The Mitsubishi Lancer Evolution X, celebrated for its performance and driving dynamics, continues to resonate with car enthusiasts and businesses worldwide, even after its production ceased in 2016. The growing demand for Evo X car parts presents significant opportunities within the global aftermarket landscape. This article delves into the various aspects that influence the supply chain dynamics, performance upgrades, and key manufacturing regions. By exploring market trends and regulatory considerations, business owners can strategically position themselves in this niche market, ensuring quality and reliability in sourcing high-performance components.

Global Motion: The Dynamic Supply Chain Behind Evo X Car Parts

The Mitsubishi Lancer Evolution X remains a pulse point for enthusiasts who chase performance long after the model itself stopped rolling off the assembly line. Its aftermarket ecosystem is not a single storefront or a handful of workshops; it is a living, distributed network that stretches from exacting Chinese factories to racing teams in distant continents. The supply chain for Evo X parts is a story of specialization, coordination, and continuous iteration. It thrives because demand persists among tuners, rally teams, and independent shops that treat performance not as a momentary fad but as a disciplined practice. What makes this ecosystem function so reliably is a combination of regional prowess, rigorous quality systems, and the acceleration of logistics that connect small precision jobs to large-scale production curves. In this context, China acts as the beating heart of high-performance component manufacture, organized around clusters that concentrate expertise, equipment, and export capability in ways that are difficult to replicate elsewhere. Guangdong Province, anchored by Guangzhou and Shenzhen and reinforced by bustling ports such as Nansha and Shekou, stands at the center of this activity. Here, complex assemblies—intake manifolds, suspension systems, turbocharger housings—emerge from a tightly woven network of machine shops, testing facilities, and finish process lines. The proximity to export hubs translates into shorter lead times and more reliable shipping, a critical advantage when a shop in Europe or North America needs a steady cadence of parts to keep a customer’s Evo X in peak form.

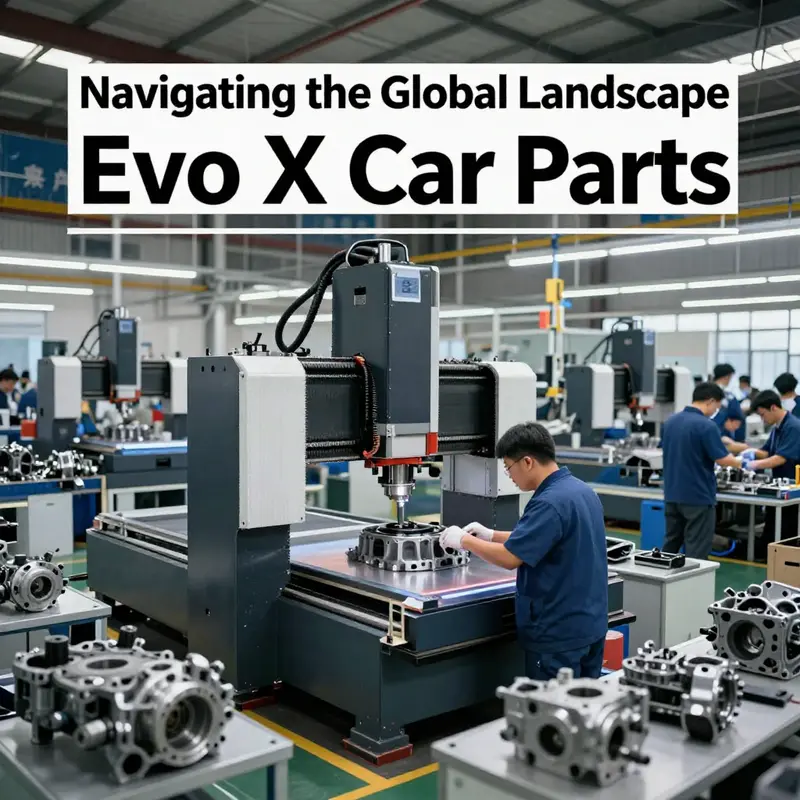

But the story does not stop in Guangdong. The broader Chinese landscape provides a spectrum of capabilities that together create a robust, end-to-end supply framework. Zhejiang, for instance, is renowned for precision engineering and CNC machining. Forged internals like crankshafts and connecting rods emerge from facilities that couple high-quality alloy fabrication with close ties to technical universities, fueling a pipeline of improvement in materials science and engine dynamics. Jiangsu specializes in die-casting and sheet metal forming, supplying exhaust systems, intercoolers, and durable ABS body kits. These regional strengths—CNC finesse in one province, casting in another, and sheet forming nearby—permit buyers to source multiple components from a single, well-coordinated supplier ecosystem, a critical advantage for OEM-tier clients and professional racing teams who demand repeatable performance.

Yet new centers continue to emerge, expanding the geographic fabric of Evo X parts production. Chongqing and Yantai in Shandong are gaining momentum thanks to government-backed industrial parks, lower operating costs, and partnerships with research institutions focused on materials science and engine dynamics. This evolving geography matters for buyers who value cost efficiency paired with ongoing innovation. The strategic sourcing playbook that guides B2B buyers in this space emphasizes a disciplined, methodical approach to supplier verification. Certifications such as ISO, IATF 16949, and CE are not decorations but gatekeepers that validate process stability, traceability, and product reliability. Prospective partners are encouraged to test samples, conduct on-site factory audits, and insist on clearly defined contract terms. In a market that blends high-performance engineering with cross-border commerce, escrow-based payments and transparent risk management become as essential as a well-tuned turbocharger.

