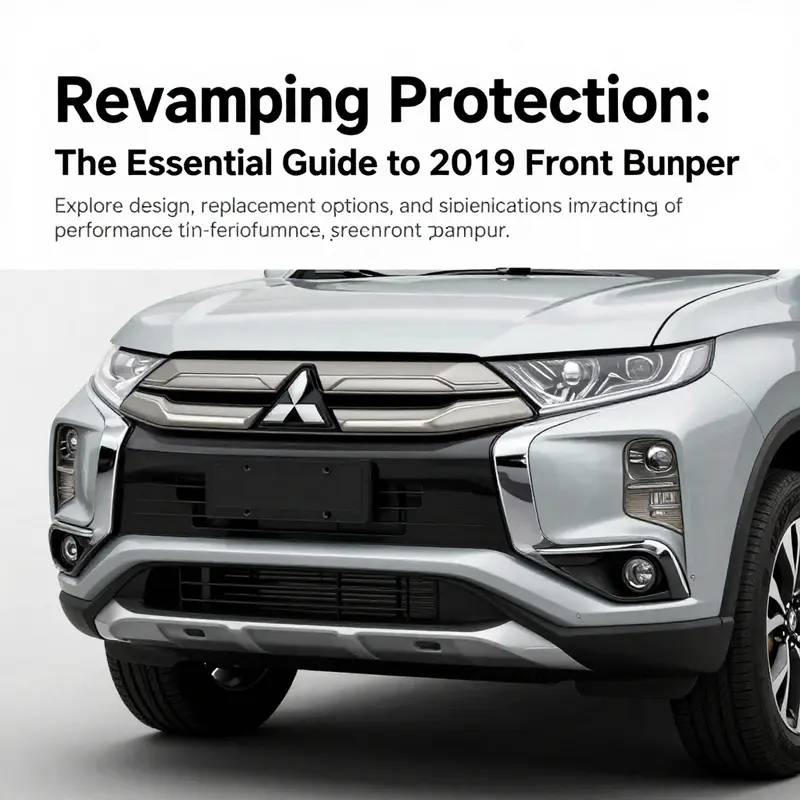

The front bumper of the 2019 Mitsubishi Outlander serves as a crucial element in the overall design and safety of the vehicle. It combines functionality with aesthetics, making it both an integral protective component and a stylish addition. For business owners dealing in automotive parts or services, understanding the importance of the front bumper, its replacement options, and the technical specifications is vital for customer satisfaction and operational success. This article delves into the comprehensive attributes of the Outlander’s front bumper, offering insights into its design and functionality, replacement alternatives, and key performance metrics.

Front-Line Engineering: Design and Functionality of the 2019 Mitsubishi Outlander Front Bumper

The front bumper on the 2019 Mitsubishi Outlander is a carefully engineered system that blends aesthetics with protection, airflow management, and compatibility with sensors and lighting. The outer skin is typically a high‑impact plastic such as polypropylene, chosen for its combination of toughness, light weight, and resilience after minor deformations. Behind the cover lies a reinforcement network that absorbs and dissipates energy in a controlled way during low‑speed impacts, helping protect headlights, the radiator, and the engine. The bumper also contributes to aerodynamics by shaping airflow under and around the nose, reducing drag and wind noise while accommodating openings for fog lamps and sensors. Structural brackets and energy‑absorbing beams tie the cover to the chassis, ensuring alignment and integrity in a crash while allowing sensor housings and mounting points to remain accessible for driver‑assist systems. From replacement and maintenance perspectives, many owners replace the bumper cover rather than the entire assembly to restore appearance and function, making sure to preserve fitment, paint finish, and sensor alignment. In short, the front bumper is a holistic component that integrates materials science, aerodynamics, energy management, and sensor compatibility to support safety, efficiency, and daily usability of the Outlander.

