The Lan Evo engine series, particularly renowned for its engineering excellence, has captivated automotive enthusiasts and business leaders alike. This article explores the progression of Mitsubishi’s engines, from the historic 4G63 to the innovative 4B11T and beyond. Each chapter reveals the evolution of performance technology, focusing on how these changes affect market perception and user choices. As we delve into the intricate details and future prospects, we’ll highlight the importance of these advancements in the automotive industry, showcasing the blend of performance and efficiency that today’s consumers demand.

心脏演化的序曲:从4G63T到4B11T,再到4G63+MIVEC的融合之路

在日系性能车的历史长河中,兰瑟的发动机家族像一颗不断跳动的心脏。它并非简单地叠加数字,而是一场关于耐久、响应和驾驭乐趣的持续对话。起点是4G63T,它以铸铁缸体和涡轮增压塑造了强大的扭矩分布与改装友好性。

随着时代对轻量化和热管理的要求提高,4B11T的铝合金缸体成为关键升级,带来重量下降和更高效的热分布,使整车响应更线性。

随后通过4G63+MIVEC的跨代融合方案,厂商与改装社区共同探索在不牺牲耐久性的前提下提升低速扭矩与扭矩线性,使涡轮迟滞被抹平,日常驾驶与赛道表现之间的鸿沟缩短。

这种融合并非简单替换,而是材料、气门控制和涡轮设计之间的协同。4G63T的钢铁基底保证了极端增压中的稳定性,4B11T的铝合金块体带来减重与更好的热管理,而4G63+MIVEC则在这些优点之间寻求平衡,让发动机在更宽的转速区间内提供更可控的动力输出。

在市场与法规的双重推动下,这一演化体现了JDM文化对机械美学与驾驶乐趣的追求。每一次改动背后,都是工程师与车迷在法规约束、材料科技和真实道路场景之间进行的对话。如今的lan evo engine被视为一个持续进化的体系,而非某一代产品的孤立光点。

外部参考资源与内部研究资料也成为持续探索的依据,帮助人们理解为何在现代公路与赛道环境中,可靠性、线性输出与改装潜力可以实现并存。

A Bold Shift in the Lan Evo Heart: Unpacking the 4B11T Era and the Architecture of Modern Performance

The transition that defined a new era for the Lan Evo lineage begins with a whisper of regulatory pressure and a louder call from the road and the track: it was time to retire the long-serving 4G63T and embrace a new powerplant that could balance raw performance with modern efficiency. When Mitsubishi introduced the tenth generation Evo X in 2008, the shift was not merely a swap of parts but a reimagining of the engine’s philosophy. The 4G63T had carried the Evo banner for nearly two decades, earning a cathedral of respect among enthusiasts for its torque-rich midrange and brutal, project-car-friendly character. Yet the road to the future demanded lighter weight, cleaner emissions, and a response that could be delivered at low engine speeds just as effectively as at redline. The answer lay in an all-aluminum, turbocharged four that could drink less fuel without surrendering the sense of urgency that made the Evo a legend. The numbers tell the story in a single sweep: the 4B11T delivered up to 295 horsepower and around 422 Newton-meters of torque, with peak torque available as low as 3500 rpm and a broad, forgiving curve that felt accessible on real roads and brutal on the race track. The engine’s redline at roughly 6500 rpm remained a performance target, but the real payoff was in the way the torque arrived—flat, linear, and confident across a wider band than many contemporaries could sustain. This was not merely a new engine; it was a conscious act of engineering repositioning, a statement that Mitsubishi could reframe performance around efficiency, precision, and reliability without losing the thrill that had defined the Evo’s driving identity.

