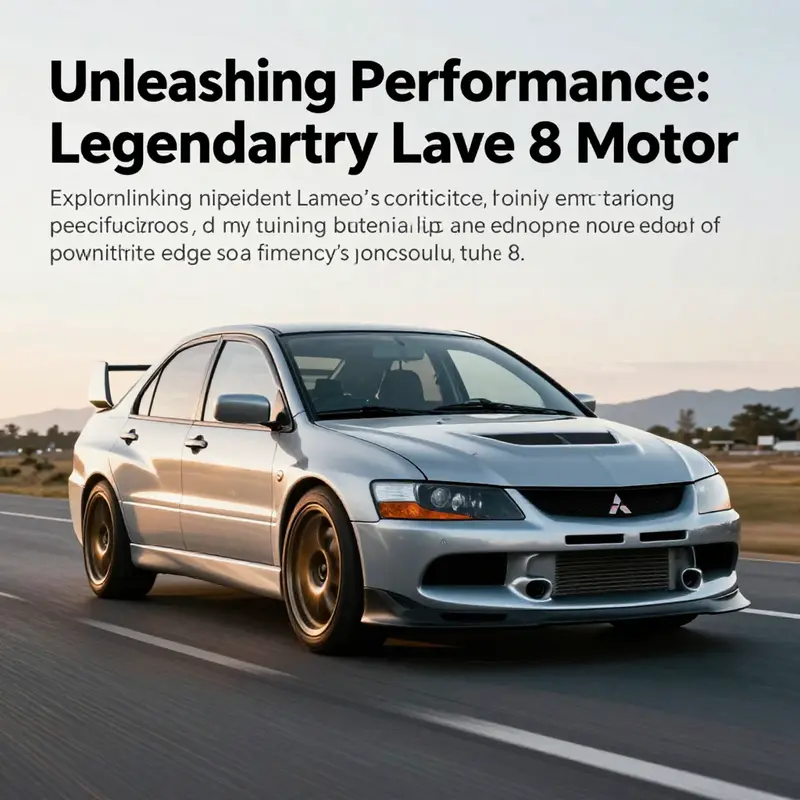

The Mitsubishi Lancer Evolution VIII (Evo 8) motor, powered by the iconic 4G63T 2.0-liter turbocharged engine, has captured the hearts of automotive enthusiasts and business owners alike. With 280 horsepower and a torque figure of 398 Nm, the engine stands as a benchmark in performance and reliability. Understanding its specifications and tuning capabilities not only appeals to car aficionados but also drives the aftermarket industry. This article systematically explores the engine’s specifications and performance metrics, illuminating its significant tuning potential, followed by a comparative analysis against other famed performance engines, providing a comprehensive overview that showcases the Evo 8’s enduring legacy and market relevance.

Heart of the Evo VIII: The 4G63T Engine’s Specs, Behavior and Performance Potential