Guarding the Front Line: Replacement Paths for a 2019 SUV Front Bumper

The front bumper of a modern SUV is more than a cosmetic shell. It is the up-front shield that blends form with function, sculpting airflow to reduce drag while absorbing the first blows of everyday life on the road. In the context of the 2019 model year, this component plays a pivotal role in protecting the radiator, headlights, and sensor arrays that keep the vehicle safe and responsive. The bumper is typically manufactured from high-impact plastics or composite materials that strike a careful balance between strength and weight. This balance matters not only for performance and efficiency but also for the ease with which a damaged car can be repaired after a minor collision or a curb encounter. At the same time, the bumper house often includes or accommodates components such as fog lights, parking sensors, and sometimes even camera hardware. All these elements must be considered when evaluating replacement options, since a correct match is essential to maintaining both safety standards and the vehicle’s original behavior on the road. The logic behind evaluating replacement parts starts with a clear assessment of damage. If the impact is cosmetic, such as surface scratches, shallow cracks, or small dents, the most economical, straightforward solution is often a fresh front bumper cover. This cover is the outermost layer that provides the visible face of the bumper and, in many cases, can be swapped without removing the entire underlying structure. For more serious damage, however, the repair story changes. The bumper cover sits in front of a reinforcement structure, a metal or metal-composite beam designed to absorb a portion of the impact energy. If this internal beam is bent, cracked, or displaced, simply replacing the outer shell will compromise the integrity of the entire safety envelope. In such cases, a more comprehensive replacement is warranted, and the repair must be approached with an emphasis on restoring the original load paths and deformation characteristics that protect the engine bay, cooling systems, and pedestrian protection systems in some markets. The decision tree thus begins with damage severity, but quickly expands to consider fitment details and long-term reliability.

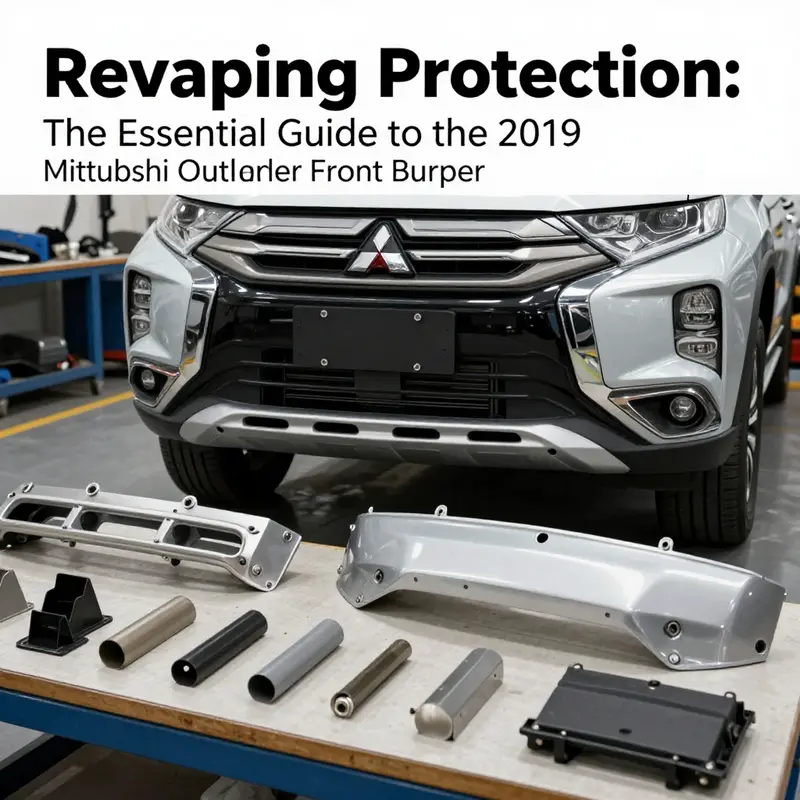

A modern bumper system is not a single part but a cascade of components that must work in harmony. The front bumper cover, by itself, is designed to resist edge impacts and to provide an aesthetically pleasing finish. It is usually crafted from a durable plastic or a reinforced composite material, selected for its ability to resist cracking and to weather sunlight, heat, and moisture. When a new cover is sourced, the key questions revolve around compatibility with the vehicle’s year, trim, and optional features such as fog lamps, sensors, or cameras. The correct cover must align with the openings for lights and sensors, and its mounting points must align with the underlying brackets and reinforcement components so that the overall fit is flush and quiet at highway speeds. The reinforcement beam behind the cover is often a critical piece of the safety architecture. It is designed to deform in a controlled way, channeling kinetic energy away from the passenger compartment and toward the bumper’s own energy-absorbing pathways. This component may be fabricated from high-strength steel or from a lighter aluminum alloy in some designs. Replacing it is not merely a matter of swapping rusty or bent metal for a fresh piece; it is a recalibration of how the vehicle distributes impact energy. Depending on the vehicle’s condition after a collision, the reinforcement beam may need to be replaced in addition to the bumper cover. The other structural members—brackets, brackets supports, energy absorbers, and mounting fasteners—complete the assembly and ensure proper alignment and vibration control. What looks like a simple cosmetic swap, if performed without attention to these ancillary parts, can result in misalignment that creates wind noise, compromised lighting, or gaps that allow dirt and moisture to creep into critical areas. In the calculus of replacement, the question then becomes not only what to replace, but how to replace it in a way that preserves alignment and ensures safe, predictable performance under a wide range of driving conditions.