Technically, the 4B11T represents a holistic upgrade that touches almost every facet of the powertrain. At the heart of the change is the shift to a cast aluminum cylinder block and head, a move that shaved several tens of pounds off the drivetrain’s mass in comparison with the iron-cased predecessor. Weight reduction matters in a high-performance chassis where nearly every gram influences handling balance, weight distribution, and suspension tuning. In the Evo X, the lighter engine helped improve front-to-rear weight balance, contributing to nimble steering and a more planted feel through corners and transitions. The engine’s architecture also features a reverse-flow, or reverse-exhaust, layout that optimizes exhaust scavenging and helps maintain charge intake efficiency under high-load conditions. This arrangement contributes to faster spool and a throatier, more linear surge as boost builds, qualities that enthusiasts often associate with a more responsive, predictably controllable driving experience.

The 4B11T’s power output is complemented by a broad torque band that remains strong from midrange through mid-to-high revs, with peak torque of 422 Nm achieved around 3500 rpm. This is the tactical edge that makes the Evo X feel lively in everyday driving—merely prodding the accelerator yields an eager response, and the engine remains engaged and usable at urban speeds, not just at the strip. Power is not delivered as a sudden burst but as a sustained push that makes overtaking on a winding highway or a racecourse feel controlled rather than frantic. In numbers often cited by engineers and drivers alike, the engine can produce about 295 horsepower (around 220 kW), with the turbocharger and intake tract tuned to deliver a wide, usable envelope rather than a narrow peak. The result is a drivetrain that rewards a driver’s input through a progression of torque delivery that feels continuous and purposeful, a characteristic that high-performance four-cylinders often strive for but rarely achieve in such a balanced manner.

To sustain this performance under diverse conditions, Mitsubishi equipped the 4B11T with a sophisticated dual MIVEC system—Misubishi Innovative Valve timing Electronic Control—for both intake and exhaust. The continuous variable timing adjusts valve opening and closing in response to engine speed, load, and temperature, optimizing airflow and combustion across the speed spectrum. The benefit is twofold: improved high-end power and better low-to-mid-range responsiveness, which translates to livelier acceleration from a standing start and steadier, more controllable throttle behavior in everyday driving. The MIVEC integration also contributes to more efficient fuel use and reduced emissions, aligning with regulatory expectations while preserving the engine’s exuberant character. It is a classic engineering trade-off resolved with elegance: more performance where it matters, without sacrificing the fuel economy that modern drivers expect.

In terms of construction, the 4B11T does not merely rely on lighter materials; it also embraces a number of design refinements that amplify reliability and durability under demanding conditions. The aluminum block and head are joined by a well-tuned, relatively quiet timing system, allowing the engine to rev more freely without the intrusive noises that sometimes accompany high-performance packages. The engine’s cooling strategy features a carefully designed water jacket system and flow paths that respond to high-load operation with enhanced efficiency. The combination of lighter mass and refined cooling helps keep thermal management predictable, an essential factor when engine and turbo temperatures rise under track workloads. The design philosophy extends to the exhaust and intake paths, where a near-balanced relationship between pressure, temperature, and flow helps to keep the engine’s response crisp even as boost climbs. When combined with the turbocharger’s redesigned architecture, the result is a unit that spools quickly, sustains boost with minimal lag, and returns a linear, progressive pull that invites precise throttle control.

The structural ethos of the 4B11T also carries into the chassis and bearing assemblies. To withstand sustained high-load operation, Mitsubishi opted for a four-bolt main bearing cap arrangement and a ladder-like structural framework in the engine that enhances rigidity without adding excessive weight. There is a deliberate emphasis on reducing vibration and noise, yet not at the expense of the chassis’ dynamic feedback. The engine’s placement and airflow design, including the reverse exhaust layout, also contribute to better under-hood packaging and more efficient air management in the compact engine bay typical of a performance-oriented sedan. In practical terms, that means more stable handling, especially on track days when heat soak is a factor and throttle application is frequent and aggressive. The synchronized balance of reduced mass, improved cooling, and robust mechanical interfaces gives the Evo X’s powertrain a resilience that matches its performance characteristics—a crucial attribute for any engine designed to be pushed hard on multiple fronts, from daily driving to time-attack sessions.

