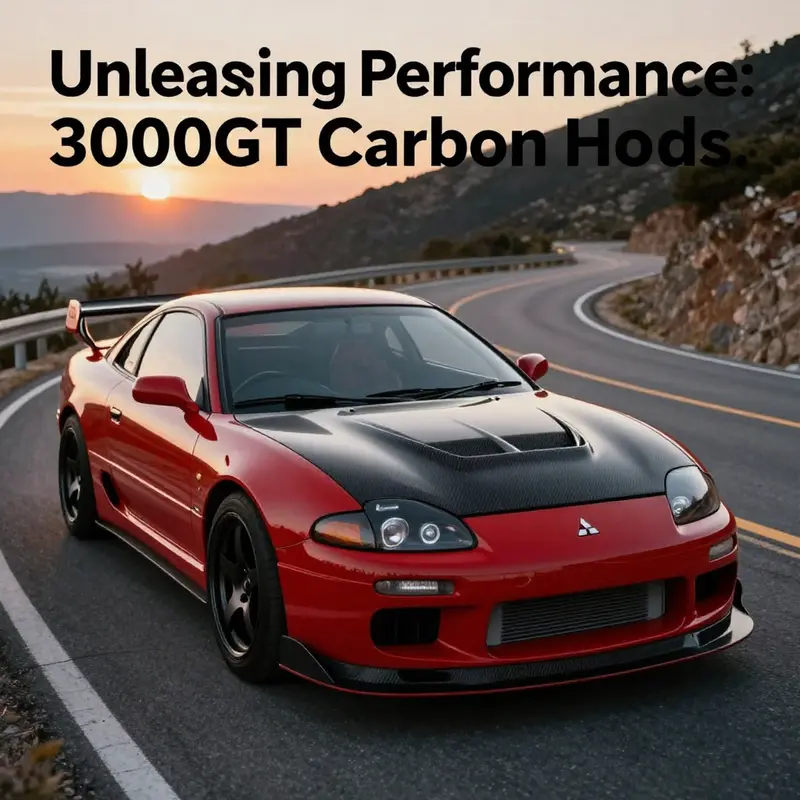

The Mitsubishi 3000GT has long been celebrated as a high-performance vehicle from the 1990s, but even timeless classics can benefit from modern enhancements. Enter the 3000GT carbon hood—an aftermarket modification that elevates not only the physicality of the vehicle but also its performance metrics. These hoods, crafted from high-strength carbon fiber, provide aesthetic upgrades while achieving significant weight reduction and improving aerodynamics. In this exploration, we will delve into the compelling aspects of carbon hoods, highlighting their impact on performance and aerodynamics, the advantages of weight reduction, the quality of materials and construction, market availability and customization options, and user experiences, ultimately showcasing why these components are essential for business owners looking to stock high-demand performance parts.

Front-Focused Power: How a 3000GT Carbon Hood Rewrites Performance and Aerodynamics

The carbon fiber hood installed on a classic performance coupe is more than a cosmetic upgrade. It embodies a deliberate design philosophy: reduce mass where air and heat meet the engine, and let the car’s dynamic balance respond with greater immediacy. For a platform like the 3000GT, whose engineering threads combine turbocharged power, a nimble chassis, and all-wheel control, swapping to a carbon hood is a strategic move. It is a small component with the potential to shift the driving experience in tangible ways. In this context, the hood becomes not just a cover for the engine bay but a functional lever that touches weight, cooling, and airflow in ways that matter when the pace quickens. The result is a cohesive upgrade, where aesthetic appeal and performance cohere rather than compete.