For those who begin their shopping with a sense of economy in mind, an important distinction emerges early. There are two broad pathways: sourcing a brand-new cover that is designed to match the vehicle’s styling and mounting geometry, or opting for aftermarket or refurbished options that may carry smaller price tags but demand careful evaluation for fit and safety compliance. A new bumper cover for the relevant model year range is often designed to be a plug-and-play replacement, with the correct cutouts and mounting points for the fog lights, sensors, and other features that may be present. Aftermarket options frequently promise a similar level of aesthetics with a price advantage, but buyers should scrutinize the materials used, the thickness of the cover, and the precision of the moldings to ensure a seamless appearance and a predictable fit. It is also common to encounter variations in the part’s finishing, such as texture or paint-ready surfaces, which can influence the final look and the time required to complete installation. The choice between OEM-equivalent covers and third-party shells hinges on concerns about fit, color-matching ease, and the availability of a clean warranty pathway in the event of fit or color issues after installation.

Beyond the bumper cover itself lies a broader ecosystem of parts that must be considered during replacement. The bumper reinforcement, sometimes called a structural beam, is not a mere afterthought. It is a primary line of defense during a collision and a component that can influence crash-test performance results and even consumer safety ratings. When replacement is necessary, it is prudent to select a reinforcement that conforms to recognized safety standards and that is compatible with the vehicle’s mounting points and the bumper cover’s interface. In many repair scenarios, the reinforcement is installed in tandem with new anchors and fasteners that ensure the assembly remains secure and resistant to vibration. The fasteners and brackets—small, often overlooked items that ride at the edge of the assembly—should also be examined. If they show signs of deformation, cracking, or corrosion, they can compromise the alignment of the bumper and produce audible rattle or wind noise at speed. Replacing these fasteners and brackets during a bumper replacement helps ensure a robust, quiet, and durable result. The practical takeaway is straightforward: when damage extends beyond the surface, the repair plan should be comprehensive, addressing the bumper cover, reinforcement beam, and supporting hardware to re-create the factory-level strength and alignment.

Shopping considerations extend beyond the parts themselves. Prospective buyers should verify that a chosen component is labeled with correct year and model compatibility, and that it is documented as suitable for the vehicle’s trim level and any optional equipment. The documentation should clearly specify whether the part is an OEM specification, a certified replacement, or an aftermarket equivalent. In the world of car parts, a precise match is more than a matter of appearance; it is about maintaining the vehicle’s intended safety performance and sensor calibration. For those who have access to service manuals or official diagnostic documentation, the path becomes even clearer. The manuals guide technicians through the sequence of removals and installations, illustrating how the bumper cover interfaces with the underlying reinforcement and supports. They also provide crucial torque specifications for fasteners and warnings about sensor alignment and calibrations that can affect features such as adaptive cruise control or parking assistance. Even seemingly minor steps, such as ensuring correct bumper alignment to the body seams or confirming that the fog light housings seat properly within their cutouts, contribute to long-term reliability and occupant safety.

Within this framework, the concept of compatibility arises as a central theme. A replacement part must not only visually match the vehicle but also function in a manner consistent with the vehicle’s safety and diagnostic systems. The bumper’s relationship with sensors is a particularly important area. Modern vehicles rely on a network of sensors embedded in or around the bumper to assist with parking, obstacle detection, and other safety functions. Any misalignment or gap introduced by a poorly fitting cover can cause sensors to read incorrectly or to trigger false alarms. When sensors are involved, some replacement paths require recalibration or reprogramming of the sensor modules after installation. This recalibration step is a reminder that even a seemingly straightforward swap can involve software and electronics, not just a mechanical swap, and that professional technicians often bring the expertise needed to complete the process without residual errors.