Within this framework, the Evo X aftermarket offers a broad spectrum of parts that illustrate the region’s capacity to deliver both performance and reliability. Reinforced front and rear sway bars, for example, address the steering precision and cornering stiffness demanded by spirited street driving and track sessions alike. Carbon fiber body components—think front bumper splitters and side skirts—showcase the capability to combine lightweight construction with aerodynamic effectiveness, a combination that large OEMs have pursued for years but which the Chinese supply network now makes available to the independent tuner with shorter lead times. Radiator replacements and updated cooling components reflect the same logic: materials science and manufacturing know-how converge to preserve engine performance under higher thermal loads. Suspension components, including control arms and anti-roll bars, follow the same principle, offering durability and precision under the kinds of load cycles that hobbyists and professionals push during hot-laction laps.

The ecosystem’s strength also lies in its ability to offer customization without sacrificing export readiness. Suppliers frequently accommodate bespoke demands, packaging optimized for overseas shipping, and compatibility with major e-commerce platforms such as eBay, Amazon, and Lazada. This combination—engineering depth plus export-readiness—permits a B2B buyer to place one order and receive a coordinated set of components that align with a single vehicle specification, a feature particularly valuable for Evo X owners who look to maintain a consistent fitment standard across multiple parts.

Within this narrative, a concrete example of the ecosystem’s depth can be found in the Evo X’s carbon fiber accessories—a product category that signals both material sophistication and precision manufacturing. A representative product in this space is the carbon fiber bonnet hood designed for Evo X platforms, which demonstrates how a single component can thread through design, testing, and mass production pipelines. For readers exploring the practical side of sourcing such items, this model demonstrates how a Chinese supplier can coordinate with CNC shops and composite facilities to deliver a high-performance, lightweight piece that meets strict tolerances. One way to visualize this is to follow a direct reference to a notable Evo X body-component page: brand-new carbon fiber bonnet hood for Mitsubishi Lancer Evo X. The link, embedded in a natural discussion about how the supply chain informs component quality, illustrates how digital catalogs and real-world machining converge in today’s market.

The supply chain’s efficacy is reinforced by a clear, industry-minded approach to quality and compliance. Certified suppliers can source SAE-grade steel, forged aluminum, and heat-resistant polymers from vetted material suppliers, ensuring that the final product meets international standards. Proximity to certification bodies aids ongoing compliance, reinforcing a cycle of quality improvement across the supply chain. For B2B buyers, this translates into shorter lead times, scalable capacity, and the confidence that a single, well-managed supplier network can deliver complex assemblies without sacrificing consistency or traceability. The decentralization of production across Guangdong, Zhejiang, Jiangsu, and the emerging hubs creates a network that is both resilient and adaptable. If demand surges for a particular component—an outcome not unusual in the Evo X aftermarket—the system can flex: extra shifts, more defined sub-supplier lines, and a rebalancing of logistics workstreams ensure that the curve remains manageable.

This resilience has downstream effects on global markets. North America, Europe, and Asia remain the primary arenas where Evo X parts are consumed, and China’s role as a central supplier is unlikely to wane soon. The combination of vertical integration across multiple stages of production, shorter lead times, and scalable capacity underpins the ecosystem’s stability. For procurement managers seeking excellence, the emphasis remains on vetting supplier certifications, validating samples, and ensuring alignment of contract terms with quality expectations and delivery timelines. A well-structured sourcing strategy also considers payment risk and the use of secure escrow arrangements to protect both buyers and suppliers in a cross-border environment. As the Evo X aftermarket continues to expand, buyers benefit from a mature, interconnected network that reduces the friction historically associated with sourcing performance parts across oceans and arcs of time zones.

For readers seeking broader context beyond the immediate ecosystem, the Evo X parts narrative benefits from external, deep-dive resources that map out Chinese manufacturers and supply paths in a B2B framework. Such resources complement the firsthand understanding of factory layouts, production lines, and cross-border logistics, offering a lens on how regional strengths translate into global reliability. The broader guide discusses how to navigate supplier relationships, assess capability, and build a durable supply chain for high-performance components across markets. This external perspective helps frame the Evo X ecosystem as part of a wider movement toward more transparent, standards-driven, and collaboration-focused international manufacturing. See the external resource for a more expansive view: https://www.example.com/lancer-evo-x-parts-supplier-guide.

In sum, the Evo X parts supply chain stands as a benchmark for how a legacy performance platform can sustain a modern, global market. Guangdong’s export prowess, Zhejiang’s precision, Jiangsu’s adaptability, and the emerging Chongqing and Yantai clusters together create a multi-layered ecosystem capable of delivering complex assemblies, customized treatments, and reliable service life. Buyers who engage this network with disciplined vendor evaluation, clear contracts, and thoughtful risk management gain access not only to parts but to a reliable pathway for keeping the Evo X aligned with its reputation for performance. That reliability, in turn, fuels a global culture of tuning and competition that preserves the Evolution’s spirit long after the factory doors have closed.