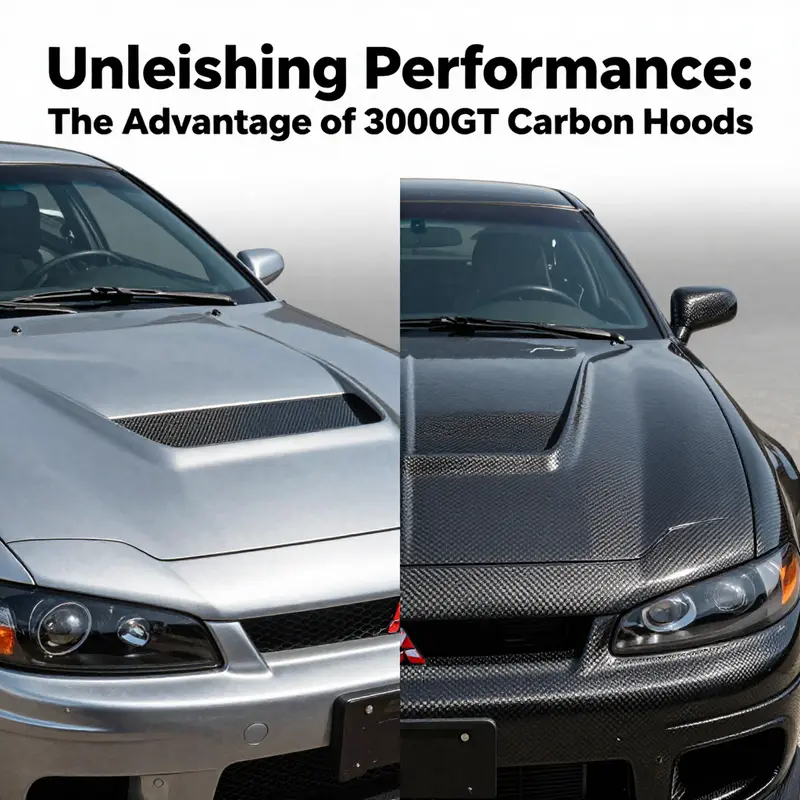

The most immediate and measurable effect is weight reduction. Carbon fiber’s density is significantly lower than that of metal, so replacing the stock hood typically trims the front end by roughly 15 to 25 kilograms. This mass savings translates into a subtle but meaningful rebalancing of the car’s front-to-rear dynamics. With less mass at the extreme front, the nose feels lighter on entry, and steering responses tighten. The front tires can react more promptly to driver input, sharpening turn-in and improving midcorner behavior. The improved transient response feeds into a more confident feel when chasing high-speed grip and precise line selection. It is not about making the 3000GT a featherweight, but about enhancing the driver’s sense of connection to the road through a more responsive front end. This kind of adjustment can also ease the load on the suspension’s early ride-height and damping performance, letting the chassis realize more of its designed handling band rather than fighting inertia at the front corners.

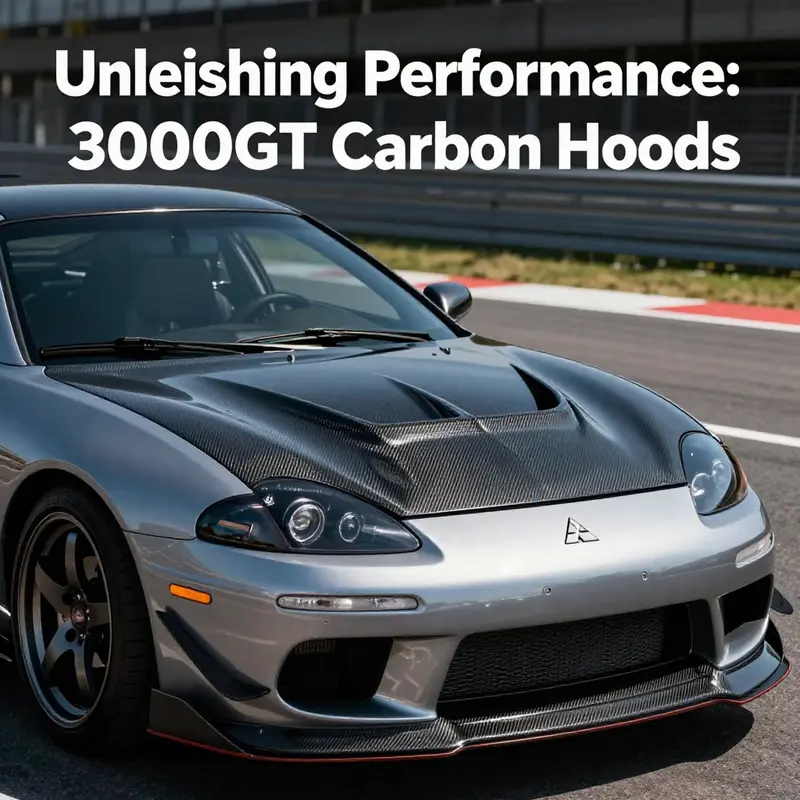

Beyond weight, cooling performance receives a meaningful uplift when the hood design includes venting or integrated air channels. The 3000GT has a high-power engine that rewards efficient cooling, especially during aggressive accelerations, sustained high-speed runs, or spirited back-road sessions. Carbon fiber hoods with vent patterns are not simply about style; they help manage air within the engine bay by channeling heat out of the bay and away from the turbochargers and intercoolers. When air is directed efficiently, intake temperatures stay lower, charge air stays denser, and the risk of heat soak in the engine and brake components diminishes. The net effect is a more consistent power delivery, with fewer temperature-induced performance limits after repeated hard driving. The hood’s vents work with the car’s overall cooling strategy, complementing the radiator layout and the under-hood airflow paths that engineers have tuned over the model’s lifetime. In practice, this means the engine maintains torque delivery more reliably and the brakes remain cooler during extended sessions, reducing the likelihood of performance fade.

Aerodynamics completes the trio of benefits with a focus on lift control and air behavior at speed. Many carbon hoods designed for performance applications subtly alter the front’s interaction with the airstream. Air channels and integrated aero elements can help manage how air travels across the hood surface and toward the windshield. A carefully considered hood geometry can reduce boundary-layer separation at the front of the car, which in turn lowers lift, improves high-speed stability, and contributes to a more planted feel in straight-line driving and during cornering. Additionally, some hood designs incorporate small front-end spoilers or lip elements that incrementally add downforce where the front tires meet the road. The combined effect—less lift, steadier airflow, and a clearer separation between aerodynamic and mechanical loads—helps the 3000GT maintain grip and confidence at speed, particularly in challenging crosswinds or on varied pavement textures. It is a reminder that performance isn’t only about power; it is also about how air and weight cooperate with the chassis to keep the car tractable and predictable.

