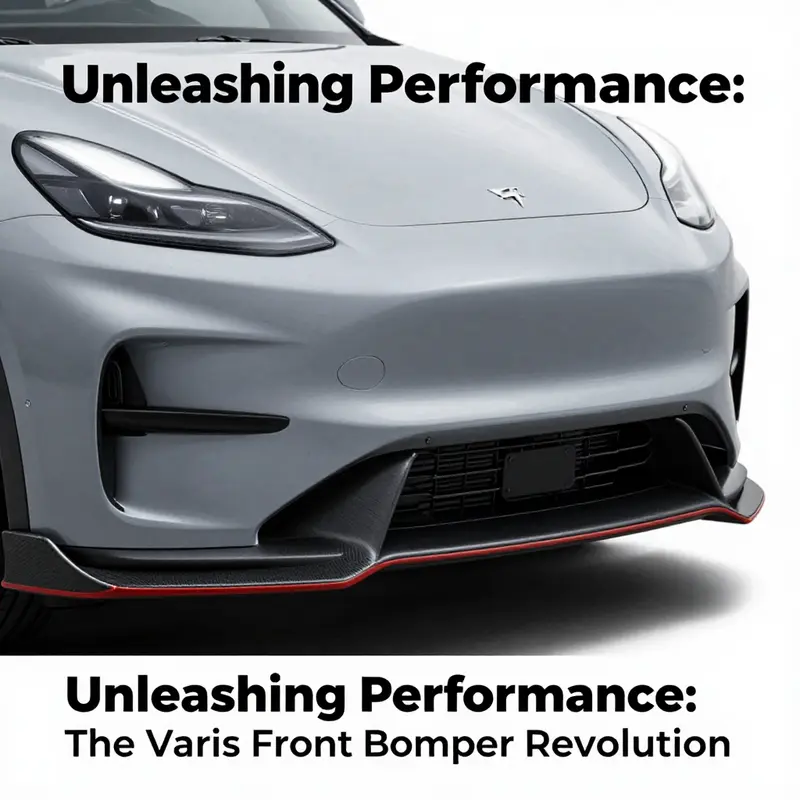

The Varis front bumper, crafted by the renowned Japanese brand Varis, represents more than just a striking automotive accessory; it amalgamates aesthetics with aerodynamic efficiency. These bumpers are tailored for high-performance models such as the Subaru WRX and Toyota Supra, making them popular amongst car enthusiasts and professional racers. Understanding the intricate design elements, performance benefits, material composition, and market dynamics associated with Varis front bumpers can empower business owners to make informed decisions in the automotive aftermarket industry. As we delve into each chapter — from airflow optimization to material manufacturing processes and market availability — we aim to illuminate how Varis front bumpers play a pivotal role in enhancing both vehicle performance and appeal.

Shaping the Wind: How Varis Front Bumpers Sculpt Airflow for Grip and Cooling

Shaping the Wind: How Varis Front Bumpers Sculpt Airflow for Grip and Cooling

A front bumper is more than a face for a performance car. It is the first aerodynamic element to meet oncoming air. In Varis front bumper design, every curve, opening, and edge has a purpose. The goal is clear: control the airflow to improve stability, increase cooling, and extract measurable gains in traction and balance. This chapter explores how those objectives are achieved through deliberate shaping, splitter placement, intake routing, and computational refinement.

The signature of a performance bumper begins with its front splitter. Varis pieces typically include a pronounced lip that extends forward and downward. When moving at speed, that lip divides air around the car and creates distinct pressure zones. Above the splitter, a relatively higher pressure region forms. Below it, a low pressure field appears. This difference generates a net downward force on the vehicle nose. That force is not dramatic like a full wing, but it reduces lift at the front axle. Less lift translates to firmer steering feel and better weight transfer under braking and cornering.

Splitter height and angle are critical. Too low and the splitter scrapes, damaging components and upsetting airflow with sudden contact. Too steep or too high and the low pressure beneath the car weakens. Varis designs position the splitter using precise angles derived from testing. Those angles guide the air smoothly under the chassis, preventing the chaotic vortices that sap stability. The splitter also channels more consistent air to the radiator and intercooler, which is essential during extended high-load driving.

Beyond the splitter, the bumper’s side profile matters. Varis often sculpts the cheeks and openings so that the airflow down the flanks is accelerated and guided toward the wheel arches and undertray. The slanted surfaces reduce the pressure differential between the car’s upper and lower regions. That reduction lowers drag while allowing a controlled increase in downforce. The beauty of this balance is that it produces added grip without an excessive drag penalty.

