The EVO X Gurney Flap is not just an aesthetic addition; it’s a strategic modification that can significantly enhance a vehicle’s performance dynamics. Designed specifically for the Mitsubishi Lancer Evolution X, this aerodynamic component provides elevated downforce at high speeds, thereby improving stability and handling. In this exploration, we will delve into the principles behind the Gurney Flap, compare materials like carbon fiber and fiberglass, walk through the installation process, assess the performance impacts on handling and stability, and review current market trends and product availability. Each chapter builds on the previous one to paint a comprehensive picture of how an EVO X Gurney Flap can transform a vehicle’s performance while appealing to business owners in the automotive aftermarket industry.

How the EVO X Uses the Gurney Flap: Aerodynamic Principles, Practical Sizing, and Track-to-Street Integration

The Gurney flap is deceptively simple, but its role on the EVO X is far from trivial. A narrow, perpendicular lip added to the trailing edge of a wing changes the airflow there. That change boosts effective camber and produces extra downforce where it matters most. On a high-performance sedan like the Mitsubishi Lancer Evolution X, carefully sized Gurney flaps on both front and rear elements help tune balance, improve cornering grip, and stabilize the car at speed.

Originally applied to inverted racing wings, the Gurney flap creates a local pressure redistribution. Air striking the trailing edge encounters the small vertical plate. Upstream of the plate, pressure rises. Downstream, a low-pressure wake forms. This pair of pressure zones effectively lengthens the wing’s curvature. The net result is more lift for the wing profile, or more downforce in racing terms. The drag penalty is modest when the flap is scaled correctly, which is why designers favor it for small, predictable aerodynamic gains.

On the EVO X, engineers and tuners use Gurney flaps to nudge the car’s aerodynamic balance. Mounted on the rear wing, a modest flap increases rear downforce and enhances traction through high-speed corners. When placed on front splitters or canards, a smaller flap helps manage vortex formation and increases front-end bite. The combination gives drivers a more neutral, predictable chassis at the limit. Because the device is passive, it requires no moving parts or complex controls, but its effect depends on height, placement, and the baseline wing geometry.

Sizing matters more than most owners expect. Wind tunnel work and published experiments show that a Gurney flap height of roughly 1% to 2% of the wing chord often yields an excellent compromise between added downforce and drag increase. For many typical wing chords on the EVO X, that translates to a flap only a few millimeters tall. Larger heights keep adding downforce up to a point, but drag scales faster and can upset balance. Incremental changes of a millimeter or two will alter the aerodynamic center. When tuning an EVO X, small adjustments to the flap height can be the difference between understeer and a balanced turn-in.

Material choice affects weight and stiffness, and therefore the consistency of the aerodynamic response. Carbon fiber is the preferred option for race-focused builds. It stays rigid under high loads and keeps added mass minimal at the wing tip. Fiberglass or reinforced polymers work well on street cars, offering lower cost and tolerance for minor impacts. Installation generally anchors the flap to the rearward edge of the existing spoiler or wing. This preserves the original aero geometry while adding the flap’s beneficial wake effects.

A practical advantage of the Gurney flap is its precision. Unlike sweeping changes to wing angle or major body mods, a small flap modifies pressure distribution without altering lift curve slope drastically. That means tuners can dial balance with less compromise. If the rear feels loose under power, a slightly taller rear flap will move the aerodynamic center rearwards and restore traction. If the nose lifts or the front loses grip, reducing rear flap height or adding a front flap can re-establish neutrality.

However, the device is not magic. Its effectiveness depends on attached flow at the trailing edge. On highly separated profiles or within heavily turbulent wakes, a Gurney flap may induce complex vortices and unpredictable drag. For the EVO X, this means the flap performs best when used alongside properly shaped wings, diffusers, and underbody management. A rear diffuser that accelerates flow under the car complements the flap’s effect on the wing. For those integrating broader aero packages, combining a tuned Gurney flap with a matching diffuser yields smoother pressure gradients and stronger, more usable downforce. For example, when pairing a rear wing flap with a carbon rear diffuser, the overall system works in harmony to stabilize the aft end and reduce unwanted buffeting. For a compatible diffuser option, see this carbon rear diffuser V-style for Evo 10 and similar models: carbon rear diffuser v-style for Evo.

