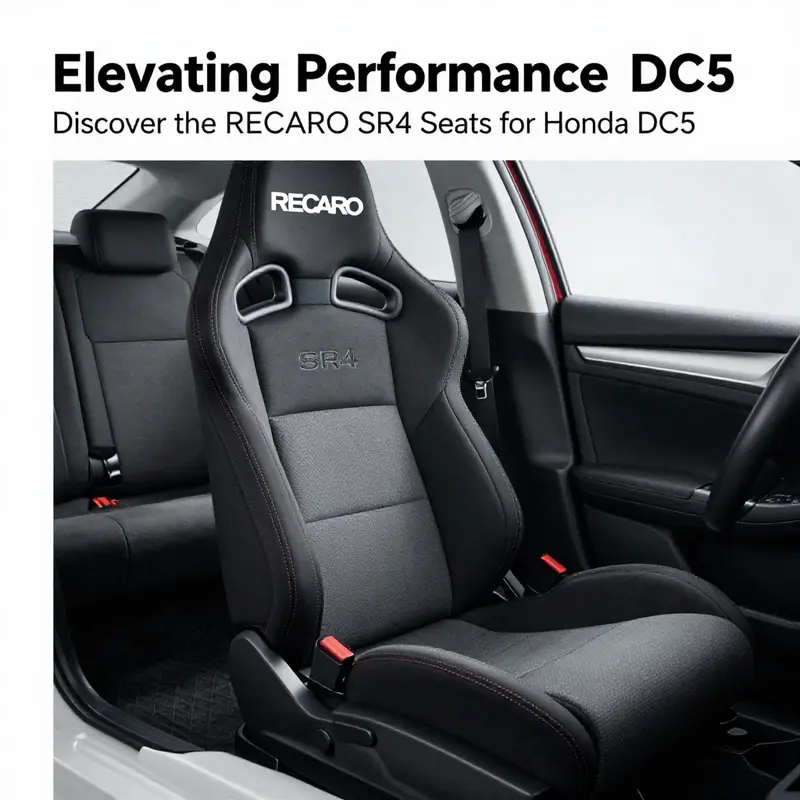

The choice of seating in a performance vehicle is crucial to ensure safety, support, and overall driving experience. For business owners in the automotive customization sector or those managing performance vehicle fleets, understanding the advantages of high-quality seats like the RECARO SR4 designed specifically for the Honda Civic DC5 can be a game changer. These seats offer unparalleled side support and comfort, which are essential during intense driving conditions. This article will delve into the performance features, installation compatibility, market availability, and innovative design of the RECARO SR4 seats, providing valuable insights that could influence purchasing decisions for both personal use and resale. Each chapter builds upon the last, equipping business owners with the necessary information to make informed choices.

Between Fit and Feeling: Navigating DC5-Compatible Bucket Seats for the Honda Integra

When a driver chases the edge of control, the seat becomes more than a place to rest the body. It is the interface through which intent translates into movement. In the Honda Integra chassis that enthusiasts loosely call a DC5, the search for a bucket seat often begins with two questions: how much of the seat s shape translates into real contact on the road, and how much contact can remain consistent as the miles stack up. The allure of a high grip, sculpted seat is strong. A well designed bucket can knit the driver to the car with a kind of silent math—the hips held steady, the torso guided by the side bolsters, and the head aligned so that vision remains uninterrupted. Yet the romance of a fixed-back, race inspired shell hides practical challenges. The journey to find the right DC5 compatible seat becomes a careful balance between fit, feel, and the realities of mounting, safety systems, and everyday use.

As the search unfolds, it s essential to acknowledge the landscape of naming and model codes that often creates confusion in the scene. In some circles, the DC5 label is used to refer to a particular high performance Honda chassis, while others point to it as a broader Generational frame tied to similar platform dynamics. Within the same conversations, you may encounter references to an SR4 or other seat variants labeled for Integra or Civic lines. This mix of model codes and SKU names can blur what a seat actually is and what it can do on a given car. The bottom line is simpler in practice: there is no single, universally sanctioned DC5 seat model that sits in a factory catalog. Instead, there are seats designed to fit a DC5 like footprint—seats whose shapes, mounting patterns, and materials respond well to the geometry of a compact performance chassis. That realization reframes the whole pursuit. It asks not for a brand badge or a model number, but for a seat that can deliver predictable hold, safe support during aggressive cornering, and a mounting path that plays nicely with the car s rails, sliders, and belts.

What follows, then, is a narrative of fit and feel, of how a seat s geometry interacts with a driver s posture, and of the compromises that sit in the margins between performance and practicality. A bucket seat does not merely clamp the torso in place; it sculpts an angular corridor through which the rider s center of gravity must pass with each twist of the wheel. The best seats for a DC5 like platform balance three essentials: lateral support that holds the torso without cutting off circulation, thigh support that preserves leg drive without pinching the knees, and a shell shape that tolerates the driver s shoulder height while allowing a clear view of the instrument panel and apexes ahead. In this space, foam density, shell stiffness, and fabric or leather texture all converge to determine how the body and the car behave as a unit. Some materials feel more reassuring in the long haul; others offer a sharper edge for the sprint from corner entry to exit. The point is not merely tactile pleasure but repeatable geometry: repeated, consistent seating position under a wide range of throttle and brake pressures.

