The Mitsubishi Lancer back bumper serves as more than just a protective component; it is integral to the vehicle’s performance and safety. As manufacturers innovate, the back bumper has evolved to include advanced technologies that enhance functionality while maintaining compliance with safety standards. This guide delves into the various aspects of the Mitsubishi Lancer back bumper, focusing on its advanced features, materials and manufacturing processes, safety regulations, market trends, and performance enhancements. Understanding these elements provides business owners with valuable insights into making informed choices for repairs, upgrades, and aftermarket products.

Beyond Protection: How the Mitsubishi Lancer Rear Bumper Enhances Safety, Aerodynamics and Style

Integrated purpose and performance

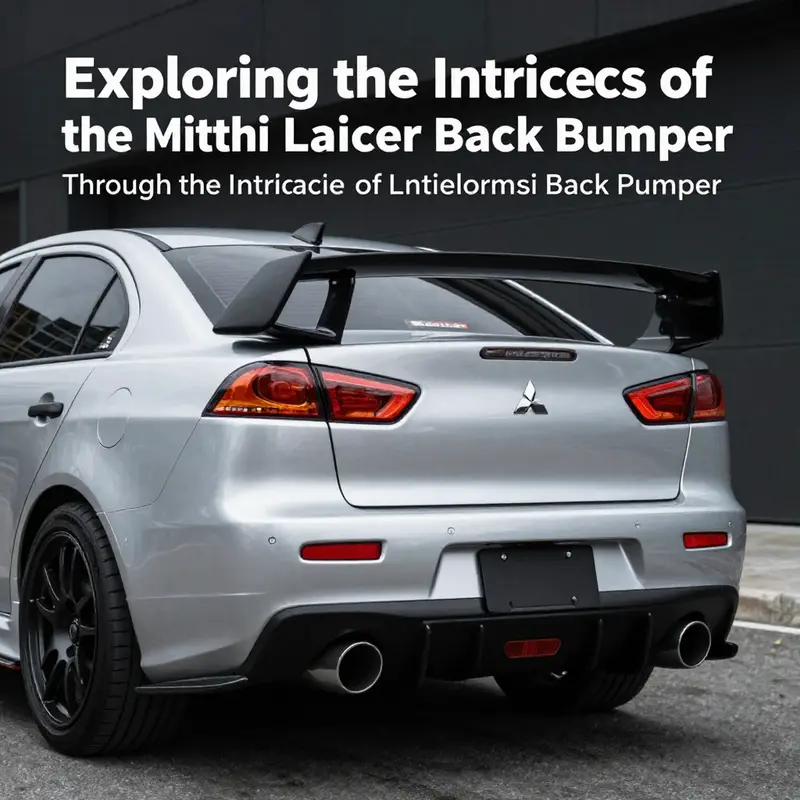

The rear bumper of the Mitsubishi Lancer does more than cushion minor impacts. It is a multifunctional module that balances crash protection, aerodynamic control, and visual identity. On standard sedans it manages low-speed energy absorption and houses reflectors and mounting points. On performance-oriented variants it becomes an aerodynamic tool. Designers and tuners use shapes, materials, and mounting details to tune downforce, streamline airflow, and integrate modern parking aids. Those choices influence stability, handling, repair costs, and even fuel use.

Performance-inspired rear bumpers often include a diffuser-like valance. This component guides air leaving under the car. By smoothing that airflow, the bumper reduces turbulence and lowers drag. The result is improved high-speed stability and marginal aerodynamic efficiency. For drivers who push their Lancer on highways or twisty roads, the change in stability is noticeable. The diffuser’s geometry affects how quickly wake turbulence decays behind the car, which in turn alters rear lift. In race-derived designs a small rear lip or rocker edge adds predictable downforce at speed. That extra load on the rear tires helps maintain traction in fast corners.

Material selection is central to advanced bumper function. Factory units usually use high-strength thermoplastics like PP/ABS blends. These materials give a good balance of flexibility, impact resistance, and cost. Aftermarket and performance bumpers may use reinforced plastics, fiberglass, or carbon fiber composites. Each material has trade-offs. Thermoplastics tend to return to shape after low-speed impacts. Fiberglass is lighter and stiffer but can crack under stress. Carbon fiber offers the best strength-to-weight ratio, yet it raises cost and can shatter on hard impact. Choosing the right material depends on intended use, budget, and repairability.