For customers who may be weighing the balance of cost versus coverage, a practical heuristic emerges. Light cosmetic damage often calls for a bumper cover replacement alone, preserving the original reinforcement and attachments, provided there are no signs of structural compromise. If there is any doubt about the integrity of the reinforcement beam or the fasteners, a more thorough inspection is warranted. In these cases, replacing the entire front-end assembly or engaging a shop with the capacity to assess alignment, re-torque critical fasteners, and verify sensor operation is the prudent course. The goal is to achieve a result that looks right and performs reliably, with the kind of confidence that comes from a job completed to factory standards. When it comes to parts sourcing, buyers do well to verify the part numbers, confirm year-range compatibility, and look for products that clearly indicate their fitment with the vehicle’s systems. Parts sold with clear, explicit compatibility information and a reputable warranty are easier to return or exchange if fitment issues arise after installation.

The landscape of replacement options also reflects the accessibility of online marketplaces and specialized suppliers. In today’s market, several retailers offer new bumper covers suitable for the 2019–2020 model year range, with delivery typically within a few business days to a customer’s location. These offers vary in price and finish, but the common thread is a commitment to providing a component that matches the vehicle’s exterior contours and mounting geometry. For a door-to-door solution, buyers can pursue a package that includes the bumper cover plus integrated fog-lamp openings or cutouts designed to accommodate factory equipment. Alternatively, some configurations may present an option to purchase a separate fog-lamp assembly or to integrate lighting features through add-on kits. The practical outcome is that buyers have a spectrum of choices, from a straightforward shell replacement to a more complex package that preserves or enhances lighting and sensor functionality. The choice depends on the extent of damage, the desired level of OEM authentication, budget constraints, and the willingness to handle or delegate the installation to a professional shop.

As part of a comprehensive approach to replacement, the practical steps after selecting a part involve a careful inspection of the vehicle’s front-end assembly. The technician should verify the integrity of the impact-absorbing structure and inspect the frame rails for misalignment or offset. If the vehicle has emergency braking or advanced driver-assistance systems, the calibration of these subsystems after reassembly is an essential step. The process should also include a check of the sealing surfaces between the bumper cover and the body to prevent moisture intrusion and to preserve the vehicle’s corrosion resistance. If the vehicle’s original protective coatings show signs of wear around the mounting points, technicians often reapply protective coatings or sealants to maintain long-term durability. The stage is thus set for a careful, multidimensional replacement that respects both the aesthetics and the safety engineering of the vehicle. The result is not merely a new face on the front end but a restored balance of aerodynamics, protection, and device-enabled safety features that integrates with the vehicle’s broader design language and its engineering principles.

For readers seeking direct guidance on practical procurement while avoiding guesswork, consider using a reputable bumper replacement page that offers precise compatibility information and documented fitment for the relevant year range. This resource can help a buyer confirm that the chosen part aligns with the vehicle’s mounting points, sensor interfaces, and lighting openings. It also provides a clear path to confirm whether the supplier offers guidance on installation, return policies, and warranty terms. The importance of choosing a source with transparent specifications cannot be overstated, since a well-documented product reduces the risk of ordering errors and the time spent on re-shipping and returns. In any case, the overarching message remains stable: the front bumper is a composite system whose components must be considered together. A sound replacement strategy evaluates cosmetic damage, structural integrity, sensor compatibility, and the availability of fasteners and brackets that ensure a clean, noise-free installation. It also recognizes that the best results come from a careful, technically informed approach, ideally guided by official service documentation or by a certified technician’s assessment. To explore a dedicated bumper replacement page that aligns with these considerations, you can visit the bumper replacement page for the relevant vehicle model. bumper replacement page. This internal resource offers guidance on compatibility and typical installation considerations while remaining mindful of the diverse configurations that can exist across markets and trim levels.

In closing, the path to replacing a front bumper on a 2019 SUV involves more than swapping parts. It requires a holistic view of how the bumper, the reinforcement behind it, and the mounting hardware work together to maintain the vehicle’s safety, performance, and appearance. The process begins with an accurate assessment of damage, followed by a careful selection of parts that match the vehicle’s specifications. From there, the installation demands attention to alignment, sensor interfaces, and the re-tuning or recalibration of any electronic systems affected by the work. With these steps, the front end can be restored to its intended strength and look, supporting the vehicle’s overall safety profile and preserving the owner’s confidence on the road.