On the street, drivers often want improved high-speed stability without excessive noise or fuel penalty. The Gurney flap offers a mild, efficient option. Properly sized flaps produce noticeable improvements beyond cosmetic appeal. Yet street use demands attention to local regulations, ground clearance, and practicality. Taller flaps may scrape on speed bumps or during aggressive parking. Carbon parts, while light and stiff, require careful placement to avoid brittle failure from sudden contact.

Race teams and aerodynamicists refine flap geometry beyond simple straight plates. Serrated or asymmetric edges can mitigate noise and tame vortex shedding. Asymmetric Gurney flaps may suit the EVO X when track layouts feature long, high-speed corners on one side. Modular flaps allow rapid experimentation. Many teams trial a set of small flaps with varying heights and profiles during track days. Data logging and driver feedback then determine the best compromise between lap time gains and drivability.

Installation and maintenance are straightforward but matter for consistency. Secure mounting prevents micro-movements that would change aerodynamic response at speed. Sealed joints reduce moisture ingress and prevent adhesive degradation. Periodic inspections should check for delamination, loose fasteners, or edge damage. A damaged flap not only underperforms; it can trigger unpredictable wake disturbances that degrade handling.

When tuning an EVO X, consider the broader aerodynamic context. A Gurney flap is a tuning tool more than a standalone cure. It works best with the rest of the aero package. Adjusting ride height, wing angle, and diffuser geometry will influence how the flap affects balance. Data-driven testing, whether via a wind tunnel, track telemetry, or a controlled test loop, yields the best results. Start with conservative height settings, then increase in small increments while logging times and handling notes. Driver feel is crucial; measurable downforce means little unless it translates into faster, repeatable laps.

Finally, aesthetics play a role. Many owners choose carbon fiber for its visual presence. A subtle flap adds function and a purposeful look without the visual bulk of oversized wings. Well-integrated flaps maintain the EVO X’s aggressive lines while hinting at the car’s performance potential. For those who want track-proven gains and a restrained appearance, the Gurney flap remains a smart, efficient upgrade.

For a deeper technical background on the device and its performance characteristics across airfoil types, refer to a comprehensive overview of the Gurney flap and its aerodynamic mechanisms: https://www.sciencedirect.com/topics/engineering/gurney-flap

Material Choices for EVO X Gurney Flaps: Carbon Fiber vs. Fiberglass

Choosing a rear gurney flap for the Mitsubishi EVO X is a decision measured in grams, stiffness, and long-term value as much as in aero theory. The EVO X earns its reputation from a chassis tuned for high-speed stability and aggressive cornering, where even a narrow, strategically placed flap can shift the balance of downforce across the rear axle. The material that forms that modest, edgewise blade matters because it touches every facet of the car’s behavior: weight, moment of inertia, structural integrity, and how the aero package ages under heat, vibration, and tire smoke. In this chapter, the focus is on two common paths for EVO X gurney flaps: carbon fiber and fiberglass. Each brings a distinctive blend of performance, durability, and cost, and the choice is rarely purely about one characteristic. It tends to be a composite decision that factors in how the car is used, how much money is invested in the whole aero system, and how the owner values the look of carbon fiber against the practicality of a more economical FRP option. As with most aero components, the answer is not simply which is better, but which is better for a given driving mission, a given budget, and a given tolerance for maintenance and repair.