Structural reinforcement beneath the cover also matters. Reinforced mounts, stronger brackets, and energy-absorbing foam cores help protect the trunk and rear lighting assemblies. Many performance bumpers incorporate thicker mounting flanges and metal reinforcement plates at key attachment points. This reduces flex and improves the fit and finish. A properly reinforced bumper helps maintain alignment of the tail lights and license plate, even after repeated track days or rough road travel.

Advanced functionality now includes sensor integration. Modern bumpers often carry reverse cameras, ultrasonic parking sensors, and radar modules. These systems require accurate mounting positions for reliable performance. For example, a rear parking camera must be positioned to give a stable field of view and avoid water intrusion. Radar sensors used for collision avoidance or adaptive features need unobstructed line-of-sight and precise factory-location placement. High-quality replacement bumpers and performance kits maintain cutouts and mounting points that preserve the original sensor geometry. That keeps safety systems working without recalibration.

A practical concern for owners is compatibility. Well-made aftermarket bumpers are designed to accept factory trim pieces, reflectors, and brackets. They match OEM mounting points so installation is simple. They also allow reuse of factory wiring harnesses and bulbs. This reduces complexity and avoids the need for custom drilling or bracket fabrication. When fitment is poor, gaps and misalignments will appear. These flaws can worsen aerodynamic behavior and rattle under load. Always check that a replacement bumper confirms fitment to your model year and submodel.

Weight reduction is another reason enthusiasts choose advanced rear bumpers. Swapping a heavy stamped steel or reinforced original bumper for a lighter composite part lowers unsprung mass. Even modest reductions can sharpen responsiveness in braking and cornering. Reduced weight also improves acceleration and contributes to a slightly better fuel economy. However, lighter materials may sacrifice impact resilience. Owners must weigh performance gains against the likelihood of damage in everyday driving.

Aesthetic impact is unavoidable. The rear bumper defines the car’s stance and perceived width. Diffusers, integrated vents, and sculpted lines make the Lancer appear lower and faster. Side extensions and integrated skirts create a cohesive body kit that visually ties the rear to front spoilers. On performance variants, a pronounced rear lip or extension not only looks purposeful but also helps generate downforce at higher speeds. Paint matching and finish quality are crucial. A poor paint job or mismatched finish can make even a technically advanced bumper appear aftermarket and inconsistent.

Practical installation and maintenance considerations should guide choices. High-quality bumpers use pre-molded clips and standardized fasteners to simplify mounting. This reduces time and labor during replacement. Paintable primed surfaces allow precise color matching, which maintains resale value and visual unity. Owners planning to add sensors or cameras should ensure the bumper provides sealed housings. Water ingress can undermine electronics. Additionally, check for easily replaceable trim pieces. Modular trim avoids needing to replace the whole bumper after small scrapes.

Regulatory and safety compliance cannot be ignored. Bumpers must include reflectors and license plate mounting surfaces that meet local laws. They should not obstruct tail lights or reverse lamps. When selecting an aftermarket option, verify that the design retains legal elements and does not reduce performance of active systems. Choosing a bumper that preserves these features keeps inspections and registrations straightforward.

For those considering upgrades, research and fitment verification are vital. Look for parts that explicitly state fitment for your model year and submodel. High-quality vendors provide test-fit images and compatibility notes for sensor systems. When possible, choose parts that keep factory brackets and harnesses. If custom paint is needed, use a professional shop to avoid color mismatch. Finally, balance material choice with expected use: durable thermoplastics for daily driving, composite or carbon options for track-focused builds.

Upgrading the rear bumper of a Mitsubishi Lancer can change how the car looks and behaves. It can refine airflow, protect critical components, and support modern driver aids. The best choices preserve OEM system compatibility, meet regulatory needs, and offer the right balance of weight and durability. For those seeking parts and reference options tailored to the Lancer Evo X years, consult this 2008–2015 Lancer Evo X rear bumpers page for examples and fitment notes.

Source: manufacturer product page: https://www.duraflex.com/product/109415

From Mold to Road: Materials and Manufacturing Pathways Behind the Mitsubishi Lancer Back Bumper

The rear bumper of a Mitsubishi Lancer is more than a surface to which taillights and license plates attach. It is a purpose-built interface that blends protection, aerodynamics, and practicality. In everyday use, it mitigates minor collisions, shields the trunk area, and provides a mounting plane for lighting, sensors, and reflective elements. The materials chosen and the way those materials are manufactured determine how effectively energy is absorbed, how easily the part can be repaired after a scrape, and how closely it can match the car’s original appearance over time. For drivers, this means that a bumper is not just a cover, but a composite of engineering decisions that influence safety, performance, and the long-term value of the vehicle.