Engineering the Evo X: Performance Upgrades, Precision Tuning, and the Art of Customization

The Mitsubishi Lancer Evolution X has long been more than a car; it is a platform that invites iteration, a blank canvas for enthusiasts who measure progress in torque curves and corner speeds as much as in street presence. Even after its discontinuation, the Evo X remains a living project, a chassis that rewards careful preparation with predictable, repeatable gains. In this chapter, we trace how performance upgrades and customization options come together to extend the Evo X’s life on the road and on the track. The discussion moves beyond a checklist of parts to a philosophy of harmony—power, control, and appearance working in concert to deliver a coherent driving experience. The heart of any Evo X build is its engine, where the most noticeable improvements begin with a thoughtfully assembled performance kit. The typical upgrade path centers on the 2.0-liter turbocharged engine, where opportunities exist across the intake, charge cooling, exhaust, and engine management. A high-flow turbocharger to reduce restriction, paired with an upgraded intercooler to resist heat soak, lays the foundation for more air to reach the combustion chamber. A performance exhaust system further reduces backpressure, while a cold air intake can shorten the path of incoming air to the turbo. None of these changes, however, work in isolation. The true payoff arrives when ECU tuning solutions are calibrated to the revised flow characteristics, ensuring the engine breathes cleanly at higher load and remains within safe limits for fuel delivery and ignition timing. This is the art of the upgrade: balancing increased air and fuel flow with reliable timing, heat management, and fuel pressure. Without a coordinated approach, gains can be brief or offset by heat build-up and imperfect fuel delivery. The Evo X rewards patient tuning, where a high-flow fuel pump and appropriately sized injectors often accompany the intake and exhaust improvements, maintaining a steady supply of fuel under sustained boost and enabling the engine to realize its full potential without sacrificing reliability. The result is more horsepower and torque, more immediate throttle response, and improved turbo efficiency that makes the car feel quicker, especially on mid- to high-end boost ranges. Yet performance gains carry a responsibility: the engine’s thermal and mechanical limits shift, and the driver must respect them with supportive upgrades and precise calibration. The same logic applies to brakes. High-performance braking systems are not merely about a stronger pedal; they are about managing heat, fade resistance, and pedal feel under demanding conditions. A properly matched system uses larger rotors, high-friction compounds, and calipers engineered to dissipate heat quickly. The goal is consistent, fade-free stopping power that remains linear and predictable as temperatures rise. This is essential for track days, where the difference between a good stop and a late brake is a lap time and a rev-mimiter. The Evo X’s response to braking enhancements is direct and communicative: you feel a more confident bite, a more stable feel as you approach the limit, and a tire that remains confident under heavy deceleration. The suspension and handling kit complements the engine and brakes by translating all that power into control through corners. Adjustable coilovers enable the driver to tailor ride height and damping to the road surface and the desired balance between comfort and responsiveness. Stiffer front and rear sway bars reduce body roll, sharpening turn-in and sustaining tire contact through corners. Polyurethane bushings and performance alignment components help preserve steering precision and suspension geometry, particularly when the car undergoes aggressive cornering. The trade-off is a firmer ride on imperfect pavement, but for many drivers the improved feedback and consistent behavior through the apex are a worthy exchange. The result is a chassis that feels smaller and more decisive than the stock setup, with sharper turn-in, reduced understeer, and the ability to maintain higher speeds through corners. Aerodynamics offer another dimension of improvement, one that blends appearance with functionality. Aerodynamic body kits do more than give the Evo X a visual edge; they influence stability at speed, reduce lift, and manage drag in ways that support both handling and efficiency. A well-designed kit can direct airflow to optimize downforce without creating excessive drag, helping the car stay planted at high velocities while preserving agility on twisty roads. When executed with quality materials and precise fitment, these components contribute to a more composed ride, particularly on the track or during spirited drives along mountain passes. The choice of materials and finish also communicates a clear message about the owner’s intent—whether it is a street-oriented Jake-on-the-road look or a competition-ready machine. For those seeking to customize beyond performance, the Evo X offers an extensive range of visual and functional improvements that reinforce identity while maintaining alignment with the car’s core engineering. In this respect, the balance of power, brakes, suspension, and aero becomes an integrated tapestry: power that can be controlled, control that can be repeated, and appearance that announces intent without compromising reliability. The manufacturing and sourcing landscape that supports these upgrades is as important as the parts themselves. China, and specifically the Guangdong Province with hubs in Guangzhou and Shenzhen, has emerged as a mature ecosystem for Evo X components. The region’s mature logistics networks, skilled CNC capabilities, and proximity to material suppliers enable precise fabrication and efficient distribution, important factors for builders who require consistent fit and performance across batches. Certification capabilities for quality standards, along with access to engineers and technicians, further underpin the reliability of these parts. Zhejiang and Jiangsu are recognized as secondary hubs for precision drivetrain and forced-induction components, reinforcing a broader national fabric of high-quality manufacturing. This network makes it feasible for B2B buyers to source components that balance performance with durability and to manage supply chains that can withstand shifting demand. For procurement teams, the emphasis is on model-specific fitment and interoperability; every upgrade should align with the Evo X’s architecture so that the car remains predictable and safe. The handling of these parts often involves more than raw components. It demands a structured sourcing approach: verifying supplier certifications such as ISO, CE, and industry-specific standards; testing samples for fitment and performance; conducting on-site audits to validate capabilities; and employing secure payment practices that protect both sides during the procurement lifecycle. In the broader ecosystem, customization also extends to packaging and logistics, ensuring parts arrive in export-focused packaging that protects sensitive finishes and keeps components organized for installation. The end result is a factory-to-garage flow that respects both performance goals and the Evo X’s heritage as a car that thrived on precision and synergy between driver and machine. The beauty of this ecosystem lies in its scalability: for a track-focused project, one can assemble a cohesive package that emphasizes power, braking capacity, and aero performance; for a street-oriented build, the emphasis shifts toward balance and daily drivability while preserving a sense of theater. Critical to any build is an awareness of fitment and compatibility. Model-specific accessories matter as much as raw performance parts because poorly matched components can lead to compromised handling, mismatched tolerances, or unintended heating effects under boost. Sourcing professionals acknowledge this reality and emphasize due diligence: a clear contract with installation expectations, a robust testing protocol, and a realistic maintenance plan that accounts for higher stress levels on components exposed to boosted power. For those navigating this space, engaging with verified suppliers—preferably through trusted platforms that curate high-quality Evo X components—offers a pragmatic route to price-competitive, high-performance parts. One glimpse into the breadth of customization is the availability of carbon-fiber exterior and interior elements, wherein the finish and weight savings can subtly influence overall performance and feel. For a tangible example of related customization options, readers can explore a dedicated page about a carbon-fiber bonnet hood for the Evo X, which highlights the balance between weight reduction, rigidity, and aesthetics. carbon-fiber bonnet hood for Mitsubishi Lancer Evo X. While that example focuses on a single component, it signals the broader principle that lightweight, integrated parts can uplift the driving experience without introducing unpredictable handling traits. For those who crave a broader perspective on the Evo X’s evolution and community-driven insights, a credible external resource offers a comprehensive overview of the model’s performance ethos and development history: MotorTrend Evo X Guide. This reference provides context for how enthusiasts interpret the performance envelope and how manufacturers’ upgrades translate into real-world capability. https://www.motortrend.com/cars/mitsubishi/lancer-evolution-x/

