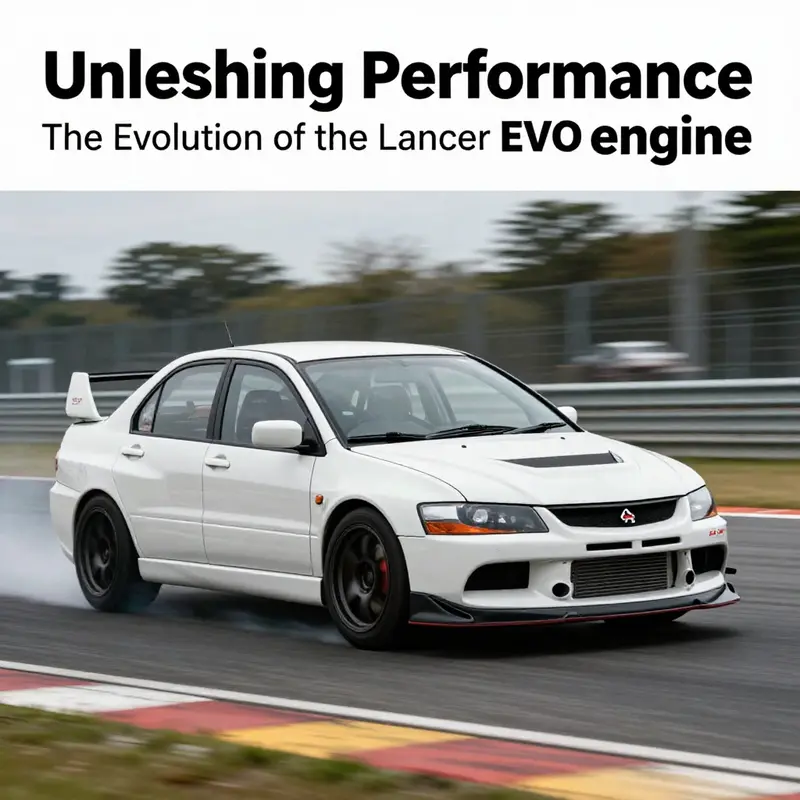

The Lancer Evolution, or EVO, remains a pinnacle in the performance car segment due to its engineered excellence, especially in terms of its engine configurations. From its inception, each iteration of the EVO has showcased advances that not only enhance power output but also reliability and drivability. This article delves into the journey of EVO engines, their impressive customization potential for enthusiasts, and the exemplary technology that defines their success. Each section uncovers how these elements contribute to a comprehensive understanding of the Lancer EVO’s legendary status in automotive history.

Engine at the Edge: The Lancer Evo Powerplant Odyssey

The engine is more than a number on a spec sheet; it is the living core of a philosophy. In the Lancer Evolution story, the powerplant keeps time with the chassis and the road. Across generations, Mitsubishi’s EVO line distilled a single idea: small displacement, immediate response. The early 2.0L 4G63T block combined iron durability with turbocharged aggression, evolving through iterations that refined airflow, cam timing, and turbo response. By EVO IX and X, Mitsubishi introduced MIVEC and an aluminum-block 4B11T to reduce weight and improve heat management, broadening the usable power band and sharpening throttle feel. The transition from iron to aluminum wasn’t just about mass; it redefined the engine’s interaction with the drivetrain, cooling system, and electronics that govern boost and fuel delivery. The story is not simply about peak horsepower but about a reachable, repeatable envelope of performance that a driver can trust on road and track. The turbine, intercooler, and intake paths are not standalone parts but parts of a coordinated system that translates a driver’s input into confident speed. External references and manuals offer deeper context, but the core message remains: the EVO engine evolved to be lighter, cleaner, and more responsive while maintaining the immediacy that defined the platform. For enthusiasts, the engine saga is a map of material science, turbo philosophy, and control strategy, all aimed at turning a small displacement into proportional, controllable speed.