The practical implications of transitioning to a carbon hood extend into daily usability and long-term ownership. Compatibility is essential: the hood must align with the factory hinges, latch geometry, and mounting points, and it must maintain an even seal against the weather. A poorly fitted panel can introduce wind noise, gaps that disrupt the intended airflow, or misalignment that interferes with proper hood operation. Carbon fiber’s stiffness is an advantage here, but it also means that careless impact or improper mounting can lead to cosmetic or functional issues. Maintenance planning matters too. While carbon fiber resists corrosion and can retain its crisp surface longer than some metal panels, the finish—whether a clear-coated weave or a coated, color-matched surface—will require care to prevent UV-related degradation and micro-scratches that can become more noticeable on a high-gloss or exposed weave. Practically, this means inspecting mounting hardware and hood seals on a regular basis and ensuring that the hood latch remains secure, particularly on vehicles that see track use or rough pavement. For many owners, the payoff of care is a hood that maintains its light, clean look while continuing to function as a performance component rather than merely a cosmetic one.

Choosing a carbon hood also invites a broader conversation about how it fits into a broader build. The hood does not operate in isolation; its value blossoms when paired with deliberate attention to weight distribution, cooling efficiency, and aerodynamic coherence across the vehicle. It harmonizes with the existing drivetrain and chassis package, echoing the car’s performance intent rather than standing apart as an isolated improvement. In this light, the hood becomes part of a unified upgrade strategy that respects the platform’s original design language while pushing its capability a notch higher. This is why many enthusiasts approach the upgrade not as a standalone tweak but as a step in a broader journey toward more precise steering, consistent performance, and a more cohesive driving experience overall.

For readers who want to explore the available design language and integration options for early 1990s to mid-1990s models, there are avenues that reflect the heritage of carbon fiber in this niche. A representative path in the market emphasizes a balance of lightweight construction and compatibility with the vehicle’s silhouette, offering a way to preserve classic lines while capturing contemporary performance benefits. See the following internal link for a conceptual reference: advan-velpar-design-1991-1993-mitsubishi-3000gt-carbon-hood. It is not a sweeping endorsement of any single product, but a concrete example of how the carbon hood design language can align with the car’s heritage while delivering real performance gains.

The broader takeaway is clear. A carbon fiber hood on a 3000GT is a focused, purposeful upgrade that touches three core aspects of performance: weight, cooling, and aerodynamics. Each facet reinforces the others, producing a driver experience that feels more immediate and more controlled when the pace rises. The hood’s lightness translates into quicker, more direct steering feedback; its venting and channeling help manage heat under load; and its aerodynamic shaping supports stability at speed. The result is not a dramatic transformation but a coherent improvement that makes the car feel more responsive, more predictable, and more eager to exploit its performance potential. For readers who want a tangible reference to the material realities of carbon fiber hoods in this niche, an external resource on market availability offers practical context: https://www.alibaba.com/product-detail/Carbon-Fiber-Hood-for-Mitsubishi-3000GT_1601048977565.html

Weight Down, Edge Up: How a Carbon Hood Redefines Front-End Feel

The hood that covers a sports car’s heart is more than a sheet of metal or a cosmetic upgrade. In performance applications, swapping to a carbon fiber hood is a deliberate mass management choice that alters front-end feel, rotation, and how the car communicates through the steering wheel. By shedding weight from the nose, a carbon hood lowers front-end inertia and frees up grip for the tires to exploit through corners. The result is quicker turn-in, more linear response, and a chassis that feels lighter even when the scales haven’t moved much on the morning of a track day.

That weight reduction does more than just change how the car turns. It shifts the balance between front and rear grip, enabling more predictable weight transfer during braking and throttle on entry. With less mass over the front axle, the tires can load more evenly, promoting a confident line into a corner and allowing the driver to place the nose with greater precision. At the same time, vents and ducts integrated into a well designed hood can help heat management, reducing heat soak and contributing to more stable power delivery during sustained high-speed laps.

Of course, a carbon hood must be more than light; it must be stiff, fit correctly, and play well with the car’s aerodynamics. Engineers balance ply counts, resin content, and weave orientation to preserve rigidity while saving weight, while ensuring clearances against the hood, fenders, and hood struts remain consistent. When done right, the hood becomes a conduit for performance: a lighter shell that helps the chassis feel more responsive, ready to chase the next corner with the driver in complete command.