The Web of Evo X Parts: How China’s Manufacturing Hubs Shape Performance

The Mitsubishi Lancer Evolution X remains a benchmark in the annals of rally-inspired street performance, a model whose aftermarket demand continues to be buoyed by a tightly woven global supply chain. Beyond the street-credible aesthetics and mechanical bravado, the real story is how the Evo X ecosystem is sustained by a network of manufacturing clusters in China. These clusters have evolved into a layered, tightly integrated fabric that channels ideas from engines and suspensions to carbon fiber aero and body panels through a sequence of highly specialized workshops, skilled technicians, and logistics platforms. The result is not merely a catalog of parts but a dynamic, incremental system that shortens prototyping cycles, scales production, and reduces risk for buyers who need reliable, repeatable performance upgrades. In this context, Guangdong Province stands as the undisputed epicenter of Evo X parts development. Its dense constellation of auto parts manufacturers has built around turbocharged systems, suspension components, ECUs, and exterior aero elements a mature, vertically integrated environment. The proximity to major ports, a mature logistics backbone, and a culture of rapid iteration make it possible to move from concept to customer with a speed that few other regions can rival. CNC machining centers dot the landscape, enabling tight tolerances and repeatable results for components that must survive the high-stress conditions typical of performance tuning. A factory floor in this region can mold a manifold, machine a precision shift fork, or assemble an ECU with practiced efficiency. The geographic advantage is not merely about speed; it is about the flow of information and materials. Proven suppliers can source high-grade billet aluminum, composite materials, and the copper and steel alloys needed for enduring parts while maintaining lean inventories and shorter lead times. The ecosystem’s strength lies in how quickly new ideas can be validated and moved into tooling and production. This, in turn, reduces the cycle from concept to first sale, a critical advantage for teams chasing performance milestones or responding to evolving rules in the aftermarket space. Beyond Guangdong, the Yangtze River Delta, especially Zhejiang and Jiangsu, provides a different yet complementary capability set. Here the emphasis is on precision engineering and high-volume, efficient production. The region shines in the injection molding of bumper covers and exterior panels, with sophistications in polypropylene and thermoplastic olefin materials enabling cost-effective mass production without compromising fit and finish. Zhejiang also hosts advanced composites manufacturers, including carbon fiber and FRP specialists, which are invaluable for aero parts that demand lightness and rigidity. This combination—high-precision drivetrain components, well-tuned forced induction parts, and scalable exterior panels—means buyers can source both bespoke pieces and bulk exterior bodies from adjacent clusters without sacrificing consistency. When the conversation moves to high-tolerance components and the most exacting engineering challenges, Chongqing and Tianjin emerge as rising centers of precision. Chongqing, in particular, has become a large-scale production base supported by government-backed industrial parks and collaboration with technical universities. This fosters a steady pipeline of research into materials science and engineering methods that translate into practical, durable parts. The emphasis here is not on sheer volume but on the fidelity of machining and the reliability of fit under demanding conditions. For performance restorations or upgrades that require meticulous tolerances, this regional strength ensures that even parts subjected to high thermal loads, extreme vibration, or rapid dynamic changes can maintain alignment and durability. Tianjin contributes through its own manufacturing networks, offering a balance of precision operations and export readiness. Together, these northern and central hubs provide complementary strengths to the broader Evo X parts landscape. The fourth cluster, Shandong’s coastal belt around Yantai, offers an economical option for buyers seeking value without sacrificing reliability. The region’s cost advantages are attractive in a market where price sensitivity is real and supply stability remains essential. By coupling cost-efficient production with consistent quality control, Yantai-based facilities can deliver a broad range of components—from core engine and cooling parts to suspension elements—at price points that help keep overall project budgets in check while maintaining the performance targets Evo X enthusiasts expect. Taken together, these regions form a multi-node network that can handle everything from limited-run prototypes to scalable, export-ready production lines. For a buyer, this means flexibility: you can prototype in a Guangdong shop with rapid prototyping and CNC dexterity, then scale to Zhejiang or Jiangsu for high-volume body panels, or route precision-engineered components through Chongqing to Tianjin for final assembly and rigorous testing. The practical implications extend to how a sourcing program is designed and managed. A robust supplier strategy in this space relies on formal certifications, such as ISO or CE, as a baseline for quality management systems and product safety. But