Carbon fiber is widely perceived as the premium route for any performance component that aims to shave weight while preserving stiffness. A Gurney flap made from carbon fiber typically benefits from the material’s exceptional strength-to-weight ratio. In practical terms, that translates to a flap that contributes less unsprung mass, allowing the suspension and tires to respond more crisply to the track’s demands. A lighter flap can also slightly reduce the overall moment of inertia of the rear wing assembly, which can help the EVO X rotate a bit more readily into midcorner transitions. The stiffness of carbon fiber helps the flap resist flutter and deformation at high speeds, especially when the car is pushed hard through long, sweeping bends or at the edge of the aero envelope where the boundary layer behaves unpredictably. Enthusiasts often value this stiffness because it promotes consistent downforce; the rear tires stay planted as corner speeds rise, and steering inputs translate into predictable, linear responses rather than a fluttering, uncertain tail.

Aesthetically, carbon fiber has a visual impact that many drivers find aligning with a performance narrative. The weave, the gloss, and the depth of the finish can make the EVO X look more serious about grip and speed. The downside is not purely cosmetic. Carbon fiber parts tend to come with a higher price tag due to the labor-intensive layup, curing, and finishing processes required. The raw material cost is higher, and the finished flap may demand careful handling to avoid micro-damage from impacts that are common on public roads or on rough track surfaces. Minor dents and chips can compromise the weave and, with it, the integrity of the lamination if not addressed, which in turn may complicate repairs. The repair path for carbon fiber fragments can be more involved than for FRP, sometimes requiring professional re-lamination or patching to recover the original stiffness and surface finish. In short, carbon fiber offers a strong case for dedicated track users or enthusiasts chasing the lightest possible package and a distinct, upscale look, but it asks for diligence in maintenance and a willingness to invest in higher upfront costs.

Fiberglass, or FRP (fiber-reinforced polymer), presents a different calculus. The FRP route is often lauded for its cost-effectiveness and robust real-world durability. It is typically easier to manufacture in a wider range of shapes and thicknesses, making it a practical choice for many owners who want a quick performance uplift without the premium price tag. FRP flaps are usually heavier than carbon fiber, but the weight delta is not always decisive in street-driven EVO Xs where the car spends more time in daylight traffic than at the limit on a track. The greater resilience of FRP to impact is a meaningful consideration for daily drivers and weekend racers who navigate curbs, parking lots, and frequently changing road conditions. The ability to absorb a bump without cracking or delaminating is valuable, and repairs are often simpler and more forgiving. A gel coat finish or a carbon-look wrap can mimic the visual appeal of carbon fiber without demanding the same maintenance regime, which broadens the appeal of FRP for owners who want a more understated or utilitarian appearance.

Another meaningful distinction lies in manufacturing flexibility. FRP parts can be produced with greater tolerance for variation in thickness and curvature. This flexibility translates into easier customization and fitment on cars that have small gaps or aerodynamic paint schemes that must be preserved. That is not to say carbon fiber cannot be tailored; it simply requires stricter process control and higher costs to achieve the same degree of customization. The result is that many builders will offer a carbon fiber flap as a premium option with a tight tolerance fit and uniform surface finish, while FRP variants may arrive with slightly looser tolerances but become easier to adapt to aftermarket rear wings or different spoiler geometries on EVO X platforms.

The real-world decision, however, goes beyond the weight and the finish. The EVO X’s rear aero balance, how the car behaves at the apex of a corner, and how the tail reacts to high-speed air flows depend on multiple interacting factors: the flap height relative to the trailing edge, the curvature of the rear spoiler, and the boundary layer behavior over the deck. A carbon fiber flap’s weight savings might contribute to a more immediate response in pitch and yaw, but it is not a panacea. The flap must be properly integrated with the existing rear wing and trunk or deck lid geometry to ensure the added downforce is aligned with the car’s natural aero moment. In some configurations, lighter is better only if the rest of the aero package is tuned to take full advantage of that weight reduction. If the rear end becomes too light or the downforce peak shifts unfavorably with speed, the driver may experience a harsher tail lift or a more abrupt shift in load transfer, which can unsettle stability in late-braking scenarios.

