Carbon fiber hoods for the Mitsubishi 3000GT have emerged as a significant innovation, bridging performance enhancement with aesthetic upgrades. Business owners in the automotive aftermarket industry will find that understanding the benefits of these carbon fiber components can lead to increased demand and customer satisfaction. As we delve into the advantages of carbon fiber in terms of performance and aerodynamics, explore the current market trends in hood customization, and examine the economic impact of these upgrades, it becomes clear how vital this knowledge is for making informed business decisions. Each chapter will provide insights that contribute to a comprehensive overview of the carbon fiber hood options available for the Mitsubishi 3000GT.

Shaving Mass, Shaping Pace: How Carbon Fiber Hoods Transform the 3000GT for Speed and Stability

In the realm of high performance, the hood is more than a cover for the engine. It is a strategic surface that changes the car’s mass distribution, its silence at redline, and its appetite for air. For the Mitsubishi 3000GT, a car built to blend turbocharged aggression with technological finesse, a carbon fiber hood can be a decisive upgrade. It is a choice that threads lightweight engineering, aerodynamics, and cooling into a single, coherent performance philosophy. The research into these hoods reveals a market that is both diverse and highly specialized, with offerings that span the globe from banner marketplaces to boutique workshops. What begins as a cosmetic enhancement often evolves into a careful recalibration of how the car behaves at speed, how it breathes under load, and how it feels behind the wheel when the road opens up and requires trust in the car’s front end and its ability to stay planted and predictable.

The most compelling case for carbon fiber in a hood is weight reduction. The front end of a sports car carries a disproportionate share of the vehicle’s mass, especially in a mid-engined or front-engine configuration where the engine, intercoolers, radiators, and supporting hardware cluster in a tight space. Replacing a heavy steel or aluminum panel with carbon fiber lowers that front load, yielding tangible benefits in acceleration, steering response, and braking stability. In practical terms, the lighter hood reduces inertia in the upper body of the car, which means the suspension can respond more freely to road irregularities, and the driver can feel a crisper, more direct connection to the steering feel. This is not just about top speed, though higher speeds inevitably benefit from lower mass; it is about the way the car behaves when it enters a corner, transitions midcorner, and exits with balance restored more quickly after a lift or a brake.

Weight savings become especially meaningful when the front end hosts twin turbochargers and a network of intercoolers. In a setup like the 3000GT, where cooling and air management are as important as raw horsepower, the hood design can contribute to a more efficient airflow pattern across the engine bay. A carbon hood is not a passive skin; it is often engineered with integrated ducts and vents that direct cooler air to the radiators and intercoolers. The result is twofold: engine bay temperatures stay within a tighter envelope under sustained performance demand, and the flow of air over the hood reduces pressure buildup that can sap speed and stability at high velocity. A well designed carbon fiber hood can be shaped so that the intake path and the underhood channeling work in concert with the car’s cooling system, helping to avoid heat soak that might otherwise dampen turbo performance during prolonged sessions or hot laps.

This integration of cooling and aerodynamics becomes even more interesting when we consider the broader aerodynamic package a car might wear. The hood can play a supporting role in reducing front-end lift and smoothing the transition of air from the grille to the engine bay. Vents, ducts, and carefully contoured panels minimize turbulent wake and help maintain a consistent pressure distribution across the nose. While the exact numbers vary with each design, the principle is clear: a carbon fiber hood is part of a holistic approach to achieving a modestly lower drag coefficient and a more favorable pressure gradient along the vehicle’s profile. In modern reinterpretations of the 3000GT lineage, engineers and enthusiasts alike often pursue a Cd target that reflects a balance between downforce, cooling efficiency, and ride stability at high speeds. In this sense, carbon fiber is less a single feature and more a contributor to an aerodynamic philosophy that values clean, efficient air handling as a prerequisite for the car’s performance envelope.

The aesthetic dimension of carbon fiber hoods should not be discounted. The visual impact of a woven, high-contrast surface communicates intent as surely as any badge or script. For many builders, the visual cue of carbon fiber is a signal that the car is not simply restored or preserved but purpose-built for performance. Yet in that aesthetic lies a functional potential: the hood’s form often embodies the balance between strength and lightness, and the best designs avoid adding unnecessary rigidity, weight, or complexity while still delivering the intended aerodynamic improvements. A hood with integrated vents or ducts can serve a dual role, providing a functional path for air while also contributing to the car’s aggressive silhouette. In sum, a carbon fiber hood for the 3000GT is an open invitation to rethink how a front-end panel behaves under load, how it interacts with air, and how it feels to drive the car at the limit.