Engine anatomy and real-world performance

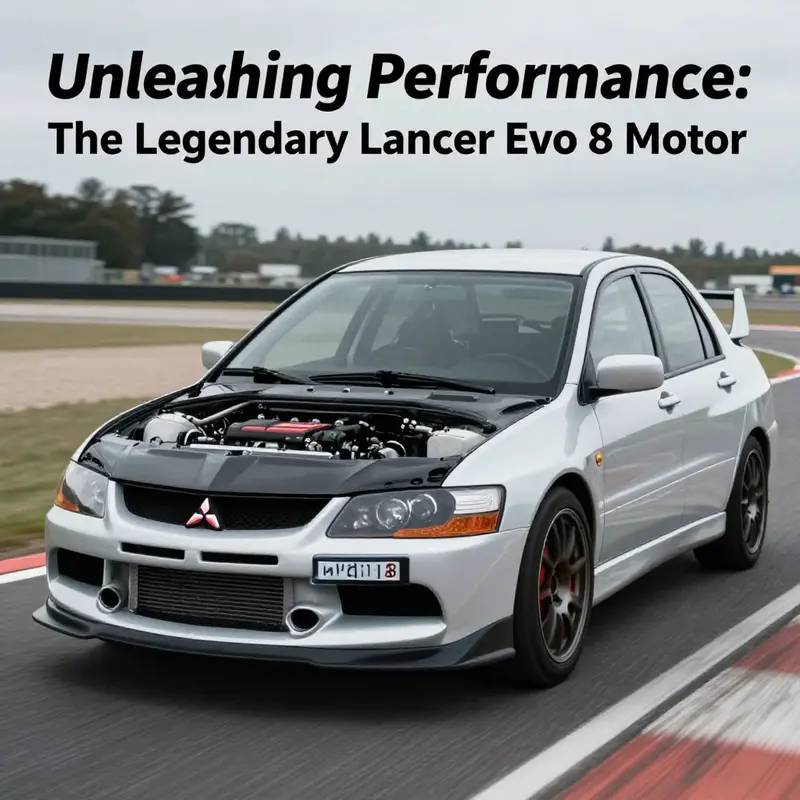

At the center of the Lancer Evolution VIII’s identity sits the 4G63T — a 2.0-liter, inline-four, turbocharged engine whose design balances brute strength with a platform built for high-performance tuning. The basic architecture is straightforward but purposeful: a cast-iron block for rigidity and durability, an aluminum cylinder head for better heat dissipation, and a dual overhead camshaft (DOHC) layout driving 16 valves. Fuel is delivered through a multi-point injection system, while a turbocharger forces a denser charge into the intake. That combination produces a compact, high-output package that responds well to both careful factory calibration and aggressive aftermarket modification.

Factory ratings vary by market and measurement method, but the most commonly cited figure for the Evo VIII in standard trim is about 265 PS (roughly 261 bhp) delivered near 6,500 rpm, with torque commonly reported around 300 Nm (roughly 221 lb-ft). Some documents and regional specifications list slightly different numbers — the way power is measured (PS, hp, or SAE net) and how manufacturers trimmed outputs for homologation or emissions can shift claims by a few percent. What matters more than a single number is how the engine delivers its power: the 4G63T in the Evo VIII is tuned for an eager, high-revving character, with a turbo boost that builds progressively and a midrange that rewards firm throttle inputs. The result is an engine that feels alive at high rpm yet remains tractable when you need precision in traffic or on technical roads.

Beyond the numbers, drivetrain layout also shapes performance. Early Evo VIII models used a five-speed manual gearbox, but later and higher-spec variants, particularly the MR, received a six-speed manual to give closer ratios and crisper engagement for spirited driving. Across the line, the AWD system and the introduction of improved limited-slip differentials, including spiral-type units in later production, help put the engine’s output to the road efficiently. Those drivetrain refinements reduce wheel slip and keep the car balanced under power, so the 4G63T does not solely shine through raw figures but through a complete system engineered for controllable performance.

Internally, the 4G63T owes its tunability to several key traits. The cast-iron block tolerates high cylinder pressures and aggressive boost levels. Its combustion chambers and valve arrangement respond predictably to changes in cam timing and intake flow. Stock internals are robust compared to many naturally aspirated contemporaries, which means modest power increases can often be achieved with relatively simple changes: improved intake and exhaust flow, a higher-flow turbo or updated compressor wheel, larger injectors, and ECU tuning to manage fuel and ignition timing. For enthusiasts, the factory architecture invites progressive upgrades; you can extract significant power without immediately requiring full engine rebuilds. That said, sustained high-power use eventually pushes the need for stronger pistons, reinforced rods, and upgraded head studs to maintain reliability at elevated boost and cylinder pressures.

Thermal management is another reason the Evo VIII’s 4G63T is respected. The aluminum head cools more quickly than cast-iron alternatives, and the combination of intercooler sizing, coolant routing, and oiling pathways reflects a performance-first approach. In track or high-boost street use, attention to cooling — intercooler efficiency, radiator capacity, and oil cooling — pays immediate dividends in consistent power delivery. Fuel quality and timing also matter; the 4G63T responds well to precise ignition mapping and higher-octane fuels where available, but incorrect timing or lean conditions under boost can rapidly erode internal components. For owners aiming for reliability alongside power, conservative boost targets and staged upgrades to fueling and cooling systems are prudent.

The Evo VIII’s performance spectrum widens remarkably when you consider factory-sanctioned or dealer-tuned special editions. Notable examples from outside Japan include heavily modified UK Ralliart variants — the FQ series — which pushed the 4G63T far beyond stock specification. Models like the FQ400 were tuned to approach 400 horsepower through a mix of mechanical upgrades, turbo swaps, optimized fueling, and bespoke ECU calibration. Those cars demonstrate the 4G63T’s headroom: with the right supporting mods and attention to reliability, the platform can sustain supercar-level outputs. But such extremes also illustrate the trade-offs: drivability can become peaky, maintenance intervals shorten, and components such as clutches, transmissions, and differentials quickly require beefing up to handle the extra torque.