External reference: https://www.ebay.com/itm/156385723456

Guarding the Front Line: Engineering, Safety, and Integration of the 2019 Outlander Front Bumper

The front bumper of a modern SUV does more than frame the grille and shield the radiator. It is a carefully engineered blend of form and function, a primary line of defense in everyday scrapes and a key component that shapes the vehicle’s aerodynamics, crash response, and perception by drivers and pedestrians alike. In the 2019 Outlander, the front bumper is presented as a cohesive system rather than a standalone cover. It sits at the intersection of aesthetics, protection, and technology, a convergence that reflects a broader trend in which every exterior panel is integrated with sensors, lighting, and structural reinforcement. To understand its role fully, it helps to trace the bumper from raw material choices through to on road performance, and to consider how replacement parts and aftermarket options fit within the vehicle’s safety and reliability ecosystem.

The bumper’s weight is a practical starting point for any performance assessment. At roughly 5.2 kilograms for the full bumper assembly, the component contributes to the vehicle weight budget without tipping the scales in terms of unsprung mass or handling penalties. This relatively light footprint is intentional. It allows the bumper to contribute to fuel economy and nimble handling while still fulfilling its protective mandate. The weight rests on a careful balance: a shell built from high strength plastic or advanced composite polymers, chosen for impact resistance and resilience, paired with an internal reinforcement that absorbs energy during minor collisions. In this sense, the bumper is not merely cosmetic; it is a critical element in how the vehicle dissipates collision energy and shields the more delicate subsystems behind it.

The dimensional footprint of the bumper further clarifies its role in the vehicle’s overall geometry. With a length of about 203 centimeters, a width near 54 centimeters, and a height around 65 centimeters, the bumper establishes the silhouette of the front end while ensuring there is adequate space for airflow channels, sensor housings, and lighting fixtures. These dimensions are not arbitrary. They align with the OEM design language for that model year, ensuring consistency with adjacent body panels, the front fascia, and the lower valance. The geometry also helps guide air around the engine bay, reducing drag and smoothing the flow of cooling air toward the radiator and intercooler components. In effect, the bumper contributes to both the vehicle’s visual stance and its aerodynamic efficiency, two goals that often compete but are here harmonized through engineering precision.

Material selection is central to the bumper’s functional profile. The bumper uses impact resistant materials, typically high strength plastics or composite polymers. These materials are chosen for their ability to absorb energy in a short interval of time, protecting the vehicle’s chassis, sensors, and lighting assemblies. The use of composites or reinforced plastics helps keep weight in check while offering a degree of toughness that is well suited to urban and highway scenarios. The result is a panel that can withstand routine scrapes and minor impacts without compromising the structural integrity of the front end. When evaluated as part of a safety system, the bumper is not a passive shell but a dynamic participant in how restraint systems and occupant protection are activated during a crash. While the bumper itself does not determine crash results in a vacuum, its energy absorption characteristics contribute to overall frontal safety performance and pedestrian protection, aligning with regulatory expectations for frontal impact and pedestrian leg injury risk.

Beyond its core protective role, the bumper is designed to accommodate a number of integrated features that add to the vehicle’s functionality and safety. For instance, mounting points are prepared for fog lights, which provide improved low visibility illumination without succumbing to the drawbacks of high beam glare in poor weather. Fog light mounting points are not just hardware placeholders; they are engineered to maintain correct lamp alignment, protect the light housing from vibration, and preserve consistent lighting performance under a range of temperatures and road conditions. These mounting locations are carefully positioned to optimize the light’s beam pattern, contributing to safer night driving and better signaling of the vehicle’s presence to other road users.

The bumper also plays a vital role in housing sensors that feed advanced safety and driver assistance systems. In many 2019 models, sensor integration is a standard expectation: sensors for adaptive cruise control, automatic emergency braking, and other support features are often located along the front face, behind the bumper cover, or within the bumper’s crash structure. The bumper’s design includes channels, mounts, and recesses that ensure sensors remain properly oriented and protected from minor impacts. Proper sensor alignment is essential for the reliability of safety systems, and even a small misalignment can degrade performance or trigger false alarms. The bumper, therefore, is a crucial interface between the vehicle’s exterior and its interior intelligence. It is where the physical world meets the digital safety net that modern driving aids rely on.