One practical thread runs through the whole conversation: mounting and rails. A seat does not exist in isolation. It sits on rails that translate the driver s intended position into a real, measurable offset from the door sill and pedals. For a DC5 like chassis, the compatibility of the seat s mounting holes, seatbelt anchor points, and the potential interference with door structures or seat sliders can define whether a seat remains a framed ideal or becomes a constant friction point. The reality is that many performance seats arrive with universal rails, but universal does not always mean universal. Some cars demand adapters, some demand slight crafting, and some demand a careful eye toward the car s belt harness configuration. When a seat is intended for competition use, the importance of harness compatibility rises. Multi strap shoulder belts and anti submarining features rely on precise geometry; misalignment can undermine the very safety the seat promises. In other words, the driver s quest for a secure, locked-in feel is part material, part engineering, and part empirical trial.

Material choices stand at the same crossroads as mounting hardware. Premium upholstery—whether plain leather, Alcantara, or a suede-like surface—introduces texture that interacts with grip and comfort. A sport seat s fabric will age differently than a leather wrapped shell; the former can become a little grippier as it wears in, while the latter can become slick if the finish is too smooth or if the driver s hands carry excessive oils, lotions, or grime. On a longer drive, the comfort layer matters as much as the hold layer. A seat s inner structure—often a composite of foam, resin, and in some cases carbon fiber or high-strength polymers—also governs how firm the support feels. A stiffer shell can hold a driver in place more reliably during aggressive maneuvers, but it can also transmit more road texture to the spine. A softer, more forgiving chamber might be comfortable for daily use but could permit more body motion during a corner exit. The balancing act is to locate a shell that preserves posture under load while not punishing the spine on a thousand miles of highway. The dream of a carbon-fiber spine with a plush suede cover grows from this tension, but so do the realities of cost and durability.

The decision between a full bucket and a more forgiving semi-bucket speaks to the driver s intent. If the car is destined for track days, the more rigid, aggressive shell can provide the fixed fixation needed for precise line selection. For a daily driver that occasionally visits back roads or a weekend track night, a semi-bucket with a supportive back can deliver the same confidence without the constant, chest-level pressure on the ribcage and shoulders. The choice is rarely binary, and the DC5 s geometry tends to reward nuanced selections rather than absolute extremes. The driver s height and torso length also come into play. A seat that cradles a longer trunk will often require more headroom or a careful adjustment to the steering wheel height to avoid the helmet brushing against the roof during aggressive cornering. These measurements are not esoteric; they shape whether a seat will be worn as a badge of performance or worn out as a source of discomfort.

The market reality mirrors these technical considerations. On the second-hand and new-seats market, the frequency with which performance buckets turn up speaks to their desirability and their price. A pair of seats with supporting rails and mounting hardware can fetch a premium, especially if they preserve a near-new finish and a balance of materials that resist wear. Yet the premium must be weighed against the practicalities of installation and fit. Some sellers advertise a dual benefit: a near-factory lightness paired with premium upholstery, and a set of rails that claims compatibility with a broad range of cars. The conversation often drifts toward the ease of installation: plug-and-play rails, the correct bolt pattern, and the right belt anchors. In many DC5-like builds, the rails and the shell are the true gatekeepers of performance. Without rails that align with the door sill and the floor pan, the seat cannot settle into a position that is both comfortable and safe. The dream then becomes less about the brand and more about the geometry that aligns with the driver s measurements and the car s cockpit layout.

This is where the value of real-world references becomes tangible. For enthusiasts seeking concrete examples of how a DC5-like seating solution translates into track-ready performance, practical previews exist in catalogs, forums, and dealer listings. These resources often describe not just the seat s surface but the entire seating ecosystem: the way the chair nests against a driver s hip contour, the way the bolster holds the ribcage at the moment of peak lateral G, and the way the seat s lumbar support works in concert with the lower back. A seat that interacts with the driver s pelvis and spine in a unified manner tends to produce faster lap times not because it makes the car go faster, but because it reduces the mental friction of maintaining posture through a demanding corner sequence. The body becomes a part of the machine s feedback loop, and that loop can become a reliable predictor of consistency from lap to lap.

In this context, the market often highlights a tension between authenticity and practicality. Some brands emphasize authentic race aesthetics—minimal padding, ultra-compact shells, and materials chosen for their lightness and heat response. Other brands emphasize everyday usability—more generous side bolsters for everyday cornering, easier ingress and egress, and upholsteries that resist daily wear and tear. For the DC5 owner, the synthesis requires a deliberate assessment of how the seat s contour aligns with the athlete s posture, how well it supports the spine under sustained driving, and how easily it can be mounted within the constraints of the car s existing structure. The experiential payoff—the feel of the car responding with precision as the steering input meets the apex—arises from the coherence of all these choices: material, geometry, rail design, belt anchor points, and the driver s own dimensions.

As a closing reflection within this ongoing pursuit, the racer s instinct often traverses more than the mere replacement of a seat. It is a careful audition for how an upgrade affects the cockpit s rhythm. A seat that locks in the torso helps the driver maintain precise weight distribution. A seat that accommodates a taller driver without forcing compromises to eyesight preserves the line of sight toward the critical apexes ahead. And a seat with a surface that remains reliable under the car s heat and sweat without becoming a slip hazard contributes to steady, repeatable performance. The DC5 as a chassis archetype becomes less about a single model artifact and more about a set of criteria that any performance seat must meet to be truly effective in this frame. In that sense, the journey is less about tracking down a particular badge and more about cultivating a cockpit that respects the body s geometry as much as the car s chassis. The result is a cockpit that feels like a precise instrument rather than an accessory a space where the line between human and machine dissolves into a single, controllable conductor.