From a maintenance standpoint, carbon fiber demands attention to impact risks and repair costs. The glossy surface can reveal micro-scratches quickly, which some owners accept as a sign of genuine performance hardware, while others see it as a visual liability. A used carbon fiber flap that has seen track duty may show delamination if inspected without the right tools, and even a small, localized repair can require curing cycles and careful masking to avoid surface irregularities. FRP, by contrast, tends to be more forgiving. It handles minor impacts with less visible damage, and when cracks do occur, the repair process—patching, resin re-bonding, and repainting—tends to be more straightforward and economical. Aesthetics still matter here; some FRP flaps are finished to resemble carbon fiber, offering a compromise that respects the budget while delivering a similar silhouette.

Fitment reliability is another practical consideration. Whether choosing carbon fiber or FRP, the flap should mount to the existing rear edge of the factory spoiler or deck with a secure bond or mechanical fasteners that no longer rely on the car’s factory structure alone. The EVO X, with its distinctive rear hatch geometry and spoiler profile, benefits from a flap that complements the line rather than fights against it. The installation process typically involves careful alignment to preserve deck symmetry, a clean bonding surface, and appropriate curing time for adhesives if used. In some cases, the flap is designed to be a simple, clip-on add-on that minimizes surgery on the car body; in others, a more integrated mounting might require minor trimming or shimming to achieve flush contact with the trailing edge and avoid gaps that could generate undesirable air leaks at high speeds.

For owners weighing carbon fiber versus FRP, a simple framework helps: define the driving mission, quantify the budget for the aero upgrade, and assess the likelihood of damage in daily driving. Track-minded users may view carbon fiber as a long-term investment that offers incremental gains in handling and steering feel, while street-oriented drivers may prioritize durability and cost-effectiveness, making FRP the sensible choice. Either path benefits from a consistent emphasis on installation accuracy, surface finish quality, and compatibility with the rest of the EVO X’s aero components. A well-chosen flap—whether CF or FRP—should feel like a natural extension of the car, not an afterthought slapped onto the rear wing. The goal is cohesion: the flap should work in concert with the spoiler, the deck, and the vehicle’s overall aero balance to deliver predictable, repeatable behavior in cornering and high-speed straightaways.

If you’re curious about how carbon fiber options can align with other EVO X components, a tangible reference point is the broader ecosystem of carbon options available on EVO-X platforms. For a tangible example of carbon fiber components applied to EVO-X aesthetics, you can explore the carbon fiber bonnet for EVO-X to understand how the same material ethos translates across a range of body parts. This example highlights how the same manufacturing discipline used for lightweight aero pieces also informs the look and feel of the car’s exterior, tying together performance cues with a unified visual language. For reference, see: https://mitsubishiautopartsshop.com/brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x

Ultimately, the choice between carbon fiber and FRP for an EVO X gurney flap comes down to how the owner wants to balance performance with practicality. Weight savings and stiffness advantages weigh in favor of carbon fiber, but budget, durability under real-world conditions, and the desired aesthetic play decisive roles as well. As with any aero modification, the flap is most effective when it is part of a thoughtfully engineered package rather than a standalone add-on. The next steps—testing, track-time feedback, and incremental aero tweaking—will reveal how the selected material performs under the EVO X’s specific weight distribution, tire setup, and driving style. In that sense, material choice is not just a technical detail; it is a fundamental input to the car’s dynamic personality on the road and on the track.