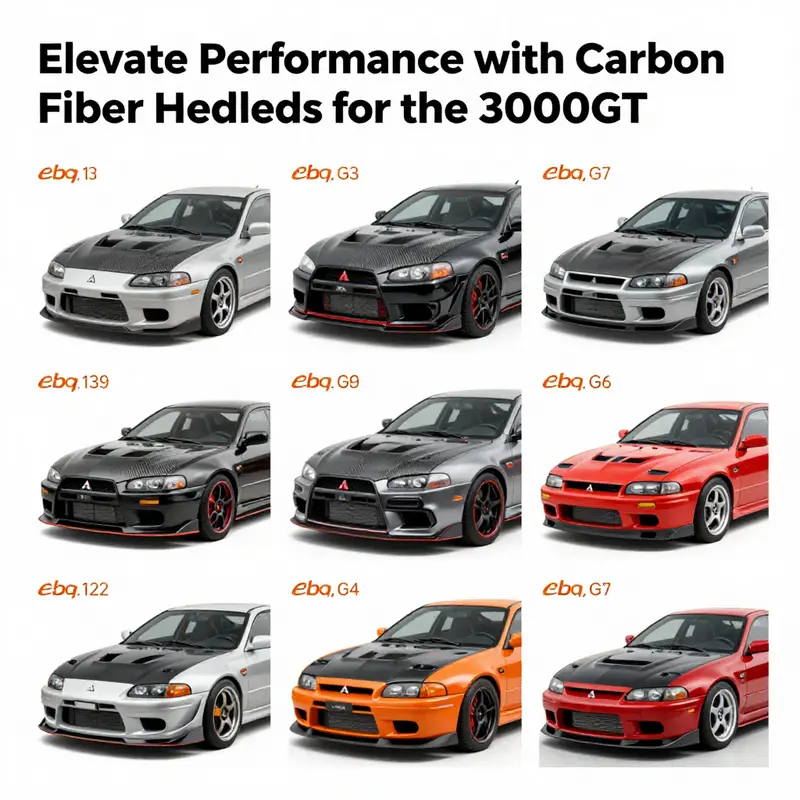

The market reality for these components reflects the car’s enthusiast base and its long-standing appeal. Online marketplaces reveal a spectrum of options that range from lightweight, OE-style carbon fiber variants to more aggressive, race-inspired designs. On one end, some listings emphasize weight reduction and durability, offering panels that are engineered to be compatible with the 1991–1993 two-door variants. On the other end, offerings target the 1994 variant with features designed to optimize airflow and cooling under high performance conditions. The practical implications of this market diversity are meaningful for a builder: the choice is not simply about weight but about fitment, heat management, and how the hood’s design supports the specific goals of the build, whether that is street performance, occasional track days, or a high-speed street car launched into a weekend project.

In the context of fit and fitment reliability, buyers tend to evaluate options in terms of how the hood aligns with the fenders, how the mounting points line up, and whether the hood’s curvature complements the engine bay’s geometry without introducing new gaps or misalignments. The reality is that carbon fiber panels require careful handling and precise mounting procedures, as the tolerances can be different from factory stamped panels. The payoff, however, can be substantial. When a hood is properly installed and properly vented, the car’s front-end weight distribution shifts in a way that encourages more balanced turn-in and more predictable steering feel. The risk, of course, is warped panels, misalignment, or underperforming ventilation that fails to deliver the intended cooling benefits. The best outcomes arrive when the selection process blends an understanding of the car’s mechanical layout with a clear plan for the hood’s aerodynamic role.

For those who prefer to explore concrete options, the market presents a variety of configurations. Some buyers opt for carbon fiber hoods that mimic original OE styling while trading the heavier metal for lighter composite fibers. Others look for sport- or race-inspired silhouettes with pronounced vents and channels that actively manage under-hood pressure. There are even variants crafted from an assembly of carbon fiber and aluminum, appealed to by builders seeking an ultra-light substrate with a different heat management profile. Each material choice comes with its own story about stiffness, impact resistance, and price. Carbon fiber offers exceptional strength-to-weight characteristics, but it can demand more careful handling and more selective maintenance than a metal hood. Aluminum can provide strong performance at a lower cost than pure carbon fiber, with its own set of tradeoffs around rigidity and heat tolerance. Fiberglass remains a lighter, budget-conscious option, but its stiffness and surface finish do not typically measure up to carbon fiber in the same high-end performance context.

