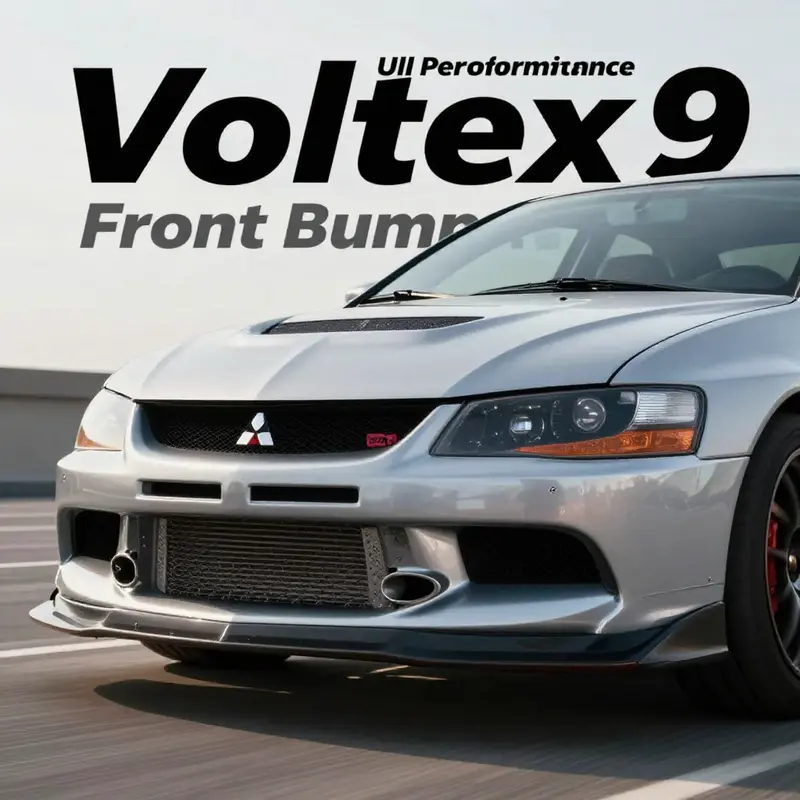

The Mitsubishi Lancer Evolution 9 Voltex front bumper is a specialized component that balances distinctive aesthetics with performance-enhancing functions. Designed for serious enthusiasts and professionals in the automotive aftermarket industry, this bumper integrates advanced aerodynamics essential for high-speed stability while showcasing an aggressive style that reflects the Evo’s robust heritage. Each chapter will delve into various critical aspects, such as its aerodynamic design, material composition, available customization options, and proper installation techniques, all of which are essential for ensuring both performance and compliance with safety standards.

Shaping Speed: How the Voltex Evo 9 Front Bumper Marries Aerodynamics and Design

Shaping Speed: How the Voltex Evo 9 Front Bumper Marries Aerodynamics and Design

The front bumper on the Voltex version of the Mitsubishi Lancer Evolution 9 is more than a styling statement. It is a deliberate piece of aerodynamic engineering that alters airflow, cooling, and vehicle behavior at speed. Where many bumpers focus primarily on looks, this design aims to reconcile aggressive visual language with functional gains for road and track use. The result is a component that changes how the Evo 9 breathes, grips, and responds, without abandoning the precise OEM fitment that owners expect.

At first glance the Voltex face reads as purposeful. Prominent splitters and well-placed vents catch the eye. Underneath that visual boldness, several key design choices drive measurable aerodynamic effects. The bumper’s sculpted contours guide air into designated channels. Integrated intakes push cool air to the intercooler and radiator. Side vents and canards help manage the high-pressure zones that otherwise buffet the front end. Those elements work together to reduce drag and to increase downforce at speed, both of which translate into higher high-speed stability and improved turn-in precision.

Material choice is part of the performance story. Lightweight materials such as carbon fiber composites or reinforced fiberglass keep mass low. Lower weight at the front improves steering feel and helps maintain the car’s intended weight distribution. Those materials also withstand temperature cycles and resist corrosion. When designed well, they recreate the strength and mounting points of the original bumper. That means a seamless installation that retains factory alignment, sensor fitment, and crash-load paths where applicable.