Strategic air intakes are another hallmark. A performance bumper must feed the engine and cooling systems, and Varis integrates intake geometry that prioritizes both volume and velocity. Intake shapes are tuned to capture ambient air efficiently while reducing the formation of separation bubbles that harm pressure recovery. The result is improved cooling airflow to the radiator and intercooler core, and a reduction in underhood heat soak during track sessions. Cooler intake air supports more consistent engine output and reduces thermal stress on components.

The interplay between front-bumper aerodynamics and engine cooling is subtle but potent. By directing a portion of the incoming flow through carefully sized ducts, the bumper ensures the radiator receives steady, pressurized air. That pressurization matters because it counters the back-pressure created by tightly packaged engine bays. With higher dynamic pressure at the cooling cores, heat exchange improves. The car sustains higher performance for longer during demanding runs.

Numerical simulation underpins many of these design decisions. Computational fluid dynamics (CFD) allows designers to visualize pressure gradients and streamline interactions long before any part reaches a carbon shop. Varis employs simulations to refine bumper inclination, lip geometry, and intake placement. CFD reveals how small changes influence the pressure field under the car. Designers iterate on the geometry until the flow separation points move to favorable locations. This process yields a bumper that elevates downforce without imposing undue drag.

A well-designed bumper also addresses turbulence around the front wheels. Wheel-induced vortices can create lift and drag. By opening or closing specific vents and shaping the bumper rails, Varis reduces this turbulence. The bumper guides airflow away from the rotating wheels and wheel wells. That reduces the chaotic low-pressure pockets that otherwise unsettle the car in high-speed corners. Less turbulence improves aerodynamic predictability, making the car easier to place mid-corner.

Material choice intersects with airflow optimization. Varis commonly uses carbon fiber for critical surfaces. Carbon fiber offers stiffness and a superior strength-to-weight ratio. A rigid splitter holds its designed geometry under load, ensuring airflow paths remain consistent. Flexible materials can flex at speed, altering splitter angle and disrupting the pressure balance. Lightweight components also lower front mass, which can improve steering response and reduce overall load on suspension components. The combined effect is more predictable handling and stable aerodynamic performance.

Integration with wider body elements is often necessary. When bumpers are part of a widebody conversion, the expanded fenders create more room for larger tires. Wider tires improve mechanical grip, but they also change the airflow around the car. Varis bumpers account for these changes by smoothing the transition between bumper and fender. This smoothness helps maintain laminar flow along the sides and reduces wake size behind the front wheels. The outcome is a coherent aerodynamic package that leverages both increased mechanical grip and refined airflow management.

Testing in wind tunnels and on-track verifies what simulations predict. Wind tunnel testing quantifies lift and drag at specified speeds and yaw angles. Track testing confirms driver impressions and thermal behavior under real conditions. Both methods are essential. Tunnel data isolates variables, allowing engineers to measure the exact contribution of the bumper. Track data validates how those contributions behave when suspension compresses, tires flex, and temperatures rise. The combination ensures the bumper delivers on its promises in real-world driving.

For drivers who push their cars on circuit days, the cooling benefits often matter more than the small downforce gains. Sustained laps generate heat, and thermal management becomes the limiting factor. By improving directed airflow to cooling devices, a well-engineered bumper delays the onset of overheating, reduces thermal throttle cutoffs, and improves component longevity. The cooling advantage is therefore both a performance and reliability gain.

At the same time, designers balance street practicality. A bumper that performs brilliantly in clean wind tunnel conditions might not suit daily use if it is too low or requires constant vigilance over potholes. Varis designs frequently aim for a compromise. They keep critical edges protected while maintaining effective aerodynamic profiles. That balance allows enthusiastic drivers to enjoy aerodynamic improvements without sacrificing everyday usability.

Fitment precision is part of aerodynamic success. Panels that align with factory mounting points preserve the intended air paths. Gaps and misalignments can create turbulent pockets and pressure losses. That is why quality mounting hardware and accurate molds are essential. Proper installation ensures the splitter angle and intake orientation match the engineered profile. When panels fit correctly, the aerodynamic performance remains consistent across vehicles of the same model.

Installation also allows for some customization. Adjustable splitters and additional canards let drivers tune front-end balance. Small adjustments can shift the aerodynamic bias, accommodating changes made elsewhere on the car, such as new rear wings or altered ride height. This tuning flexibility empowers drivers to refine balance for specific tracks or driving styles.