How the 4G63T behaves on the road reflects its engineering intent. Off-boost, throttle response is smooth and linear, which aids daily usability. As boost builds, the engine’s character becomes more urgent; the midband pulls strongly and encourages maintaining revs through corners to exploit the power band. The turbo spools with a satisfying rise rather than an abrupt hit, and the AWD system allows confident application of power mid-corner. Drivers praising the Evo VIII often highlight this blend: an engine that feels raw and committed yet controllable and surprisingly refined when needed. Engineers tuned the 4G63T to be a performance engine that could also live in daily use — a balance many tuners respect and exploit.

Maintenance and longevity are recurring themes among owners. The 4G63T is durable, but like any performance engine, it rewards proactive care. Regular oil changes with high-quality oil, periodic inspection of head gaskets and head bolts, and attention to timing belt service intervals form the backbone of responsible ownership. The turbocharger itself benefits from warm-up and cool-down habits; letting the engine idle briefly after hard driving helps spool down the turbo and reduces oil coking in the bearing housing. For those who modify, upgrading intercooler piping, fuel pumps, and engine management are critical to safely support higher boost and power. Many used-unit marketplaces also show how commonly these engines are swapped and sold as reliable cores, which underlines how widely they are maintained and revived by enthusiasts.

The aftermarket ecosystem around the 4G63T is vast. Forged internals, higher-flow turbos, performance camshafts, standalone and piggyback ECUs, and upgraded fuel systems are all mature product categories. This availability lowers the barrier for staged upgrades and allows owners to tailor performance to specific goals — streetable power, track-focused consistency, or outright drag or time-attack figures. Support pieces such as clutch kits, differential upgrades, and complete gearbox options complete the chain so that engine upgrades can be matched by driveline durability. For many, the 4G63T’s greatest asset is this ecosystem: the ability to plan a progressive build path while relying on proven hardware and documented tuning strategies.

The 4G63T in the Lancer Evolution VIII is more than a spec sheet item; it’s a platform philosophy. Its materials and layout give inherent strength. Its turbocharged nature provides dramatic scaling potential. The factory calibrations and drivetrain pairings make it both usable and thrilling. Whether you view it as a beguiling street engine or a blank canvas for high-power builds, the 4G63T’s role in the Evo VIII is central to the car’s enduring appeal. For specifics on factory published performance figures and measured results, consult performance archives that list the Evo VIII’s technical data and real-world test numbers, such as the Zeperfs specifications and performance summary: https://www.zeperfs.com/mitsubishi-lancer-evolution-viii-specs-performance/.

For those considering parts or low-mileage donor cores, resources that list genuine JDM 4G63T engines are useful when sourcing a solid starting point for a rebuild or swap, for example the genuine JDM low-mileage 4G63T engine listing. Investing in a well-documented core and planning upgrades around cooling, fueling, and drivetrain strength will let the 4G63T continue to define the Evo experience for many miles and many builds to come.