Integrated intakes are a central functional trait. The Voltex approach does not simply add larger openings; it channels airflow to specific targets. Air is directed toward the primary heat exchangers, including the radiator and the top-mounted intercooler. During spirited driving, heat rejection becomes critical. The right intake geometry helps maintain safe coolant and charge-air temperatures. Cooler intake and intercooler temps reduce detonation risk and allow consistent power delivery over extended laps or high-speed runs. Equally important, properly shaped ducts minimize the turbulence that increases drag. Smooth laminar flow through targeted ducts preserves momentum while cooling the mechanical systems that benefit most.

Contours sculpted into the bumper serve a dual purpose. On the aesthetic side, they deliver the aggressive stance associated with Voltex styling. On the aerodynamic side, they create controlled pressure gradients across the front fascia. Those gradients influence how air splits between the top and the bottom of the car. By shaping the airflow so more air travels under the car at intended speeds, designers can increase the effective downforce generated by the vehicle’s underbody. That enhances track stability and reduces lift on long straights. At the same time, carefully routed flow reduces the formation of vortices at sharp edges—a common source of drag and high-speed instability.

A front splitter is an unmistakable feature, visible on many Voltex-inspired designs. Functionally, the splitter extends the effective length of the bumper at its lowest point. It increases the pressure differential between the top and bottom of the bumper, producing a modest but useful forward downforce. The splitter also helps prevent excessive airflow from reaching the underside of the car at speed, which can cause lift. When combined with side vents and shaped inlets, the splitter contributes to a more predictable balance between front and rear downforce. That predictability aids drivers during high-speed lane changes and corner entry.

Side vents and canards perform a subtle but vital role. Side vents relieve pressure build-up in the wheel wells, where turbulent pockets can create drag and negatively impact steering feel. Vents also channel heated air away from the brakes and engine bay. Canards, smaller aerodynamic fins, generate local vortices that keep airflow attached to desired surfaces. Those vortices help condition the air entering the side skirts and undertray, improving the efficiency of the entire aero package. The net effect is a front end that reduces buffet and helps the car maintain a planted sensation when the pace climbs.

A crucial benefit of this bumper is the balance it strikes between street legality and track capability. The Voltex design retains OEM mounting and alignment to preserve crashworthiness and road compliance. Owners who drive on public roads get a refined appearance with the reassurance that the bumper mounts as the factory intended. Yet the same geometry yields measurable gains on a closed course. Those gains are not dramatic enough to require major suspension changes, but they add up: better high-speed stability, improved heat management, and slightly increased cornering grip. That makes the bumper a practical upgrade for drivers who use their Evo for daily driving and occasional track days.

Fitment fidelity is an area where attention to detail pays dividends. Properly modeled attachment points ensure the bumper interfaces correctly with existing fenders, hood, and undertray. That precision reduces the likelihood of unwanted gaps that alter airflow in unpredictable ways. It also streamlines installation, lowering the need for aftermarket modifications or reinforcement. For owners concerned with paint and finish, many replacements come in a blank white or primed state. This allows custom paintwork without compromising the component’s structural design.

Compatibility considerations are important. While many front bumper designs advertise cross-compatibility across multiple model years, some Voltex-specific trims include unique mounting brackets or slight dimensional differences. Owners should verify the fit for their chassis and model year. Professional installers often recommend checking reinforcement points and ensuring that any additional sensors or ducts are either reused or properly adapted. In some cases, small adjustments to the undertray or splitter mounts improve airflow alignment and produce better real-world results.

Aerodynamic design also carries a maintenance dimension. Openings that feed radiators and intercoolers collect road debris and insects. Regular cleaning preserves the bumper’s airflow intent and prolongs the life of heat exchangers. Carbon or fiberglass finishes, while durable, respond differently to road chips and impacts than OEM painted bumpers. Protective films or thoughtful front lips can reduce small damage during daily use. For track-focused drivers, periodic inspection for cracks or de-lamination is prudent. Early detection of material issues prevents performance degradation and preserves safety.