Maintaining aerodynamic performance over time means preserving the bumper’s geometry and the cooling inlets. Carbon fiber edges are vulnerable to chipping, and mounting points can loosen with vibration. Periodic inspection keeps the intended airflow paths intact and ensures cooling channels remain unobstructed. Cleaning the ducts and correcting minor damage can restore much of the original performance without expensive replacement.

Ultimately, a Varis front bumper is a lesson in purpose-driven shaping. It uses splitter geometry, side profiles, intake routing, and material choice to manage pressure fields and direct airflow. The benefits are tangible: reduced lift, improved high-speed stability, enhanced cooling, and the option to widen mechanical grip. Designers rely on CFD and track validation to ensure those benefits translate from theory to throttle. For drivers seeking predictable handling and better thermal durability, a thoughtfully engineered front bumper is a meaningful upgrade.

For a focused example of how front bumper inclination affects aerodynamic behavior, see the detailed engineering study here: Front Bumper Inclination on Vehicle Aerodynamic Performance – MDPI.

For those interested in a real-world application of this design philosophy on popular models, review the Evo 8/9 implementation that pairs a performance bumper with a carbon lip for improved airflow and splitter stability: Evo 8/9 Varis front bumper with carbon lip.

Precision Aerodynamics: How a Tailored Front Bumper Elevates Performance on Select Performance Models

Within the realm of high-performance tuning, the front end of a car is far more than a cosmetic statement. It is a carefully engineered control surface that shapes how air interacts with the chassis, the powertrain, and the braking system. A purpose-built front bumper becomes a tool that choreographs flow, pressure, and heat, turning aerodynamic theory into tangible gains at real-world speeds. When the bumper is designed for a specific model, the gains often multiply. The geometry is aligned with the car’s crease lines, its weight distribution, and the way air travels along the underbody. The result is not merely a more aggressive look; it is a coherent system that translates air into grip, cooling, and composure at speed. The front end thus becomes a hinge between aesthetics and performance, marrying form to function while remaining faithful to the vehicle’s baseline characteristics.

In aerodynamics, the splitter and the leading edge are not decorative features; they are active devices. A model-specific bumper typically integrates a front splitter that directs flow beneath the car, guiding air away from turbulent zones around the front wheels. This reduces the chaotic eddies that can destabilize the chassis at high speeds and in high-load corners. What makes a tailored bumper especially effective is the way the geometry is tuned to the car’s overall balance. The air that slips along the bumper is guided with precision, so the front axle receives a controlled amount of downforce without introducing excessive drag. The result is improved front-end grip, more predictable turn-in, and a higher threshold for trail-braking without the car feeling twitchy or unsettled as the speed climbs. A wider aero philosophy—combining the bumper with side skirts and a rear diffuser—can further refine how air moves from the nose to the tail, creating a more harmonious pressure distribution across the underbody and reducing the wake that lingers behind the vehicle.

Equally important is the role of cooling and heat management. Performance engines and braking systems generate substantial heat, especially during spirited driving or track sessions. A bumper engineered for a particular model often features larger or strategically placed intake openings and ducting that direct cooler air toward the engine bay and toward the brakes. This targeted cooling helps maintain peak power and minimizes brake fade, which can compromise pace and consistency on longer runs. The ducting paths are not arbitrary; they are designed to complement the car’s radiator layout, hood geometry, and brake component placement. The outcome is a front end that does more than channel air for downforce. It preserves thermal margins, allowing the engine to maintain throttle response and the brakes to sustain consistent performance under load.

Weight is another pillar of performance that a model-specific bumper can influence. Modern performance composites—such as carbon fiber-reinforced plastics or advanced polyimide-infused laminates—offer high strength with minimal added mass. A lighter front end reduces the car’s overall rotational inertia and shifts more of the vehicle’s mass toward the center of gravity. The benefit is felt most in steering responsiveness and in the car’s ability to change direction quickly and with confidence. The effect compounds when the bumper is part of an integrated aero package. Pairing a lighter bumper with equally light panels or a carbon hood can yield a more agile front end, improving turn-in and reducing the effort needed to maintain a high tempo through corners. Importantly, a high-quality, model-specific bumper preserves the structural integrity and crash energy paths—ensuring safety standards are maintained while delivering the expected performance benefits.

Another practical advantage of tailoring a bumper to a specific model is the likelihood of OEM-level fitment. A bumper built for a given chassis typically includes precise mounting points, consistent gaps, and alignment tolerances that respect the car’s existing radiator support, bumper mounts, and sensor layouts. This minimizes the need for invasive modifications and helps preserve warranty considerations where applicable. A precise fit also reduces the risk of airflow interference caused by misaligned edges or gaps that can disrupt the intended pressure fields. When installation is performed by qualified technicians, the result is a front end that looks like it belongs on the car from the factory and behaves like a purpose-built performance component on the road and on the track.

