The hood of the 2007 Mitsubishi Eclipse plays a pivotal role in not just vehicle aesthetics, but also in ensuring safety and performance. Business owners dealing with automotive parts and services will find this component essential for maintaining vehicle integrity. This article delves into four key areas: the importance of the hood in both safety and aesthetics, the distinction between aftermarket and OEM replacement options, the critical compatibility factors for successful installations, and the economic considerations buyers must assess to make informed decisions. Each chapter aims to equip business operators with the insights needed to navigate the landscape of hood replacement and maintenance effectively.

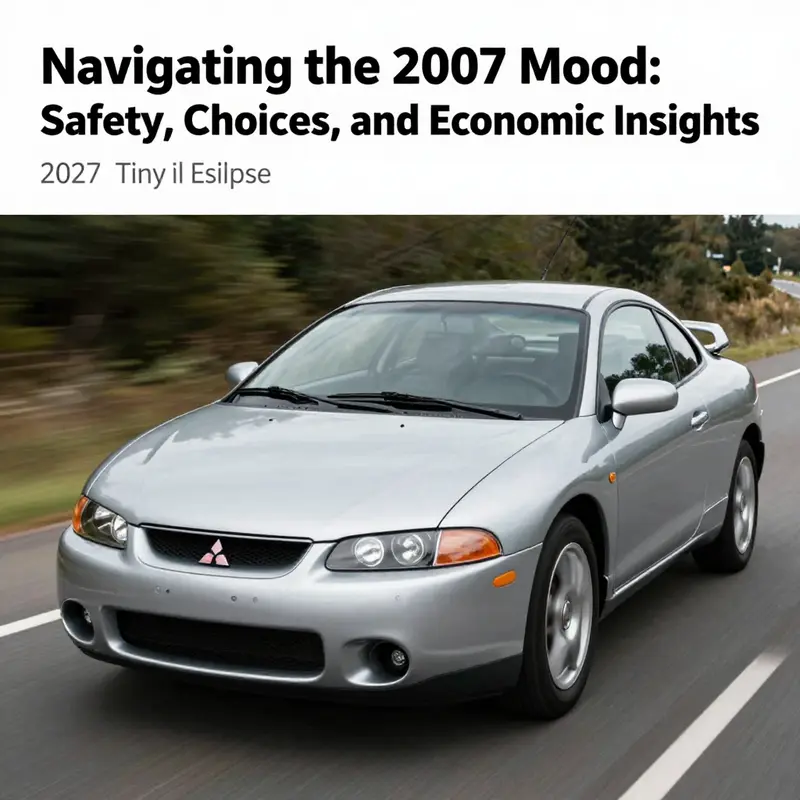

Front-Line Form and Function: The 2007 Mitsubishi Eclipse Hood as Safety Shield and Style Signal