In terms of installation and stability, the bumper is secured with a combination of durable plastic or reinforced metal brackets that anchor it firmly to the frame and to the surrounding body work. The fastening strategy is designed to minimize vibration-induced noise while maintaining precise alignment with adjacent panels. A well-installed bumper maintains continuous gaps and even lines, which not only enhances aesthetics but also reduces the risk of panel rattle under varying temperature and road conditions. The structural integrity of the bumper is also important for long-term reliability. A bumper that remains properly secured helps protect the front-end components from dirt and moisture ingress and ensures that protective energy absorption remains consistent throughout the vehicle’s life.

From a safety and compatibility perspective, the bumper’s specifications are tightly tied to the rest of the vehicle’s design, including the lighting, sensor suite, and front-end assembly. The design standard ensures it fits within the OEM configuration for the model year, preserving the alignment of the headlights, grille, and lower fascia. This compatibility is essential when replacements or repairs are necessary after minor incidents. For owners who may consider aftermarket options, the emphasis remains on maintaining proper geometry, sensor alignment, and compatibility with the fog lighting and radar or camera housings. Alterations that ignore these constraints can compromise safety functions, lead to vibration or misalignment, or degrade the intended aerodynamic performance. The careful choreography between exterior panels, sensors, and lighting has become more pronounced as safety systems rely more on accurate sensing and predictable lighting behavior to operate correctly.

Practically speaking, the bumper is an entry point to broader considerations about vehicle maintenance and ongoing reliability. When a bumper is damaged or removed for replacement, technicians must ensure that the new assembly is correctly aligned with adjacent panels and that mounting brackets are securely attached to the frame. They must verify that sensor housings and wiring are reconnected, that fog light mounts are intact, and that any protective coatings or paint finishes are matched to the vehicle’s color and texture. This process is not a cosmetic exercise; it is a careful refurbishment that preserves the performance characteristics of the safety features and the expected aerodynamic profile. The aim is to restore the front end to its original condition, not just to replace a cover.

For those who want to verify the official specifications or to source a replacement through a trusted channel, consult official service documentation or authorized dealerships. These sources provide verified OEM specifications that help ensure the replacement part will perform within the design tolerances. They also provide guidance on compatible hardware such as mounting brackets and reinforcement kits that may be needed to maintain structural integrity after a collision or during a restoration project. In practice, this means that a planned replacement often involves more than the bumper cover itself; it may include reinforced components and hardware designed to preserve the original safety and performance characteristics of the front-end assembly.

When considering replacements or upgrades, many owners explore options across major online retailers to compare fitment, materials, and finish. A new bumper cover designed for the later model years of the Outlander family can be found across online marketplaces. The emphasis remains on ensuring that any replacement part matches the 2019 design intent and is compatible with factory-installed features such as sensors and cameras. While aftermarket options can offer cost advantages or stylistic variations, the priority is maintaining the integrity of the front-end safety and performance package. The decision to pursue replacement should be informed by the vehicle’s unique configuration, the protection requirements for daily driving, and the desire to preserve or enhance its aerodynamic behavior and lighting performance.

For readers who want to explore a direct replacement option, there is a dedicated source that aligns with the 2019 Outlander front bumper design. This option is described as front-bumper-mitsubishi-outlander-19 in the product catalog, and it provides a straightforward path to a part that mirrors the OEM geometry and mounting architecture. This kind of replacement maintains the essential interface points with the frame, sensors, and lighting assemblies, which is especially important for owners who rely on active safety systems in their daily commutes. The emphasis remains on precise fitment and predictable behavior under a range of road conditions, from urban streets to longer highway trips. In this context, the bumper becomes a keystone component that supports both the exterior appearance and the vehicle’s embedded safety technologies, a dual role that is increasingly central to modern SUV design.

The sourcing landscape for these components reflects the broader market dynamics of automotive parts. While the OEM path guarantees alignment with the original design intent, there are legitimate reasons to consider alternate sourcing, including availability, lead times, and price. The discussion should balance these considerations with the understanding that a bumper is not a stand-alone cosmetic piece but a functional assembly that interacts with sensors, lighting, and the vehicle’s energy management during a collision. For those who pursue aftermarket or aftermarket-inspired options, careful due diligence is required to ensure that the replacement part provides the same load paths, mounting tolerances, and protection levels as the original. Certification and trade assurance from reputable suppliers become valuable in this context, especially for customers who require a reliable, long-term solution that preserves the integrity of the front end.