The supply network for carbon fiber hoods for the 3000GT is robust enough to reflect a broad appetite for lightweight performance. Listings often identify models compatible with different years and body styles. Some offerings emphasize Europe or Asia as primary sources, while others highlight a global marketplace architecture that allows builders to compare options, pricing, and shipping terms across borders. A notable example from the dataset shows a new OE-style carbon fiber hood priced around 7,422.32 Chinese yuan, with free shipping from various locations. This kind of price point illustrates the tension between value and quality that buyers navigate. The promise of a lighter front end, a cooler engine bay, and a more engaging driving experience must be weighed against concerns about fitment, insurance considerations, and the long-term durability of a composite hood under high-speed use and temperature cycling. In this sense, the market acts as a cohort study of performance priorities, where weight savings, aerodynamics, cooling, and aesthetics are interwoven with practical realities of installation, maintenance, and reliability.

It is here that the idea of a highly engineered, performance-focused hood begins to crystallize. The research results highlight a trend: enthusiasts who push the 3000GT toward higher speeds and more aggressive handling increasingly view carbon fiber hoods as part of a broader performance upgrade package rather than a standalone accessory. They couple the hood with other lightweight components, a refined cooling strategy, and a disciplined approach to aerodynamics to achieve what one might call an integrated performance profile. In this context, the hood becomes a keystone part of a larger effort to reduce front-end weight and improve airflow management—an architectural piece that supports the engine’s power while preserving the car’s composure at speed. The emotional and experiential payoff is real. When a driver feels steadier front-end response, steadier cornering, and a throatier, more controlled release from the turbocharged setup, the hood is a quiet hero in the story of a car that continues to defy time.

For readers who want to see a specific example of what a carbon fiber hood can offer, a well-documented option emerges in the form of a dedicated variant that targets the 1994–1999 range. This choice is often discussed in enthusiast circles for its balance of fitment, weight savings, and aerodynamic potential. The particular approach emphasizes compatibility with a two-door or four-seat layout and uses a design language that respects the car’s original lines while introducing venting and channeling that align with modern performance expectations. The result is a hood that does not simply look fast; it makes the car feel faster by reducing mass at the front and smoothing the airflow over and around the engine bay. The synergy between weight reduction and air management yields a measurable improvement in the car’s dynamic behavior: sharper turn-in, reduced front-end dive under braking, and more stable high-speed behavior. In other words, the hood becomes a lever that the driver uses to coax more from the car’s chassis and drivetrain without needing a broader overhaul of the entire aero package.

To further illustrate the practical implications, consider how a carbon fiber hood can interact with a cooling-focused design in a high-performance street configuration. Integrated air intakes can feed the radiator and intercooler with consistently cool air, preserving turbo efficiency and reducing the risk of heat-related performance drop-off during repeated hard pulls. This is especially relevant in the 3000GT family, where turbocharging and all-wheel control place additional heat and air management demands on the front of the vehicle. A hood designed to channel air toward the radiators and intercoolers can complement the car’s existing thermal management by creating a more predictable thermal environment under sustained load. The net effect is not simply a warmer or cooler engine bay; it is a more linear, reliable performance curve, where the driver enjoys consistent response and torque delivery across a wider window of operating conditions.

The discussion of weight, airflow, and cooling inevitably circles back to the bigger picture: these hoods are part of a broader culture of customization that values performance gains as much as the drama of the car’s appearance. Enthusiasts in this space seek not only faster times but also a vehicle that behaves with confidence at the edge of adhesion. In practical terms, this translates into careful selection, precise fitment, and thoughtful integration with the car’s cooling and aero strategy. The goal is to assemble a cohesive package where every component supports the same objective: to reclaim speed without compromising control. A carbon fiber hood, in this sense, is a deliberate, technical investment—an investment in weight, airflow, and the confidence that comes with a front end that remains cooperative when pushed hard.