The hood that crowns the 2007 Mitsubishi Eclipse is more than a mere sheet of metal or composite. It acts as a guardian for the heart of the car—the engine—while also serving as a visible statement of the car’s intent. In a design tradition that blends sport with practicality, the Eclipse hood embodies a balance between function and form. When you stand in front of the car, the hood’s line guides your eye along the fenders toward the grille, and that line is not accidental. It contributes to the car’s aerodynamics, reducing drag and sharpening the silhouette, which in turn reinforces the vehicle’s identity as a compact, performance-oriented coupe. But behind that aesthetic and aerodynamic role lies a deeper, often overlooked purpose: safety. The hood is designed to behave as a controlled energy sink in low-speed impacts, and that design intent matters whether you’re navigating city streets or pulling away from a routine stop at a traffic light. The hood’s structure, its materials, and the latch system together determine how reliably it stays closed at speed and how it behaves in a collision, especially in urban environments where pedestrian interactions with the vehicle are more likely. In a modern hood, energy-absorbing features and deformable zones help dissipate force, reducing injury risk if a pedestrian or cyclist comes into contact with the vehicle at modest speeds. This is not just theoretical; it is an engineered reality that informs every hood design and replacement decision a driver makes. When the hood is properly aligned and securely fastened, it contributes to safer visibility and handling. A hood that can flex, crumple, and then settle back into its intended position shows a belt-and-suspenders approach to safety: it protects vulnerable occupants and pedestrians while preserving the driver’s control and line of sight. The interplay between hood design and the opening beneath it also affects engine cooling and heat management. The Eclipse’s engine bay is compact and efficiently laid out, and the hood must clear exhaust heat and radiator airflow patterns without hampering performance. A well-designed hood maintains a steady gap with the front fascia and keeps air flowing smoothly over the engine components. This is critical for electronics longevity, turbo or V6 performance, and overall reliability. In the 2007 Eclipse, the hood is part of a cohesive front-end language that includes the grille, the headlights, and the fenders. The hood’s curvature and the crease lines work with the fender arches to create a cohesive silhouette that signals speed even when the car is at a standstill. The visual message is clear: this is a car designed with purpose, built to perform, and capable of turning heads while offering practical reliability. From a maintenance perspective, the hood can be a straightforward replaceable element, yet its replacement demands precision. Replacement parts must align with the car’s original geometry to maintain both safety and aesthetics. The hatchback and coupe configurations, though sharing an overarching design language, can present subtle differences in hood fitment due to variations in the surrounding panels. A misaligned hood can create uneven gaps, misaligned latch points, and uneven paint borders, all of which dull the cohesive look and can compromise safety by increasing the risk of loose components at speed. Thus, confirming the exact model configuration before ordering a replacement hood is not a luxury; it is a prerequisite. Owners should verify whether their Eclipse is the two-door coupe or the four-door hatchback variant and whether the engine bay layout matches the intended hood. The 3.8-liter V6 engine in the GT trim, common to many Eclipse models of this era, is another reason to approach hood replacement with care. The hood must clear the engine components, including any aftermarket air intakes or engine dress-up parts, while preserving the hood’s edge alignment with the cowl and the front fenders. When it comes to choosing a replacement, the decision is rarely about one factor alone. It is a balancing act among safety features, material properties, weight, and cost. OEM hoods are designed to fit precisely with the factory body panels and joints, ensuring the clearance and latch engagement remain predictable. Aftermarket options often promise marginal weight savings, improved aesthetics, or enhanced rigidity through different materials such as steel or carbon fiber. The choice can influence front-end weight distribution, which in turn affects suspension tuning and steering feel. In practice, many drivers lean toward steel-primed options when the goal is straightforward fitment and cost efficiency, especially for cars that see daily driving rather than track duty. Yet there is a compelling case for lighter materials for those seeking performance gains or reduced load on the hood hinges and latch mechanisms. Carbon-fiber options, while typically more expensive, offer a meaningful reduction in weight. They can also present a different surface finish and paint requirements, which adds another variable to the restoration or customization plan. For the Eclipse, the aesthetic payoff is immediately evident. The hood’s form complements the model’s coupe silhouette, reinforcing a low, aggressive stance that auto enthusiasts expect from a compact, performance-oriented vehicle. The hood’s surface catches light in a way that highlights the sculpted center crease and the subtle, wind-swept curvature toward the edges. The automation of this aesthetic is not mere ornament; it’s part of the vehicle’s storytelling. When a buyer considers replacement parts, the decision often hinges on a mix of fit, finish, and feel. A hood that resembles the factory piece, in both color-matching paint and panel gaps, preserves the visual integrity of the car. It also preserves resale value, an often overlooked yet practical concern. In this context, aftermarket alternatives can deliver value if they maintain proper dimensions and a suitable surface finish. The market includes options that replicate the OEM geometry while offering a cost advantage. Buyers should weigh the long-term implications of fit and color matching against upfront savings. The process of selecting a hood inevitably brings up the question of compatibility with the Eclipse’s two-door coupe versus the four-door hatchback. The two configurations have distinct front-end geometry, which can influence not only the hood’s length and curvature but also the positions of the hood hinges, latch, and the clearance to the grille. A hood designed for one variant may not align perfectly with the other. This makes it essential to confirm the exact model specification prior to purchase. To navigate these choices, many buyers turn to reputable listings and retailers that clearly state the intended model years and configurations. A reliable approach is to focus on listings that specify compatibility with the 2007-2012 Eclipse models, noting that certain hoods are designed for the 2-door coupe and others for the 4-door hatchback. The practical implication is straightforward: accuracy in model specification translates into correct fitment, consistent safety performance, and a harmonious appearance. The discussion of replacement parts also intersects with the broader ecosystem of online marketplaces. Platforms that offer compatibility guarantees can reduce the risk of ordering a hood that does not align with the car’s geometry. While these guarantees are valuable, they do not replace due diligence. Buyers should still verify the exact trim, the engine bay layout, and any aftermarket modifications that might affect hood clearance. Wiring harnesses, hood dampers, and weather-stripping may not be included, or they may require additional components to restore full functionality after installation. In addition to maintaining proximity to the original aesthetic, a hood replacement invites a broader look at the Eclipse’s front-end design language. The hood’s lines, its contours, and its edge treatment align with the proportions of the headlights and grille. The resulting front fascia communicates cohesion and a certain kinetic energy even before the car begins to move. This is the effect that automotive design aims to achieve: a visual promise of speed that translates into actual performance when driven. For owners who enjoy the car’s visual appeal and want to preserve or enhance it, choosing a hood that respects the original design cues is essential. A well-chosen replacement, whether OEM-spec or aftermarket, should maintain consistent paint compatibility and avoid introducing gaps or misalignments that would distract from the Eclipse’s clean silhouette. When considering materials, it is helpful to think about how a hood interacts with the car’s overall weight and balance. Heavier steel pieces contribute to a sense of solidity but can add perpetual drag and fatigue on the hinges. Lighter options, such as carbon fiber, offer performance advantages but come with higher costs and different maintenance considerations, including paint adhesion and potential color-shift needs. The importance of a reliable latch system should not be underestimated. A hood that latches securely remains closed at speed and in the event of minor impacts. It also ensures that under-hood components stay protected from debris and weather. The Eclipse hood, in its original design, embodies a disciplined approach to safety and aesthetics, one that blends seamlessly with the car’s intended use as a compact performance coupe. For enthusiasts who wish to explore aftermarket or OEM-style options, a careful evaluation of fitment, material, and finish is essential. A practical path is to discuss options with reputable suppliers who provide model-specific guidance, and to request confirmation of compatibility with both the coupe and hatch variants. In the end, the hood serves as both a protective cover and a visual banner. It tells a story about the car’s character—one of speed, precision, and a certain sport-luxury balance that has attracted a devoted following. The decision to replace or upgrade a hood should be grounded in a clear understanding of how this single panel fits into the broader context of safety, performance, and appearance. The best choices honor the Eclipse’s original design language while offering the resilience needed for everyday driving and occasional back-road thrills. For readers who want a concrete example of aftermarket options that maintain a strong blend of safety and aesthetics, consider a representative carbon-fiber hood page that discusses the Eclipse’s era and fitment. This resource helps illustrate how the practical concerns of alignment, weight, and finish translate into real-world replacements. 2006-2012 Eclipse carbon-fiber hood page provides a concrete point of reference for those evaluating the trade-offs between weight savings and manufacturing tolerances. While such pages can be helpful, buyers should treat them as starting points for deeper due diligence rather than final authority. The path from concept to installation is paved with careful measurement, precise fitment, and a willingness to balance cost against long-term safety and appearance. In the broader arc of the Eclipse’s reach, the hood remains a symbol of how a single part can influence a vehicle’s safety profile and its visual rhetoric. It anchors the front end, aligns with the car’s aggressive stance, supports effective engine cooling, and contributes to the car’s overall resilience in the face of road hazards. It is, in short, a front-line component that deserves thoughtful consideration whenever a replacement, upgrade, or restoration is on the horizon. External reference: https://www.ebay.com/itm/154389764385