Real-world user experience often emphasizes the subjective improvements alongside measurable changes. Drivers report a firmer steering feel at high speeds and reduced front-end lift. Temperatures tend to stabilize more quickly under heavy load. Visual cues matter, too: the aggressive look often signals a commitment to performance and sets expectations that the car will behave accordingly on a track. Importantly, these benefits depend on thoughtful installation and overall vehicle setup. Suspension geometry, tire choice, and aerodynamic balance at the rear play roles equal to the bumper. A well-rounded upgrade plan integrates the front bumper with broader handling and cooling strategies.

When considering aftermarket variations, some offer additional features like removable splitter sections or pre-cut ducts for optional fog lights. Those options let owners tailor the bumper to specific use cases. However, any modification should preserve the bumper’s core aerodynamic lines to maintain its functional benefits. Deviating from designed flow paths can degrade efficiency and negate downforce gains.

Finally, safety and legality deserve emphasis. Although the Voltex front bumper is engineered for performance, buyers must verify certification and compliance for street use in their region. Components that change crash-absorption characteristics or affect pedestrian protection may be subject to regulations. Checking compatibility with airbag sensors and mounting reinforcement points helps ensure that the upgrade does not compromise occupant safety.

For those who want further technical guidance on selecting and integrating aerodynamic components for the Evo 9, a useful comparison exists between factory-style choices and aggressive track-oriented kits. Many resources highlight the trade-offs between daily drivability and maximum downforce. For a practical example of a front bumper approach that mixes style and function, see the Evo 8/9 Varis front bumper with carbon lip.

For an in-depth guide on choosing aero kits and understanding their impact on an Evo 9 chassis, the following external resource offers a detailed walkthrough and performance considerations: https://www.carinterior.com/evolution-9-voltex-guide

Under the Skin: Materials, Strength and Longevity of the Voltex Evo 9 Front Bumper

Under the Skin: Materials, Strength and Longevity of the Voltex Evo 9 Front Bumper

The front bumper on a high-performance car is more than styling. It balances aerodynamics, cooling, impact management, and weight. The Voltex Evo 9 front bumper exemplifies that balance. Its primary structure uses glass fiber composite, a material chosen deliberately to meet the demands of both street and track. Understanding that material and how it influences durability, fitment, repairability, and performance unlocks better decisions for anyone upgrading or restoring an Evo 9.

Glass fiber composite combines woven glass cloth and a resin matrix to form a stiff, lightweight shell. This composite offers a superior strength-to-weight ratio when compared to traditional steel. The result is a bumper that keeps frontal mass down, which helps handling and braking precision. Lower unsprung weight also reduces the inertia the suspension must control, improving responsiveness on varied road surfaces. For a car tuned around agility and grip, these gains are meaningful.

Beyond weight, glass fiber has intrinsic corrosion resistance. Unlike metal bumpers, it does not rust when exposed to moisture and road salts. That resistance preserves structural integrity in regions with harsh winters and coastal climates. The resin matrix seals the glass fibers, preventing water ingress that can otherwise delaminate layered materials. This property makes glass fiber an excellent long-term choice for exterior bodywork.

Impact resistance and deformation behavior are central to bumper performance. The Voltex front bumper is engineered to absorb and distribute collision energy. Glass fiber’s behavior under load differs from metals. It tends to flex and crack rather than bend permanently. In the event of a hard impact, fiberglass may localize damage to a tear or split. This containment often simplifies repairs compared to crushed or warped metal, where replacement may be necessary. Proper layup techniques and adequate wall thickness reduce the risk of catastrophic failure.

Manufacturing quality matters. A well-made fiberglass bumper uses consistent glass weave patterns and a controlled resin content. Too much resin produces a heavy, brittle part. Too little resin leaves voids and weak bonding. High-quality layups use woven roving and multi-directional cloth to balance stiffness and impact tolerance. Some manufacturers add chopped strand mats in low-stress zones and heavier woven fabric where mounting points and aerodynamic loads concentrate. Reinforcement at mounting flanges and tow-hook areas prevents cracking under stress.