Fitting a Carbon Gurney Flap to the EVO X: Practical Installation and Setup

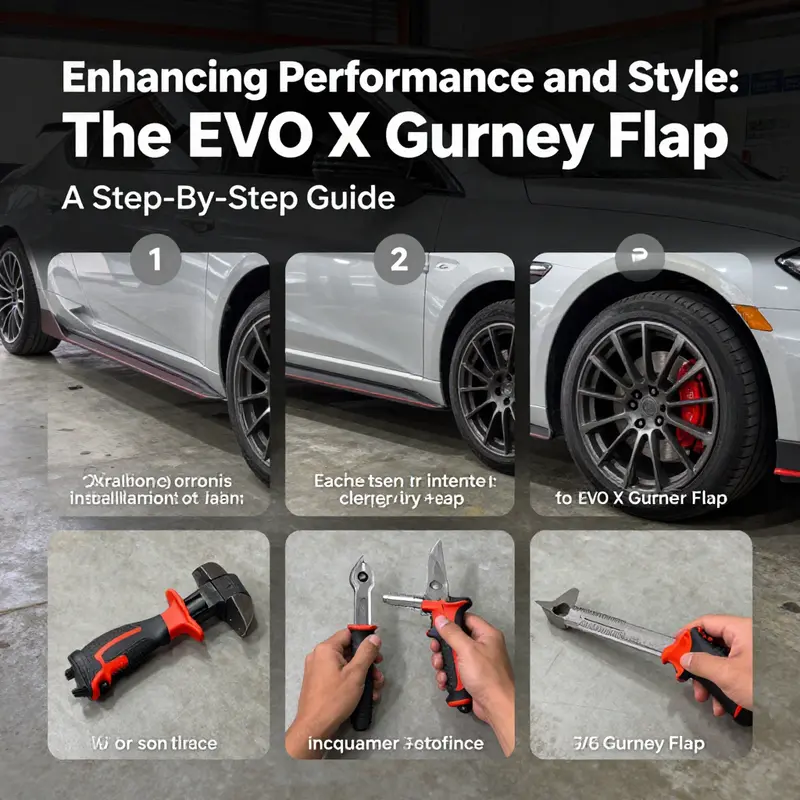

Preparing and Installing: a Practical, Step-by-Step Narrative

Fitting a Gurney flap to the rear wing of an EVO X is one of the most direct ways to influence rear-end grip without replacing the entire wing. The process follows a clear, repeatable flow: inspect and prepare, measure and mark, attach and seal, then check and tune. This chapter walks through that flow with practical detail so the installation feels deliberate, safe, and reversible when possible.

Begin by gathering the right tools and materials. You need a clean, well-lit workspace and basic hand tools: metric sockets and spanners, a torque wrench, drill with bits and countersink, rivet gun or rivnut tool if using threaded inserts, masking tape, a straight edge, measuring tape, and a marker. For bonding installations, include solvent (isopropyl alcohol), a scuff pad, structural adhesive tape, and clamps or strong double-sided tape. For fastened installs, bring stainless steel bolts, washers, and corrosion-resistant locknuts; bring small backing plates if the spoiler is thin. Wear nitrile gloves and eye protection.

Next, inspect the wing and flap. Place the Gurney flap on the trailing edge to check fit and contour. Carbon fiber flaps are stiff but may not exactly match every spoiler profile. Confirm there’s full contact along the seating surface and note any gaps at the ends. Examine the spoiler underside for existing ribs or reinforcements: these will dictate whether you can fasten through the spoiler safely. If the spoiler is a factory item or an aftermarket carbon wing, identify thin areas where you should avoid overtightening. If the spoiler is a painted OEM rear lip, account for paint thickness when planning adhesive bonding.

Centering is crucial. Use the trunk latch or license plate centerline as the car’s axis and confirm with a straight edge across known reference points—edge of tail panel or rear bumper corners. Mark the centre on both the flap and the wing with masking tape. Transfer that center mark to the wing with a small guideline running left to right; this will be your reference for symmetric placement.

There are two common attachment philosophies: mechanical fastening and structural bonding. Mechanical fastening uses bolts, rivnuts, or pop rivets and gives a removable result. Structural bonding uses high-bond tape or epoxy to create a continuous attachment with minimal hardware. Many installers combine both: adhesive for immediate load distribution and bolts for positive retention.