For readers who wish to explore a specific option while keeping the conversation grounded in hands-on practicality, there is a familiar anchor in the form of a dedicated carbon fiber variant for the 1994–1999 range. This option embodies the themes described here: weight reduction, improved airflow, integrated cooling considerations, and a design that respects the car’s original geometry while enhancing its capabilities. The availability of such hoods through global marketplaces underscores a vibrant ecosystem of configurations and price points, underscoring how a seemingly simple panel can become a focal point for a larger performance project. In this spirit, the hood stands as a bridge between the car’s classic identity and a modern performance narrative that honors speed, balance, and the tactile pleasure of driving at the limit.

For those who want to delve deeper into a concrete example and see how a carbon fiber hood is positioned within a broader build, one representative option can be examined in detail here. Pit Fighter carbon fiber hood for 1994-1999 Mitsubishi 3000GT. This link provides a window into the practicalities of the market—how the hood fits, what it weighs compared to the stock panel, how vents are implemented, and how the hood integrates with the car’s cooling strategy. It is a reminder that the benefits discussed—weight reduction, improved airflow, and enhanced cooling—are not abstract concepts but tangible outcomes that show up in the car’s behavior on the road and on the track. The pursuit of a carbon fiber hood is, in many cases, the start of a focused upgrade path that merges the art of bodywork with the science of aerodynamics and thermal management, all aimed at making a historic sports car feel like a more precise, more capable machine on modern roads.

As the journey toward a carbon fiber hood for the 3000GT unfolds, readers are invited to keep in mind a few guiding principles. First, the weight savings must be weighed against the fitment and the price of the panel, recognizing that the most aggressive designs may demand more meticulous installation and maintenance. Second, airflow and cooling are not mere marketing claims; they are real contributors to engine performance, especially in turbocharged configurations that depend on consistent temperatures to sustain power and efficiency. Third, the aesthetic and psychological benefits—seeing a carbon weave and feeling the lighter front end under the hands—should align with a well-planned performance objective rather than a stand-alone visual upgrade. When these factors align, a carbon fiber hood becomes more than a component; it becomes a catalyst for a broader, more coherent take on speed and stability that honors the car’s legacy while embracing the potential of lighter, smarter engineering.

External resource: https://en.wikipedia.org/wiki/Carbon_fiber

Weight, Wind, and Awe: The Carbon Fiber Hood as a Calculated Upgrade for the 3000GT

A carbon fiber hood does more than alter the look of a classic performance car. It signals a deliberate shift toward deliberate engineering—where every gram saved and every vent tuned matters. For the 3000GT, a model that has long stood as a bridge between aggressive styling and serious performance potential, the hood becomes a focal point of an upgrading philosophy. Owners who are drawn to its lines often want something more than cosmetic changes. They seek a component that respects the car’s heritage while delivering tangible, track-ready benefits. In this context, carbon fiber hoods occupy a unique position in the market: they are simultaneously a statement of intent and a tool for refinement. The market around these hoods has matured toward a balance of authenticity and innovation. Buyers increasingly prioritize high-quality, precisely engineered pieces that preserve the silhouette of the original car while offering modern performance advantages. This is visible in the way listings on popular platforms present options. Some hoods are offered as OEM-style replacements that maintain the classic profile, which appeals to purists who want the factory stance with a lighter, stiffer construction. Other options embrace the promise of ultimate weight reduction and advanced airflow, with integrated ducts and carefully engineered ventilation routes intended to feed intercoolers and engine bays more efficiently than the stock arrangement. The net effect is a spectrum that spans faithful reproduction to purpose-built performance parts, all sharing the common aim of improving the car’s balance between power, handling, and cooling under demanding conditions.

From a market perspective, the supply chain for these components reflects a global, multi-channel ecosystem. Enthusiasts can access carbon fiber hoods through well-established marketplaces where listings cater to different model years and specifications. In the broader narrative of the 3000GT’s evolution, this is not just about replacing a sheet of material; it is about integrating a new material science into a platform that rewards precision and consistency. The lightweight nature of carbon fiber—often cited as a weight reduction in the range of 15 to 25 pounds compared with stock fiberglass—translates into perceptible handling improvements and more responsive throttle behavior, especially when the car already carries performance-oriented upgrades. This is not merely a vanity metric. In many builds, the reduced weight in the front of the vehicle helps with weight balance, reduces inertia during cornering, and enhances brake performance by lowering the demand on the system. For track-focused machines, every pound matters, and the prospect of shaving weight from the hood is particularly attractive because it is one of the most accessible points of the car to address.