From the driver’s seat, the benefits extend beyond measured numbers. A well-executed bumper contributes to a perception of stability at the limit. A front end that maintains grip during aggressive corner entry sends a subtle signal to the driver: the chassis is more planted than before, and the steering response is more immediate. The sensation of weight transfer to the front tires becomes more predictable, which encourages a cleaner line and more confident throttle modulation through bendy sections. This psychological dimension is part of the performance story, because confidence in the front end translates into consistency over laps and more precise steering input under dynamic load. It is not only about how hard the car can push; it is about how predictably and how early the car can react to driver intent.

The concept of a model-specific bumper grows even more powerful when viewed as part of a broader aero philosophy. A bumper alone can deliver meaningful gains, but the true potential emerges when it sits within a holistic package. Side skirts widen the effective track and help direct air along the undercarriage, while a properly engineered rear diffuser helps manage the rear wake and reduce indeterminate turbulence at the back of the car. The combined effect is a balanced aero platform in which the front and rear work in concert rather than at cross purposes. In this sense, the bumper becomes a keystone in a chassis architecture designed for higher-speed stability, easier cornering, and sustained performance under load. To illustrate the practical integration of a high-performance bumper within a broader aero approach, consider the case of a front-end assembly that pairs a carbon lip with a contoured splitter. This configuration demonstrates how material choice, edge geometry, and duct routing work together to deliver real-world advantages on a track-focused build. See how the front-end package can be visualized here: Evo 8/9 Varis front bumper with carbon lip.

The broader lesson is clear: when a bumper is designed for a concrete model, it is more than a cosmetic upgrade. It is an aerodynamic tool crafted to respect the car’s native geometry and to exploit the vehicle’s inherent strengths. The result is not just a sharper silhouette, but a front end that actively contributes to grip, cooling stability, and overall chassis balance. The approach makes sense for enthusiasts who understand that performance is a system-level attribute—where every piece must work in harmony with the others to deliver the kind of confidence that allows a driver to push the envelope with precision.

For readers who are curious about how these principles apply in practice, the lesson remains the same across brands and chassis lines: tailor the front end to the car. This may mean adopting a larger, more aerodynamically efficient splitter for the nose, adjusting duct positions to feed cooling air more effectively, and selecting materials that minimize weight while preserving safety margins. It also means recognizing the limits of a single part. An improved bumper can unlock a new baseline of performance, but maximum gains come when the bumper is part of a coordinated program that includes suspension tuning, tire selection, and braking optimization. In that context, the front bumper is not merely a feature; it is a strategic component that defines how aggressively a car can accelerate toward its performance potential.

As a closing reflection, it is worth acknowledging that the car community values authenticity and engineering transparency. Model-specific front bumpers embody that ethos by offering a solution that respects the car’s original intention while elevating its capabilities. The result is a vehicle that not only looks more formidable but also behaves more predictably at the limit. Enthusiasts who balance performance with daily usability will appreciate that a well-chosen bumper can deliver meaningful gains without sacrificing reliability, comfort, or the car’s established identity. The narrative around such a modification is therefore not about spectacle alone; it centers on how thoughtful design can translate into measurable, track-ready performance while preserving the everyday appeal that drew drivers to the car in the first place.

External resource: https://en.wikipedia.org/wiki/Automobile_aerodynamics

Under the Skin: Material Composition and Crafting Techniques of Varis Front Bumpers

The front end of a performance-oriented car is more than a visual statement. It is a carefully engineered interface between the engine bay, the road, and the atmosphere through which air must travel. In this space, the choice of material and the method of manufacture do far more than shape appearance; they determine weight, stiffness, crash performance, and how air is directed toward the radiator, intercooler, and brakes. For bumpers inspired by a renowned tuning lineage, the material palette is both a practical decision and a design language. Across Varis-style front bumpers, two broad families emerge: fiber-reinforced composites and engineered plastics. Each family carries its own set of trade-offs, tuned to different goals—ultra-lightweight performance, tactile stiffness, cost efficiency, and the unmistakable aesthetic of high-end weave or a matte, uniform surface.