For readers who want to explore a concrete example of the type of seating solution discussed here, consider the DC5 semi bucket front seating option which illustrates how a compact, purpose built shell can align with the DC5 cockpit while maintaining practical connectivity with rails and belts. This kind of reference point helps translate the theory of fit into the reality of a tangible install. It is through such specific configurations that the broader discussion about seats for this chassis can transform into a real actionable path toward a cockpit that feels both faster and more trustworthy. As with any upgrade that touches safety, comfort, and control, the best approach remains methodical measure, fit, test, and iterate. And when the right balance is achieved, the DC5 s cockpit can finally exist as a true extension of the driver s intent a place where the body and the car become a single, responsive unit.

Fitting RECARO Seats to a DC5: Practical Fitment, Safety and Compatibility Insights

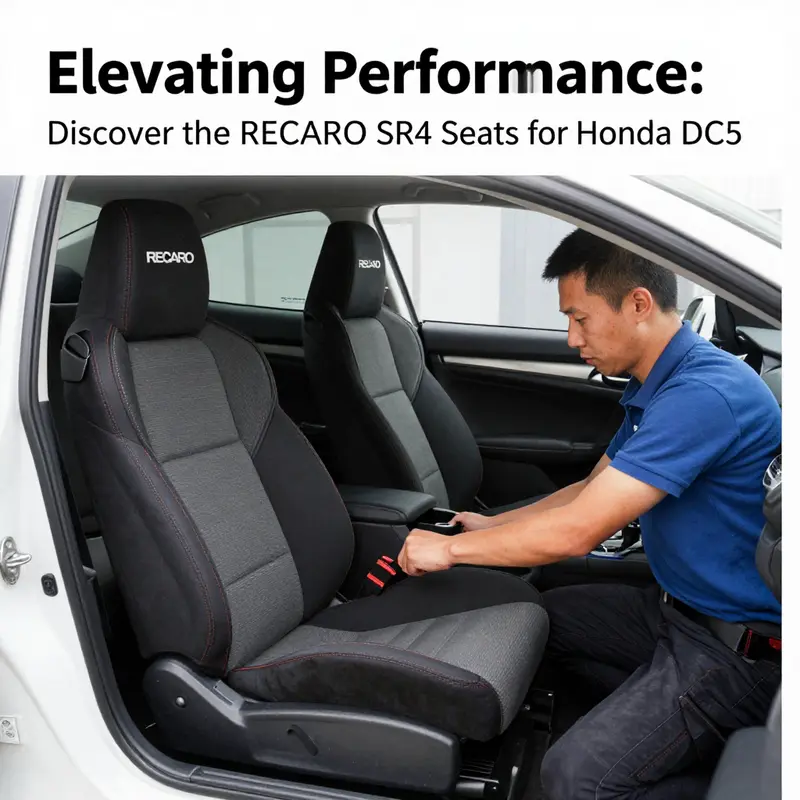

Installing high-performance bucket seats into a DC5 requires more than swapping cushions. The Integra Type R cabin was not built for direct replacement with aftermarket race seats. That means careful planning, the right hardware, and respect for safety systems. This chapter walks through the real-world steps and decisions you must make to fit RECARO-style seats into a DC5 while keeping functionality, comfort, and safety intact.

From the start, accept that a true bolt-in fit seldom exists. Most dedicated bucket seats need custom brackets or a full interior transplant to mount correctly. The DC5’s factory mounting points, seat rails, and electronics often do not line up with an aftermarket shell. Owners typically remove the original seats and install a tailored mounting kit. Those kits adapt the seat’s rail pattern to the car’s floor bolts. When properly chosen, they provide secure, repeatable fitment and preserve seat position adjustability.

Match the seat model to the car’s interior dimensions and intended use. Narrower shells suit daily-driven cars, while wider shells may be needed for larger drivers or heavy padding. Consider the seat back height and shoulder openings. Too tall a shell can rub the headliner. Too wide a shell can interfere with the door armrest or center console. Visualize the seat in the cabin before purchase, and confirm head clearance, legroom, and steering wheel reach.

Mounting hardware is the foundation of a safe installation. Use dedicated adapters or brackets designed for the DC5 where available. Universal rails are a stopgap but often place the seat too high or too far back. Custom brackets allow the seat to sit at the correct height, tilt, and distance from the pedal box. Bolts should be high-grade, threaded to factory specifications, and torqued to recommended values. If you replace the seatbelt anchor or bolt through a new plate, use the same grade and torque as factory anchors.

Seat belt functionality must remain uncompromised. If you use the original three-point belt, ensure the lap and shoulder angles are preserved. Bucket seats with pronounced side bolsters can force the belt webbing off the pelvis. In those cases, a proper sub-belt or lap belt conversion may be necessary to prevent submarining. If you intend to fit multi-point harnesses for track use, plan for reinforced anchorage. Do not bolt harnesses to sheet metal. Anchor points must be tied into the chassis or reinforced points capable of handling high loads.

Airbag systems and seat occupancy sensors present another layer of complexity. Many DC5 models include seatbelt pretensioners and passenger occupancy detection. When swapping seats, maintain or replace occupant sensing systems if required by law. Disconnecting or bypassing sensors may trigger warning lights or disable safety systems. If a new seat lacks a sensor, consult the vehicle service manual. In some cases, professional reprogramming of the airbag control unit is needed.

Wiring for power functions and indicators requires attention. Heated seats, electric lumbar, and seat position memory may not transfer. Cut, splice, or adapt wiring only with correct pinouts and connectors. Use heat-shrink and proper crimp connectors. If your replacement seat supports a seatbelt warning light or ISOFIX, verify the indicator behaves correctly after installation. Some seats include color indicators or locking legs that must be adjusted to show green, confirming secure ISOFIX engagement.