Material Mastery and Construction Quality: How a Carbon Hood Redefines the 3000GT

The allure of a carbon fiber hood on a 3000GT goes beyond fashion. It is a deliberate, performance-driven choice that redefines how the car feels on the road and on the track. The carbon hood that fits a 1990s-era Mitsubishi sports car embodies a philosophy: lighter is faster, but only if strength and stiffness accompany the weight reduction. In this light, material selection and construction quality become the quiet, unseen engineers behind the loud noise of improved acceleration, sharper steering, and a more responsive front end. When researchers and enthusiasts discuss a 3000GT carbon hood, they are really debating how the hood can sustain high-speed airflow and heat while staying true to the factory geometry that keeps the car predictable in corners and stable at high speeds. The chapter that follows reads as a single thread through material science, manufacturing discipline, and real-world performance, weaving a narrative that never loses sight of street usability and track pedigree alike.

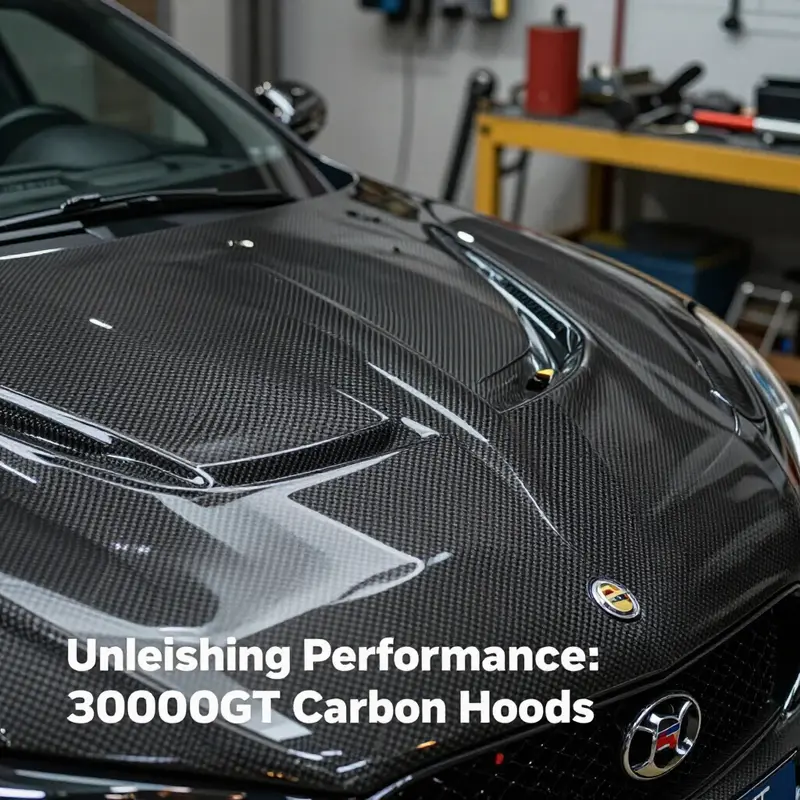

At the heart of every high-end carbon hood is the material itself. The specific hood studied here for the 1991-1993 Mitsubishi 3000GT uses 100% ISO-certified, Grade-A carbon fiber. This is not mere branding. ISO certification signals an independent standard of consistency and quality, while Grade-A designation points to a high-grade weave and resin system chosen for structural integrity and surface finish. Carbon fiber, by design, offers an exceptional strength-to-weight ratio, a feature that is especially valuable on a front-engine, high-speed sports coupe where weight distribution and front-end dynamics are critical. The choice of material is paired with a manufacturing approach that respects the science behind carbon fiber composites rather than simply turning out a glossy shell.

The manufacturing process employed is a two-part molding method. This distinction matters as much as the material itself. A two-part mold enables the hood to take on a precise geometry that matches the original profile with tighter tolerances than a single-mold approach. When a hood sits on a 1991-1993 3000GT, misalignment can translate into fogging gaps, imperfect latch engagement, or rubbing against the fender edge during full lock and unlock cycles. The two-part approach minimizes those risks by guiding the laminate through a controlled layup and cure within matched halves. The result is a hood whose curvature, crown height, and vent contours—if present—align with the car’s body lines as designed. Practically, this means a hood that sits flush at the cowl, aligns with hood hinges, and closes with consistent feel at the latch. It is not an aesthetic afterthought; it is a functional system designed to preserve the car’s front-end geometry under dynamic loads.

Two-part molding also translates to structural integrity. The lamination can be oriented to optimize stiffness along the bend lines and across the span of the hood. In performance contexts, rigidity matters because it reduces panel flex when the hood is subjected to wind shear at speed and when the engine and its accessories create localized vibrations. Every gram of rigidity gained through the laminate design translates into improved resistance to flutter and reduced hood vibration. For a car like the 3000GT, where the front-end geometry is closely tied to airflow and cooling, rigidity helps maintain consistent sealing with the radiator shroud and the under-hood air paths. In short, the two-part molding process supports a front module that behaves as a single, predictable unit rather than a composite that could shift or sag with heat and time.