Among the most common realities behind the Lancer’s rear bumper are the contrasts between OEM parts and aftermarket options. OEM bumpers are typically molded from ABS plastic, a durable thermoplastic that can absorb low-speed impacts without cracking and that accepts paint and finish well. ABS’s resilience and workability make it a sensible baseline for mass production, where tight tolerances and repeatable quality matter. Yet ABS is not without limitations. It sits heavier than some alternative materials and can deform under sustained high heat exposure—an important consideration in sun-drenched climates or on vehicles that endure long idle periods in hot environments. The result is a bumper that performs reliably in day-to-day driving while requiring mindful care in extreme heat or prolonged sunlight exposure.

When owners seek something beyond stock fitment, the marketplace offers a spectrum of materials that trade off weight, stiffness, and repairability. Fiberglass remains a popular aftermarket option for those who value design freedom and lower initial cost. It is strong enough for everyday use and can be shaped into complex forms that meet unique styling goals. However, fiberglass is typically finished with a resin system that can require more careful finishing and repair work than plastic. Repairs may involve patching with fiberglass cloth and resin, followed by careful sanding and blending to restore a seamless surface. For hobbyists and builders, this path offers the most design latitude, but it also elevates the skill level needed to achieve a smooth, durable finish.

Polyurethane bumpers occupy a middle ground that blends resilience with flexibility. They resist impact-based shattering more readily than rigid plastics and can absorb energy through a slight give that helps prevent cracking. This makes polyurethane a favored choice for performance-inspired or more aggressively styled kits where the bumper endures more physical contact. Yet polyurethane paint preparation can demand extra surface treatment to ensure optimal adhesion and topcoat durability. The result is a bumper that is forgiving in impact yet requires methodical prep to achieve a flawless, long-lasting finish.

For those seeking the pinnacle of stiffness and weight savings, carbon fiber offers a striking, low-weight option. Carbon fiber can dramatically reduce mass while delivering exceptional rigidity, which can contribute to perceived handling and aerodynamic behavior. In practice, carbon fiber bumpers are often used as protective or cosmetic enhancements rather than complete replacements for daily driving, due to their higher cost and specialized repair requirements. A carbon fiber rear panel can guard against scratches while providing a premium aesthetic, but repair work tends to be more involved than with sheet plastics.

Beyond the raw materials, the manufacturing pathways chosen for each bumper type shape performance in meaningful ways. OEM bumpers are almost universally produced through injection molding, a process that injects molten thermoplastic resin into precise metal molds. This approach yields parts with consistent thickness, smooth surfaces, and tight tolerances. The automation and repeatability of injection molding help ensure that a new bumper installs with factory-like alignment, commonly preserving mounting points and closure tolerances that support seamless integration with the rest of the bodywork. Injection-molded bumpers also respond well to shop repainting, enabling color matching that remains stable across years of sun exposure and weathering.

In the aftermarket world, fiberglass bumpers are often created via hand layup. Skilled technicians apply layers of resin and glass fiber onto a mold, building up a part that can be strong and lightweight. The hand layup method provides design flexibility and the ability to create unique rear bumper shapes to suit custom styling goals. It also demands meticulous control of resin saturation and air entrapment to prevent voids and delamination. The finish stage typically requires more post-processing than an OEM plastic part, with sanding, filler work, and careful primer application to achieve a surface that takes paint evenly and resists cracking under minor flexing.

A third pathway, common in performance or protection-focused kits, uses polyurethane and related fabrication methods that emphasize impact resistance and flexibility. In practice, polyurethane bumpers might be produced through casting or molding processes that allow for flexible yet strong panels. The material’s elasticity helps absorb higher-energy impacts without fracture, a valuable trait for parts that risk contact with curbs, parking barriers, or track debris. Yet the finish quality and surface hardness can vary with the resin formulation, necessitating precise surface preparation and topcoat layering to maintain a pristine appearance under daily use.

While the fundamental choices in materials and processes are technical, they translate into practical consequences for drivers. ABS OEM bumpers tend to deliver reliable durability and precise fitment, with straightforward repair pathways when scratches occur. Fiberglass-based kits offer broad design latitude but demand higher skill in shaping and finishing to achieve a seamless look. Polyurethane versions strike a balance, delivering resilience and repairability that suits spirited driving and more aggressive aesthetics. Carbon fiber options provide lightweight, high-end styling and outstanding stiffness, at a price and repair complexity that keeps them within a narrower segment of the market. The parade of options underscores a simple truth: the rear bumper is a platform where safety, performance, and style intersect, and the material choice is the quiet driver of that intersection.