Practical fitment also involves interior trim. A race-style bucket often clashes visually with the stock interior. Many owners pair seats with trim kits to achieve a cohesive look. Matching materials and colors reduces visual mismatch between fresh seats and aged panels. If you want to preserve a factory-like appearance, consider upholstery choices that echo the original fabric. For a motorsport aesthetic, contrasting materials like suede or alcantara can be used for bolsters.

Seat positioning affects ergonomics and control. Low mounting improves the center of gravity and gives a sportier feel. However, sitting too low can impede visibility and comfort for long drives. Adjust seat height so your hips are level with or slightly above your knees. That promotes better pedal feel and reduces fatigue. The rake of the seat influences wrist position on the wheel. Tune the seat angle so your shoulders sit naturally behind the wheel for better steering inputs and leverage.

When choosing between carbon-fiber shells, composite frames, and steel-reinforced options, consider both strength and repairability. Carbon shells are light and rigid, ideal for weight-sensitive builds. But they tend to be expensive and require careful inspection for cracks. Polypropylene and stamped steel frames offer resilience and easier repair. For a daily-driven DC5, a robust composite shell balances comfort with durability.

Structural integrity is critical. Inspect any used seat for frame damage, loose rivets, or cracked mounts. A compromised frame cannot guarantee occupant safety. Look for manufacturer inspection stickers, serial numbers, and evidence of crash repair. Replace any seat with unknown history. Seat foam condition matters too. Excessive compression reduces lateral support and can promote sliding during hard cornering.

Compatibility extends to seat rails and sliders. A good slider allows fore-aft positioning while maintaining structural strength. Some adapters force the slider to sit higher or lower than intended. Pay attention to the slider mounting orientation. The rails must be fully engaged and lock solidly. Test the slider under load before driving. Smooth operation reduces the temptation to adjust on the fly and helps maintain focus while driving.

For harnessed seats, the shoulder belt path is key. Many RECARO-style shells provide harness slots ready for 4- or 5-point harnesses. Mount harnesses so they align with shoulder height, and avoid excessive upward angles that can cause rib or clavicle loading during a crash. Use a harness bar or reinforced roll structure for proper shoulder anchor points. Do not attach harness belts to the factory seat belt anchors.

A full interior transplant is sometimes the cleanest solution. That involves moving carpet, center console, and possibly the console wiring to accommodate new rails. A transplant lets you route harnesses, locate anchor points, and integrate all sensors cleanly. It is more work but results in a professional fit without hacked wiring or ill-fitting trim.

Professional installation is recommended when safety systems are involved. A trained technician can verify anchor integrity, airbag compatibility, and electrical continuity. They also follow torque specs and can advise on chassis reinforcement for harness anchors. For those confident in DIY, document every step and keep the factory parts unless they’re being replaced. Preserve factory bolts, spacers, and brackets; some adapters reuse those components.

Sourcing seats brings decisions between new and used. New seats offer warranty and known history. Used seats can provide value and period-correct style but require careful inspection. Verify authenticity and condition. Check for seller images showing mounting points and frame condition. If purchasing internationally, confirm shipping terms and potential customs duties. Some sellers ship from the U.S. with “no customs” claims, but buyers should still confirm local import rules.

Legal compliance varies by region. Some jurisdictions restrict the removal of safety systems or the installation of non-original seating. Check local laws around seat anchors, presence of airbags, and harness use on public roads. Track use has different rules, and a harness that is legal for competition may be illegal for road use. Keep documentation for any parts installed and, if necessary, carry receipts to demonstrate proper installation in inspections.

Final fitment checks are simple but essential. Sit in the car and test full range of motion. Check pedal clearance and steering wheel position. Buckle the belts, and verify the indicator lights. Drive at low speed and make progressive stops to ensure the seat remains solidly anchored. Re-torque mounting bolts after the first few miles, as components can settle into place.

Small details elevate the finished installation. Use trim spacers where needed to protect upholstery. Seal exposed bolt heads with protective caps. Label any rewired connectors for future maintenance. Keep factory seat components stored in case you ever wish to return the car to stock. These steps preserve value and reduce surprises at resale.

If you want to preview options in the marketplace, compare specifications like shell width, mounting bolt pattern, and weight. Look for seats that specify compatibility with DC5 adapters or note fitment with vehicles of similar interior dimensions. For a practical starting point, explore listings and kits targeted specifically at DC5 owners, such as the DC5 semi-bucket front Recaro seats available through specialist suppliers. That resource can help you identify kits and rails designed for the Integra cabin.

An excellent visual guide can clarify the installation process. For step-by-step demonstration of ISOFIX mounting, indicator behavior, and support leg locking, review the recommended installation video: https://www.youtube.com/watch?v=example. Use it as a supplemental walkthrough, but always adapt procedures to your specific seat model and the DC5’s layout.

A safe, comfortable fit requires patience, correct hardware, and respect for the vehicle’s safety architecture. Plans that balance day-to-day comfort, track capability, and legal compliance deliver the most satisfying results. With the right preparation and attention to detail, a RECARO-style seat can transform a DC5’s cabin into a precise, driver-focused space while maintaining safety and functionality.

Contours of Availability: How RECARO Seats Find a Home in the DC5 Chassis

The search for the right seating in a high-performance chassis is more than a shopping list. It is a conversation with the car’s silhouette, weight distribution, and the driver’s own relationship with the road. In the DC5 era, the hatchback’s compact dimensions and tight cockpit demand seats that can hold a driver firmly yet support the long stints of track sessions or spirited street miles. The narrative around RECARO seats in this context is not merely about a brand name or a model that appears in a listing. It is about how a renowned sport-seat philosophy translates to a DC5-compatible experience—one where lateral support, lumbar containment, and adjustability converge without compromising the car’s compact balance. Within this frame, market availability becomes a living map rather than a static catalog. It reveals not only what exists, but how enthusiasts interpret fit, safety, and performance as they tinker with a chassis that has earned its reputation through the love of driving itself.