A recurring theme in the current market is the functional design embedded in the hood itself. Modern carbon fiber hoods often go beyond aesthetics to integrate air intakes and ducting that directly support turbocharged power delivery. For a turbocharged 3000GT, the intercooler and charge air paths are especially sensitive to thermal load and intake pressure. The hood can be engineered to channel air efficiently toward the intercooler, using strategically placed ducts that minimize turbo lag by reducing intake temperatures and maintaining consistent boost during aggressive driving. This kind of design work emphasizes the synergy between bodywork and powertrain, illustrating how a well-crafted hood can contribute to a broader performance package rather than merely acting as a cosmetic upgrade. It is not unusual to see a hood design that includes reinforced ribs fabricated through CNC processes. The reinforcement is not just about rigidity; it is a control measure against deflection under high-velocity airflow or during hard cornering, where a thin sheet of carbon could otherwise chatter or flex. In this context, the material choice becomes a functional ally, a partner in the engineering story rather than a standalone cosmetic element.

The market also reflects a preference for authenticity alongside innovation. A notable portion of listings emphasize OEM-style compatibility and finish, emphasizing that the hood will align with the original silhouette and mounting points. There is value placed on preserving the iconic profile of the 3000GT, even as enthusiasts push the envelope with modern composites. This tension between preserving a familiar shape and pursuing modern performance marks a thoughtful consumer mindset: buyers want a product that respects the car’s heritage while delivering measurable upgrades. The result is a thriving category where the best offerings present a refined, factory-accurate look tempered with contemporary materials science and precision craftsmanship. In some cases, the evolution is so subtle that it appeals to owners who want a clean, understated upgrade that remains true to the car’s design language. In other cases, the refinements are more assertive, featuring gloss or matte finishes and visible weave patterns that communicate the high-tech nature of the component without compromising the car’s classic stance.

Within this market, the material choice often comes down to a triad of carbon fiber, aluminum, and fiberglass. Each option carries distinct tradeoffs. Carbon fiber offers the strongest strength-to-weight ratio and a level of stiffness well-suited to performance-focused setups. It delivers meaningful weight savings relative to fiberglass, and it typically provides better torsional rigidity, which translates to more precise steering feel and improved crash energy management in the hood area. Aluminum options, when pursued for weight reduction, bring excellent rigidity as well, but they can fall short of carbon fiber in terms of overall stiffness and vibration damping. Fiberglass, while the most affordable, rarely matches carbon fiber’s strength-to-weight balance and can introduce more flex under high-load conditions. The dialogue around these choices is not merely about what the hood is made of; it is about how the material interacts with the entire system—the hood hinges, mounting points, latch mechanisms, and the air paths that serve the intercooler and engine bay. In a performance build, those interfaces matter as much as the core material itself.

The market’s current trajectory also shows a growing appreciation for customization without losing fit and durability. Premium, hand-finished carbon fiber hoods have become the norm in many circles. Manufacturers and fabricators temper the weave with careful resin curing, ensuring a consistent appearance from edge to edge and a resilient surface that can withstand the weather and rough handling that everyday use can impose. Clients who invest in these advanced hoods frequently expect a multi-layer protection strategy: polished surfaces that resist UV degradation, clear coatings to preserve the weave, and reinforced reinforcements where the hood aligns with critical mounting points. The result is a component that not only looks the part on a showroom floor but can survive the rigors of track days or spirited street drives.

Another facet of this story is the way buyers identify value in the balance between originality and modern performance. OEM-style replacements are particularly appealing for those who want to maintain the classic visual footprint of the 3000GT while benefiting from weight savings and improved rigidity. These replacements respect the proportions and contours of the stock hood and are designed to integrate with existing hood hardware and alignment. Yet there is a broader market segment that pushes beyond those boundaries, seeking a more aggressive stance or enhanced airflow. In those cases, the hood serves as a performance module that complements other upgrades—intercoolers, uprated radiators, improved intake systems, and turbocharger or supercharger hardware. The idea is to build a cohesive upgrade path where each component reinforces the others, delivering a predictable, repeatable increase in performance metrics.