In many of the premium configurations, the core material is a fiber-reinforced composite. Here, the base matrix is combined with reinforcing fibers—carbon fiber or fiberglass—to create a laminate that is exceptionally stiff for its weight. Carbon fiber, when used in a front bumper, is celebrated for its lightness and high strength. It offers a remarkable stiffness-to-weight ratio that helps keep the unsprung weight down and can contribute to sharper handling characteristics, especially when paired with a broader aero package. The surface finish commonly associated with these parts is a matte black fiber appearance, which highlights the weave or the smooth, unidirectional finish of the fibers. The beauty of this choice lies not only in the look but in how the lamination can be tuned to meet load paths around the bumper’s corners, where vibrations and minor impacts tend to concentrate. In a well-executed CFRP bumper, the layers are laid with precision to optimize energy transfer in a minor collision and to resist cracking during daily use, fuel-sipping on weight while preserving strength where it matters most.

The manufacturing method paired with carbon or fiberglass is typically a resin-infused process. Epoxy resin infusion, often executed through vacuum-assisted methods, allows manufacturers to saturate dry fiber preforms with resin in a controlled environment. The result is a dense, uniform laminate with fewer voids than simple hand lay-up. Venting and bagging techniques ensure that resin flow fills every fabric tunnel, producing a consistent thickness and an intact fiber architecture. Vacuum molding or hand lay-up accompanies these infusion steps, depending on the scale of production and the desired surface outcome. The infusion approach is praised for its light weight, reduced resin-rich zones, and the potential for high-tensile performance at the critical load-bearing areas around the bumper’s mounting points and lower edge where airflow transitions into the wheel wells.

But not every Varis-inspired front bumper sits on a CFRP pedestal. For a broader market, especially where price sensitivity is a priority, some kits employ engineered plastics such as ABS or polyurethane. These materials are easier to mold and finish, and they lend themselves to high-volume production with consistent tolerances. ABS, for instance, can be vacuum-formed into complex shapes and can accept textured finishes or paint with good adhesion. Polyurethane is resilient, capable of absorbing minor impacts, and it can be tuned to mimic certain stiffness characteristics of composites while keeping the price point more accessible. The downside is the weight difference and, in some cases, reduced stiffness compared with carbon fiber or fiberglass laminates. Yet for a certain generation of enthusiasts who want the aggressive silhouette and a robust, serviceable shell, ABS or polyurethane variants offer a compelling balance of form, fit, and function.

A nuanced picture emerges when you consider “Varis style” as a design language rather than a single material recipe. Premium variants explicitly marketed as carbon-fiber or CFRP often rely on resin infusion or vacuum molding techniques to achieve the superior stiffness and the clean, uninterrupted planes that the aesthetic demands. In those cases, the bumper components are not merely shells; they are engineered assemblies with carefully considered wall thickness and layup sequences designed to preserve impact resistance while keeping weight low. The result is a part that can be integrated with confidence into OEM crash structures and mounting systems, with an attention to tolerances that minimizes gaps and misalignments after installation. This attention to compatibility is not an afterthought; it is an integral aspect of the design, ensuring that the visual aggression of the bumper is matched by a precise fit that does not require excessive trimming or field modification.

The manufacturing narrative also includes post-processing and finishing, which are essential to the final look and feel of the bumper. Even when the core is CFRP, the outer surface is often treated to protect the resin matrix and to deliver the finish that customers expect. The weave, if present, is typically sealed with a clear coat that both protects against UV exposure and maintains a consistent gloss or matte appearance. For those preferring a uniform “carbon look” without visible weave, the finished surface can be treated to a laminated, smooth appearance that still conveys the sense of high-end engineering. The finishing step is also where technicians evaluate edge quality, corner radii, and the precise alignment of the bumper with adjacent panels. The best results stem from a tightly integrated workflow—design, lay-up, infusion, curing, trimming, and finishing—all performed with a rigorous quality-control mindset.

The material strategy also speaks to integration with other performance enhancements. A widebody aesthetic often paired with Varis-style front bumpers creates additional wheel well space, allowing for wider tires and larger wheels. This combination of lighter composite skins with a broader stance has implications for aerodynamics and downforce, and it can influence how the bumper channels air toward side canards, intercoolers, and the undertray. In this way, the bumper is not just a static cover but a functional piece of the vehicle’s aerodynamic system. Engineers plan the bumper’s thickness, internal stiffeners, and the location of venting channels to ensure a smooth flow of air, minimizing separation at high speeds and reducing the tendency for the front end to experience lift. The decisions in material choice and manufacturing method reverberate beyond weight savings; they influence how the entire front-end package behaves in fast, demanding driving conditions.