certification is only the starting point. Before committing to large orders, procurement teams should request product samples and conduct on-site factory audits to evaluate processes, equipment, and quality-control checklists. In a sector where fit can determine performance and reliability, the ability to verify process controls, gauge calibration, and trace material origins matters as much as the part’s geometry. The governance of payments also plays a pivotal role in reducing transactional risk. Escrow arrangements and clearly defined contract terms can shield both sides from misalignment or late deliveries, especially when supplier capacity is linked to multi-month cycles or fluctuating demand. For buyers, the aim is a stable, predictable supply chain that can weather market swings without sacrificing performance standards. When it comes to actual Evo X parts, the landscape is rich in both classic performance upgrades and modern, weight-conscious components. Engine-focused upgrades include high-strength components that can withstand the stresses of a turbocharged inline-four motor, along with intake and cooling modules designed to improve air flow and heat management. Suspension components—such as upgraded control arms and anti-roll bars—help sharpen handling characteristics by balancing stiffness with compliance. Carbon fiber body parts, including aero elements like front splitters, side skirts, and rear diffusers, can yield meaningful gains in downforce and weight reduction, translating to more precise cornering and faster response in dynamic driving scenarios. Radiator replacements and cooling hardware, too, play a crucial role as the Evo X pushes temperatures higher under spirited driving. The manufacturers in these clusters often offer customization options, export-focused packaging, and the ability to serve broad, global distribution channels. This adaptability is essential for meeting the diverse demands of markets across Europe, the Americas, and Southeast Asia, where different compliance regimes and logistics realities shape how a part is specified, packaged, and shipped. For procurement managers seeking best-fit partners, the emphasis should be on reliability and repeatability. The sourcing guides emphasize testing product samples, validating process controls, and establishing clear, enforceable contract terms. A supplier who can demonstrate consistent quality across multiple lots, maintain tight tolerances, and provide traceability for materials will typically deliver a more stable supply chain than one with sporadic performance. In this sense, the Evo X parts ecosystem mirrors the broader shift in advanced manufacturing: the most successful buyers treat supplier relationships as long-term collaborations rather than transactional touches. The advantage of engaging with Chinese clusters is not just cost; it is access to a full stack of capabilities—from meticulous machining and high-volume molding to sophisticated composites and precision assembly. This integrated capacity enables a smoother, more predictable path from idea to finished piece. It also supports the lifecycle realities of Evo X upgrades, where a project may begin with prototyping a carbon-fiber aero piece and evolve into a full, coordinated package that improves airflow, chassis rigidity, and overall balance. For readers seeking a concrete touchstone in this ecosystem, the industry routinely points to the availability of carbon-fiber and composite options, a broad spectrum of engine and drivetrain components, and the capacity to tailor combinations of parts to distinct driving styles and tuning goals. The journey from concept to track-ready form is made tangible by the regional strengths described above, complemented by a disciplined sourcing framework, supplier verification, and risk controls that ensure long-term supply chain stability. For those who wish to explore a tangible example of the kinds of carbon-fiber aero parts that are commonly requested, see the related product offering for Evo X where a carbon-fiber bonnet hood is listed in catalog-like formats, illustrating how a lightweight, rigid shell can be integrated with existing front-end geometry to improve cooling and aero balance. carbon-fiber bonnet hood for Mitsubishi Lancer Evo X. As you navigate this space, keep in mind that the most successful Evo X sourcing programs treat regional strengths as complementary rather than substitutable. A Guangdong workshop can deliver rapid prototyping and high-precision machining; Zhejiang and Jiangsu can handle large-volume body parts with consistent finishes; Chongqing and Tianjin can push the envelope on precision and tolerances; and Shandong can supply cost efficiencies that sustain competitiveness over the long term. The chapter on supplier verification and risk management underscores that this is not a race to the smallest unit price but a careful balance of quality, lead time, and total cost of ownership. In the end, the Evo X parts landscape is a living map of capability concentrated in a few Chinese regions, each contributing a unique capability to the broader pursuit of performance, reliability, and innovation. External reading on quality management standards can provide additional context for how suppliers demonstrate consistency and continuous improvement in these complex, multi-part ecosystems. For broader standards on supplier quality management, see https://www.iso.org/iso-9001-quality-management.html.