null

null

Hood Replacement Realities: Achieving a Proper Fit for the 2007 Mitsubishi Eclipse

Replacing the hood on a 2007 Mitsubishi Eclipse is about alignment as much as it is about coating and color. Compatibility is a layered concept that includes exact year, body style, and engine configuration. The 2007 Eclipse belongs to a generation that shares design cues with later years, but small changes in mounting points and hood curvature can create fit issues if a hood is not explicitly made for this year. A hood that appears to fit at a glance may not seal properly or latch evenly, leading to wind noise and moisture intrusion. Begin by verifying the hood is designed for the 2007 Eclipse, noting the coupe or hatchback variant and the 3.8L V6 engine if applicable.

Body style matters. Coupes and hatchbacks have different hood contours and hinge spacing. Verifying the exact body style helps ensure the hood clears fenders and bumper and sits flush with the grille.

Engine considerations matter too. The 3.8L V6 affects hood cutouts and engine bay height. Hood designs intended for other engines can misalign with the firewall and radiator support, causing interference or gaps that compromise sealing.

Material choices affect weight, stiffness, and durability. Steel hoods are common, durable, and economical, but heavier. Carbon fiber hoods save weight but may require extra care in finishes and climate exposure. Car builders weigh the trade offs based on reliability, cost, and desired performance.