Lancer Evo发动机的改装潜力与演进之旅:从4G63到4B11T的性能传承

在赛车传统与可持续性能之间,Lancer Evo的发动机被视为一台会说话的心脏。它不仅决定了车身的呼吸频率,也在多年发展中逐步将高功率、耐久性与可控性绑定在一起,形成了独特的工程哲学。尽管外表看似简单,EVO系列的动力系统其实是一条横跨十几代的技术长卷,记录着涡轮增压、小排量与四驱协同在极端驾驶环境中的协作艺术。从最早的2.0L DOHC 16气门4G63起步,到后来的4G63的持续改良,再到EVO X的全新4B11T铝合金缸体与可变气门正时技术,这条传承之路并非线性提升,而是在权衡重量、热管理、耐久性与响应速度之间不断自我再设计。故事的核心,是如何在“性能极限”的边缘,将一个发动机平台打造成一个可持续改装的基座,既能在日常驾驶中展现可靠性,又能在极端竞技场合爆发出惊人的潜力。”

- “\n\n”

- “4G63发动机自诞生起就被誉为改装界的‘黄金基石’。这并非空穴来风,而是对其铸铁缸体、长冲程设计和稳健机械结构的真实写照。铸铁缸体不仅在高热负荷下显示出卓越的耐久性,还允许在高压下维持结构完整性,从而为后续的增压与强化提供了足够的容错空间。原厂阶段的马力输出在EVO I到EVO III逐步提升,从250匹左右稳步跃升至270匹(约273匹),借助更大涡轮和改良的进排气系统,涡轮增压的响应性与高转速区的供给质量也得以提升。这一代的核心理念,是用小排量实现大功率的高效方案,同时保持可控与耐久并存的底线。\n”

- “\n”

- “进入EVO IV至EVO IX,4G63的技术基因被进一步强化。厂家在缸体、活塞、连杆等内部部件上进行了系统性升级,涡轮系统也迈向更高效的中冷器和大口径涡轮组合,热管理与气流控制成为提升动力的重要环节。此阶段的改进并非单点突破,而是通过整体工艺链的优化,使小排量发动机在低油耗与高输出之间达成更稳定的平衡。部分高性能版本在官方标定之外的极限状态下,马力仍能接近或突破300匹,引导改装圈重新评估“改装空间”的边界。此时,4G63不仅是强劲的动力来源,更成为改装者情感与技术对话的桥梁。\n”

- “\n”

- “进入EVO X,三菱选择了全新的4B11T发动机,并把铝合金缸体与MIVEC可变气门正时技术带入车系核心。这台新发动机使得发动机重量明显下降,同时通过更高效的热管理和更平顺的扭矩曲线,将S-AWC四驱系统的潜力推向新的极限。最大功率保持在约300hp级别,峰值扭矩达到420Nm,车身响应在中段与高转区都显著改善,与新一代的四驱系统协同工作时,抓地力与转向信心得到明显提升。这一代的技术转型虽然标志着一个时代的结束,但也为未来的改装框架提供了全新的设计语言:在更轻的缸体、在更高效的气门正时控制下,如何在保持可控性与耐久性的同时,继续扩展极限输出。\n”

- “\n”

- “改装潜力并非只来自厂商标定的线性提升。4G63平台之所以被视为改装圣杯,恰恰在于它的结构强韧与适应性极强。铸铁缸体的耐久性与长行程设计,使得在进行涡轮增压、点火系统强化、内部件锻造以及进排气系统优化后,仍能维持相对稳定的寿命和可靠性。官方极限的约束往往隐藏着更深层的潜在空间。一旦解除ECU层面的限制、升级涡轮、换装更高承载能力的连杆与曲轴、配合更高效的冷却系统,马力的提升可以远超过最初的设定。这也是为什么无数改装工作室将4G63视作“起点中的起点”,并在其基础上发展出一整套被广泛实践验证的改装组合。”

- “\n”

- “在这条改装路径中,存在一条广为流传的“黄金组合”:坚固的核心件通过轻量化的外部设计进行平衡,涡轮增压通过更大口径与更高效的中冷器实现更好的气流管理,而点火系统、燃油供给与涡轮控制则以精准的ECU调校来实现协同。某些改装案例甚至尝试将4G63的耐久性与4B11T的先进技术相结合,形成以铝合金缸体为核心、以可变气门正时和高效热管理为辅助的混合动力版本。这种跨代的融合,验证了平台在跨越排量与代际的过程中,仍然保持高度的适应性和成长空间。\n”

- “\n”

- “关于车型平台的改装热潮,EVO VII和EVO IX在圈内尤其被视为改装圣杯。它们在公众与媒体的曝光中,逐渐被塑造成极致功率和极限操控的象征。这不仅是因为原始机械结构的耐用性,还因为它们承载着广泛的改装文化与技术积累。电影与流行文化的影响也不可忽视——多部影视作品让人们对这类车辆的改装潜力与速度美学产生直观的情感共鸣。这种共鸣推动了全球改装市场对4G63平台的持续关注与再创新,使得新旧技术在跨代之间不断对话与碰撞。\n”