Heritage, Hardware, and Global Trade: The Evo X Parts Market in an Era of Precision and Persistence

The Mitsubishi Lancer Evolution X stands as the final act in a lineage built on driving purity and engineering discipline. In 2026 the Evo X parts market is quietly undergoing a resurgence, not as a fad, but as a disciplined response to heritage value and the realities of modern emissions and maintenance economics. Enthusiasts who want to preserve the original character of their cars—while still enjoying reliable performance—drive a steady demand for authentic, high-fidelity replacements and well-engineered upgrades. The result is a market that rewards precision, compatibility, and longevity as much as raw horsepower. This is not a short-run trend; it reflects a sustained commitment to keeping a legacy car on the road with the confidence that its core dynamics—steering feel, balance, and throttle response—remain faithful to the factory intent.

Across the global supply chain, specialized manufacturing clusters have matured. In Asia, major corridors concentrate in regions that blend CNC machining prowess with skilled labor and efficient logistics. Guangdong Province, especially the hubs of Guangzhou and Shenzhen, plays a central role. Here factories harness advanced milling, turning, and finishing capabilities, paired with rigorous quality control. For buyers, this means parts that align with OEM tolerances and behave predictably under race‑level loads or daily driving. The presence of robust port access and streamlined export operations reduces lead times for distributors serving markets from Europe to North America. A mature supplier ecosystem in the Pearl River Delta supports engine components, chassis hardware, and body‑aero parts with a level of reliability that is harder to achieve in more dispersed regions. The regional advantage is reinforced by collaborations with technical universities and research institutes, which push materials science, heat treatment, and corrosion resistance forward while keeping costs in transparent bounds.

Within this landscape, the Evo X aftermarket ecosystem thrives on a few core categories. First are engine and cooling components that keep the car at its intended performance envelope while meeting evolving emissions standards. Second are chassis upgrades—stiffer mounts, tuned suspension links, and reinforced anti‑roll systems that preserve handling precision without sacrificing daily comfort. Third are carbon fiber and other lightweight panels and aero pieces that restore the car’s aggressive stance without adding bulk. Suppliers also offer radiator replacements, which can be critical as heat management remains a defining constraint under spirited driving. Across the board, product quality hinges on materials science, precise tolerances, and packaging designed for international shipment. Many producers tailor their offerings for export, preparing components that fit standard mounting points and can be integrated with minimal modification. In this environment, certification programs and standard testing procedures help distinguish components that will endure vibration, temperature cycles, and the occasional track session from those that will not.

The market’s growth is reinforced by the broader trajectory of the automotive parts economy. The e-commerce era has shifted how enthusiasts and repair facilities access components. Global online platforms now capture a sizable share of the aftermarket flow, with buyers willing to pay a premium for authenticity and fitment confidence. This shift has spurred manufacturers to invest in export packaging, clear technical documentation, and after‑sales support. Procurement managers seeking stability increasingly rely on verified supplier networks and formal certifications. In this context, industry perspectives emphasize audits, sample testing, and transparent contract terms. An important principle is to verify supplier credentials, annually review quality management systems, and establish risk‑sharing mechanisms such as escrow payments. A disciplined sourcing approach helps ensure long‑term supply continuity, even as demand fluctuates with hobbyist trends and regulatory cycles. Within Guangdong’s ecosystem, contract clarity and ongoing performance reviews become as important as price, because the cost of downtime or misfit parts can exceed the initial savings.

Analysts looking at the 2026 horizon note a pattern that resonates with Evo X enthusiasts. For the Evo VIII era, demand for authentic components surged around 22 percent year over year, driven by tightening emissions rules that make aging performance cars more attractive to keep on the road rather than retire. While the Evo X is a newer generation, the same dynamics—emphasis on genuine parts, precise fit, and durable materials—apply. Owners increasingly value parts that preserve the vehicle’s original steering feel, throttle response, and balance. This creates a premium segment where high‑fidelity, OEM‑spec derivatives are favored over low‑cost replicas. As a result, supply chains that can reliably deliver authentic or near‑OEM quality parts during peak maintenance windows become essential to maintaining performance narratives and resale value. The outcome is a market where provenance matters almost as much as performance, and where buyers scrutinize every packaging detail for signs of genuine engineering intent.

Beyond the product itself, the market rewards transparency and predictable service. The end‑to‑end journey from order to installation matters. This includes documentation for each component, traceability of materials, and standardized testing protocols that reassure buyers about long‑term durability. For many B2B buyers, this also means practical tools for risk management: escrow arrangements, clearly defined service levels, and a roadmap for replacement cycles aligned with maintenance schedules. In practice, this translates into on‑site supplier audits, controlled samples, and clear packaging standards that make cross‑border shipping straightforward. As regional hubs evolve, distributors increasingly segment their portfolios by performance tier and by compatibility with the Evo X’s engineering philosophy, ensuring that a given component preserves the car’s intended dynamics rather than altering its character arbitrarily. The result is a mature market where buyers expect not only a part but a comprehensive package: instructions, performance data, and post‑sale support that helps sustain the vehicle’s drive feel long after installation.