RECARO has long stood as a beacon in the automotive aftermarket sport-seat segment. From street performance to circuit readiness, the brand’s core messaging centers on support, durability, and the kind of posture that encourages precise control during aggressive cornering. In a landscape crowded with options, RECARO’s reputation helps a DC5 owner trust that a seat designed for high-G scenarios will translate into meaningful gains on a road course or winding back road. This product focus—driven by the aim to deliver comfort under load, reduce fatigue in endurance driving, and retain a protective hold through dynamic maneuvers—shapes how the market sees DC5 compatibility. The availability story then follows a logic of fit, weight, and mounting compatibility rather than a simple price tag or aesthetic appeal. Enthusiasts naturally evaluate whether a seat can be mounted on standard rails or requires a custom solution, whether the cover materials can survive daily street use or track abuse, and whether bolsters can cradle the torso without restricting movement in a way that would make quick corrections tedious.

The DC5 Integra community surrounding the Honda DC5 chassis is not a passive market audience. It is a vibrant ecosystem of builders, track addicts, air-fuel specialists, and suspension tioneers who constantly push the envelope of what a compact performance car can do with the right hardware. This community matters for the availability equation because it creates a sustained demand for seating solutions that can endure the stress of high-speed turns and rapid weight transfer. The appeal of a sport seat in this context goes beyond mere aesthetics. It centers on the promise of a more connected driving experience—the kind that keeps the driver securely in position when the car begins to bite into a corner and demands more from the chassis than a stock perch can comfortably offer. This is not a market that tolerates vague fit or flabby side support. Enthusiasts want seats that align with the DC5’s behavior: responsive, predictable, and capable of translating the driver’s inputs into a tangible relationship with the road.

From a market presence perspective, the logic is straightforward but telling. The sport-seat segment serves a niche that still commands attention from specialized modification channels. RECARO, as a globally recognized sports-seat producer, maintains a footprint across professional modification shops, online automotive parts retailers, and direct-from-manufacturer channels. For a DC5 owner, this means multiple pathways to acquire a seat that respects the vehicle’s dimensions, harness mounting patterns, and overall driving posture. The shops that specialize in performance chassis often curate seating options that can be adapted to the DC5’s cockpit geometry, providing rails and brackets that enable forward-backward, height, and tilt adjustments. These channels are not merely about stock availability; they reflect a broader ecosystem that understands the importance of weight considerations, seat shell rigidity, and the precision needed for competitive driving. In this sense, the market presence is as much about the service network that supports installation and after-sales fitment as it is about the seat itself. The availability narrative becomes a testament to the DC5’s enduring appeal among performance enthusiasts who expect not only better support but a sustainable upgrade path rather than a one-off purchase.

Of course, the actual status of stock or backorder is seldom disclosed in a universal way. The best practical takeaway for a DC5 owner is to work through informed channels—specialized shops, trusted retailers, and, where possible, direct inquiries to the manufacturer or authorized distributors. The dialogue with vendors often reveals two crucial realities. First, availability can be regionally dependent. A seat that is in abundant supply in one market may require longer lead times in another, driven by supplier allocations, import duties, and logistics realities. Second, the DC5’s age and popularity can influence how aggressively a seat company maintains stock. In some instances, a current model line may be readily adaptable to the DC5 through universal rails, while in others the fit requires a more bespoke approach. This reality does not undermine the value of RECARO seating; it simply underscores the practicalities of aftermarket distribution for a chassis with specific dimensional constraints. In such cases, the discussion often turns to the details of installation: whether a given seat can be anchored with a simple five- or four-point harness, how the seat’s curvature interacts with the DC5’s belt lines and console geometry, and what kind of backrest angle can be achieved without compromising the driver’s visibility and comfort when entering or exiting the cabin.

For enthusiasts who are inventory-minded, the market can appear as a mosaic of used, refurbished, and new options that have been cataloged across forums, e-commerce marketplaces, and specialty listings. The appearance of a pair of seats in a listing—often advertised as a set for a specific model chassis—carries with it a narrative about shipping, duties, and the potential for cross-border transactions. The DC5 owner who contemplates a purchase may weigh factors such as whether the seat upholstery suits daily driving needs, the feel of the bolsters during mid-corner acceleration, and the tolerance of the seat’s contour to taller drivers who require more legroom. A well-considered decision may also entail evaluating the weight distribution changes that a sport seat introduces. In a car that already aims to balance nimble handling with practical daily usability, even a modest weight difference between stock seating and a performance shell can influence throttle response, brake balance, and the overall sense of vehicle dynamics at the limit.

An important nuance in this availability narrative is the role of compatibility. The DC5’s cockpit is not a perfectly modular environment. A seat’s compatibility is not only about width and mounting hole patterns but also about the seat’s depth, its recline range, and the clearance it allows for the driver’s helmet during aggressive cornering. The market has evolved to address these needs through multiple mounting solutions. Some rails are designed with universal applicability in mind, offering adjustable sliders that can align with a broad range of seat types. Others are more specialized, requiring adapters or custom brackets to preserve the seat’s intended geometry while maintaining safety-critical aspects such as seatbelt routing. The availability equation then becomes a question of whether the seller or installer can deliver a turnkey solution or if the buyer must navigate a staged process involving measurement, compatibility checks, and perhaps on-site modification. In either case, the goal remains the same: to deliver an integrated upgrade that respects the DC5’s chassis integrity and the driver’s preference for a connected, race-inspired seating posture.