- “\n”

- “尽管EVO X开启了铝合金缸体与双离合变速箱的新篇章,关于未来的设想并未就此止步。行业内部的传言和研究者的推演指出,若在三年内重新设计一代Lancer Evolution,可能回归更先进的底盘架构,甚至以1.8升涡轮机配合前后双电机的插电混动系统来实现全新的性能表达。这样的设想并非单纯的排气量提升,而是对动力传递、热管理、电子控制系统以及动态稳定性系统的全面再工程。无论未来走向哪种路径,核心思想始终围绕“给发动机以新的呼吸、用更智能的控制来释放潜能、在极限条件下保持可控与耐久”的目标。此类愿景并非空谈,而是在对4G63时代积累的经验进行现代算法与材料科技的再加工后,继续向前推进。\n”

- “\n”

- “在现代工程语境下,理解Lancer Evo发动机的改装潜力,等于理解一种跨代的设计哲学。它强调在同一底盘之上,保持高效的热管理、稳定的扭矩传递、灵活的涡轮控制以及可靠的机械结构。无论是以4G63为核心的历史路径,还是以4B11T为标志的现代转型,内在驱动力始终是相同的——用有限的重量与能量,换取无限的速度与控制。为了实践中的具体改装,工程师与技师们会关注如铸铁缸体与铝合金缸体之间的权衡、内部件的耐久性与刚性、以及混合动力系统在不牺牲响应速度前提下在高载荷下的热管理表现。正是在这类综合考量中,EVO发动机的改装潜力不断被挖掘、被验证、被传承。若你愿意深入未来的细节,值得关注的并不仅是单一部件的升级,而是一整套跨代的设计语言如何在新一代车型中重构并延续。作为改装者与工程师共同书写的章节,这个故事仍在继续。\n”

- “\n”

- “参考资料与进一步阅读可通过权威历史与技术综述获取。对4G63到4B11T的技术演进以及各代车型的发动机规格,可以参阅公开历史资料与技术汇编。\n\n内部参考链接:在关于铝合金缸体与高强度部件的改装潜力方面,读者可查看内部资源以获得更具体的部件级别信息与兼容性分析:4B11T billet block。\n\n外部参考:关于三菱Lancer Evolution的完整历史与技术演进,权威性较高的英文资料可见维基百科页面,供读者对比不同代车型的具体参数与技术演变。外部参考链接: https://en.wikipedia.org/wiki/MitsubishiLancerEvolution

Pulse, Precision, and Power: The Engine at the Core of the Lancer Evolution

The engine is not merely a component in the Lancer Evolution; it is the living heart that shapes the car’s character, the force that drives its reputation through every corner and straightaway. Across generations, Mitsubishi’s compact, turbocharged four-cylinder layout has been the thread linking performance, reliability, and the thrill of push-rod engineering meeting race-inspired ambition. From the earliest EVOs onward, engineers sought not only horsepower, but a deliberate, linear surge of power that answered driver inputs with crisp response and unwavering stability under load. The evolution of the EVO’s engine, therefore, reads like a disciplined chronicle of small-displacement hardware that consistently outgrew its own limits through clever architecture, advanced materials, and a relentless focus on cooling, timing, and flow. It is a story of progress that rarely shouted, yet always delivered when it mattered most on the track and on the road alike.

At the core of the EVO’s legend lies a lineage anchored in a 2.0-liter, turbocharged inline-four strategy. The early models built their strength around the 4G63 family, a platform that would become a benchmark in tunability and durability. This engine’s reputation as a “modding-friendly” baseline was not merely a consequence of horsepower figures; it was the outcome of a robust block design, strong cylinder walls, and a turbine-driven breathing system that made power feel controllable rather than explosive. Engineers capitalized on this platform by refining the intake and exhaust paths, upgrading the turbocharger, and tuning the engine management to deliver a wide torque window. By EVO III, power had risen from the original figure into the 260s, a meaningful step that, coupled with upgraded internals, still preserved the engine’s tractability and reliability at high revs.