Aftermarket hoods vs OEM ones. Universal fit claims can be misleading; verify hinge spacing, latch type, and trim integration with OEM specifications. A correct hood should align with mounting points and sit correctly at the leading edge with the grille and bumper.

Practical workflow. Confirm year, body style, and engine; check hinge and latch compatibility; evaluate material implications; compare to OEM specs. If possible, obtain exact measurements or mounting diagrams from the seller or view the hood in person.

A tangible starting point is to prefer a steel-primed option that explicitly lists compatibility with the 2007 Eclipse for both coupe and hatchback and the 3.8L V6. This helps ensure proper mounting geometry, edge radii, and finish durability with minimal modification.

In practice, coat and paint matching should be considered during replacement to preserve the Eclipse’s front-end aesthetics. The overarching goal is a hood that fits as the factory intended, maintaining front-end geometry, sealing performance, and visual balance.

Weighing Cost, Fit, and Value: Smart Economics for Replacing a 2007 Mitsubishi Eclipse Hood

Balancing Cost, Fit, and Long-Term Value When Replacing an Eclipse Hood

Replacing the hood on a 2007 Mitsubishi Eclipse requires more than selecting the cheapest option. The hood sits front and center on the car. It affects looks, weight distribution, and resale value. Making a financially sound choice means thinking beyond sticker price. Consider materials, fitment, installation, warranties, and long-term ownership costs. With careful planning, you can get the best value for your budget.

Material affects both price and performance. Steel is the baseline choice. It’s affordable, easy to repair, and common among original equipment parts. Aluminum hoods cost more but offer a lighter alternative without extreme price premiums. Fiberglass is often cheaper than advanced composites and can mimic shapes and vents, yet it may be heavier than some carbon fiber pieces and is more brittle under impact. Carbon fiber represents the upper end of cost. It looks sporty and cuts weight significantly. Those benefits come at a premium, though, and repairability is limited. When evaluating materials, factor in the intended use of the car. If the Eclipse is a daily driver, a steel or aluminum hood often gives the best balance of cost and durability. For show cars or performance builds, carbon fiber may justify its price through reduced weight and enhanced visual appeal.

Another major decision is whether to buy an OEM part or an aftermarket hood. OEM hoods match factory specifications closely. They typically fit without modification and maintain original crash and latch performance. This often reduces installation time and alignment costs. OEM options usually carry some warranty coverage and may preserve the vehicle’s perceived value. Aftermarket hoods vary widely. Some closely replicate OEM fit and finish. Others require significant adjustment. Aftermarket pieces can save several hundred dollars upfront. But poor fitment, panel gaps, and surface imperfections can lead to additional body shop time and cost. Assess the reputation of the seller and the return policy before buying aftermarket. Read fitment reviews and ask for photos from other buyers who have the same model. A modest upcharge for a high-quality aftermarket hood can still be cheaper overall, if it reduces installation headaches.

Fitment differences matter for the 2007 Eclipse. The hood must match the specific body style and engine layout. Confirm whether your vehicle is a two-door coupe or a hatchback variant that alters hood geometry or latch positions. Also confirm trim or aftermarket modifications that change hinge locations. A mismatch can mean costly modifications at installation. Sellers that guarantee fit for 2007–2012 models might simplify buying. Still, verify the exact part number or physical measurements before purchase. If buying used, inspect for previous repairs and alignment consistency. A poorly repaired used hood may hide structural rust or weakened hinge mounting points. Those weaknesses can create safety risks and future expense.

Installation costs can be as significant as part costs. A professional shop will charge for labor, alignment, and possibly adjustments to the hood latch, hood prop, or hood bumpers. Expect labor to add several hundred dollars to the project. Specialized hoods—those with vents, scoops, or finished carbon weaves—can increase labor time due to careful alignment and clearance checks. If you choose a painted hood, painting and blending with existing panels adds cost. Painting can exceed the price of the hood itself, depending on finish and color matching complexity. For owners comfortable with mechanical work, a DIY installation can avoid labor charges. However, hood alignment and latch function are safety-critical. A small misalignment can cause wind noise, poor closing, or even lift at speed. If you consider DIY, ensure you have a second pair of hands and the tools to measure gaps and adjust hinges precisely.