Curing and finishing processes further influence durability. Proper heat cure enhances resin cross-linking, which increases tensile strength and fatigue life. Post-mold trimming and chamfered edges reduce stress risers. A final gelcoat or primer layer provides UV protection, improved adhesion for paint, and a smoother surface. Without these steps, the part risks premature surface degradation and moisture-assisted delamination. When evaluating a bumper, look for consistent gelcoat thickness and smooth transitions at joins.

Repairability is a strong advantage of fiberglass. Small cracks and chips can be rebuilt with patch kits and additional fiberglass cloth. Technicians apply new layers, feather the surrounding area, and re-gelcoat. Complex repairs can restore structural function and finish quality with less cost than replacing a composite part entirely. That said, repeated repairs add weight and may alter aerodynamic surfaces. For that reason, serious track teams often replace damaged pieces instead of repeatedly repairing them.

Comparing material options clarifies why glass fiber is chosen for this bumper. Thermoplastic alternatives, such as polypropylene or polyurethane, offer excellent impact rebound and flexibility. They return to shape better after low-speed hits. However, thermoplastics are heavier at equivalent strength levels and can be harder to sculpt in complex aerodynamic forms. Carbon fiber offers unmatched stiffness and lower weight than glass fiber. Yet carbon fiber carries higher cost and can shatter more suddenly under impact unless specifically engineered with hybrid layups. Glass fiber stands between these extremes, delivering a balance of cost, weight, and serviceability that suits both enthusiast drivers and professional teams.

The bumper’s integration with other components affects durability in practical use. Proper mounting hardware, support brackets, and crash boxes reduce point loads that cause stress cracks. On the Voltex Evo 9, mounting points are engineered to match OEM locations precisely. That ensures the bumper aligns with headlights, fenders, and bodylines without forcing stress into the shell. When installing an aftermarket or replacement bumper, verify bracket compatibility and consider reinforcing plates behind bolt points if planning track use.

Aerodynamic loads contribute to long-term fatigue. At high speeds, downforce and airflow pressure push and pull on lips, intakes, and canards. The composite layup must resist flexing that can create vibration or loosen fasteners. Reinforced ribs and internal stringers reduce flex and maintain aero geometry. These internal structures are not always visible from the outside, so inspection of the inner surface and mounting areas is valuable. Signs of stress include micro-cracking around screw holes and slight distortion of intake openings.

Environmental resistance goes beyond corrosion. UV exposure can degrade resin over time, causing gloss loss and surface brittleness. A quality gelcoat or UV-stable primer prevents this degradation for many years. Temperature cycling also affects adhesives and bond lines. In climates with large day-night temperature swings, bonded seams that use substandard adhesive can separate. For longevity, all adhesives and tapes used in assembly should be rated for automotive use and temperature extremes.

Paint and finish choices impact durability as well. Many replacement bumpers are supplied in a blank white primer, allowing custom paint. Proper surface prep, high-quality primers, and automotive paints ensure a durable finish. Clear coats protect against chips and chemicals. Keep in mind that repeated paint sanding and refinish work reduces the laminate thickness, which can expose woven fibers and make the part more vulnerable. When repainting, professionals follow controlled processes to preserve the composite’s protective layers.

Maintenance practices help extend service life. Regular cleaning removes road grime and salt that can abrade the surface. Promptly attend to chips and cracks. Small repairs prevent water ingress. For track cars, frequent inspections after sessions reveal fastener loosening or hidden damage. Replace worn washers and grommets to prevent vibration-induced cracking. If the bumper has integrated vents or ducts, check inner leading edges for impacts and cracks. Small internal failures can grow under aerodynamic loads.

Weight savings from a composite bumper also has measurable performance effects. Even modest reductions at the car’s front reduce understeer tendency and ease turn-in. Engineers design these bumpers to shift the vehicle’s balance subtly without compromising crash performance. Less frontal weight lowers the yaw inertia, allowing quicker direction changes. For tuned suspension setups, the weight reduction can complement spring and damper choices for a more connected feel.