Surface quality is another crucial facet of construction. Carbon fiber surfaces are prized for their visual appeal, but the performance story hinges on the finish as well. The hood must withstand engine heat, UV exposure, and the occasional impact from road debris without the surface microcracking or chalking that can dull the weave. A high-grade process uses careful resin selection and precise layups to ensure the weave remains uniform under clear coat while offering reliable adhesion to automotive paints. The clear coat, in turn, must provide UV stability and scratch resistance, preserving the aesthetic and contributing to long-term durability. When you stand before a 1991-1993 3000GT wearing a carbon hood, the glossy or semi-gloss surface tells a story about both the craftsmanship behind the hood and the care the owner devotes to keeping the finish pristine.

Beyond strength and beauty lies a practical, even economic consideration: fitment. A well-made carbon hood performs in tandem with the rest of the car’s front-end components. The two-part mold supports dimensional accuracy so that the hood aligns with the hood pin or latch, closes evenly along the leading edge, and clears the headlights and bumper geometry without modification. This is not just about aesthetics; it is about reliable service under everyday use. A hood that fits poorly can create wind noise, fan interference, or even hood flutter that undermines the driver’s sense of control at high speeds. In that sense, material and construction quality are inseparable from the driving experience. When a brand emphasizes ISO-certified materials and a two-part mold process, it signals a commitment to a product that behaves consistently across a range of climates and driving conditions, from damp city streets to dry, high-speed freeway straights.

For enthusiasts who approach the project with a blend of passion and precision, design variations become more than cosmetic choices. A carbon hood can be a statement about performance intent, weight management, and the desire to preserve or reshape the car’s front-end silhouette. In the context of the 3000GT, one notable design option comes from a well-known design line that emphasizes clean lines and a carbon finish that remains faithful to the car’s original spirit while offering a modern, track-ready edge. This option demonstrates how a carbon hood can be the focal point of a larger modification strategy, aligning with upgraded suspensions, aero components, and intake or cooling upgrades. The design choice is not merely about how the hood looks; it is about how it supports the car’s overall handling envelope and the driver’s ability to push the car to its limits with control and confidence.

For readers curious about the concrete pathways available to source such a hood, one example centers on a specific design lineage that has become a touchstone for enthusiasts seeking authentic look and fit. The Advan Velpar design for the 1991-1993 Mitsubishi 3000GT carbon hood represents how a dedicated design house translates engineering rigor into a piece that preserves factory geometry while delivering the benefits of modern composites. This option, accessible through dedicated parts catalogs, demonstrates how a carbon hood can be integrated with the car’s existing hardware and hardware mounting points, minimizing the need for dramatic chassis work or bespoke fabrication. The presence of a trusted, well-documented design underlines the practical reality that high-quality carbon fiber hoods can be compatible with a broad range of restoration or upgrade plans. For readers who want to explore this particular option further, a concise reference point would be to examine the Advan Velpar design in the context of the 1991-1993 3000GT carbon hood landscape, which illustrates how diversity in design can coexist with the shared goals of weight reduction and durability.

The discussion would be incomplete without acknowledging how such components fit into a broader ecosystem of performance parts. Carbon hoods interact with the cooling system, air intake routing, and even hood gaps that affect aerodynamics. The two-part molding approach supports a geometry that can accommodate vents or smooth panels, depending on the builder’s intent. In track environments, vents can assist heat extraction from the engine bay, while a smooth, vent-free hood may be preferred for laminar flow and reduced drag. Either path hinges on robust construction quality. The laminate’s integrity must endure heat cycling, repeated opening and closing, and extended exposure to road salts or moisture, all while remaining in spec with the car’s front-end tolerances. A well-made hood stands as a quiet partner to the engine bay, complicating not the driver’s control but the driver’s confidence that the vehicle will behave consistently under pressure.

In practice, the decision to install a carbon hood rests on a balanced assessment of weight savings, rigidity, fit, and long-term durability. The science behind the material and the craft of two-part molding combine to deliver a product that remains faithful to the car’s original proportions while pushing the performance envelope. It is not merely about reducing weight; it is about preserving stiffness, ensuring a precise fit, and maintaining a front-end architecture that responds predictably to the driver’s inputs. For the 3000GT, where front-end performance contributes significantly to handling and mid-corner stability, the carbon hood becomes an instrument of control as much as an aesthetic statement.

For readers who want to dive deeper into the material specifications and manufacturing process behind this kind of performance hood, an external reference offers a detailed snapshot of how engineers translate carbon fiber into a durable, well-fitting panel: https://www.made-in-china.com/products/vis-racing-3000gt-carbon-fiber-hood-1991-1993-91mt3k2doe-010c.html

Under the Carbon Hood: Availability, Craftsmanship, and Customization for the Mitsubishi 3000GT

The Mitsubishi 3000GT has long stood as a symbol of late twentieth-century performance, a car whose lines and engineering invite enthusiasts to look beyond stock specs toward lighter, faster, more aerodynamically intelligent configurations. Among the most influential upgrades in the car’s modern lineage is the carbon fiber hood. It is not merely a cosmetic change; it is a deliberate engineering choice aimed at reducing weight, sharpening handling, and opening more airflow to cooling systems that can otherwise hinge on the car’s performance in track or spirited street use. The carbon hood’s allure rests in its ability to shave pounds off the front end while preserving or even enhancing rigidity, a combination that translates into crisper steering response, improved weight transfer during acceleration, and a more connected driving experience overall. For many builders and collectors, the hood becomes a keystone upgrade that redefines the car’s presence on the road and at events, pairing the timeless silhouette of the 3000GT with a contemporary material narrative.