A critical dimension of this discussion lies in how bumpers integrate with the vehicle’s evolving safety and driver-assistance features. The modern Lancer often embeds sensors and cameras within the rear bumper area, along with housing for reflectors and plate mounts. These embedded elements create cavities, mounting surfaces, and precise tolerances that constrain how the bumper can be shaped and finished. In practice, this means that the bumper’s inner geometry must accommodate sensor modules without creating gaps, interference, or misalignment that could degrade system performance. The interplay between structural design and electronics becomes an exacting exercise in engineering, where even the choice of paint thickness and sealant type can influence sensor calibration and weather sealing.

From an aerodynamic standpoint, the bumper’s rear profile can also affect tailflow and drag. In higher-performance or visually aggressive configurations, designers add diffuse sections or integrated air-guiding features to manage wake and lift. These design elements demand materials that can hold fine, consistent edges and resist warping under aerodynamic loads. Here again, the material selection matters: a rigid, well-matched ABS shell can sustain sharp lines after painting, while a fiberglass or carbon fiber option must be finished with care to preserve that precision across temperature swings and road grit. The result is a rear bumper that not only looks right but behaves predictably at the speeds where a car begins to shed lift and the air tells on handling.

For owners weighing their options, fitment and regulation are practical anchors. OEM bumpers are designed to align with factory mounting points and the vehicle’s body lines, delivering a near-seamless continuation of the car’s silhouette. Aftermarket choices, while capable of matching the original form, often require verification of mounting positions, screw patterns, and clip locations. Some vendors advertise 100% fitment, but the true test comes with a hands-on install and a close visual audit in daylight and after a wash. It is worth noting that the integration of reflectors and license plate mounts is not merely cosmetic; these elements ensure nighttime visibility and compliance with traffic regulations, reducing the risk of noncompliance fines and the embarrassment of misaligned lighting.

Within this landscape of materials and methods, there is a clear throughline: the best bumper for a given Lancer depends on the owner’s priorities. If absolute alignment and a straightforward repair path matter most, the OEM ABS option remains compelling. If design freedom and weight savings are the goal, a fiberglass or polyurethane path can deliver striking looks and robust performance, provided surface finishing and repair strategies are respected. If the purpose is premium aesthetics with cutting-edge stiffness, carbon fiber offers a distinctive edge, acknowledging the higher cost and specialized maintenance that accompany such a choice. In all cases, the bumper is a practical collaboration between form and function, a canvas where engineering meets daily driving and where every material choice quietly conditions the car’s safety, handling, and long-term value.

For readers looking to explore specific aftermarket options and installation contexts, one representative resource highlights the broader landscape of rear bumper availability across model years and configurations. See the page titled 2016 Mitsubishi Lancer front and rear bumpers for a sense of how aftermarket suppliers frame compatibility and fitment across a mid-cycle year. This resource illustrates how variations in mounting points, trim details, and finishing expectations shape the path from part to road.

External reading for broader context: https://www.alibaba.com/product-detail/Mitsubishi-Lancer-Rear-Bumper-2009-2017_1601548325589.html?spm=a2700.gallery-internal.0.0.6c7d3b7aKZvCfP

Rear Armor and Regulations: Ensuring Your Mitsubishi Lancer Back Bumper Meets Safety and Compliance

Rear bumpers do more than finish a car’s look; they protect structures, people, and legal standing. For Mitsubishi Lancer owners, understanding safety and compliance for the rear bumper affects repair choices, modifications, and daily peace of mind. The rear bumper is an engineered assembly. It absorbs and redistributes low-speed impact energy. It also supports lighting, reflectors, camera systems, and sensors. Modern designs combine an impact-resistant frame and energy-absorbing materials. These features reduce repair costs after minor collisions. They also protect vital components like the trunk lid, taillights, and rear subframe.

Design choices begin with material selection. Many Lancer rear bumpers use high-strength thermoplastic blends. Those blends, commonly PP/ABS or similar polymers, offer a balance of light weight and impact resistance. Behind the visible cover sits a structural beam. That beam is tuned to deform predictably during impact. It works with foam or honeycomb energy absorbers. Together, they limit intrusion to the cabin and to critical understructure. Bumper curvature and edge geometry play a role in pedestrian safety. Smooth, rounded profiles reduce injury risk in collisions with pedestrians or cyclists. This shape also helps meet regulatory standards in many markets.