Safety and crashworthiness remain paramount. Good composite bumpers are designed to manage energy predictably. They work with crash boxes and absorbers to protect critical components under impact. While glass fiber does not deform like metal, controlled fracture behavior can still dissipate energy. Manufacturers and distributors often provide specifications and test data showing compliance with durability benchmarks. When buying a replacement, request technical documentation if possible. Verify certification and fitment claims to ensure the bumper meets expectations.

Compatibility matters for fit and finish. Some variants produced for visually similar models have small differences in mounting points and vent geometry. Verify the bumper’s intended model years and trim levels before purchase. Subtle mismatches require trimming or adapter brackets. That can weaken the structural integrity if not handled properly. When in doubt, use an option specifically listed for your model, or consult a specialist who understands Evo-era bodywork.

Finally, consider the intended use. A street-driven Evo benefits from the corrosion resistance, weight savings, and repairability of a fiberglass Voltex bumper. For motorsport applications, confirm reinforcement at key points and consider spare parts. Track incidents are inevitable, and quick replacement keeps the car competitive. For show cars, ensure paint and gelcoat quality are flawless to preserve appearance for events.

For additional reading on compatibility and related components, a practical resource covering front and rear bumpers offers installation tips and comparisons. That guide helps owners match parts to their car and determine which upgrades align with their goals: front and rear bumpers guide.

In summary, the Voltex Evo 9 front bumper’s glass fiber composite construction delivers a considered blend of light weight, corrosion resistance, and serviceability. Manufacturing quality, layup design, curing, and finish determine how these benefits translate into real-world longevity. Proper installation, maintenance, and use preserve durability and performance. For those who demand both looks and function, understanding the material science and practical trade-offs helps ensure the bumper performs as intended over many seasons.

For technical specifications and the manufacturer’s data on this bumper, consult the official product page: https://www.voltex.com/products/lancer-evolution-9-front-bumper

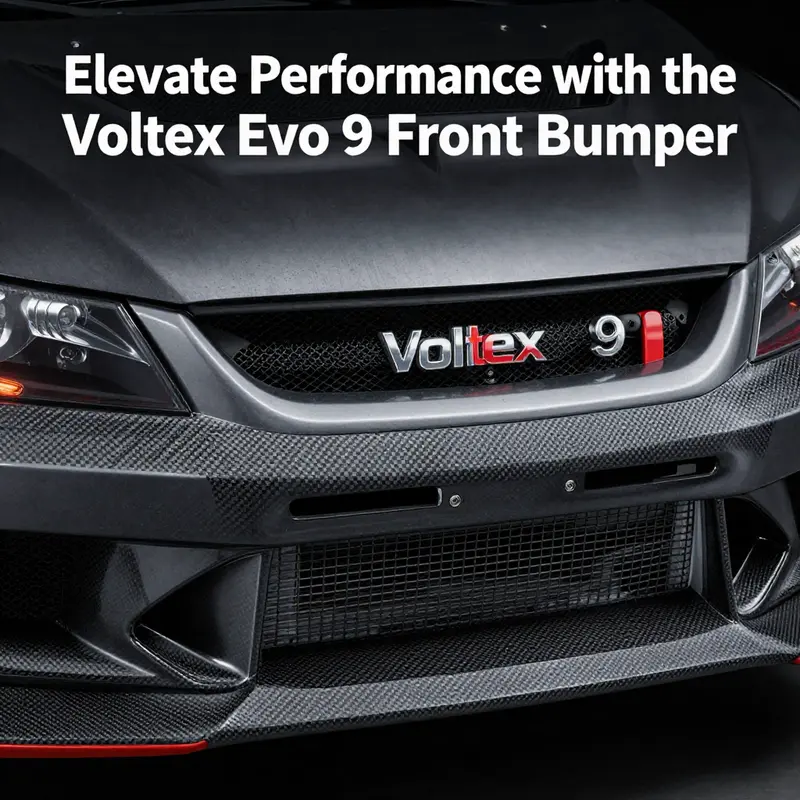

Voltex Evo 9 Front Bumper: Precision Aero, Fitment, and Customization

The front end of a performance-focused Mitsubishi Lancer Evolution signals intent before the driver even presses the throttle. For the Evo 9, Voltex’s front bumper did more than look aggressive; it sought to refine airflow, support cooling, and preserve the car’s balance at the limit. The Voltex Evo 9 front bumper became a benchmark for enthusiasts who want authentic aero cues without sacrificing daily usability or track readiness.