A practical illustration of the market’s integrated nature can be found in the way sellers present Evo X components to international buyers. Some suppliers emphasize compatibility and factory‑direct pricing, while others highlight engineering fidelity and materials superiority. The balance between price and performance becomes a decision point for buyers who must justify premium components against the cost of a full rebuild. For buyers who want to examine offerings before committing, a practical reference exists in Evo X component catalog pages that show how a major rebuild path can be planned and executed with minimal downtime. For example, a dedicated page can serve as a focal point for assembling critical sections of the car while preserving alignment and geometry. A practical entry point that demonstrates the packaging and fitment logic can be found on this Evo X halfcut resource. See evo-x-halfcut. evo-x-halfcut. It illustrates how a core set of components is organized for a rebuild, how fasteners and mounting brackets are considered, and how the sequencing of parts supports a smoother installation experience.

The broader context lies in market growth as a macro backdrop. The Reuters projection of a global automotive parts e-commerce market rising to 343.1 billion by 2032 provides a meaningful frame for these developments. It captures how digital channels, cross‑border logistics, and standardized procurement practices converge to support niche performance segments. For Evo X buyers and suppliers alike, this means an ecosystem that can scale without sacrificing the authenticity that enthusiasts prize. While the precise volume of Evo X part sales remains diffuse in public data, the trajectory is clear: a long tail of dedicated fans and professional rebuilders who demand high fidelity, consistent supply, and predictable delivery windows. In this context, sourcing practices—verification, testing, audits, and clear contracts—become competitive differentiators, not mere compliance requirements. They translate into reliable lead times, better uptime, and higher confidence in long-term ownership.

As this market continues to mature, the cadence of innovation in materials and manufacturing will influence which parts endure and how future generations will approach preservation. More manufacturers will invest in non‑destructive testing, corrosion‑resistant coatings, and heat‑resistant composites to extend service life under demanding conditions. The Evo X, a symbol of the era, will thus be kept on the road not through a single perfect component but through a balanced portfolio of authentic replacements, compatible upgrades, and expertly packaged kits. The result is a dynamic, global trade in parts that respects the car’s heritage while leveraging modern manufacturing discipline to ensure every bolt, bracket, and panel serves the driver faithfully for miles to come. External resources continue to illuminate the broader market story, helping practitioners align strategic choices with evolving consumer expectations and regulatory landscapes. For broader context on the market, refer to the global automotive parts market projection provided by Reuters: https://www.reuters.com/business/autos-transportation/global-automotive-parts-market-to-reach-343-billion-by-2032-2025-09-15/

Compliance as the Fast Lane: Navigating Regulatory and Certification Pathways for Evo X Car Parts

The Evo X car parts ecosystem operates at the intersection of high performance and strict governance. For buyers and suppliers alike, the path from factory floor to vehicle is paved not only with torque curves and material science, but with a maze of standards that guard safety, reliability, and market access. In this landscape, regulatory and certification considerations become as critical as the engineering specs themselves. A well-structured compliance program doesn’t just prevent recalls; it accelerates risk-adjusted growth by enabling faster approvals, smoother cross-border shipments, and clearer, trust-based relationships across the supply chain. The story of Evo X parts begins in the clusters outward from the Pearl River Delta, where advanced manufacturing talent and logistical networks converge. Here, suppliers routinely operate within ISO-based frameworks and pursue international quality certifications that reassure buyers from Europe to North America. Yet for any procurement manager seeking stable, long-term supply, the regulatory terrain cannot be treated as an afterthought; it must be woven into every sourcing decision, product development plan, and contract clause.

At the heart of credible Evo X parts supply lies supplier qualification grounded in robust quality management. The automotive industry has long codified its expectations through an international standard that represents the gold standard for process discipline in manufacturing. Choosing partners who are certified to this standard is not merely about ensuring defect rates fall below a threshold. It is about embedding a culture of continuous improvement, traceability, and systemic problem-solving into every part produced for the Evo X. In practical terms, that means audits, documented procedures, and a visible track record of corrective actions when deviations occur. It also means that suppliers are prepared to extend their quality systems into the real world of customer feedback, warranty handling, and service in multiple markets. This is where certification is more than a badge; it is a framework for reliability that translates into fewer disruption events in the supply chain, lower total cost of ownership for end users, and greater predictability for procurement teams managing global inventories.

Beyond supplier qualification, product certification and regulatory compliance encompass the standards that determine whether a component can be legally and safely installed on a vehicle in a given market. The North American market foregrounds certain safety standards that a component must meet to be considered street-legal, such as compliance with performance and safety criteria under relevant agencies. In Europe, compliance with established provisions for safety and environmental stewardship is equally indispensable. When we talk about critical safety components—such as braking systems, steering interfaces, or suspension assemblies—the absence of appropriate certification flags a non-starter for sale. Even for aftermarket parts, which may offer performance advantages, the legitimacy of claims and the verifiable presence of certification marks become a legal shield against misleading marketing and potential liability. The row of regulatory markers—from safety to emissions, labeling to packaging—functions as a universal gatekeeper that prevents non-conforming parts from entering international distribution channels.