When we examine the Evo 8/9 variant specifically, a striking example of the CFRP and resin-infusion approach can be observed in the front bumper with a carbon lip. This configuration embodies the synergy between advanced materials and disciplined manufacturing. The carbon lip is not merely decorative; it serves as a high-stiffness, low-drag edge that works with the rest of the bumper’s geometry to maintain consistent airflow along the bumper’s lower edge. The use of infusion techniques ensures that the resin is not merely an adhesive layer but an integral part of the laminate’s load path. The result is a panel that resists bending under wind pressure while preserving the crisp lines that define the model’s aggressive face. For readers who want to see this principle in action, one representative reference shows how the carbon lip and CFRP structure deliver both aesthetic clarity and structural integrity in a single package. You can explore this variant here: evo-8-9-varis-front-bumper-with-carbon-lip.

Repairability and service life are practical concerns that influence how materials are chosen. CFRP bumpers, though light and stiff, demand careful repair planning when damaged. Small chips can be touched up, but deep gouges may require professional repair or partial replacement. The repair process often involves resin repair or resin-rich patching that matches the original laminate’s stiffness. In contrast, ABS or polyurethane versions tend to be more forgiving for field repairs but may show color mismatch after paint, especially if an OEM-like finish is intended. Irrespective of the material, the connection between the bumper and its mounting points, the underlying crash structure, and the compatibility with the vehicle’s electrical harnesses and sensor placement must be preserved. Front bumpers in this class are not isolated shells but components within a tightly integrated system. This reality drives a design ethos that respects both the need for lightweight performance and the demands of real-world use.

The decision matrix that guides material selection, therefore, is not a single preference but a spectrum. Enthusiasts who chase ultimate lightness and stiffness may gravitate toward carbon-fiber composites with resin infusion. Those who prioritize cost efficiency and accessibility may opt for high-grade ABS or polyurethane while still appreciating the aggressive silhouette and the opportunity for widebody fitment. In either case, the manufacturing technique—the choice between hand lay-up and resin infusion, or vacuum molding and post-curing—shapes the final product’s performance envelope. It dictates how the bumper behaves under load, how it disperses impact energy, and how reliably it can be installed with precision. The artistry in these parts lies in balancing the material’s intrinsic properties with the aerodynamic intent and the user’s expectations for aesthetics and durability.

In closing, the material composition and the manufacturing techniques of Varis-style front bumpers reveal a disciplined craft that blends science with street-ready design. The spectrum—from CFRP and resin infusion to ABS and polyurethane—is not merely about cost or weight; it is about achieving a predictable, repeatable performance that aligns with a driver’s ambitions. The best examples demonstrate that when material choice and process are aligned with an aerodynamic strategy and a precise mounting approach, the bumper becomes more than a look. It becomes a reliable, integral part of the vehicle’s dynamic character, capable of withstanding the rigors of track days and spirited street drives alike. External resources and product documentation can offer deeper technical specifics, while real-world installations reveal how these decisions show up in fit, finish, and on-road behavior. External reference: https://www.ebay.com/itm/Carbon-Varis-Style-Look-Front-Bumper-Canards-FULL-SET/395248767552

Navigating Global Access and Smart Procurement for Varis Front Bumpers: Where Quality Meets Availability

The market for Varis front bumpers has evolved from a niche, locally sourced choice into a globally accessible option that many enthusiasts and professional installers now consider part of a legitimate performance upgrade. As car culture has become more interconnected, the demand for aero components that promise not just visual impact but also measurable aerodynamic benefits has surged. Buyers today approach Varis front bumpers with a mix of curiosity and caution, seeking a balance between authentic fit, material performance, and a reliable supply chain. For vehicles ranging from compact sport sedans to high-powered options, the ability to source a bumper that integrates cleanly with the vehicle’s structure and electronics has shifted from a trial-and-error process to a more informed, data-driven purchase. This shift is powered, in large part, by the expansion of global business-to-business (B2B) platforms that connect OEM-aligned studios, established modification shops, and individual enthusiasts to certified suppliers across continents. In this landscape, a Varis front bumper is no longer a simple cosmetic upgrade; it is a modular performance component that can influence handling balance, weight distribution, and even the acoustic character of the car at speed. The modern buyer is less concerned with simply acquiring a piece that looks the part and more focused on acquiring a part that fits precisely, performs predictably, and can be supported by a network of technicians and installers who understand the nuances of the brand’s design language as well as the car’s original engineering. The result is a marketplace where the promise of carbon fiber clarity and the promise of safe, compliant installation converge, and where the best decisions are made with a clear understanding of the trade-offs between material choice, production origin, and after-sales support.