If you choose bonding, prepare both surfaces. Clean the spoiler trailing edge and the flap seating area with isopropyl alcohol until all wax and grease are removed. Lightly scuff the bonding areas on the carbon flap with a scuff pad; this increases surface energy for stronger adhesion. Avoid aggressive sanding that alters the flap profile. Apply a primer if instructed by the adhesive maker. Use appropriately rated structural tape or an automotive-grade adhesive. Apply strips of tape along the length of the flap’s base, remove the backing, and press the flap to the spoiler, ensuring alignment with your center mark. Hold or clamp evenly for the adhesive’s recommended cure time. Do not drive immediately; adhesives gain strength over hours to days.

For mechanical installation, decide on fastener spacing and type. A common layout is one fastener every 6–10 inches, more toward the ends if the flap spans a wide wing. Drill pilot holes in the flap first on your workbench, using clamps and a sacrificial backing to avoid chipping the carbon fiber edge. Transfer hole positions to the spoiler by placing the flap in position and marking through the pilot holes with a center punch or scribe. Remove the flap and drill the wing holes carefully. If fastening into thin material, install rivnuts or use small backing plates beneath the wing skin to spread load.

When drilling carbon fiber, take precautions: use sharp carbide or diamond-tipped bits and light pressure to prevent delamination. Wear a dust mask; carbon dust is abrasive. Countersink the top surface if you want flush fasteners, but preserve fiber integrity by not over-drilling. For aluminum spoilers, use standard metal drilling practice with cutting fluid.

Fasten with stainless hardware and oversized washers to distribute load across the carbon fiber to reduce stress concentration. Use nylon-insert locknuts or threadlocker to resist vibration loosening. Tighten bolts progressively and evenly, watching for signs of compression or distortion at the flap edge. Do not overtighten; carbon structures give a tactile warning—if the flap begins to crush or the paint cracks, stop and add a backing plate or use a larger washer.

Seal all fastener penetrations to prevent water ingress and corrosion. A bead of automotive-grade silicone or seam sealer applied on the underside around each hole keeps moisture out. If you used adhesive under the flap, a thin bead of sealant along the joint’s top edge smooths water runoff and hides any minor gaps.

Alignment checks are more than visual. With the flap installed, measure the gap behind the flap and along the wing to verify symmetry left-to-right. Use a straight edge along the wing top and measure the flap height off that straight edge at multiple points. A consistent height creates the intended aerodynamic effect; an uneven height can produce unwanted yaw-dependent forces. If your flap curves with the wing, the front-to-back angle should mirror the wing’s trailing edge contour so the flap presents uniformly to airflow.

Consider the flap height. Small Gurney flaps often range from 5–15 mm high relative to the local boundary layer. Taller flaps increase downforce but also raise drag and add stress to mounting points. If the flap is too tall for your wing profile, trim the base slightly, or accept a reduced height for a safer, stiffer installation.

After installation, perform a staged road test. Start with low-speed maneuvers to check for rattles, looseness, or unusual vibrations. Progress to highway speeds in a safe environment, monitoring the flap for movement and listening for wind whistling or flapping; these indicate imperfect sealing or loose hardware. If the car feels more stable in high-speed direction changes, that’s a sign the flap is doing its job. If you notice rear instability at a specific speed range, remove and inspect for uneven pressure distribution or edge lift at the flap ends.

Fine-tuning is iterative. Small adjustments to angle, height, or trailing-edge clearance can change balance. Some drivers add small endplates or tip seals that reduce spanwise flow and make the flap more effective near the wing tips. Others trial different adhesive thicknesses or additional fasteners to reduce flex. If you track the car, log lap-by-lap behavior before and after changes so you can correlate modifications with handling shifts.

A few installation tips specific to carbon fiber parts: avoid clamping directly on the finished face; use padded clamps or tape to protect the weave. When tightening through carbon, use washers on both sides when possible to reduce localized stress. If you must drill into a painted surface, reapply touch-up paint around each hole to prevent corrosion and discoloration.