Beyond the technical specifics, the 4B11T’s adoption carried a broader significance for Mitsubishi’s product strategy. The engine’s modular, aluminum-based platform was not only a response to emission standards; it also offered a flexible foundation for future iterations and platform sharing across the company’s lineup. This versatility became evident as the same technology mapped onto other models in the family, illustrating a design philosophy that favored cross-application efficiency without sacrificing the core attributes that define the Evo driving experience. Yet the fan base did not universally embrace the change. Purists who cherished the raw, almost brutal simplicity of the 4G63T argued that the lighter, more refined 4B11T softened the car’s iconic edge. The practical counterpoint—and one that justified the shift in Mitsubishi’s engineering direction—was that the new engine, with its broader torque curve and more liveable manners, offered a more usable, real-world performance envelope. It balanced the soul of Mitsubishi’s performance heritage with the realities of modern automotive engineering: lower emissions, better fuel economy, and consistent performance across a wide band of operating conditions.

In the broader context of the Lan Evo engine family, the 4B11T’s introduction did more than replace a powertrain; it redefined what performance could look like when it is coupled to advanced variable valve timing, aluminum construction, and a carefully engineered exhaust path. It served as a bridge that carried the Evo line into a new era of efficiency, while still offering the immediacy and confidence that enthusiasts value in a high-performance machine. The technology did not simply promise speed; it promised a balanced, repeatable, and accessible driving experience. This is especially evident when one considers how the platform has allowed Mitsubishi to apply the same fundamental engineering approach across multiple models, making the 4B11T a keystone not just for the Evo, but for the broader performance-oriented lineup it supports. The result is a powertrain that embodies a philosophy: performance does not demand waste; it demands precision, intelligent design, and a confidence-inspiring relationship between the driver, the machine, and the road.

For readers who want to explore the kind of advanced, component-level engineering that underpins this era, a deeper dive into the broader context of inline-four engine architecture can be insightful. Inline-four engines have long been favored in compact performance applications for their packaging efficiency and potential for torque across a broad speed range. To gain a broader technical perspective on this class of engines, see the resource on Inline-four engines. Inline-four engines.

As the Lan Evo engine family evolved, the 4B11T stood as a bold testament to how a storied performance lineage can be rejuvenated through thoughtful material choices, clever valve timing strategies, and a willingness to redefine the engine’s emotional cues. The result was not merely faster numbers on a spec sheet, but a more coherent driving experience—one that could translate the Evo’s fierce lineage into a machine that was both exhilarating and practical. The 4B11T era marked a pivotal moment in Mitsubishi’s engineering narrative, a moment that echoed through subsequent evolutions and set a course for how power, efficiency, and driving pleasure could coexist in a single, turbocharged package. And within that story lies the core message of the Lan Evo engine: technology can honor heritage while relentlessly pursuing the next horizon of performance.

For enthusiasts seeking a tangible connection to the technology, the engine’s evolution also highlights ways to think about upgrades and repairs. In particular, dedicated performance communities have explored bridging concepts, such as transplanting proven valve-timing methods between generations to retain character while unlocking new efficiency and driveability. The ongoing dialogue—between preserving the raw feel of earlier iterations and embracing contemporary engineering—remains a living part of the Evo’s legacy. And while the 4G63T retains its cult status as a chassis and tuning cornerstone for many fans, the 4B11T era demonstrates how a modern powerplant can extend a legendary lineage without compromising the emotional core that made the Evo a benchmark in the first place.

Internal link reference: For a detailed look at a key component related to the 4B11T’s construction, see the 4B11T billet block page. 4B11T billet block.

Heart Refashioned: The 4G63–MIVEC Synthesis and the Reawakening of the Lancer Evolution’s Drive

The ninth generation of Mitsubishi’s Lancer Evolution carried a paradox at its core. On one hand, it stood as the culmination of a lineage built on the iron-clad reliability and brute torque of the 4G63T. On the other hand, it carried the promise of modern efficiency and refined control that only electronic management could deliver. The chapter that follows examines a pivotal moment in that evolution: the deliberate fusion of the legendary 4G63-based turbocharged architecture with Mitsubishi’s own MIVEC variable valve timing system. This was more than a feature upgrade. It was a purposeful recalibration of how power is produced, delivered, and felt across the rev range. In this synthesis, the engine’s character—once defined by raw midband rumble and mighty, if blunt, overloads—was reshaped into a more versatile yet still thrilling driving experience. The result is not simply more horsepower; it is a more coherent relationship between the driver’s input, the turbine’s response, and the car’s overall tempo on the road and the track.