For many buyers, the first practical step toward acquiring a Varis front bumper is recognizing the range of platforms that now host legitimate suppliers and verifiable product information. While direct manufacturer catalogs remain a touchstone for authenticity, global marketplaces have become indispensable in providing transparent pricing, spec sheets, and user feedback that helps buyers gauge fitment and durability before placing an order. A central example of this shift is the way Alibaba and similar B2B ecosystems aggregate suppliers who not only list exact model fitment but also publish material data, welding standards, and inspection certificates. The availability of multiple options—standard ABS or fiberglass baselines, with carbon fiber accents or full sections in carbon weave—enables buyers to tailor their choice to priorities such as weight savings, stiffness, and cost. In practice, this means a Subaru WRX owner, a Toyota Supra aficionado, or an Altezza enthusiast can compare several configurations side by side, weighing how each option aligns with their goals for downforce, aesthetic cohesion, and annual driving conditions. Such transparency also helps buyers anticipate the installation process, since technical sheets often note mounting holes, sensor clearances, and the potential need for minor fender or bumper lip adjustments. The modern market, therefore, channels the excitement of a visual upgrade into a disciplined, procurement-driven journey, where the right bumper is as much about reliability and compatibility as it is about appearance.

The core factor buyers confront early in the process is fitment accuracy. The Varis front bumper is designed with a precise interface to a vehicle’s chassis and bumper mounting points. Even if a bumper is labeled as compatible with a given model and year, subtle variations in regional production runs, trim packages, or facelift updates can alter the exact geometry. This is where the value of supplier transparency becomes critical. Buyers should request detailed fitment notes that specify model year, trim designation, and any required revisions to mounting brackets or under-hood hardware. In some cases, the bumper may be offered as part of a wider aero kit that includes a front lip, side skirts, and a widebody reinforcement. Each component must align with the vehicle’s existing safety and crash-structure design, not simply the outer silhouette. Material quality also matters in this equation. ABS plastic provides a cost-effective, impact-tolerant option that can resist environmental wear, while fiberglass offers rigidity and ease of repair, albeit with potential weight penalties. The more premium paths—carbon fiber front sections or carbon-reinforced composites—deliver stiffness, a refined surface finish, and a lighter profile, but they typically command higher prices and longer lead times. This spectrum makes supplier selection crucial, because the cheapest listing might come with inconsistent resin content, variable weave quality, or inconsistent coating, all of which could undermine both fit and long-term durability. As a buyer, a careful review of the material disclosures—down to resin system, weave weight, and finish coat—serves as a practical predictor of lifetime performance and repairability after impact.

Beyond material and fitment, compliance with local regulations and road-use standards is essential. A bumper that looks aggressive but fails to meet legal requirements or sensor integration standards risks not only a failed inspection but also compromised safety in everyday driving. Real-world legality involves several dimensions: crash structure compatibility, pedestrian safety ratings, and, increasingly, compatibility with driver-assistance sensors embedded in the bumper. For those in regions with stringent aftermarket modification rules, verifying that the bumper authorizes proper airbag and sensor operation is not just prudent, it is mandatory. Suppliers often provide documentation or engineering statements that assert alignment with certain standards or OEM-plant revision numbers, which can help buyers present a credible compliance narrative during installation or inspection. A responsible procurement path will always include a review of the documentation that accompanies the kit, along with confirmation of any warranty implications tied to non-OEM fitments or non-standard mounting procedures.

When selecting a supplier, reputation and reliability rise to the top of the decision matrix. A disciplined buyer seeks verifiable credentials, not merely a glossy product image. This means prioritizing suppliers with traceable business licenses, issuer certifications, and robust user feedback from previous buyers. The risk of ultra-low prices is never zero in the global marketplace, and prices that undercut typical market rates by a large margin often correlate with corners cut in production, quality control, or post-sale service. The prudent path is to favor authorized dealers or well-established third-party manufacturers who can guarantee dimensional accuracy and product support after delivery. In this context, the communication cadence matters as much as the price. A responsive supplier who promptly answers fitment questions, shares CAD data or measurement references, and offers post-purchase support signals a higher probability of a smooth installation and predictable afterward care. The purchase experience then extends beyond the moment of sale to include installation coordination, return policies, and potential warranty coverage. This is particularly important when a bumper is intended for large-scale or repeated use, such as in competition prep, where any misalignment or material failure can ripple into performance penalties or unscheduled downtime.