Market dynamics around Mitsubishi 3000GT carbon fiber hoods are distinctly niche, drawn to a small but highly engaged cohort of JDM enthusiasts, restoration specialists, and performance tuners who treat weight reduction as a core performance lever. This market is characterized less by mass production and more by specialization. Availability is largely anchored in suppliers based in China, a center of gravity for aftermarket auto body components that caters to low-volume, classic, and performance-focused builds. In this ecosystem, precision manufacturing and cost-effective execution coexist, enabling high-quality carbon components to reach builders around the world without the price tag of premium original-equipment materials. Regions with advanced composite production capabilities, especially in coastal manufacturing hubs, have built up robust ecosystems for carbon fiber and FRP parts. The advantage of this concentration is twofold: it creates a broad spectrum of options that range from standard-fit hoods to fully customized pieces and it facilitates rapid iteration through CAD-driven design cycles that can tailor the hood to a specific trim, cooling need, or aesthetic preference.

A practical reality of this market is the diversity of customization pathways available to buyers. Suppliers in major urban industrial zones offer not only standard-fit carbon hoods but also deep customization. The options extend from tailored shaping to ensure exact alignment with existing mounting points, to functional integrations such as built-in air intakes or dedicated cooling ducts that channel air toward the radiator or intercooler. Some providers even offer CAD design services to guarantee a precise fit and to optimize the hood’s geometry for aerodynamics. This level of customization matters because the 3000GT’s narrow engine bay and distinctive silhouette place a premium on fitment accuracy; even small deviations in hood curvature or hinge alignment can alter hood line aesthetics and the way the hood seal interacts with the fenders at speed. The ability to customize is not simply about looks; it is about harmonizing materials, weight, and airflow with the specific performance goals of the build.

In the broader supply chain, price is a function of complexity, material quality, and production method. Standard carbon fiber hoods typically begin in a range that reflects the base material and molding process, while fully customized, race-ready pieces that incorporate higher weave grades and bespoke aerodynamics can surpass several thousand dollars. Material choices such as 1K versus 3K carbon weave play a central role in both price and performance. A thinner or plainer weave may save a bit of weight and cost, but a higher-quality weave often yields a more uniform surface finish and improved long-term resistance to environmental exposure. The manufacturing approach—hand-crafted autoclave processes versus molded laminates—further modulates both price and structural integrity. The result is a spectrum of offerings that lets a buyer balance budget, desired weight savings, and the need for professional fitment.

For buyers planning to source a carbon hood, supplier reliability becomes as crucial as the hood’s appearance. The most effective procurement strategies hinge on a few practical criteria: repeatable production quality, transparent technical specifications, and dependable post-sale support. Buyers should seek vendors that publish clear manufacturing details, such as resin systems, weave specification, and anticipated tolerances. A supplier with robust quality controls, demonstrated on-time delivery performance, and a willingness to support customers after purchase elevates the risk profile of a project and can dramatically reduce installation friction. In this specialized market, a well-documented process covering everything from prep work to finishing and mounting hardware compatibility helps builders avoid misalignment, paint mismatch, or unanticipated fit problems that can derail a project timeline. Across early 2026 industry guides, seasoned buyers often prioritize partners that can deliver not just a hood, but a complete, coherent upgrade package, including CAD-assisted fitment checks and post-delivery warranty or support arrangements. For a buyer seeking a verified option, a relevant and authoritative source is a carbon hood listing that emphasizes customization and compatibility, featuring detailed specifications and supplier performance data making it a current and comprehensive resource at the time of purchase.

The decision to adopt a carbon hood on a 3000GT also hinges on practical installation considerations. Installers should expect a weight reduction to alter the vehicle’s front weight distribution subtly, which can influence suspension setup and steering response. It is prudent to evaluate hardware compatibility, including hood hinges, latch systems, and hood pins, because aftermarket carbon hoods, especially those built to very tight tolerances, sometimes require minor modifications to maintain proper alignment. High-quality finishes demand careful surface preparation before painting, ensuring that clear coats adhere evenly and that the weave pattern remains uniform under UV exposure. Paint matching itself is a nuanced exercise; the goal is to preserve the hood’s aesthetic cohesion with the rest of the body while accounting for potential color shift across the hood’s curvature under sun exposure and heat. For enthusiasts chasing a concours-level presentation, the finish becomes almost as important as the weight savings; a flawless weave, clean seam lines, and an even gloss are markers of a well-executed upgrade.