The mid-to-late EVO generations continued to chase higher power figures while preserving a sense of balance that made the car usable in daily driving and effective on the track. The 4G63-equipped EVO IV through EVO VIII iterations reinforced a philosophy: to squeeze more performance without sacrificing engine longevity. The core engine saw reinforcement of the block, pistons, and connecting rods, and the turbo system was refined with larger units and more efficient intercooling. The result was a steady climb in horsepower, with several high-performance variants nudging into the 300-horsepower neighborhood. It was a demonstration that the EVO’s engine could be tuned to engage high-gear momentum and low- to mid-range surge with equal poise, a crucial trait for a car intended to bridge rally heritage and road-going track capability.

As the ninth generation arrived, the engines took a crucial turn with the introduction of MIVEC timing control on the 4G63 platform. This electronic variable valve timing system changed how the engine breathed across the rev range, smoothing the throttle response and reducing turbo lag. In practical terms, MIVEC on the EVO IX delivered a more linear power curve and enhanced low-end torque, which made the car feel more eager off the line and more controllable in mid-corner boosts. The change was more than a lift in peak numbers; it was a real shift in the engine’s personality, enabling sharper responses without the typical compromises of turbocharged small-displacement performance. The EVO IX thus became a turning point where the induction strategy and valve timing worked in concert to deliver a more flexible and driver-friendly experience at the limit.

Then came the tenth generation, where Mitsubishi set a turning point not just in tuning, but in material science and overall engine architecture. The EVO X marked a transition to a new engine family, the 4B11T, which introduced an aluminum alloy block to replace the traditional cast-iron design that had long served the 4G63 family. Aluminum brought a notable reduction in weight and improved heat management, which is essential for a turbocharged engine operating at the edge of performance. The 4B11T also carried the legacy of sophisticated turbocharging and intercooling, paired with a modern intake system and a compact, efficient exhaust route. Notably, the EVO X carried a max horsepower in the high-280s to around 300 horsepower range, with peak torque comfortably delivered across a broad band. The new architecture retained a strong torque curve, a hallmark that let the EVO X maintain its momentum through the midrange while keeping throttle response snappy and predictable, even when the engine was under significant boost.

Crucially, the EVO platform’s performance has always depended not only on the engine itself but on how power is delivered to the road. The engine’s turbocharging strategy—unified with a well-tuned intercooler and a dedicated cooling circuit—ensures the intake charge remains dense and reliable even under sustained high-load conditions. The cooling strategy, including dedicated air pathways for intercooling and engine bay cooling, reduces heat soak and helps preserve the turbo’s efficiency. In short, the EVO’s engine design is a package—a tightly integrated set of components designed to harness fast spool, high reliability, and consistent output under aggressive driving. The goal is not just to reach a number on a dyno, but to preserve a balance between raw speed and controlled, repeatable performance in a race-like environment where every second counts.

What makes the EVO’s engine narrative remarkable is how it refuses to stand still. Even when a factory specification seems robust, the engineering culture around the EVO keeps pushing endurance, response, and potential. A well-documented example from the tuning community demonstrates the extraordinary lengths to which enthusiasts push the platform: a renowned tuning team demonstrated remarkable results by pushing a much smaller engine beyond any factory expectation. In controlled, high-boost conditions, outputs reached staggering levels—over 1,500 horsepower at 30 psi, rising to around 1,700 horsepower at 42 psi, and ultimately approaching extraordinary values in extreme states. Those feats, while not representative of street-legal realities, underscore a central message: with the right combination of materials, precision machining, and cooling, a small, well-engineered engine can deliver power significantly beyond its stock rating while maintaining a coherent drivability envelope. This is not a claim about raw horsepower alone; it is a testament to the engineering discipline that underpins the EVO platform—a discipline that seeks to extract reliable performance while honoring the car’s rally-bred DNA.

The engine’s core configuration—whether the early 4G63T or the later aluminum-block 4B11T—speaks to a broader trend in the automotive world: the shift from iron to aluminum for high-performance applications. The transition was not merely a weight reduction exercise. Aluminum blocks opened new doors for thermal efficiency, allowing the engine to rev higher with a more robust heat management system. The use of a modern timing strategy, particularly with MIVEC in the later models, ensured that torque delivery stayed broad and linear across the rev range, a quality highly prized by performance drivers who aim for predictable behavior on twisty descents and fast, flowing sections alike. In practical terms, the EVO’s engine delivers not only peak horsepower and peak torque figures but a precise, well-damped torque curve that translates into confidence. This is especially noticeable when the car is pressed into a series of tight corners, where throttle-induced steering and wheelspin can either sharpen or erode a driver’s sense of control. The EVO’s engineering thus integrates engine dynamics with chassis behavior to produce a vehicle whose speed is matched by its handling and its ability to maintain grip under challenging conditions.