Within the conversation about upgrades, it is instructive to consider specific, real-world examples that illuminate the market’s direction. For instance, a noted internal reference page highlights a variant designed to fit the mid-1990s era of the car while incorporating carbon fiber’s benefits. This reference point helps explain why some owners gravitate toward particular configurations: compatibility with the car’s era-specific chassis geometry, hood latch location, and fan-out routes for air intake. The link serves as a reminder that such upgrades are not generic add-ons; they are integrated parts of a broader performance philosophy. To explore this idea, you can view the internal page for a 1994-1999 carbon fiber hood variant, which demonstrates how a design can honor historical lines while delivering today’s material performance. internal page for a 1994-1999 carbon fiber hood variant. This page illustrates the thinking behind an OEM-inspired approach that still leans into the possibilities offered by modern composites. The presence of such variants in the market underscores a broader truth: the 3000GT’s identity is resilient, and its owners want to preserve that identity while making it lighter, more capable, and more responsive to the demands of both street and circuit.

The conversation about hood upgrades inevitably returns to the question of practical installation and maintenance. A carbon fiber hood, regardless of the exact weave or resin system, requires careful handling and precise fitment. The hood must align perfectly with the fenders, grille opening, and engine bay contours. This precision is not a luxury; it is a necessity for reliable deployment during high-speed driving or during the frequent opening and closing cycles that a performance-focused vehicle endures. Buyers often assess whether the hood’s weight savings justify the installation time and potential need for professional alignment. They consider latch and hinge compatibility, as well as the potential need for wind tunnel-informed venting design to maintain safe performance under sustained high-speed runs. In a well-executed build, the hood complements the rest of the car’s aerodynamics, contributing to a more coherent and balanced performance profile rather than acting as a standalone visual modification. The market’s best offerings acknowledge this interconnectedness, presenting a holistic package that integrates hood design with intercooler routing, ducting, and engine cooling paths.

The ongoing dialogue around carbon fiber hoods also emphasizes the role of storytelling in the customization culture surrounding the 3000GT. Enthusiasts value not only the technical benefits but the narrative that an upgrade can convey about a car’s life and its owner’s priorities. A hood with a visible weave can signal pride in engineering choices, while a more understated, OEM-like finish can reflect a desire to keep the car’s classic silhouette intact. Both approaches have a rightful place in the market, depending on the owner’s aims. And as the market matures, the conversation expands to include the broader ecosystem of carbon fiber fabricators and the evolving standards for quality control, warranty coverage, and post-purchase support. Buyers increasingly seek firms that demonstrate consistent testing, meticulous quality control, and transparent documentation of the manufacturing process. In this light, a carbon fiber hood is not merely a product; it is a piece of a larger, disciplined approach to performance and preservation.

For readers who want to explore a concrete example of the broader category while maintaining a practical focus, the internal page described earlier offers a useful touchstone. It shows how an upgrade can respect the car’s original character while delivering substantial performance improvements. It also demonstrates how the aftermarket ecosystem supports builders at different levels of investment, from street-driven cars to track-oriented machines. If you are assessing options for a 3000GT, a careful evaluation of weight savings, airflow optimization, mounting compatibility, finish quality, and support from the fabricator will guide you toward a solution that uniquely fits your project. In this market, the most successful upgrades are often the ones that feel invisible until you push the accelerator and feel the car respond with improved immediacy and steadier cooling under load.

As the chapter closes on this snapshot of the market, it is clear that carbon fiber hoods for the 3000GT have matured into a sophisticated and purposeful category. They are no longer merely cosmetic enhancements; they are components that can define a car’s performance envelope. They reflect a commitment to modern materials science while honoring a car’s storied past. For owners who want to blend authenticity with forward-looking engineering, the hood represents a practical, well-considered path to elevating both driving experience and visual impact. The conversation continues as new fabricators refine their processes, new models and years become compatible, and drivers push their cars to the limit on track days and in spirited street sessions. In the end, the carbon fiber hood for the 3000GT is less about a single feature and more about a philosophy: that form and function can align so that lightness and precision become inseparable from the car’s character and grip on the road.

External reference: https://www.ebay.com/itm/1992-Mitsubishi-3000GT-SL-OEM-Red-Hat-FWD-3-0L/384752483768

The Price of Lightness: Economic Currents Shaping Carbon Fiber Hoods for the 3000GT

The marketplace for aftermarket carbon fiber hoods aimed at the 3000GT sits at an intersection of engineering ambition, aesthetic differentiation, and price discipline. On the surface, these components promise a drop in mass and a striking silhouette that signals advanced engineering. But beneath that veneer lies an economic narrative of material costs, specialized manufacturing, and a global distribution network. For enthusiasts, a carbon fiber hood becomes more than a component; it is a signal of a performance trajectory. The market reflects model-year nuance: classic 1991–1993 two-door variants versus the 1994 upgrade, each with its own demand profile and fitment realities. The spectrum of offerings ranges from matte laminates to OE-style replicas, each priced according to the level of prep work, finish, and performance claims. The economics are a ladder: entry-level composite blends, mid-range prepregs, and premium, meticulously finished laminates. Each rung corresponds to different production approaches and risk profiles for the buyer.