This is where the role of the online and offline communities becomes most tangible. Forums, rebuild logs, and ride-alongs with tracking notes often reveal what has worked well for real-world DC5 users. They discuss the feel of a seat during a tight map of corners, the way the seat’s materials perform after a long day under the sun, and how easy it is to manage seat adjustments when gloves or racing suits are part of the equation. For someone new to the scene, this experiential knowledge is often more valuable than a mere specification sheet. It translates the numbers and the claims about support into a lived experience—the sense of security when the car leans into a bend, the confidence to push the steering wheel a fraction more, and the reassurance that the seat remains a stable anchor under load. The DC5 community, in this sense, acts as a continuous feedback loop for both manufacturers and sellers, guiding the evolution of adjustable rails, padding, and available upholstery options that are compatible with the DC5’s interior aesthetic and ergonomic demands.

To illustrate the practical side of availability, consider the channels most commonly used by DC5 owners seeking sport seating. Professional modification shops that specialize in performance builds are frequently the first stop for those who demand precise fit and certified installation. These shops can assess the cockpit’s geometry, recommend a seat with compatible shell and base, and manage the installation with appropriate safety measures, including harness compatibility and adjustability testing. Online automotive parts retailers offer a broader market view, presenting multiple options and price points while providing shipping details, return policies, and compatibility notes that help buyers make informed decisions. Direct-from-manufacturer options, when available, present a different value proposition—potentially better lifespan guarantees, access to official brackets, and a clearer path for warranty coverage should a performance seat require service after installation. The existence of these diverse channels reflects a market that respects the DC5’s standing among performance aficionados and recognizes the need for flexible pathways to upgrade, depending on the buyer’s technical confidence, budget, and long-term plans for the car.

In this landscape, it is both natural and prudent to be patient and methodical. Availability is not the sole indicator of a good upgrade. The right seat is one that aligns with the DC5’s dynamics, supports a comfortable driving posture for the driver’s body type, and can be integrated without eroding the car’s structural safety nets. The buyer’s decision often hinges on a balance between immediacy and reliability: if a seat is readily available, is it the correct fit for the vehicle’s harness system and seat rail geometry? If a seat is sourced through a specialist shop, does the shop offer a turnkey solution with installation that preserves track-ready safety without imposing a heavy installation burden on a daily-driver platform? And if the only viable option is a lightly used or refurbished seat, does the price reflect the seat’s condition, its padding integrity, and the absence of structural wear that could compromise performance under track conditions? These questions embody the essence of the DC5 seating upgrade journey and highlight why, for many enthusiasts, the market’s availability narrative is inseparable from the car’s driving philosophy.

The practical takeaway for anyone navigating this space is simple in its core: seek a solution that respects the DC5’s compact, driver-centric cockpit while delivering the performance and confidence that RECARO’s design philosophy promises. This means asking targeted questions about fit, compatibility, and long-term durability. It means recognizing that a seat is not just a surface to sit on but a tool that shapes the car’s psychology—the way the car communicates with the driver through tactile feedback and perceived mass distribution. It also means acknowledging that availability will vary by region and by the level of customization you are prepared to undertake. In some situations, a patient buyer who can wait for the right setup—one that provides both a solid hold and a reasonable weight penalty—will eventually secure a solution that feels inevitable once installed. In others, a more proactive approach, combining measurements, shop consultations, and a willingness to adapt rails or brackets, will turn an occasional impulse purchase into a lasting performance upgrade.

For readers who want a concrete starting point in this quest, there is a pathway that aligns with the DC5’s unique constraints and the RECARO seating philosophy. A DC5-focused semi-bucket option, for instance, represents a practical balance between rigidity and practicality. This kind of seat often exists in listings that emphasize universal rails, straightforward mounting patterns, and upholstery choices that can withstand daily use while still offering the racer’s containment around the torso and hips. The interest in such options reflects a broader trend: enthusiasts are seeking seats that can preserve the car’s nimble weight distribution while delivering the ergonomic support necessary for aggressive driving. If you are exploring this further, you may encounter listings that position themselves with clear notes on shipping, duties, and installation readiness. These details can be critical when evaluating whether a seat will slot into your DC5 without a protracted installation period or significant additional fabrication.

As this market continues to mature, the DC5 community’s collective experience helps with the decision-making process. It is not just about finding a seat that fits the car’s geometry; it is about confirming that the seat will maintain its performance characteristics under load, endure the stresses of track work, and remain comfortable enough for long-day sessions. The interplay between seat design, chassis dynamics, and the driver’s evolving series of preferences means that the availability map is iterative. New rail systems, revised mounting brackets, and updated upholstery fabrics can shift the perceived value of a given option. The chapter of the DC5 seating story, therefore, is not closed with a single purchase; it continues as owners share install notes, post-year reviews after long road trips, and contribute to a more resilient understanding of what makes a seat truly suited to the DC5’s spirit of nimble, engaged driving.

For readers seeking a direct pointer into the market landscape, the DC5-specific semi-bucket front Recaro seats page offers a concise snapshot of current listing options and mounting considerations. This resource helps bridge the gap between high-level market realism and practical, hands-on decisions about fitment, comfort, and safety in the DC5 cockpit. DC5 semi-bucket front Recaro seats. Even as such listings illustrate a path to upgrade, remember that the ideal choice for your DC5 is one that harmonizes with your own driving goals, whether those goals are daily usability, weekend track sessions, or a blend of both. The interplay of availability, compatibility, and user experience remains central to achieving that harmony, and it is this balance that keeps the conversation about RECARO seats for the DC5 chassis both practical and endlessly engaging.