Beyond immediate performance and aesthetics, there are broader considerations that shape the value proposition of a carbon hood. The 3000GT’s legacy as a platform for a wide array of performance alterations means that a hood upgrade may be part of a staged improvement weight reduction followed by enhanced cooling, then a tuned engine response. When owners plan to maximize overall system harmony, they may pair the hood with complementary components such as low-friction underbody shields, venting optimizations, and carefully matched aerodynamic accessories. The reduction in weight at the front can influence braking dynamics, cornering behavior, and even tire wear characteristics if suspension tuning is co-optimized around the new mass distribution. In this context, a carbon hood is not simply a one-off cosmetic tweak; it is an enabling part of a broader performance strategy that demands thoughtful planning, precise fitment, and ongoing verification under real-world driving conditions.

For readers seeking practical, actionable next steps, the path often begins with a clear specification of intentions: whether the aim is a track-ready machine with optimized cooling and airflow, or a street-focused build that prioritizes weight savings and aesthetic presence. From there, the choice of supplier becomes a gateway to achieving those goals. Buyers should request a full bill of materials, production method details, and a post-purchase support plan. They should also consider the total cost of ownership, including potential paint work, installation labor, and any adjustments needed to the car’s existing front assemblies. The market offers a breadth of customization possibilities, and with careful selection, a carbon hood can transform not only the car’s appearance but its entire behavioral envelope on the road and on the track.

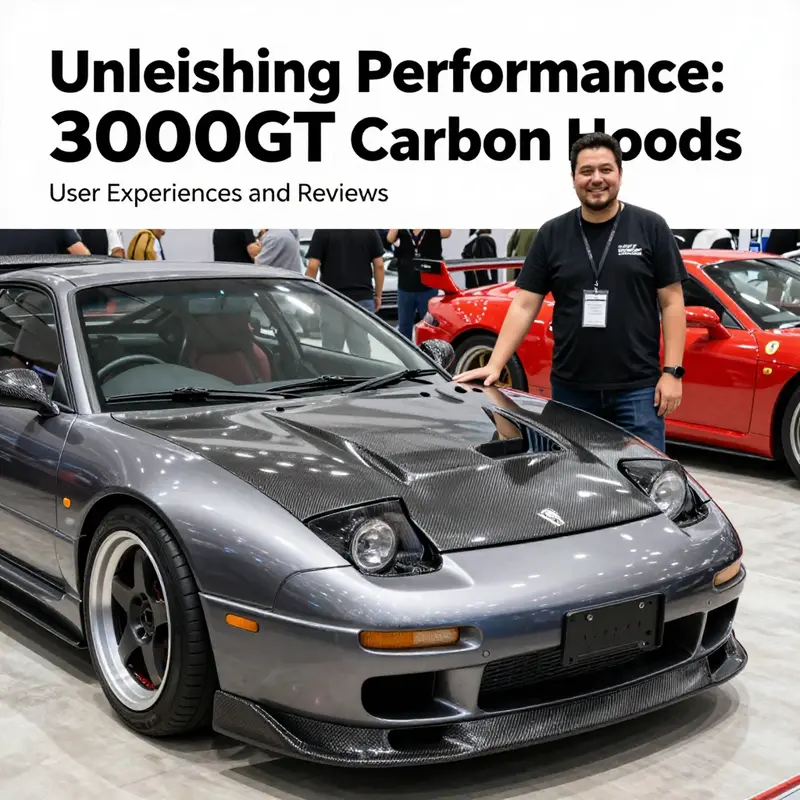

Real Owners Speak: How a Carbon Hood Transforms a 3000GT

Visual Impact and First Impressions

A carbon fiber hood changes the 3000GT’s presence immediately. Owners consistently describe a more aggressive, focused look. The weave and finish of real carbon catch light differently than painted metal. That visual depth often convinces enthusiasts the car has received a meaningful upgrade. Beyond looks, the hood’s weight advantage is the most tangible early benefit. Many drivers note the front end feels lighter, with small but noticeable gains in turn-in and transient response. These changes are subtle, not dramatic, yet they matter during spirited driving and track days.

Fitment and Installation Realities

Fit varies with manufacturer quality. Hoods crafted to original specifications tend to align with factory holes and hinges. These parts usually require minimal adjustment. Conversely, low-cost, generic pieces need trimming, filler, or new hood pins to sit right. Improperly fitted hoods can introduce wind noise and stress points. Several owners recommend checking hinge alignment and latch engagement before painting. If the hood alters hood clearance around the windshield or bumpers, address it early. Professional installation reduces the risk of mismatches and ensures the latch and safety catch work reliably.

Beyond physical fit, consider how the hood integrates with other engine-bay components. Some carbon hoods change the way struts or props attach. Verify hood props or aftermarket struts have sufficient load capacity. If vents are present, confirm they clear engine components and ducting. A well-chosen hood should blend with the car’s overall geometry, not force compromises.

Performance and Handling Effects

Weight reduction at the front axle improves balance. Owners who track their cars report crisper turn-in and slightly faster cornering due to reduced understeer. On the street, the difference is more about feel than lap-time gains. Acceleration benefits are modest, particularly in cars without extensive drivetrain changes. Still, shaving pounds at the front can be one of several cumulative upgrades that appreciably improve performance.