To appreciate the significance of this fusion, it helps to recall the engine’s lineage. The 4G63T had long been celebrated as a compact, robust workhorse. It delivered torque with immediacy, responded eagerly to midrange throttle, and tolerated aggressive tuning with impressive durability. It was a powertrain that invited modification, that welcomed the half-second, half-gear shifts that defined a racer’s rhythm. Yet as emissions and efficiency demands grew, Mitsubishi sought a more modern solution. The result was the 4B11T, which, with an aluminum block and a reimagined turbocharger package, pushed peak numbers higher and refined the engine’s response curve. Still, there remained a tension among enthusiasts: the lightness and refinement of the newer design could feel detached from the raw, visceral personality of the 4G63T when the car was driven with real aggression. The 4G63–MIVEC fusion did not erase that tension; it rebalanced it, allowing the core engine to breathe in a way that preserved its fundamental DNA while smoothing its edges.

MIVEC—the Mitsubishi Innovative Valve timing Electronic Control system—arrived in this context as a precise, targeted instrument. In the EVO IX’s 4G63T, the system did not try to revolutionize every valve lift profile across every rpm. Its core contribution was to the intake side: the cam phase could adjust when the intake valves opened. The result was a clear, practical improvement in how the engine met turbocharged air at different speeds. At low speeds, advancing the intake cam timing reduced turbo lag. The boost threshold felt more immediate, and the engine could pull from lower RPMs with confidence. The throttle’s first response became more linear, which translated into smoother starts, more decisive midrange acceleration, and a better feeling of predictability through corners and straights alike. At higher revs, the same adjustment kept the intake flow efficient, reducing the tendency for turbo overboost to create abrupt surges, and enabling the engine to sustain a more sustains-driven power delivery rather than a sharp peak followed by a quick fade.

This is where the fusion reveals its most telling virtue: it does not merely add a feature for the sake of hype. It redefines the engine’s operating envelope. The MIVEC-controlled intake phase broadens the power band, balancing torque and horsepower so that the car feels alive and composed from the moment the clutch comes out to the moment the tach needle kisses the redline. The practical upshot for drivers is a more linear and expandable torque curve. The turbocharged backbone remains—still capable of the big pushes when you want them—but the car now invites you to explore the revs more deliberately. The same torque that once arrived in a sudden flood now arrives as a steady stream that you can modulate with the right amount of throttle and steering wheel finesse.

To support this sophisticated control scheme, Mitsubishi introduced a handful of supportive hardware upgrades that complemented the MIVEC logic. An intake temperature sensor was added to capture rapid shifts in ambient and interstage air quality, allowing the ECU to fine-tune timing and fueling with greater precision. The turbocharger itself saw a notable hardware evolution: a lighter, quicker-spooling magnesium alloy turbine wheel. While lighter, the wheel maintained strength and rotational inertia in a way that shaved seconds off turbo lag and improved response at lower boost levels. The intercooling system was upgraded with greater thickness, improving heat rejection and reducing the risk of knock while the engine pulled through heat-soaked corners or long, demanding laps. These changes were not cosmetic; they were essential to ensuring that the refined yaw of MIVEC did not outpace the engine’s ability to deliver it reliably in real-world conditions.