Visibility and lighting are another compliance dimension. Rear reflectors and license plate illumination must meet photometric standards. These rules define light intensity, beam pattern, and visibility angles. Meeting them keeps the car legal to operate on public roads. When a bumper is replaced, the mounting points for reflectors and plates must align precisely. Misalignment can reduce reflector performance and cause inspection failures. Increasingly, rear bumpers also accommodate backup cameras and parking sensors. Properly fitted sensors need accurate positioning and correct wiring. A seemingly small installation error can alter sensor calibration and yield false readings.

High-performance Lancer variants add aerodynamic elements, such as integrated diffusers. Those features improve stability at speed. They must still meet crash and pedestrian safety benchmarks while maintaining airflow advantages. Aftermarket pieces that change the bumper’s profile may alter crash behavior. That change can affect both safety performance and regulatory compliance. For owners who prefer a sportier look, choosing parts that state OEM fitment and compliance is essential.

OEM versus aftermarket replacements present different trade-offs. OEM parts are designed to the vehicle maker’s specifications. They match mounting points, material properties, and paint codes closely. This alignment helps preserve factory crash performance. It also reduces the risk of warranty disputes. Quality aftermarket products can match OEM fitment and safety when built to automotive standards. Reputable suppliers provide test reports and material certifications. These documents show compliance with standards used in specific markets.

When evaluating parts, look for evidence of testing. Certificates for material properties, impact testing, and photometric compliance are useful. In North America, adherence to DOT and SAE lighting standards is critical. In Europe, UNECE regulations and Euro NCAP protocols matter. For consumer-level verification, inspect the part for molded compliance markings. Ask the supplier for test reports. Confirm fitment claims with a clear return policy. For performance or race-oriented components, note the intended use. Track-only parts may not be street-legal.

Correct painting and finish carry both cosmetic and safety implications. Paint that is too thick can hide minor fitting imperfections. Mismatched coatings may flake or corrode exposed fasteners, compromising attachment points. For sensors and cameras, paint or adhesives must not impede signal transmission. Color-matching should be done with automotive-grade paints. Proper curing prevents premature fading or cracking. When replacing the bumper, ensure all fasteners and clips are OEM-equivalent. A loose cover can increase damage in an impact event.

Installation matters as much as compliance documentation. Proper alignment ensures the bumper’s energy-absorbing path works as designed. Wiring harnesses for cameras and sensors must be routed and secured per manufacturer guidelines. Recalibration is often required after sensor relocation. For backup cameras, verify image alignment and unobstructed fields of view. For radar or ultrasonic sensors, professional calibration restores accurate range detection. Failure to recalibrate can reduce system reliability and raise safety risks.

Legal issues extend beyond physical safety. Lighting that exceeds permitted intensity or that alters beam patterns may violate road laws. Aftermarket reflectors or LED assemblies must meet photometric and color standards. License plate illumination needs correct mounting and brightness. In many regions, inspectors will check these details during vehicle examinations. Keep records of replacements and certifications to simplify inspections and resale.

Practical maintenance and checks improve long-term safety. Periodically inspect mounting hardware for corrosion or wear. Look for paint cracks or gaps between the bumper and body panels. Check that reflectors and lights are secure and clean. Test backup cameras under low light conditions. Verify sensor warnings produce expected alerts. After minor collisions, have a professional assess internal absorbers and the structural beam. Visible cover damage may hide deeper structural compromise.

For Lancer owners seeking replacement or upgrade parts, review available options carefully. Confirm the supplier states OEM fitment and automotive-grade materials. Inspect packaging for quality control marks and compliance labels. If a part advertises integrated camera or sensor accommodation, verify wiring harness compatibility. Some suppliers list compatible model years and trims. For a practical reference on Evo X specific rear bumper options, review this resource on Evo X rear bumpers (2008–2015). It gives an idea of available designs, fitment claims, and pictured mounting interfaces.

If you plan to modify the bumper’s profile or add aftermarket aerodynamic bits, consider an engineer’s review. Alterations can change how the absorber deforms. They can also affect pedestrian safety metrics. For any modification that moves sensors, factor in recalibration costs. For insurance and inspection purposes, document the work. Keep receipts, certifications, and installation records. These documents make claims and compliance checks smoother.