Regional manufacturing hubs in Asia, particularly in high-volume centers like Guangdong and Zhejiang, play a consequential role in shaping both the cost and the lead times of Varis front bumpers. These regions have honed rapid prototyping and scalable production, enabling shorter cycles from concept to finished product. The production ecosystems there also support a broad ecosystem of supply partners, from resin suppliers and weave technicians to finishers and packaging specialists. For buyers planning high-volume orders, leveraging regional supply chains can translate into significant cost efficiency, with figures in the 20–40 percent range relative to Western production alternatives. Yet, lower unit cost must be weighed against the importance of consistent quality control, clear serialization, and reliable logistics. Buyers should request certifications or inspection reports that reassure them of consistent outcomes across batches, especially for components that must integrate with the car’s structural and electronic systems. A well-managed procurement should also address logistics concerns such as packaging integrity, shipping insurance, and the availability of replacement parts or minor trim adjustments should a shipment arrive with minor cosmetic flaws or minor dimensional variances. In practice, a buyer can work with a reputable supplier who can commit to a staged delivery schedule, enabling testing and fitment trials before committing to a full sequence of installations. This approach minimizes downtime and enhances confidence in the kit’s adaptability to specific car configurations.

Authenticity and warranty are the cornerstones of a buyer’s long-term satisfaction with a Varis front bumper. Buyers should confirm that the bumper is designed for the target model year and variant, with a very clear statement on whether the kit is intended for OEM-level fitment or aftermarket customization. The presence of a manufacturer’s warranty—whether a limited, material, or workmanship guarantee—provides a frame of protection that can be critical when dealing with high-performance aero parts. Warranty terms often hinge on installation accuracy and adherence to recommended mounting practices, so following the installation guidelines becomes a critical extension of the warranty’s validity. In many cases, legitimate suppliers will include installation manuals, mounting templates, and sensor clearance diagrams with their packages, further reducing the risk of misfitment and unintended sensor interference. Where a warranty is not explicit, buyers should seek clarified terms and, ideally, obtain a written assurance that the kit will be supported through a reasonable service window following purchase.

The interplay of design fidelity, material choice, and supplier reliability culminates in a practical, performance-oriented purchasing pathway. A well-informed buyer will approach the Varis bumper not as a single object but as a system that interacts with the car’s aerodynamics, weight distribution, and mechanical interfaces. The aesthetic payoff—clean lines, aggressive stance, and a cohesive brand expression—must ride alongside the functional gains: improved downforce at speed, more direct airflow to the intercooler or radiator in certain configurations, and a clear, balanced silhouette that remains coherent with the vehicle’s original design language. As with any high-end automotive modification, the elegance of the final result lies in the precision of the fit, the predictability of the performance, and the confidence that the installation and ongoing maintenance will be supported by experienced professionals who understand the subtleties of this particular brand’s engineering philosophy.

For readers seeking a concrete example of a model-specific Varis front bumper, consider the Evo 8-9 variant, which exemplifies how carbon lip accents, refined lip geometry, and precisely matched mounting points come together to deliver both aesthetic and aerodynamic value. This example also demonstrates how a single product page can anchor broader decisions about fitment, supplier credibility, and after-sales support. In navigating the broader marketplace, buyers are advised to approach each purchase with a structured checklist: confirm the exact model year compatibility, review the material and finish specifications, request all mounting data and sensor clearance notes, assess the supplier’s credentials, and consider the implications of regional manufacturing differences on lead times and price. The goal is to arrive at a decision where the selected bumper not only enhances the vehicle’s appearance but also aligns with the owner’s performance targets, driving expectations, and legal responsibilities. As the market continues to evolve, the combination of transparent supplier information, robust regional supply networks, and disciplined buyer due diligence will remain the backbone of successful Varis front bumper acquisitions.

To further support informed decision-making, readers may consult a practical buying guide published on a major B2B marketplace, which outlines how to compare fitment accuracy, material integrity, and warranty terms across multiple suppliers. For a direct reference to a model-specific example and its installation considerations, you can explore this page: evo-8-9 varis front bumper with carbon lip.

External resource: https://www.alibaba.com/product-detail/How-To-Choose-The-Best-Varis-Bumper-For-WRX_1601537983938.html?src=google&spm=a2700.189072.0.0

Final thoughts

In conclusion, the Varis front bumper stands as a testament to the fusion of high-performance engineering and sleek design. For business owners in the automotive sector, understanding this product’s intricate details—from its airflow optimization capabilities to the quality of materials used—can significantly influence purchasing decisions and customer satisfaction. As the demand for performance enhancements rises, aligning your offerings with reputable brands like Varis can enhance your market positioning and attract a loyal customer base. By prioritizing quality and performance through the adoption of components like the Varis front bumper, business owners can ensure their clientele receives the very best in automotive enhancement.