The philosophy behind these evolutions also extends to the intake and exhaust flow management. The turbocharger actuation and the associated piping have always been designed to minimize lag and maximize surge response. While the blocks and bore centers evolved, the fundamental aim remained: maintain efficiency under load, reduce heat generation in the critical zones, and preserve engine reliability during long sessions at high boost. The cooling system, too, evolved in tandem. In the early decades, engineers relied on robust oil and water cooling to manage high exhaust gas temperatures. As the engine platforms advanced, tighter packaging and better intercooling made it possible to sustain higher boost levels with less heat buildup. The result is an engine that can sustain aggressive mappings over longer durations while maintaining factory-like levels of reliability—a critical asset for a performance car that also sees road use and occasional track days.

As the story moves from the era of the 4G63 to the 4B11T, a broader engineering context emerges: the EVO is a showcase for how turbocharged, small-displacement powertrains can be paired with advanced drivetrains to produce a compelling, well-rounded performance package. The four-wheel-drive system—an essential partner in translating turbine-driven torque into traction on a messy road surface—complements the engine’s character. The drive system distributes power with sensitivity to grip levels, ensuring the power is not simply available but usable. This synergy between engine and drivetrain has helped the EVO carve out a reputation for cornering speed and on-throttle stability that few peers could match in its class. The combination of a lightweight, highly rigid platform, a turbocharged heart, a sophisticated valve-timing system, and an AWD architecture created an environment where drivers could exploit the car’s capabilities with confidence, making the EVO a benchmark for enthusiasts who chase precision, predictability, and high-end performance in a compact package.

The torch carried by the EVO’s engine is not merely about chasing ever-smaller milliseconds; it is about a philosophy of engineering where every component speaks the language of speed while staying mindful of durability. The early engines taught the team to respect heat and flow; the late engines taught the team to respect weight and efficiency without surrendering power. That balance remains central to the EVO’s enduring appeal. Even years after the factory line has ceased to churn out new versions, the engines continue to inspire because they demonstrate what disciplined engineering can achieve: a small engine that can rev, respond, and endure in the most demanding environments. The EVO’s engine is not a relic of a previous era but a living blueprint for anyone who believes that performance can be a product of thoughtful compromises rather than reckless excess.

For readers seeking a compact reference on the engine’s historical arc and specifications across generations, a comprehensive, authoritative history is available in established reference literature. The broader narrative is complemented by rare cases and performance studies that illustrate the extreme ends of the tuning spectrum, offering a sense of the engineering ambition behind the EVO’s legacy. In that sense, the EVO engine is more than a set of numbers; it is a story about how a manufacturer and a community of enthusiasts collaborated to push a compact powerplant into the realm of the extraordinary, while preserving the car’s original intent: to offer a unit that is light, quick, and capable of delivering a driver-centric experience at the edge of control. The engine’s evolution thus stands as a powerful reminder that high-performance engineering is a confluence of material science, aerodynamic optimization, thermal management, and human curiosity—a blend that makes the Lancer Evolution a lasting symbol of the art and discipline of speed.

To explore a tangible example of how the EVO platform’s weight-saving and structural optimization extended beyond the engine, one can examine the related componentry that supports performance, such as the carbon fiber hood developed for the EVO-X platform. This link highlights how weight reduction and stiffness improvements contribute to overall handling and cooling efficiency, reinforcing the idea that every element in the car works in concert with the engine to achieve superior dynamics. For readers who want to see how such a component is presented in contemporary parts catalogs, this page offers a concrete glimpse into the kinds of materials and engineering choices that accompany the engine’s evolution on the EVO platform. carbon fiber hood page

External reference: https://en.wikipedia.org/wiki/MitsubishiLancerEvolution

Final thoughts

The Lancer EVO engine represents a remarkable blend of innovation, performance, and potential for enhancement. From the effective turbocharged configurations of its early models to the advanced engineering techniques seen in the EVO X, each generation offers a foundation for both thrill-seekers and automotive enthusiasts. The extensive customization options further amplify its allure, inviting a passionate community dedicated to maximizing performance. Recognizing these nuances not only solidifies the Lancer EVO’s status in automotive history but also inspires future innovations in performance engineering.