly 7 liters per 100 kilometers in many 1.8-liter configurations, and the mid- to high-30s in miles per gallon when running lean—illustrate a design intent that supports daily practicality without forcing compromises on performance when needed. For many buyers, it is precisely this blend—the sense that you have adequate power for daily travel and enough efficiency to make long trips viable—that defines success in a modern Lancer.

As performance curiosity has grown, so too has the appetite for thoughtful upgrades that preserve the essence of these engines while nudging them toward a more engaging driving experience. In the realm of hardware, the choice of engine mounts—hydraulic, solid rubber, or polyurethane—shapes how the engine communicates with the chassis. Hydraulic mounts excel at suppressing vibration and noise, yielding a quieter cabin suited to daily commuting and long-distance travel. Solid rubber mounts, by contrast, emphasize rigidity and durability, offering a lower-cost path to beekeeping the engine’s timing and response under more demanding duty. Polyurethane mounts stand as a middle ground, balancing improved control with enough vibration absorption to keep the ride comfortable. The right mount choice can meaningfully affect steering feel, throttle modulation, and the overall sense of connection to the road, which in turn informs the driving experience more than raw power figures alone.

From there, the conversation naturally turns to airflow and intake efficiency as a straightforward route to meaningful gains without major overhauls. An upgraded throttle body can improve the engine’s breathing, helping to reduce throttle lag and refine fuel-air mixing. In practical terms, enthusiasts have observed increases in power and efficiency when airflow is optimized through compatible, well-matched components. In the context of the Lancer’s 4B11 and 4A11 platforms, a targeted upgrade—carefully matched to the engine’s intake provisions—can yield a noticeable improvement in driveability, especially in the mid-range where most daily driving occurs. For those who want to explore deeper internal work, a billet-block option for the 4B11T variant exists as a high-end engineering path. This particular upgrade is specifically relevant to performance-oriented builds where strength, reliability under higher boost, and precision clearances become pivotal. Interested readers can explore the 4B11T billet block option here, which represents a possible direction for serious enthusiasts who are aiming for race-ready consistency in a street-legal context.

With each of these threads—valve timing, displacement choices, mounting strategies, and airflow refinements—the Lancer engine family reveals a careful synthesis of performance responsiveness and everyday practicality. The modern Lancer is not a single engine, but a family of powerplants calibrated to serve different driving styles while preserving the fundamental Mitsubishi focus on efficiency and reliability. That balance is evident in the way the 1.5-liter and 1.8-liter variants deliver tractable daily driving, and in how the 2.0-liter NA variant returns a measured, confident highway presence. Even the high-performance turbo variants sit within a framework that rewards controlled power delivery and predictable behavior. In short, the Lancer’s engines are not simply about chasing higher numbers. They are about preserving a dynamic range—the flexibility to blend economy with spirited performance—so that the car remains approachable for the everyday driver and compelling for the enthusiast alike.

For readers seeking a broader view beyond the numbers, contemporary reviews and testing provide a more tactile sense of how these engines perform in real-world conditions. A supplementary analysis from a current automotive publication highlights how different engine configurations respond under varied load and temperature, showcasing how valve timing, turbocharging, and intake design translate into measurable on-road behavior. This external perspective complements the engineering narrative and helps readers understand how the Lancer’s engine options hold up in everyday driving, from city streets to long open roads. While numbers offer a map, the experience of driving a Lancer with one of these engines brings the chart to life. The story of the Lancer engine is therefore a story of choices made to balance practicality and excitement, ensuring that there is a model for nearly every driver—from the daily commuter who values cost of ownership to the weekend enthusiast drawn to a track-inspired thrill.

External resource for further reading: https://www.caranddriver.com/mitsubishi/lancer/engine-review

Final thoughts

Understanding the engine technology behind the Mitsubishi Lancer offers business owners a comprehensive view of its capabilities, aligning performance with efficiency. Whether you need a reliable option for urban commuting or a high-performing vehicle for spirited drives, the Lancer provides various engine configurations tailored to specific needs. MIVEC technology showcases Mitsubishi’s commitment to innovation, ensuring fuel efficiency without sacrificing power. Selecting the right engine can profoundly impact your operational efficiency, making the Mitsubishi Lancer a worthy investment for those in the business sector.