Unleashing the 4G63T: Practical Tuning Paths for the Lancer Evo 8 Motor

Unleashing the 4G63T: Practical Tuning Paths for the Lancer Evo 8 Motor

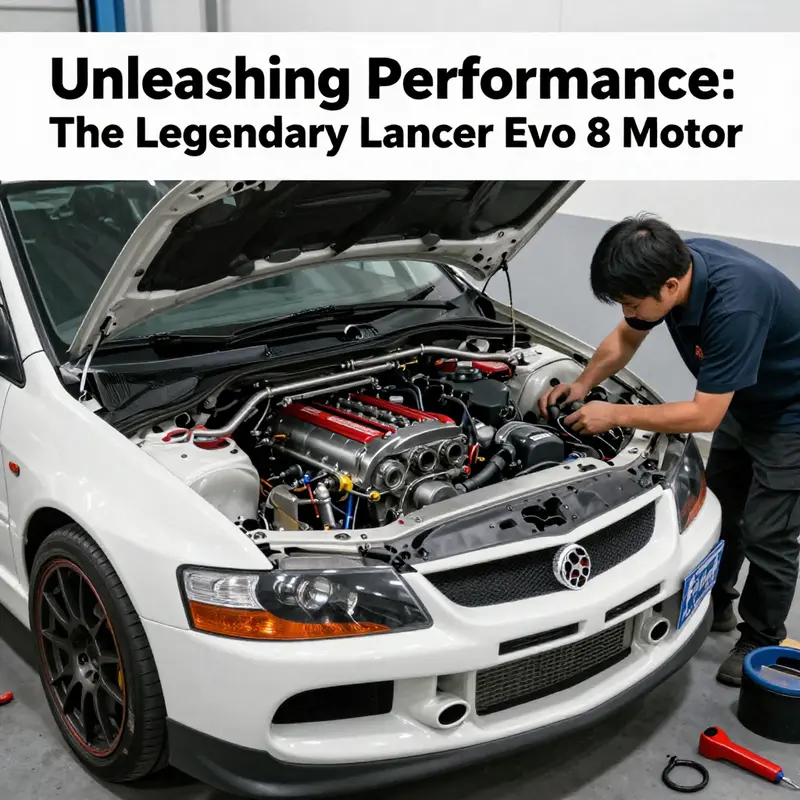

The Lancer Evolution VIII’s 2.0-liter 4G63T engine offers a rare blend of strength and adaptability. Its cast-iron block and aluminum head provide a durable base. That structure resists detonation and handles repeated heat cycles. Those traits make this engine ideal for progressive builds. From mild street tunes to extreme track monsters, the 4G63T scales well with careful planning.

At the core of any sensible build is power-goal clarity. Decide early whether the car will remain a daily driver, a weekend canyon runner, or a dedicated track car. Each direction shapes component choices and costs. The factory turbo and supporting systems were tuned for balanced response and reliability. That balance makes the stock turbo a sweet spot for conservative upgrades and street-focused builds up to roughly 350 horsepower. For many owners, that is the most logical first tier of tuning: quick, durable, and satisfying.

A logical first step is to strengthen fueling and breatheability. Larger injectors, a higher-flow fuel pump, and an efficient intercooler reduce risk during higher boost runs. These parts work together: injectors supply fuel for increased boost, the pump keeps pressure steady under load, and the intercooler lowers intake charge temperature. Cooler air reduces engine knock and allows safer timing and boost ramps. Alongside these, a well-calibrated engine management strategy is essential. A properly tuned ECU ensures air, fuel, and ignition work as a cohesive system. Custom tuning on a rolling road, with datalogging, lets you extract safe gains while protecting the engine from detonation.

For drivers who want a responsive street car with strong midrange, the stock TD05-style turbo is ideal. It spools quickly and produces usable torque low in the rev range. This makes the car feel lively in everyday driving. With modest bolt-ons and tuning, the stock turbo reliably supports power in the 300–350 horsepower zone. That range often only requires supporting mods rather than internal work. Owners keep drivability and avoid the lag associated with larger turbos.

If you aim higher, moving toward 400–450 horsepower, several systems must be upgraded in concert. The turbo choice becomes critical. A larger TD06, a hybrid TD05, or a modern equivalent can provide the required flow. But bigger turbos usually cost spool speed. To mitigate lag, match turbine housing size and compressor map to your rpm targets. A well-selected turbo, ceramic or forged turbine, and improved oil lines will preserve response and reliability.

For fueling at this level, high-flow injectors and either an upgraded in-tank pump or an additional external pump are standard. Many builders opt for multi-pump setups to maintain pressure under sustained high boost. Fuel pressure regulators and return-style fuel systems allow finer control. These components reduce the chance of lean conditions during long pulls.

Engine management becomes non-negotiable when pushing toward 450 horsepower. Custom ECU calibration or a standalone management system enables precise control of boost, ignition, and fuel. This level of control supports strategies like knock control, boost-by-gear, and launch control. Accurate closed-loop fueling and map switching add safety margins for different fuel qualities and operating temperatures.

Headwork and intake flow improvements help the 4G63T breathe better at high power. Porting, valve work, and performance camshafts increase flow and raise the power ceiling. Combined with high-flow intake manifolds and freer-flowing exhaust, these upgrades aid top-end power without sacrificing low-end torque excessively. Keep in mind that aggressive cam profiles may alter idle characteristics and cold drivability.

As power climbs beyond 450 horsepower, the engine’s bottom end faces increasing stress. Many builders plan for forged pistons, stronger rods, and upgraded head studs once they target sustained high boost or track use. Forged internals resist thermal and mechanical stress far better than stock items during extended high-load runs. Upgraded head studs improve clamping force and reduce the risk of head gasket failure. For those seeking extreme figures, a complete short-block build with balanced rotating assembly is the prudent path.