The essence of this integration can be expressed as a philosophy: performance should not be measured only by peak horsepower or peak torque. In the EVO IX, the experience of power across the entire throttle and rpm spectrum mattered just as much as the numbers at the engine’s peak. The MIVEC intake-phase adjustment did not blindly chase higher figures. It sculpted the timing so that the engine’s responses, from idle to redline, were more predictable, more controllable, and more enjoyable. This is where the 4G63’s enduring strength—its ruggedness and tunability—met modern electronic control in a way that preserved the engine’s rough romance while smoothing its rough edges. The result was a powertrain that could be driven with precision and then pushed to the edge without a sudden, unexpected shift in behavior. In this sense, the fusion embodied a deeper engineering aim: to provide the driver with a sense of intimate control over speed, torque, and dynamism, regardless of the car’s speed or the road’s character.

From a handling and driving experience perspective, the marriage of 4G63 with MIVEC also had a practical consequence for everyday use and for track work alike. Low-end torque—crucial for confident street starts and brisk midrange acceleration in everyday traffic—became more accessible. The car could pull from a standstill with less clutch drama and more smoothness, which translated into a more forgiving, yet still thrilling, driving experience. At the same time, high-rpm power delivery remained explosive when commanded, but it carried a sophistication that encouraged a more skillful approach to corner exits. In practice, this meant the EVO IX could be driven with a lighter right foot on daily drives, yet transformed into a genuine weapon for track days when pushed by a capable pilot who understood the engine’s temperament and timing.

The reception among enthusiasts reflected this nuanced improvement. While some purists longed for the raw, almost unbridled voice of the older 4G63T, many recognized the advantages of a modernized control logic that did not compromise the engine’s essence. The fusion was seen not as a departure from the EVO’s roots but as a sophisticated evolution of them. It was a bridge that connected the era of iron-block reliability with the era of electronic precision, delivering a driving experience that remained faithful to the EVO’s lineage while expanding its potential in a responsible, thoughtful way. This perspective aligns with Mitsubishi’s broader engineering culture: a relentless pursuit of performance, coupled with a careful balance of efficiency, durability, and drivability. The 4G63–MIVEC integration stands as a testament to that philosophy, a moment when the Evo’s heart grew more complex yet more truthful to its core promise—an exhilarating, engaging driving machine that rewards skill, insight, and rhythm.

For readers who want to trace the lineage of this engine’s evolution, the discussion naturally intersects with the broader question of how Mitsubishi balanced the old with the new across the EVO timeline. The late-2000s shift toward aluminum blocks, lighter components, and variable timing strategies signaled a shift in how performance engines were designed and managed. But the EVO IX’s 4G63 with MIVEC shows that modernization did not necessarily mean abandonment of legacy strengths. Instead, it illustrates a deliberate synthesis: preserve the 4G63’s dependable architecture and robust tolerance for modification while layering the nuanced control of MIVEC to deliver a driving experience that felt both responsive and refined. In the grand arc of the Lan Evo engine family, this moment stands as a clear, deliberate pivot—one that demonstrates how Mitsubishi, in real time, reinterpreted its most famous powerplant for a new era without erasing what had made it famous in the first place.

Internal link reference: genuine-jdm-low-mileage-1995-1999-jdm-mitsubishi-4g63t-2-0l-dohc-turbo-engine-evo-7-bolt-eclipse-talon-awd-automatic-transmission-and-ecu-attached

External reference: https://www.motortrend.com/cars/mitsubishi/lancer-evolution-ix/