Ultimately, the rear bumper is a system, not a cosmetic add-on. Its role spans crash energy management, pedestrian safety, and functional integration of lights and sensors. Choosing the right part involves matching materials, fitment, and documented compliance. Installing it requires correct alignment, wiring, and calibration. Regular inspections maintain safety and legal standing.

For official U.S. safety standards and more detailed regulatory guidance, consult the NHTSA website: https://www.nhtsa.gov

Aftermarket Momentum: Trends, Choices, and Buyer Guidance for Mitsubishi Lancer Rear Bumpers

The market for Mitsubishi Lancer rear bumpers has shifted from simple replacement parts to a varied ecosystem of functional upgrades and style options. Aging Lancer models, particularly those produced between 2008 and 2015, have created steady demand for replacements. Many original bumpers are reaching the end of useful life, and owners want solutions that restore safety and preserve appearance. At the same time, enthusiasts seek sportier looks and aerodynamic gains. The result is a broad aftermarket that blends durability, fitment accuracy, and performance-driven design.

Many buyers start by asking whether to choose an OEM-style replacement or pursue a performance-minded upgrade. OEM-style bumpers typically match factory dimensions and mounting points. They use high-strength plastics such as PP/ABS and offer reliable impact resistance. These parts are attractive to owners who prioritize a stock look and straightforward installation. Aftermarket suppliers have responded with high-fidelity reproductions that emphasize dimensional accuracy, paint-ready finishes, and consistent material quality. That makes them a practical option for routine repairs.

Parallel to OEM-style choices is a thriving segment of upgraded bumper covers and body kits. These are aimed at drivers focused on aerodynamics and visual statement. Integrated diffusers, larger vents, and sharper contours change airflow around the rear of the car. On performance variants, these elements reduce lift and improve high-speed stability. Many kits also provide mounting points or provisions for modern convenience features, such as parking sensors and reverse cameras. For owners retrofitting technology into older Lancers, these provisions simplify the installation of parking assistance systems.

Material selection matters. PP/ABS blends deliver a good compromise between toughness and flexibility. They absorb low-speed impacts and resist cracking under stress. Higher-end kit components sometimes use reinforced composites for added rigidity and improved finish. These can deliver a more precise fit and a more premium surface for painting. When comparing materials, consider daily driving conditions. Urban drivers benefit from resilient plastics that flex on impact. Track-focused builds may favor stiffer composites that maintain aerodynamic shape under load.

Manufacturing hubs in Asia have scaled to meet demand, producing an array of parts with competitive pricing. That scale has lowered prices while improving consistency. However, quality still varies. Expect a range from economical, unpainted covers to premium, finish-ready bumpers that include mounting hardware and reinforcement brackets. Detailed listings now commonly state fitment compatibility and included components. Look for suppliers who provide clear photos of mounting points and close-up shots of clips, brackets, and reinforcement areas. Those details greatly reduce the risk of fitment surprises after purchase.

Integration of modern safety and convenience features has become a differentiator. Many rear bumpers now ship with cutouts or mounts for reverse cameras and ultrasound sensors. Some performance covers even include enhanced reflector arrays and license plate illumination that meet regulatory needs. For owners adding these systems, confirm that wiring channels and sensor mounts are present. Small design choices, such as reinforced sensor bosses and pre-cut camera pockets, make installations neater and more reliable.

Pricing reflects this diversity. Basic replacement covers are the most affordable. Conversion kits and performance bumpers command higher prices. Expect a premium for parts that include integrated aerodynamic elements or that come pre-painted to factory colors. Shipping and import considerations can also affect total cost. Factor in paint, hardware, shipping, and any necessary trim pieces when estimating the final outlay. For some owners, a slightly higher initial expense for a higher-quality bumper reduces repeat purchases and fitment headaches.

Fitment accuracy remains a common concern. Aftermarket vendors often advertise “100% match” to factory dimensions. Still, minor variations are possible, especially when changing from one year or trim to another. Inspect fitment notes closely and compare part numbers when available. Photos showing installed bumpers on vehicles of the same year and trim are helpful. If a vendor offers test-fit guarantees or returns for fitment issues, that can provide important protection.