From the consumer viewpoint, the decision is a balance of upfront cost and longer-term asset value. Real carbon fiber commands a premium tied to material properties, fabrications skills, and consistent finishes. Buyers expect weave integrity, resin stability, and durable latching systems, and the price reflects those expectations. The market segments into tiers: affordable appearances-oriented laminates, weight-focused laminates with measured gains, and high-end, show-ready laminates that prioritise finish quality. These tiers map to supplier networks and warranty regimes, shaping both initial outlay and replacement costs.

The shopping landscape for these hoods is global. Platforms like eBay have long served the 1991–1993 coupe/steep-price niche, blending parts for performance and appearance. In contrast, marketplaces emphasizing materials capability and weight savings tend to align with later model years and performance claims. This split illustrates how model-year differentiation creates parallel markets, each with its own price signals, supply chains, and expectations of durability and fit.

A concrete illustration of these dynamics is the pricing delta between a general appearance hood and a dedicated performance laminate. Real carbon fiber involves higher manufacturing complexity and quality control, and the resulting price premium is not simply vanity: it reflects weight reduction, stiffness, and the potential for sharper handling. Buyers weighing performance against daily usability make trade-offs that can yield a longer-term payoff through improved handling and resale appeal when the car is positioned as a performance build.

Market actors—suppliers who specialise in carbon fiber parts and fabricators with track records in performance builds—sustain an ecosystem of availability, customization options, and post-sale support. The existence of a robust supplier base signals reliability and encourages longer ownership cycles and more ambitious builds, reinforcing a positive feedback loop: demand fuels higher-level fabrication, which in turn supports more sophisticated finishing and more precise fitment. In a global market, this loop accelerates dissemination of best practices from weave patterns to curing and finishing techniques, shaping the ultimate price level and the rate of market expansion.

Cautionary notes remain. Fitment quality, curvature accuracy, and compatibility with structural elements are practical concerns that influence risk assessment. Subpar laminates can introduce warping or paint lift, degrading aesthetics and performance. In a market that prizes precision, these risks translate into depreciation or remediation costs. Builders often insist on sourcing high-quality laminates and the expertise to ensure precise mounting, proper sealants, and durable latching mechanisms. The financial stakes rise with the level of customization. In short, the carbon fiber hood is a microcosm of the broader customization economy: a buyer must balance upfront investment with long-term asset stability while enjoying a display of technical sophistication that resonates with performance-minded buyers.

The broader trend toward lightweight, high-strength materials is reshaping expectations across the automotive aftermarket. Willingness to pay a premium for carbon fiber hoods reflects a market consensus that weight savings and engineering craftsmanship are valuable signals, influencing resale dynamics and the pricing of related modifications. It also demonstrates how a narrow product category can influence an entire customization program, driving demand for compatible components and specialized fabrication services.

To close, a concrete example can anchor these ideas: a 1994–1999 Mitsubishi 3000GT upgraded with a carbon fiber hood alongside other weight-saving components, illustrating how weight reductions, fitment considerations, and exclusive branding intersect with sourcing, fabrication, and resale value. The chapter’s broader lesson remains: the premium for lightness, the craftsmanship required, and the potential for a resale premium when the build communicates serious intent. External reading that contextualizes the market for carbon fiber components highlights material specifications, supplier ecosystems, and current dynamics in this niche.

Final thoughts

The integration of carbon fiber hoods into the Mitsubishi 3000GT not only enhances performance but also reflects the evolving landscape of automotive customization. As business owners, recognizing the trends and economic benefits associated with these upgrades can substantially impact customer engagement and sales. The advantages of carbon fiber – including weight reduction, improved aerodynamics, and aesthetic appeal – positions it as a desirable option for vehicle enthusiasts. By staying attuned to market developments and understanding the comprehensive benefits of these products, businesses can effectively cater to the demands of an enthusiastic consumer base looking to enhance their driving experience.