The documentation backbone of compliance is traceability. Manufacturers and distributors must be able to map every component to its origin, production batch, and testing results. This is not merely an internal quality exercise; it is the means by which authorities, customers, and insurers can trace failures back to their source and implement targeted recalls when necessary. The Evo X ecosystem benefits from the scale of Chinese manufacturing clusters that are adept at integrating material science research with manufacturing execution systems. Yet scale intensifies the need for meticulous record-keeping: supplier certifications, test results, material declarations, and change notices must all be captured, stored, and accessible. A robust documentation regime enables rapid response to regulatory audits and supports product recalls with precise, verifiable data. It also improves the ability to demonstrate environmental compliance for parts that touch emissions control or end-of-life considerations, aligning with increasingly strict global environmental standards.

Distinctly, the Evo X space requires a careful delineation between original equipment manufacturer (OEM) parts and aftermarket offerings. OEM parts carry a higher expectation of compatibility and documentation, including access to technical data and warranty frameworks. In contrast, aftermarket parts can vary in quality and documentation, which elevates the importance of due diligence before procurement. Marketing claims about performance or durability must be underpinned by objective testing data; misrepresentation exposes sellers to legal risk and damages brand trust. A disciplined approach to product categorization helps buyers apply the correct regulatory pathway. For instance, even when an aftermarket component is certified, it may still require verification that its performance data are applicable to the Evo X chassis and to the market where it will be distributed. Clear differentiation of this kind reduces regulatory ambiguity and supports transparent communication with customers.

A practical procurement lens will emphasize the reliability of contractual terms as a risk-mitigation mechanism. Suppliers in high-stakes markets often welcome escrow-based payment arrangements, a structure that aligns incentives for both sides and provides a secure mechanism for releasing funds only when verified milestones—such as testing, batch release, and shipment—are met. Contracts should also define the transfer of technical documentation, change-control procedures, and post-market support commitments. It is essential to specify the responsibilities for conformity assessments across markets, including any required third-party laboratories or test reports. In turn, buyers must insist on up-to-date certificates of conformity, maintenance of regulatory dossiers, and a clear process for handling deviations and non-conformances. When these elements are in place, a supply chain can absorb volatility in demand or supplier capacity without compromising compliance or safety.

The regional dimension adds another layer of nuance. Guangdong’s manufacturing clusters bring together precision machining, clear supplier qualification processes, and integrated logistics that facilitate timely cross-border delivery. The same clusters, however, operate within the ambit of both national rules and international expectations. For buyers, this means that verifying certifications is not a one-and-done exercise; it requires ongoing supplier development and periodic re-audits to ensure continuing compliance as production lines evolve and new materials are introduced. A strategic approach to supplier management leverages the local ecosystem while maintaining global visibility over product specifications, regulatory status, and shipment documentation. It also means recognizing that different markets may impose additional labeling, packaging, and environmental requirements that affect how parts are presented and shipped. Clear labeling and robust packaging not only protect against damage but also carry regulatory compliance signals that facilitate import clearance and consumer confidence.

For the procurement manager, the practical journey from supplier selection to post-sale support begins with a disciplined supplier assessment, grounded in recognized certifications. A recommended starting point is confirming that suppliers adhere to a rigorous automotive quality framework, which reduces the likelihood of quality deviations that could trigger recalls or warranty disputes. While this framework is universal in its intent, the exact certification mix—ranging from quality management to environmental compliance—will vary by market. In addition to process certifications, the ability to demonstrate product-level compliance through test reports, material declarations, and conformity statements is indispensable. The next step is to validate documentation end-to-end: raw material sourcing records, production batch histories, and final inspection data that confirm the part meets the applicable standards for its intended use. In practice, these checks translate into smoother regulatory approvals and more predictable lead times for inventory replenishment, even in the face of supply disruptions.

An integrated approach also means embracing a selective use of internal and external links to strengthen the narrative of reliability. For example, readers can explore a representative Evo X component page that illustrates how carbon-fiber parts are positioned within a broader compliance-conscious supply chain, linking to a detailed product document that demonstrates material traceability and safe handling. This integration reinforces the argument that compliance is not a barrier but a driver of performance in the Evo X aftermarket landscape. Such alignment between engineering rigor and regulatory discipline is what allows trusted suppliers to outperform in a crowded market, delivering parts that meet or exceed safety and performance expectations while navigating the complexities of global trade.

In sum, building a credible Evo X parts supply chain hinges on a balanced, proactive approach to regulatory and certification considerations. It requires selecting suppliers with solid quality systems, ensuring that every part bears appropriate conformity markings, maintaining exhaustive traceability, clearly distinguishing OEM from aftermarket offerings, and embedding sound contract terms that protect both sides. It also demands familiarity with the regulatory footprints of target markets and a willingness to adapt packaging, labeling, and documentation to meet those standards. When these elements come together, regulatory compliance ceases to be a gatekeeping burden and becomes a strategic capability that accelerates market access, strengthens customer trust, and sustains a robust, global Evo X parts ecosystem. For further context on component sourcing and quality assurance practices, consider exploring internal resources on carbon-fiber Evo X components, such as this representative product page: brand-new-original-carbon-fiber-bonnet-hood for Mitsubishi Lancer Evo X.

External resource: https://www.iatfglobaloversight.org/

Final thoughts

The aftermarket for Evo X car parts is thriving, providing ample opportunities for businesses that understand its dynamics. By focusing on reliable sourcing, performance enhancements, and regulatory compliances, companies can not only meet but exceed the expectations of a loyal customer base. Embracing these insights will empower businesses to navigate this complex market and fuel sustainable growth in a niche that remains popular among automotive enthusiasts.