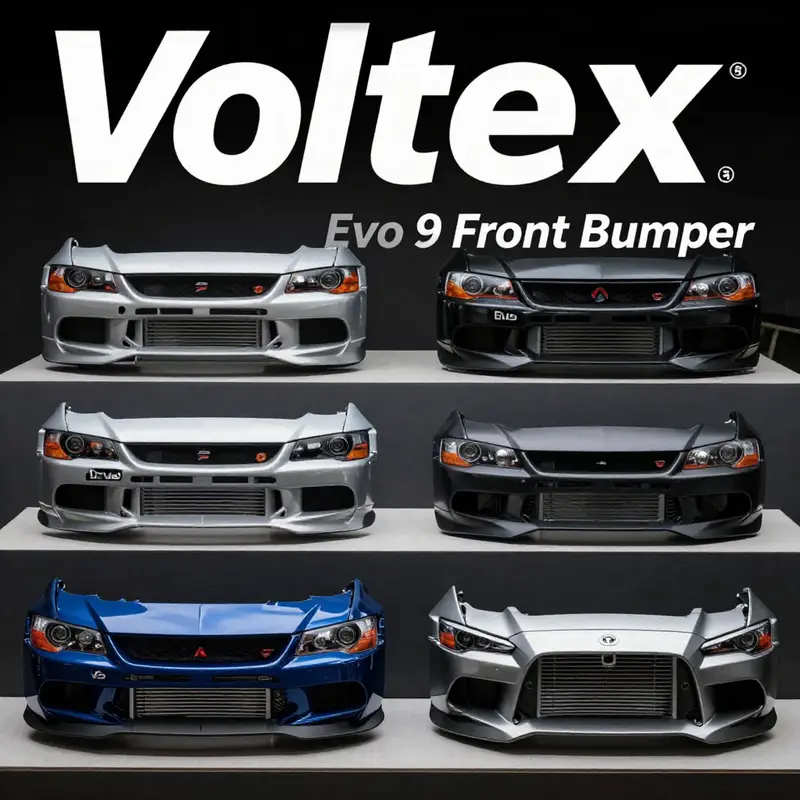

Material choices are central: carbon fiber and fiberglass variants are common. Carbon fiber offers a high strength to weight ratio and a crisp, premium feel, while fiberglass remains a pragmatic alternative for budget builds. Both materials must be engineered for exact OEM specific fitment so the installation remains seamless. For Evo 8 and Evo 9 platforms, some Voltex variants share mounting points, but year and trim differences require careful verification before purchase.

Pricing threads through the discussion: genuine Voltex kits carry a premium reflecting meticulous build quality and fit, often reaching four figures and sometimes five when options and shipping are included. Replica front bumpers and fiberglass or composite versions appear at lower price points, but they may trade off weight, precision, and long term durability. The decision often comes down to how the car will be used and how much investment in maintenance and repainting one is willing to make.