Aerodynamics matter when vents or scoops are involved. Functional vents that guide heat away from the engine bay can improve consistent performance on long runs. However, non-functional aesthetic vents can trap heat or allow water ingress if poorly designed. Real-world users warn against choosing style over substance when vents and ducts are included.

Durability, Finish, and Maintenance

Carbon fiber resists corrosion and won’t rust. That makes it an appealing long-term option for an aging car. The primary vulnerabilities are surface damage from chips and UV degradation of clear coats. Owners suggest frequent inspections for cracks, especially around mounting points. Small chips can be repaired, but deep damage often requires specialist work.

Cleaning routines differ from metal hoods. Harsh chemicals and abrasive pads can dull or damage the finish. Most users recommend pH-neutral car shampoo and soft microfiber towels. Regular waxing with a UV-protective sealant preserves clarity and prevents yellowing. If the hood is painted to match the car, attention to paint prep and primer is crucial to avoid adhesion problems.

Value and Cost Considerations

Cost ranges widely depending on construction and finish. Many owners see the upgrade as an investment in both style and performance. The initial price often includes manufacturing complexity and finishes like clear-coat or paint-ready prep. Buyers who opt for raw carbon or uncoated finishes may save money, but they must be prepared to finish and protect the surface themselves.

Resale value is context-dependent. On a well-maintained car, a high-quality carbon hood can add desirability. On a vehicle with mismatched panels or poor installation, it can detract. Owners advise budgeting for installation, possible painting, and alignment work on top of the purchase price.

Common Owner Pitfalls and How to Avoid Them

A recurring issue in owner discussions is assuming all carbon hoods are equal. They are not. Inspect laminate schedules, weave patterns, and core materials. Single-piece, high-grade carbon is lighter and stronger than cheap layups with inconsistent resin content. Check for voids, resin pooling, or irregular weave under the clear coat.

Another common mistake is neglecting functional checks. Verify hood latches, safety catches, and alignment before finalizing installation. Some owners had to retrofit additional hood pins or supports when the original latch geometry changed. Take the time to test hood release mechanisms and confirm closures under various temperatures and road conditions.

Painting a carbon hood can hide minor imperfections. Yet, paint adds weight and can reduce the visual effect of exposed weave. If you value the raw carbon look, invest in a proper clear coat application to shield the fibers. If you need a painted finish, use a shop experienced with composite substrates.

Long-Term Ownership Notes

Owners who live in sunny climates emphasize UV protection. Clear coats can oxidize and yellow over time if untreated. Regular maintenance and high-quality sealants extend lifespan dramatically. Those in colder regions stress checking mounts after winter. Road salt and debris can chip the finish, and chips left unattended can lead to moisture intrusion at repair spots.

Repairability is another real-world concern. While surface scratches can often be sanded and re-cleared, structural damage requires specialist carbon work. Owners report that affordable local shops may not have the expertise for composite repairs, leading to higher-than-expected costs.

Deciding Factors for 3000GT Owners

For many 3000GT enthusiasts, the carbon hood is as much about identity as function. It signals a thoughtful approach to performance and aesthetics. If you prioritize originality, seek a hood that matches original contours and mounting points closely. If you want a bold visual statement with vents and scoops, ensure those elements are engineered, not merely cosmetic.

One useful resource documents a carbon hood option tailored for the 1994–1999 3000GT. That page offers specific fitment and finish details for owners seeking model-specific options. For a real-owner perspective on how a carbon hood influenced handling and chassis feel, see a detailed forum discussion where an owner shares post-install observations: https://www.reddit.com/r/CarAdvice/comments/1d6qk7z/3000gtspydercarmodsand_upgrades/.

Practical Buyer’s Checklist

Before purchasing, inspect the hood for consistent weave and resin coverage. Confirm that mounting points align with factory locations. Ask about weight savings and compare them to the stock hood. Verify the finish—paint-ready, clear-coated, or raw carbon—and understand the extra costs for finishing. If possible, view an installed example on a car like yours. Finally, plan for professional installation if you lack experience with composite parts.

Owners who follow these checks report fewer surprises and greater satisfaction. The carbon hood can be a defining part of a tasteful build. When chosen carefully, it enhances appearance without compromising fit or function. When rushed or selected for looks alone, it can create headaches that outweigh the benefits. Balance aesthetic goals with practical checks, and the upgrade will likely become a long-lived highlight of your 3000GT.

Final thoughts

In every transformation from stock to sport, the Mitsubishi 3000GT carbon hood stands as a testament to innovation in automotive performance. With significant advantages in aerodynamics, weight reduction, and material quality, these hoods not only serve aesthetic purposes but also vastly enhance driving dynamics. As the market continues to embrace customization, the ability to offer various designs can meet consumer demands for personalization. Positive user experiences further solidify the carbon hood’s status as a sought-after upgrade. Business owners have a prime opportunity to stock these performance-enhancing components and cater to the dedicated enthusiast market, ensuring customer satisfaction and increased sales.