Installation choices influence both cost and outcome. DIY installation is feasible for many owners with basic tools and a helper. Removing and installing a rear bumper usually involves a combination of fasteners, clips, and bumper retainer panels. However, more elaborate conversion kits can require trimming, reinforcing, or modifying adjacent panels. Professional installation reduces alignment risk and ensures any integrated sensors or cameras are calibrated correctly. Shops experienced with Mitsubishi models will complete the job faster and can manage paint matching and refinishing, but labor costs must be factored into the overall budget.

Regulatory and safety compliance should not be overlooked. Reflectors, license plate illumination, and required structural clearances vary by market. Choose bumpers that either meet local regulations or allow compliant components to be fitted. For cars that retain their original crash structures, the bumper cover plays a cosmetic and low-speed protective role. But for vehicles involved in a collision, proper bumper reinforcement and energy-absorbing elements are critical. When replacing rear bumper covers on an older vehicle, verify that impact-absorbing elements and mounts are in suitable condition.

Customization remains a major draw. Owners can select textured finishes, color-matched paint, gloss accents, and decals. Many kits are paint-ready, allowing for bespoke color matching. Some aftermarket bumpers offer modular elements, like removable diffuser inserts, making it easier to change the look without replacing the entire bumper. If resale value matters, choose reversible modifications and maintain original parts. That approach preserves options for buyers who prefer factory appearance in future sales.

For owners of performance-oriented Lancer models, like the evolution variants, the aftermarket offers dedicated rear bumper designs. These emphasize airflow management and aggressive styling. Many of these designs are road-legal while offering improved rear downforce and enhanced cooling for brake ducts or other components. When selecting such parts, validate that they match the vehicle’s performance intent and do not introduce unwanted drag or noise.

Buyer guidance centers on three core priorities: fitment, material quality, and feature integration. Prioritize vendors who provide clear fitment information and who supply detailed photos. Verify that the material chosen aligns with how the car will be used. Confirm that needed provisions for sensors or cameras are present. When in doubt about installation or regulatory compliance, consult a specialist.

If you want to explore aftermarket options tailored to the Evo X and similar models, see this Evo X rear bumpers page for examples and fitment notes: https://mitsubishiautopartsshop.com/2008-2015-mitsubishi-lancer-evo-x-rear-bumpers/.

Recent market signals show increasing online interest. Industry listings note a significant rise in searches for rear bumpers. That growth mirrors a wider supply chain capable of delivering fits that balance cost and capability. For many owners, the expanding aftermarket now makes it possible to replace a worn bumper with a part that restores safety and enhances aesthetics. As always, careful selection, attention to fitment, and sensible budgeting produce the best results.

Source: https://www.alibaba.com/product-detail/22-increase-in-web-searches-for-Mitsubishi-Lancer_1600937061972.html

How the Mitsubishi Lancer Rear Bumper Shapes Speed, Stability, and Strength

Aerodynamics, Structure, and Practical Gains

The rear bumper of a Mitsubishi Lancer is more than a styling element. It plays a measurable role in aerodynamics, structural resilience, and overall driving dynamics. Thoughtful design channels airflow, reduces turbulence behind the car, and manages lift. At the same time, modern bumpers balance lightweight construction with impact resilience. This balance yields real-world benefits: improved high-speed stability, sharper handling under load, and a small but useful improvement in fuel efficiency.

Aerodynamic shaping begins with profile and transitions. A rear bumper that tapers smoothly and closes the gap between the body and the road helps tame the low-pressure wake behind the car. When turbulent air is reduced, drag falls and the rear end feels more planted. Designers borrow techniques from motorsport, integrating subtle lips and contours that coax air toward an intended path. Those contours can reduce separated flow and soften pressure gradients, which directly lowers the aerodynamic drag coefficient.

Integrated diffusers and lip spoilers magnify these effects. A diffuser uses a stepped transition to accelerate underbody airflow and recover pressure more smoothly behind the vehicle. This creates a small amount of rear downforce without large, drag-inducing wings. The result is improved rear traction at speed and enhanced cornering stability. Lip spoilers at the bumper’s trailing edge trim airflow separation and prevent abrupt pressure drops that lift the tail. Together these elements tune the Lancer’s balance, especially when the car carries passenger or luggage weight.

Aerodynamic gains are particularly visible on performance-oriented versions. Models with factory or aftermarket diffuser profiles show reduced lift at the rear, which translates into a steadier feel through high-speed sweepers. Drivers report more predictable rear grip and less twitch when transitioning between throttle and braking. For track or spirited road use, that predictability allows drivers to push harder while maintaining control. Even for daily driving, reduced turbulence can translate to a marginal improvement in fuel consumption when cruising at highway speeds.