In summary, the 2019 Outlander front bumper is a microcosm of modern automotive design. It embodies a careful distribution of weight and material properties, a geometry tuned for aerodynamics and crash energy management, and an array of integrated features that support lighting and sensing. It is also a practical example of how maintenance and replacement intersect with safety and performance. The bumper remains a frontier where exterior styling, engineering rigor, and electronic safety converge. It is not merely a cover; it is a system that upholds the vehicle’s safety envelope, preserves its performance potentials, and sustains its aesthetic appeal across the life of the model. The nuanced interplay between material choice, structural reinforcement, and sensor compatibility makes the bumper a focal point for owners and technicians alike, a reminder that every panel on a modern SUV serves multiple, overlapping purposes.

For readers who want to go deeper into sourcing and verified specifications, official documentation and trusted suppliers provide the clearest path to high-quality replacements. These sources help ensure that the installed bumper preserves the intended alignment with the lighting and safety systems, maintains the original aerodynamic characteristics, and continues to protect the vehicle during its daily journeys. In practice, this means taking a measured approach to replacement, verifying fitment against the OEM design, and prioritizing reliability and safety alongside cost and convenience. And for those who are curious about direct access to a replacement option or who want to see how such parts are positioned within a broader aftermarket ecosystem, a dedicated link to a product catalog is available as a practical reference point: front-bumper-mitsubishi-outlander-19. This link provides a direct route to a part that aligns with the vehicle’s 2019 design language and interfaces cleanly with the existing sensor, lighting, and structural hardware. As always, cross-reference with official documentation to confirm compatibility and fitment before making a purchase or undertaking a repair project.

In the broader context of front-end design, the bumper serves as a tangible reminder that a small component can influence a vehicle’s safety, efficiency, and visual identity. It is an interface between the dynamic forces of the road and the controlled environment of the car’s mechanical and electronic systems. Every bolt, bracket, and mounting point plays a role in this ongoing balance. The pursuit of accurate specifications, robust materials, and precise installation practices is what ensures that the bumper continues to perform its protective duties while contributing to a refined driving experience. The 2019 Outlander front bumper encapsulates this philosophy, standing as a testament to how thoughtful engineering can yield a product that supports safety, aesthetics, and performance in equal measure.

External resources and verified data can augment this understanding. For researchers and practitioners who want to compare OEM specifications with marketplace offerings, consult the external reference from a major supplier that catalogs these parts with standard dimensions and material properties. This resource is not a replacement for official documentation but provides a practical context for how bumper components are described, evaluated, and presented in real-world sourcing scenarios. By integrating the official guidance with practical sourcing information, readers can approach replacement with a clear, data-driven frame of reference, ensuring that the front end of the vehicle remains a reliable, well-integrated system that supports safety and driving enjoyment for years to come.

Internal link to a direct replacement option for the Outlander front bumper provides a convenient touchpoint for practitioners reviewing fitment and alignment concerns. This URL, which is structured to reflect the 19 model year, offers a straightforward path to a part designed to preserve original geometry and mounting compatibility. It is important to use such a resource with due diligence, confirming compatibility with the exact vehicle configuration, and to cross-check with official service documentation when in doubt. The bumper’s role as a protective and functional component remains central to its value, reminding readers that even cosmetic decisions must be weighed against safety and performance considerations. Practitioners who approach replacement with this mindset are better positioned to achieve outcomes that are durable, reliable, and aligned with the vehicle’s overall safety strategy.

External resource: https://www.alibaba.com/product-detail/Mitsubishi-Outlander-2019-2020-front-bumper_1600487197532.html

Final thoughts

In summary, the front bumper of the 2019 Mitsubishi Outlander is not just a cosmetic feature but plays a multifaceted role in ensuring vehicle safety and aesthetic appeal. By understanding its design, exploring various replacement options, and recognizing the technical specifications, business owners can make informed decisions that enhance customer service. This knowledge empowers automotive professionals to address client needs effectively and ensures that the integrity of the vehicle’s safety features is maintained.