Cooling and lubrication systems also need attention in high-power builds. An oil cooler, high-capacity radiator, and more efficient thermostats maintain stable temperatures. Improved oiling reduces the risk of starvation during hard cornering or extended high-rpm operation. Many owners also install upgraded oil pumps and windage trays in serious builds. These measures preserve oil pressure and reduce parasitic power loss.

The drivetrain must be matched to engine output. The Evo VIII’s driveline was engineered for aggressive use, but certain parts benefit from upgrades when power rises. A high-clamp clutch or twin-plate unit improves engagement and longevity. Gearboxes can remain stock for moderate power increases, but higher torque often requires reinforced or sequential options. The factory spiral limited-slip differential enhances traction and balance. Upgrading the differential and half-shafts prevents premature failure under stress.

The car’s electronic all-wheel-drive systems remain major advantages when tuning. Active systems that manage center and yaw dynamics augment traction and cornering at high power. When calibrating power delivery, consider how differential mapping and torque split influence wheelspin and stability. Proper tuning of these systems, alongside suspension geometry and tire selection, translates raw horsepower into usable lap times and safer street manners.

A pragmatic building philosophy reduces headaches. Stage upgrades so each step is validated on the road or dyno. For example, start with intake, intercooler, exhaust, and a conservative tune. Confirm temperatures, fuel trims, and knock behavior. Then progress to fueling and turbo changes. This layered approach spreads cost and reveals weak links early.

Maintenance is also a pillar of any long-lived build. The 4G63T tolerates stress, but only with proper care. Regular oil changes with high-quality oils, coolant refreshes, and valve-clearance checks extend life. Pay attention to consumables like belts, hoses, and mounts; they often fail first under higher stresses. Also, monitoring systems such as wideband O2 sensors and EGT probes provides early warning of combustion issues. Safety margins built into tuning maps reduce the risk of catastrophic failure.

The 4G63T also carries a deep aftermarket ecosystem. That makes sourcing parts and expertise easier. Salvage or genuine replacement blocks and complete engine assemblies help ambitious builders. If internal failures occur in extreme builds, a replacement short block allows quick turnaround. For owners who prefer a bolt-in approach, well-sorted turnkey options and crate engines are an alternative. One such resource is a genuine JDM low-mileage 4G63T engine listing, which can provide a solid donor unit for rebuilds or swaps: genuine JDM low-mileage 4G63T engine.

Beyond hardware, the tuning community offers knowledge that shortens the learning curve. Shared maps, build threads, and dyno logs help refine choices. Still, every engine and vehicle has unique traits. Local altitude, fuel quality, and driving style change outcomes. Treat other builds as guides, not absolute blueprints.

A final point concerns diminishing returns and drivability trade-offs. A larger turbo pushes peak horsepower but can reduce throttle response at low rpm. Aggressive camshafts raise peak power but may degrade idle and cold behavior. A too-stiff suspension can compromise daily comfort. Balance performance with the car’s intended use. Most successful builds find a middle ground that maximizes usable power.

To summarize the practical tiers: stay largely stock with a conservative tune for daily reliability and modest power. Add fueling, cooling, and ECU tuning to reach 300–350 reliable horsepower. For 350–450, upgrade turbo, fueling, and strengthen some internals. Past 450, build the bottom end, improve lubrication, and invest in a purpose-built gearbox or strengthened drivetrain components. Each stage needs a coherent plan and appropriate testing.

The Evo VIII’s 4G63T is legendary because it scales predictably. It rewards methodical upgrades, careful tuning, and diligent maintenance. Whether the aim is a street warrior with instant response or an all-out track car, the engine provides a clear path. With the right combination of parts and tuning, the 4G63T can deliver dramatic performance without sacrificing balance.

For deeper reading on how far the Evo VIII platform can be pushed, a detailed analysis and case studies are available that cover turbo choices, fueling strategies, and real-world dyno results: https://www.performancecar.co.uk/features/tuning-the-evo-8-how-far-can-you-push-it/.

null

null

Final thoughts

The Mitsubishi Lancer Evolution VIII’s 4G63T motor encapsulates what it means to innovate in performance engineering. Its specifications not only make it a formidable contender on the racetrack but also provide an extensive canvas for tuning enthusiasts. Comparisons with other renowned performance engines highlight its competitive edge, showcasing why it remains an enduring legend in the automotive world. For business owners in the automotive industry, understanding the Evo 8 motor is essential for harnessing its potential and catering to a market eager for high-performance cars.