Materials and construction matter as much as shape. High-strength thermoplastics and PP/ABS blends deliver good impact absorption without excessive weight. Weight saved at the rear helps lower the car’s moment of inertia around its vertical axis, which can make the steering response slightly crisper. Lightweight bumper covers also reduce unsprung mass when combined with integrated components like diffuser inserts or flexible valances. Durability is critical too; materials that resist cracking and UV degradation preserve aerodynamic shape and structural performance over time.

Manufacturing quality determines how closely an aftermarket piece matches intended performance. A bumper that deviates from OEM fitment can create gaps and misalignments. Those small errors disturb airflow and erode any aerodynamic advantage. Precision-molded replacements and high-quality covers often promise a 100% fit and retain mounting point integrity. This ensures the diffuser angle and lip geometry align correctly with the underbody. For owners who want both visual and dynamic upgrades, choosing a component that maintains factory dimensions is essential.

Bumpers also serve as mounting platforms for sensors and safety systems. While many of these systems typically locate on the front or within the body, rear bumpers frequently accept reflectors, cameras, and proximity sensors. Thoughtful integration of these devices preserves airflow paths and avoids creating cavities that trap vortices. When sensors sit flush and housings are aerodynamically faired, they keep the diffuser and lip working as designed. This integration supports both performance goals and modern convenience features.

Beyond pure airflow, rear bumper design contributes to crash energy management. A properly engineered bumper absorbs energy in low-speed impacts, protecting the trunk, tail lights, and rear structural rails. Reinforcement beams, crush boxes, and foam cores are tuned to deform predictably. This protective behavior limits repair costs and preserves the vehicle’s integrity after a minor collision. When considering a performance-style bumper, it is important to confirm that any aftermarket reinforcement meets or mirrors OEM standards. Aesthetic upgrades should not sacrifice crash performance.

Practical installation considerations influence the real benefits owners experience. A bumper that is difficult to fit can result in poor alignment and stress on mounting tabs. Proper installation restores intended panel gaps and preserves aerodynamic continuity between bumper and rear fascia. Many upgraded rear bumpers come with pre-mounted brackets and cutouts for lights and sensors, simplifying fitment. Where customization is desired, small adjustments such as trimming inner liners or fine-tuning bracket positions often yield the best aerodynamic results while maintaining structural safety.

The measurable performance advantages are often incremental but meaningful. Reduced drag can slightly improve highway fuel economy. Increased rear downforce enhances traction and lap times in spirited driving. Weight savings lower inertia and refine steering feel. Those benefits sum to a different driving experience: steadier at speed, more confident through bends, and visually sharper. For owners seeking both function and form, an upgraded rear bumper can be one of the most effective exterior changes.

Choosing between OEM-spec replacements and performance-oriented aftermarket designs requires a clear objective. If preservation of warranty and original safety behavior is paramount, OEM-fit parts provide reassurance. If the goal includes aerodynamic enhancement and a sportier stance, a carefully chosen aftermarket bumper with proper fitment can deliver gains without undermining crash protection. When evaluating options, inspect material quality, confirm sensor and reflector accommodations, and verify mounting precision. A test fit or a reputable supplier’s fitment guarantee reduces installation risk.

For enthusiasts who want examples or fitting guidance on performance-style rear bumpers, a focused resource on Evo X rear bumpers can illustrate how diffuser geometry and bumper contours were developed for handling gains. See this Evo X rear bumpers overview for a deeper look at shape, fitment, and design intent: Evo X rear bumpers overview.

Overall, a Mitsubishi Lancer rear bumper designed with aerodynamics and structural integrity in mind can offer both tangible and intangible rewards. It stabilizes airflow, reduces lift, and supports modern sensors. It protects the car and can sharpen its character. When selection prioritizes fitment, material quality, and preserved safety features, the upgrade enhances performance in balanced, reliable ways.

Source: https://www.ebay.com/itm/154769539895

Final thoughts

The Mitsubishi Lancer back bumper plays a crucial role not only in the aesthetic appeal of the vehicle but also in its safety and performance. As advancements continue in design and technology, business owners must stay informed about the best options available in the market. Upgrading or maintaining back bumpers with quality parts ensures compliance with safety standards and enhances vehicle performance. A thorough understanding of the bumper’s features, materials, safety regulations, and market trends empowers business owners to make decisions that benefit their operations and maintain customer satisfaction.