传承与回响:兰瑟进化发动机群的市场反馈与真实驾驶体验

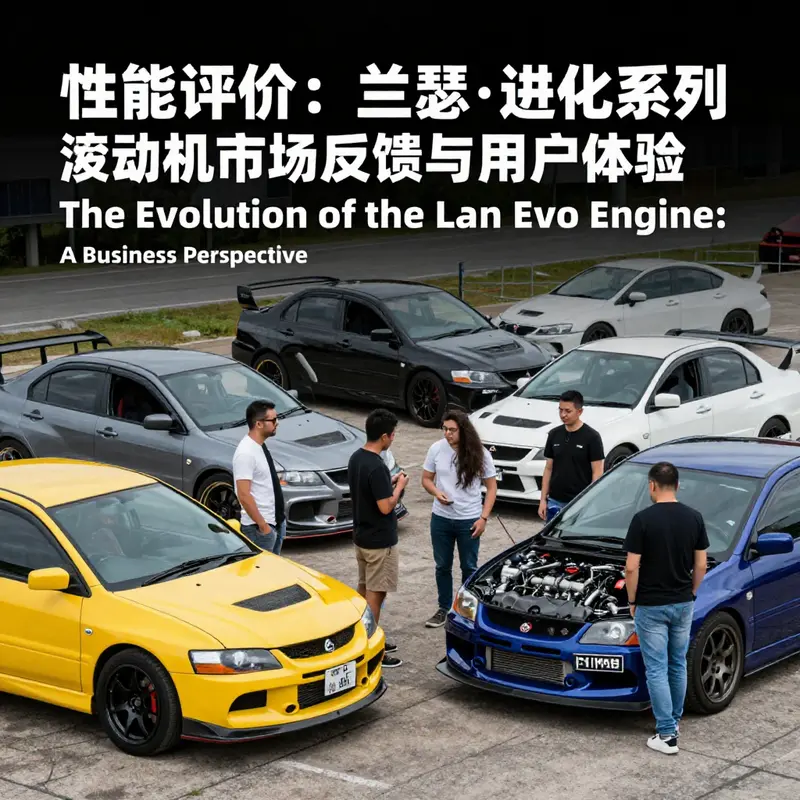

在兰瑟进化系列的引擎谱系里,市场的声音并非简单的数字对比,而是一组关于激情与日常可用性的对话。车主、改装圈、赛车场的测试笔记,以及媒体的长期观察,汇聚成一个关于“ Lan Evo engine”不断进化的真实画像。对许多性能车爱好者而言,这个标签不仅代表一段历史,更是一种对驾驶乐趣的承诺。无论是久经市场检验的4G63,还是更轻量化、结构更先进的4B11T,亦或是两者结合的创新方案,这条技术线都在以不同的方式回应着车迷的期待与现实的使用场景。正是这种持续的市场回声,让兰瑟进化成为一个活生生的现象级案例:技术与体验的互动,在每一代车型的拥有者身上被不断放大与再创造。

首要的市场反馈集中在动力输出与响应的感官体验上。4G63T作为系列的“传奇发动机”,凭借2.0升排量所展现的强劲扭矩和中低转速的直接响应,一直是改装圈的心头好。到了第九代车型,最大马力达到约280匹,峰值扭矩约350牛米,这组数据不仅仅是数字,更是一种在赛道上实现“充足扭矩供给、快速响应”的能力体现。车主们普遍描述,在日常驾驶与赛道切换之间,这颗发动机像一颗稳定跳动的心脏,确保动力线性、可控而富有弹性。无论是离合点前后的爆发,还是在高速段的持续推进,4G63以其耐久性与改装潜力在全球改装界树立了难以动摇的基准线。

然而,随着排放法规和高效燃油经济性的压力,第四代进化的核心动力也在寻找新的平衡。4B11T的出现,是对这一挑战的直接回应。全铝缸体的引入使重量显著下降,约减重12.5公斤左右,带来整车重心与操控性的改善。更重要的是,MIVEC连续可变气门正时系统在高转速效率与中低速响应之间找到了更好的折中点,从而提升了高转速的效率与全域的响应速度。官方数据表明,最大功率约217千瓦(291马力),峰值扭矩407牛米,这在同级别发动机中算是极具竞争力的表现。对追求更高端技术与更低油耗的人群而言,这是一种“进步的代价”的权衡:更轻的结构、更先进的电子控制,但同时也带来对整车件成本、维护成本的再评估。