In closing, the market availability story for RECARO seating in the DC5 chassis is less a binary of in-stock versus out-of-stock and more a continuous negotiation among fit, safety, weight, and driver confidence. It reflects a community that prizes control and connection with the machine, and it demonstrates how, in the realm of performance upgrades, availability is as important as capability. The DC5’s enduring popularity owes much to this dynamic: a chassis that rewards precise, well-informed upgrades and a culture that helps each owner navigate the complexities of fitment with clarity and trust. When a seat finally meets the needs of the car and driver, the DC5—the little performance icon that could—feels suddenly more assertive, more communicative, and more thoroughly alive to the thrill of the road. External resource: https://www.recaro-automotive.com

Weight, Grip, and Precision: The Materials and Design of DC5 Recaro Seats

The cockpit of a Civic from the DC5 era is a study in how driver confidence and chassis communication begin with a seat that can hold you in place without fighting you. For enthusiasts who chase corner speeds and linear, predictable feedback, the seating system is not an afterthought but a fundamental part of the car’s dynamic equation. In this chapter we explore how the materials and design choices behind a DC5 compatible full bucket seating solution blend performance, comfort, and engineering rigor. The approach is not about novelty for novelty’s sake; it is about creating a seat that translates the driver’s inputs into controlled motion, even when the tempo rises toward the edge of the tire’s adhesion. The story begins with the rail system that anchors the seat and ends with the kind of material innovation that reduces weight while increasing strength and resilience under stress. It is a story of what it takes to keep a driver secure, comfortable, and aligned with the vehicle’s intent during spirited, trackable driving and daily usability alike.

At the heart of the DC5 seating experience is the rail system that carries the seat itself. Recaro’s full bucket designs are anchored by slide rails built for high rigidity and precise positioning. The emphasis on rigidity is not a stylistic preference; it is a quality born from the need for repeatable seating geometry under dynamic loading. When a driver shifts weight during a hard corner, the seat should not flex in a way that whispers inconsistency into the driver’s sense of balance. Instead, the rails must respond with a clean, repeatable response that supports both the torso and the hips while maintaining stable contact with the thighs. In practical terms, this means the rails resist twist and deflection even as lateral forces peak. For road or track use in a DC5, that translates to more consistent steering feel, improved pedal timing, and a more reliable platform for even the most demanding driving styles. The result is a seated experience that remains predictable as grip levels wax and wane, a foundational attribute for anyone who traces a line through a set of corners with intention.

The material composition of the seat shells and their rail assemblies tells a parallel story about weight, stiffness, and sustainability. Recaro has pushed the envelope by introducing recycled carbon fiber into seat shells, replacing a portion of traditional short-cut glass fiber with dry recycled carbon fiber sourced from industrial waste streams. This choice reduces weight—about a 1.4 kilogram (3.08 pounds) reduction compared with previous glass fiber models—without sacrificing the rigidity and strength needed to maintain driver containment. The shift toward recycled carbon fiber is more than a single performance metric; it signals a design philosophy that treats seat shells as critical structural components. For high-performance variants within the Recaro range, where the demands of driver containment and structural integrity are most intense, this material approach provides an important balance between lightness and safety.

In the DC5 context, the shell material’s role is to distribute the dynamic loads that arise when the vehicle is pushed aggressively through corner arcs. The goal is to maintain a controlled deformation profile that keeps the driver centered in the supportive saddle of the bucket seat, ensuring the hip and shoulder areas stay in contact with the shell and shield the torso from excessive movement. The effect is a sense of immovability that paradoxically grants greater freedom of movement in the hands and feet. This design aim is intimately linked to the broader engineering approach of the brand, which consistently seeks a harmony between ergonomics, durability, and premium aesthetics. The seat shell must not only hold its own under lateral G; it must also accommodate a driver’s body during long sessions, providing breathability and comfort that do not compromise containment. In this light, the use of recycled carbon fiber is a practical leap toward a lighter, stiffer structure that better resists fatigue over time, a key advantage when a seat endures the micro-movements of aggressive driving and the macro-loads of endurance sessions.

The DC5 seat rail itself, while the specifics of core materials are not always published in every public document, is clearly engineered to withstand the dynamic forces that accumulate during spirited driving. The core materials are typically high-strength steel or advanced alloys chosen for their combination of rigidity, yield strength, and long-term durability. The design priority is to ensure that the seat remains immovably in place when the driver is under heavy lateral load, yet still allow for precise, repeatable adjustments for different drivers or track configurations. This balance between immovability under load and adjustability during routine use is a subtle but crucial aspect of high-performance seating. It also speaks to a broader philosophy seen across the high-end seating families: you want a seat that can reliably support you when the car demands peak responses, while remaining comfortable enough for everyday driving. The challenge is to achieve both with a structure that is not so heavy that it erodes performance gains, but not so flexible that precision is sacrificed.

The design philosophy of these seats is thus a fusion of ergonomics, durability, and style, a theme that runs through the entire Recaro lineup. The emphasis on driver containment is not simply about preventing movement; it is about enabling the driver to inhabit a seat that fosters confident micro-adjustments that translate into macro performance. The seat surfaces—whether wrapped in premium leather or high-end suede-like materials—are chosen to provide both tactile luxury and grip where it matters most. The interface between the driver and the seat surface is essential. It is here that the human factors engineer collaborates with the materials scientist, ensuring that the seat not only looks the part but also supports the body in a way that minimizes fatigue and maximizes control. Even the choice of seating cover materials matters. The fabric or leather must resist wear in high-stress areas, provide a stable friction coefficient that helps the driver stay planted through transitions, and maintain comfort across temperature fluctuations. In a DC5 application, with its reputation in enthusiast circles for precise, track-ready responses, the seat becomes a tangible extension of the driver and the car’s chassis personality. The seat and the chassis have to feel as though they are tuned to the same tempo, with the seat acting as a fixed, reliable anchor that translates the driver’s intent into the vehicle’s kinetic energy.