Shipping and handling are hidden but real costs when ordering a hood online. Large panels require crating and special freight services. Freight charges can add hundreds to the final bill, depending on distance and courier rates. Some vendors include freight in the listed price, while others add it during checkout. Always confirm shipping costs and damage policies. Freight damage on large panels is common. Inspect the hood carefully upon delivery. Document any dents, scratches, or cracks before signing the delivery receipt. A damaged hood may be rejectable under the shipper’s insurance policy, but only if documented promptly.

Long-term considerations extend beyond immediate purchase and installation. Durability affects lifetime cost. Cheaper materials or poor manufacturing can lead to warping, delamination, or corrosion. Carbon fiber is resistant to rust but can delaminate if moisture intrudes. Steel can rust if paint chips and exposure follows. Consider environmental factors where the car is driven and stored. Salted winter roads favor non-steel alternatives for reduced corrosion risk. Warranties also play into long-term economic value. OEM parts or reputable manufacturers sometimes include limited warranties for fitment or finish. These warranties reduce risk, especially when combined with professional installation.

Insurance and registration are often overlooked. Some insurers view aftermarket modifications as a reason to increase premiums. A lightweight carbon fiber hood, for example, may be considered a modification. Notify your insurer about major changes. Failure to disclose modifications might complicate claims after a loss. Conversely, an OEM replacement usually keeps coverage unchanged. Check with your insurance provider before spending large sums on non-OEM hoods.

Resale value is another layer. A correctly fitted, high-quality hood can improve curb appeal. Carbon fiber or well-executed aftermarket styling may attract buyers who value visual upgrades. Yet, poorly fitted or mismatched hoods can be a deterrent. For vehicles likely to be resold, choosing an appointment of fit and color that matches factory appearance preserves broader market appeal. If your plan is to build a unique car and keep it, then more radical choices may be economically sensible.

Cost-saving strategies exist without sacrificing quality. First, source multiple quotes for the part and installation. Compare local salvage yards, aftermarket suppliers, and OEM dealers. A used OEM hood from a low-mileage donor car can be a major saving. However, inspect it closely for alignment and rust. Second, buy the hood unpainted to reduce upfront price. Painting locally after fitment ensures color matching and saves the paint-blend surcharge some vendors add. Third, consider trading services for parts. Some body shops accept parts credit when you supply the hood. This can lower labor cost. Fourth, time purchases around seasonal sales or promotions to capture discounts. Finally, bundle replacement work; combining a hood swap with other body repairs can reduce total labor per job.

When price and quality are balanced, verification becomes critical. Ask sellers for part numbers, measurements, and proof of fit for your specific model year. Request high-resolution photos of the product. For online marketplaces, review seller ratings and buyer feedback carefully. For used pieces, demand information on past repairs and any rust or dents. For painted hoods, inquire about paint warranty and color code matching.

A prudent approach also considers the aftermarket ecosystem. Some specially styled hoods are designed specifically for performance variants or widebody conversions. Ensure vents, scoops, or reinforcements do not affect hood clearance with engine components. Confirm that hood pins or aftermarket latch systems are compatible with the car’s safety systems.

Finally, keep documentation. Save receipts, warranty papers, and installation records. These documents support resale and simplify insurance communication. A clean record of parts and professional installation increases buyer confidence.

Thoughtful purchasing turns the hood replacement into an upgrade rather than an unexpected expense. By weighing material costs, fitment accuracy, installation labor, shipping, insurance, and long-term durability, owners can make choices that serve both the wallet and the vehicle. Where aesthetics and performance matter, investing in a quality hood can pay back through improved handling and strong curb appeal. Where budget is tight, a well-chosen OEM or properly vetted used hood preserves function and safety without overspending.

For owners considering high-end carbon or style-specific options, review comparable hood designs for fit and finish. One useful reference on similar carbon hood styles can be found here: 2006–2012 Monster GT–style carbon fiber hood for Eclipse.

For a direct look at a carbon hood product page relevant to 2006–2012 Eclipse hoods, see:

https://www.k2industries.com/products/2006-2012-mitsubishi-eclipse-carbon-creations-oem-look-hood

Final thoughts

Replacing the hood of the 2007 Mitsubishi Eclipse requires careful consideration of safety, compatibility, and economic factors. This article has aimed to provide a comprehensive understanding of those elements. With the right information, business owners can make informed decisions that align with both quality and budget. By emphasizing the importance of the hood, exploring replacement options, and analyzing economic implications, we aim to facilitate the success of vehicle maintenance operations and maximize customer satisfaction.