但技术的演进并非单向的光谱线。Kansai Service等知名改装厂在业界推动了一项具有里程碑意义的融合方案——把4B11T的MIVEC系统移植到4G63发动机本体上。这一举措在改装社区内部掀起了热议:既保留了4G63传统的耐久性和改装友好性,又通过MIVEC实现了低速扭矩的改善和中高转速的提升,使整条动力曲线更加平滑、线性。结果是,改装后的4G63+MIVEC组合在维持“爆发力”的同时,显著降低了涡轮迟滞,提供更可控的力量输出。这一方案的传播,说明发动机层面的创新并非只能通过全新铸件实现,而是可以通过软件、气门正时定位与机械协同的优化来拓展潜力。改装社区与车主的反馈显示,4G63+MIVEC带来的驾驶体验更加“顺滑而有力”,在起步、低速转弯与中速巡航等场景中的可用性有了明显提升,同时还能在高负荷下保持稳定的热管理与耐久性。

市场对这些技术演变的真实评价,既包含对极限性能的赞叹,也包含对日常实用性的理性权衡。以第十代EVO X为例,其核心动力系统在多项指标上达到了新的水平:官方数据与车队披露普遍指向最大输出约313马力,峰值扭矩约366牛米,配合六速双离合变速箱,换挡快速、响应迅捷,整车在赛道和公路上的加速感更显“直接而强悍”。这让EVO X在很多人心中不仅是“高性能紧凑型轿车”的标杆,也是对当代发动机工程的一次演绎。不过,市场反馈也并非一边倒的赞歌。许多车主在日常应用中发现,尽管高速段的表现无可置疑,但城市路况下的燃油经济性并不乐观,常见的油耗区间约9-10升/百公里,尽管高速巡航可以降至6.5升以下,依然高于普通家用车的常态水平。这直接影响购车的综合成本考量,并让一些潜在买家在“性能至上”与“日常可用性”之间做出权衡。

悬挂调校方面的反馈亦呈现两极化趋势。高性能车的天然属性使得悬挂偏硬成为常态,直观体验是路感清晰、过弯支撑出色,但在城市不规则路面上的舒适性会相应下降。这也是许多车主在日常通勤场景下的痛点之一。与此同时,改装与维护成本的高企也成为现实的阻力。高性能部件、专用轮胎、刹车系统与独特的舱内配置,无疑提升了车主的参与感与驾驶乐趣,但也带来更高的长期维护成本与升级需求。

兰瑟进化系列在市场上的地位,离不开其在历史上的战绩与文化意义。自1996年问世以来,系列在世界拉力锦标赛上的辉煌战绩,尤其是1996至1999年间车手总冠军的连胜,使其在全球车迷心中建立了“拉力赛王者”的象征。这种传奇既提升了品牌的认知度,也让发动机被视作“驾驶者之心”的代表。正因如此,许多车主在购买和改装时,会以历史声望作为情感锚点,同时也在通过技术改进来回应市场对现代化、合规性与持续性能的需求。

从改装文化的角度看,兰瑟进化的市场反馈呈现出一个有趣的两极分化态势。对一些拥护原汁原味4G63的车迷而言,那股“暴力”的低速扭矩和可无限扩展的改装潜力,是他们对这款车永恒的情感支点。他们乐于追逐大马力的极限、在发动机舱里进行反复的部件挑选与调校,并以此来延续那个由WRC辉煌所铺就的传奇。与此相对的,是更年轻的用户群体与现代化驾驶需求的崛起。他们欣赏4B11T带来的重量削减、气门正时技术带来的高效性,以及更整洁的排放表现所带来的合规性与可持续性。对于这部分人而言,改装的“可塑性”并非唯一的驱动因素,可靠性、维护成本、日常使用的舒适性与对新技术的接受度同样重要。

在这一切真实的用户体验与市场反馈中,外界的评价往往被引申为对未来方向的指引。有人提出,若能在保持4G63传统耐久性的同时,进一步通过电子控制与机械优化来缓和涡轮迟滞,或许就能在c道上实现加载更高的动力而不牺牲日常用车的平衡性。这种需求正推动厂家与改装厂一道,探索不仅是更强的动力输出,更是更线性的功率曲线和更稳定的热管理。正因如此,Lan Evo engine并非一个静止的型号,而是一整套持续进化的技术体系。它由经典的4G63所奠基,经历4B11T的重量化与高效化改造,再由4G63+MIVEC融合的方案进行再次扩展。每一次变革都被市场以不同的语调回应,有的赞许速度的提升与线性输出,有的则对改动后的改装潜力、日常使用的体验提出更高的要求。