As with any performance upgrade, the DC5 owner must consider compatibility and installation realities. The seating system is not a purely cosmetic improvement; it interacts with the car’s seat rails, mounting points, and, in some cases, the occupant classification system or airbag logic. The installation process for a full bucket seat on a DC5 is a careful exercise in alignment, clearance, and safety. The rails are chosen to align with the car’s floor pan and mounting points, preserving necessary space for leg movement, pedal travel, and steering wheel clearance. It is not unusual for enthusiasts to recalibrate pedal box position or adjust steering column height in concert with seat installation to maintain comfort and control across a broad range of driving scenarios. The need for precise fitment is not a mere afterthought; it is part of the rational design process that ensures the seat works harmoniously with the table stakes of modern driving—driver safety, vehicle control, and a consistent, repeatable driving position. A well-engineered DC5 seating setup gives you a feeling of being firmly connected to the vehicle, a sense that your body and the car are moving as one through corners, straights, and the transition between extremes of grip and slip.

Inconsistencies between seat fitment and driver body size can obscure the real benefits of high-performance seating. This is why the modern DC5 style bucket is often adjustable across multiple axes: height, rake, and fore-aft positioning all contribute to a driver’s ability to adopt a posture that maximizes leverage and minimizes fatigue during long sessions. The more precise the rail system and the seat’s own geometry, the more consistent the feedback, which translates into the driver being able to push the car toward its limits with greater confidence. The emotional result is not simply a tighter hold on the body but a more open line of communication between the driver’s hands and the car’s front axle response. It is this kind of tactile clarity that converts a seat upgrade from a cosmetic improvement into a performance enabler, turning a DC5 into a more capable tool for skilled driving.

The broader ecosystem around these systems includes the availability of rails and mounting platforms that ensure compatibility with a range of aftermarket tracks. In some markets, you may find DC5 compatible options that are marketed for both street and track use, offering a balanced compromise between daily comfort and track performance. The thorough engineering behind the rail and shell combination enables a level of safety that matters, particularly for those who push the vehicle toward its limit on a regular basis. The seat becomes a critical element in an integrated approach to performance that does not neglect daily usability. For the DC5 owner, this means embracing a seating system that can both cradle for long, comfortable drives and clamp down for aggressive track days without requiring a different car or a second, race-specific cockpit. The result is a more versatile vehicle, one that can be driven to the track and then returned to a daily routine with minimal compromise to the driving experience.

One small but meaningful note about the practicalities of choosing a DC5 seating option is the availability of different covering materials and trim levels. Premium materials may contribute to comfort during long sessions, while higher-friction surfaces help maintain positioning during aggressive maneuvering. The choice of material, however, should be guided by the driver’s priorities: maximum hold and support in corners, or a blend of grip with enduring comfort for daily driving. Either path, when paired with a properly engineered rail system and a carefully designed shell, will deliver a more connected, engaging driving experience. For readers who want to explore a DC5 specific option further, consider the DC5 semi-bucket front Recaro seats, discussed in automotive parts communities and vendor catalogs. This option demonstrates how a seat can be tailored to the Civic’s cockpit while preserving the essential balance between weight, rigidity, and driver containment. dc5-semi-bucket-front-recaro-seats

The larger story behind these engineering decisions is one of continuous improvement. Recaro and similar manufacturers regularly push on the edges of material science, ergonomics, and safety testing to deliver seats that keep pace with evolving vehicle performance requirements. The DC5, already a favorite among a generation of enthusiasts for its approachable performance envelope, benefits from seats that can translate that envelope into real-world, repeatable performance. In practice, that means a seat rail that does not flex under pressure, a shell that resists fatigue after hours of aggressive driving, and a surface that keeps the driver locked in place without becoming uncomfortably restrictive. It also means that the seat is easy to install and adjust for different drivers, which is essential for shared-use cars, sports-wocused daily drivers, and track-prepped machines alike. This is not simply about speed or cornering; it is about the confidence that a driver gains when the seat and chassis behave as one cohesive unit.

If the story ends with a practical takeaway, it is this: the DC5 seating solution is most effective when it is part of a holistic approach to performance that respects weight, rigidity, and ergonomics as interdependent factors. The small weight savings from recycled carbon fiber, the rigid rail system that preserves seat geometry, and the ergonomic shell design all contribute to a driving experience that feels precise, controlled, and intuitive. For the DC5 owner who wants a seat that respects the car’s heritage while embracing modern engineering, these elements offer a path forward that remains faithful to the underlying goal of high-performance driving: to connect driver intention with a predictable, communicative chassis response. For readers who want the most current, technically informed context on seat material innovation, see the broader industry discussion about recycled carbon fiber in seat shells, which illuminates why such materials are increasingly selected for high-performance seating. Further reading: Recycled carbon fiber in seat shells.

Final thoughts

The RECARO SR4 seats for the Honda Civic DC5 represent a superior choice for performance-oriented vehicles, combining necessary safety features with unparalleled comfort and aesthetic appeal. For business owners involved in automotive sales or enhancement, recognizing the value of integrating high-performance seating can enhance vehicle offerings and drive customer satisfaction. Understanding their performance capabilities, installation compatibility, market presence, and the quality of materials used in their design ensures that decisions made can lead to increased business success and customer safety. Investing in RECARO SR4 seats is not merely about enhancing a car’s interior but about providing a high-end driving experience that resonates with performance enthusiasts and leads to better sales outcomes.