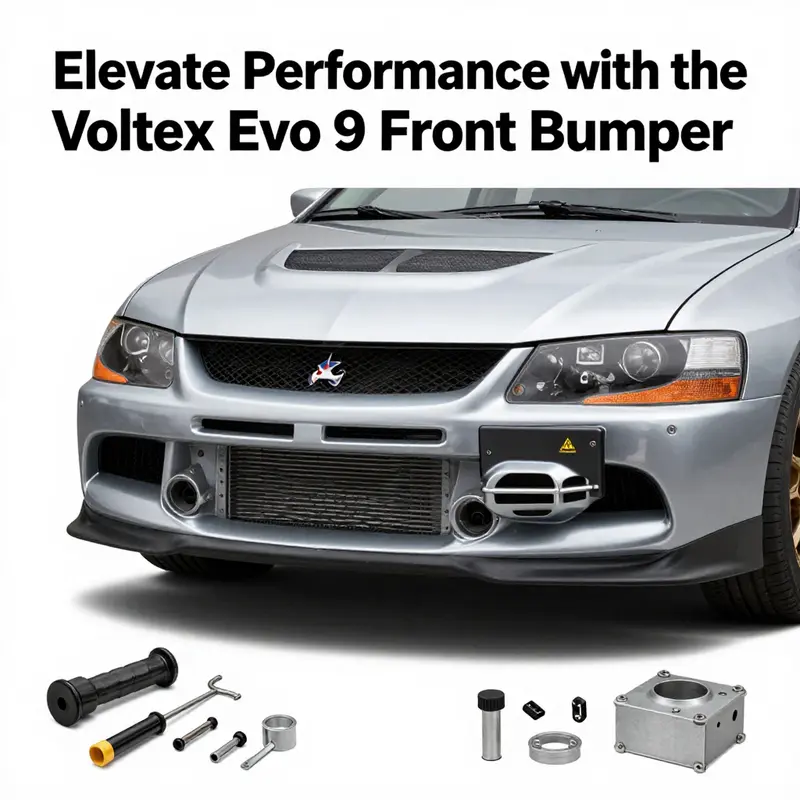

Installation discipline matters. Even the strongest bumper design can underperform if mounting points are misaligned or gaps uneven. Verified fitment documentation, guided install steps, and professional alignment help guarantee a pristine, crashworthy installation. A high quality shell paired with correct fasteners and careful finishing yields a result that feels like a factory upgrade rather than a hack.

Beyond the Voltex kit, the aftermarket ecosystem includes other front bumpers that aim to complement the Evo chassis family. Carbon CVS style or other look alike designs can offer varied aero profiles, weight, and fitment. Traders should seek suppliers that provide clear fitment data, verifiable certification, and support resources to verify crashworthiness and structural reliability rather than rely on cosmetic similarity alone. For readers exploring options, the landscape benefits from comparing different aero philosophies within the same platform, such as racing inspired variations that preserve the car’s iconic lines while rethinking intake geometry.

Conclusion: the Voltex Evo 9 front bumper embodies precise aerodynamics, measured weight, and a finish that respects the original silhouette while pushing the envelope in cooling and front end stiffness. The right choice balances aesthetics, performance goals, installation discipline, and total ownership costs.

Voltex Evo 9 Front Bumper: Precision Fit, Aerodynamic Focus

The Voltex Evo 9 front bumper is designed for the CT9A platform and aims to preserve OEM geometry while delivering improved airflow and a more aggressive stance. Available in carbon fiber or fiberglass, it balances stiffness, weight, and durability for street and track use. Proper fitment depends on using a bumper version matched to Evo 9 (and compatible with Evo 8/9 packages that share mounting geometry). Installation focuses on respecting factory mounting points, securing the bumper, and verifying alignment at key reference points to maintain uniform gaps. The bumper’s integrated vents direct air toward the intercooler and radiator; ensure no obstruction and verify clearance with hood seals, wiring looms, and headlamps. If fog lights or LEDs are present, route wiring carefully and secure brackets to avoid contact with moving parts. Post-install, inspect for cracks or loose fasteners; check ground clearance and rake; painting options; carbon fiber requires UV protection; fiberglass needs edge sealing. Compatibility and references: Some sources discuss cross-reference with other brands and their mounting; while not direct swaps, they share mounting anchors and edge alignment considerations. Conclusion: With proper prep, the Voltex Evo 9 bumper improves cooling, downforce potential, and front-end appearance, while maintaining a clean OEM-like silhouette.

Final thoughts

The Mitsubishi Lancer Evolution 9 Voltex front bumper represents a perfect merger of style, functionality, and customization potential. Its design enhances both aesthetics and performance through superior aerodynamics, while its robust material composition ensures durability under demanding conditions. With a range of aftermarket options available, enthusiasts have the flexibility to personalize their vehicles, making this front bumper an integral choice for Evo 9 owners interested in both performance and visual impact. By focusing on compatibility and installation strategies, business owners can position themselves to meet the needs of this niche market effectively.