在这一章里,市场反馈与用户体验并非孤立的评述。它们像转速表上的指针,随着不同世代的加入而改变指向。对许多车主而言,兰瑟进化的发动机已经成为一种“驾驶者的语言”:你要的是真正的速度与操控的乐趣,同时也希望在日常出行中保持相对稳健的成本与可靠性。正如他们在不同场景下所表达的那样,发动机的故事不仅写在纸上的性能数据里,更写在每一次起步时、每一次弯道内外的反馈里,写在你把钥匙握在手心、把座椅调整到最贴合自己的那一刻。

如上叙述所示,兰瑟进化系列的市场反馈呈现出一个复杂而真实的画面:强劲的性能、先进的工程、清晰的驾驶乐趣,同时也伴随着现实的油耗压力、悬挂硬度对日常舒适性的影响,以及高维护成本带来的谨慎权衡。正是在这样一个多维度的声音场景中, Lan Evo engine的魅力被不断放大、再塑形。对于未来的版本与改进,市场的回声将继续指向一个方向:让高性能更具可持续性,让激发激情的同时变得更易于被普通车主接受。

外部资源与进一步阅读:如果你希望了解更广泛的历史背景和工程演变,可以参考维基百科关于兰瑟进化的条目,了解车型代际与发动机技术的演化脉络。 外部资源: https://en.wikipedia.org/wiki/MitsubishiLancerEvolution

内部参考链接:在讨论发动机与改装路径时,相关外观与机盖选项在改装社区中具有一定代表性,可以浏览以下页面以了解具体的外观升级选项之一:

mitsubishi-lancer-evolution-evo-x-hood-phantom-black-oem-u02

持续进化的心脏:兰瑟发动机技术在未来蓝图

当谈论兰瑟进化的发动机时,人们往往聚焦于爆发力、瞬时响应和后段的极致耐久。然而,若将目光拉长,便会看见一种贯穿世代的工程哲学:发动机不仅是数值的堆叠,更是一种可持续的性能观。为了避免将兰瑟进化的理念误解为飞机领域的同名概念,有必要先明确一个前提:兰瑟进化来自于高性能四驱轿车的动力系统研究,其核心诉求是把强劲动力、平顺性与驾驶乐趣三者巧妙地融合在一个可日常使用的机械心脏中。这一思路也让人们认识到,所谓的“未来展望”并非单纯追求更高的马力,而是在保留可控性、耐久性与驾驶参与感的前提下,推动技术的跨代传承与再创新。正是在这样的背景下,兰瑟进化的发动机技术谱系显现出一种持续进化的逻辑:从经典的、以低速到中速扭矩为主线的设计理念,到逐步引入更轻量化结构、更加精细的气门控制,以及与整车动态系统深度耦合的智能化管理。尽管官方的更新步伐在某一阶段走向了相对沉寂,但这并不意味着创新的终止,而是更像是一种变速中的积累——以更高的热管理效率、材料科学的发展和混合动力理念的引入,继续为高性能汽车的发动机系统树立新的参照。为理解这一点,需要把视角从单一型号的风格切换到一个技术体系的演进之路:核心的涡轮增压技术、轻量化材料带来的热力与动力学效益,以及与车辆控制系统的协同优化。这三条主线,像三条并行的轨道,持续推动发动机在响应速度、扭矩线性、耐久性和维护成本之间找到新的平衡点。

Final thoughts

The evolution of the Lan Evo engine represents a journey marked by innovation and adaptation, satisfying both the passion of performance enthusiasts and the demands for efficiency in today’s automotive market. Understanding this evolution not only provides insight into automotive engineering but also highlights the significant impact these engines have on user experience and market dynamics. Mitsubishi’s continuous dedication to improving their engines offers a glimpse into the future of performance vehicles, blending tradition with cutting-edge technology.