Finally, treat the job with patience. A well-installed flap is nearly invisible yet contributes measurably to high-speed balance. The added visual of a carbon flap complements the EVO X’s aggressive rear end, and when installed correctly, it is both durable and serviceable. If you are uncertain about drilling structural parts or worried about carbon fiber integrity, seek a specialist for rivnut installation or adhesive bonding. For a visual reference of a carbon flap made to fit an EVO X rear spoiler, see this product listing: https://www.ebay.com/itm/384062951248. Also review fitting options alongside other rear-end components, such as EVO X rear bumpers, to ensure the whole rear aero package works together: 2008-2015 Mitsubishi Lancer Evo X rear bumpers.

If you follow these steps—inspect, center, choose attachment method, protect and fasten, then test and tune—you create a repeatable installation that enhances the EVO X’s rear stability. A properly fitted Gurney flap is a small modification with a clear purpose: it lets the car use airflow more intelligently at speed, giving the rear tires added bite when you need it most.

Rear-Deck Precision: Exploring How an EVO X Gurney Flap Refines Handling and High-Speed Stability

The EVO X Gurney flap is more than a simple appendage at the rear of a spoiler. It sits at the intersection of aerodynamics and driver confidence, translating a compact, cost-efficient idea into tangible handling benefits. To understand its purpose, it helps to picture the boundary layer along the trailing edge of a car’s rear wing. In high-speed conditions, fresh air tends to detach from the surface, forming a smaller but more turbulent wake behind the vehicle. A Gurney flap, a narrow vertical plate attached to the trailing edge, disrupts that wake in a controlled way. By introducing a sharp, localized change in pressure distribution, it increases the downward force acting on the rear axle. This is not merely about more grip; it is about a more predictable rear-end response when the speeds climb and steering inputs become subtler yet more demanding. In practice, the flap reshapes the airflow just behind the spoiler, nudging the boundary layer toward a state where the rear tires maintain better contact with the road during aggressive cornering and abrupt throttle changes. While the changes may seem modest in isolation, the cumulative effect can translate into a chassis that feels more composed on the edge of grip, especially at track speeds where the slightest gust of crosswind or abrupt lift of the front axle can unsettle balance. The principle is simple at heart: a tiny addition to the trailing geometry can steer the airflow in a way that yields measurable gains in rear stability without imposing a heavy penalty in drag. For dedicated EVO X drivers chasing precise handling, that balance is the essence of an effective upgrade. The Gurney flap’s use of carbon fiber as a primary material compounds these benefits in two meaningful ways. First, the reduced mass of carbon fiber lowers the unsprung weight and reciprocally shifts the inertia of the rear end toward a more agile response. Second, the rigidity of carbon fiber ensures the flap maintains its intended geometry under the rigors of high-speed airflow and road debris. This stiffness matters because a deformed or flexing edge can alter the location where flow separation begins, undermining the very stability the device is meant to deliver. In short, carbon fiber offers a twofold advantage: a lighter package and a geometry that remains faithful to its aerodynamic intent even after thousands of miles and countless laps. Yet, the allure of downforce must be weighed against potential drag increases and cosmetic preferences. A well-designed Gurney flap is sized to deliver the right amount of downforce at the rear across the vehicle’s speed range, with attention paid to how it interacts with the spoiler and the vehicle’s overall aero balance. When a flap is too tall or mounted without regard for the rear wake, it can marginally raise drag and alter the rear-wheel load distribution in ways that diminish the gains from other aero components. Consequently, the best outcomes arise from a holistic approach: the Gurney flap is chosen and tuned to complement the existing rear spoiler, the tail’s wake, and the car’s wider high-speed strategy. The EVO X community has often treated the flap as an amplifier of stability rather than a stand-alone performance cure. It functions best when the rest of the aero system—endplates, diffuser, and even the underbody—creates a coherent flow field. In such an integrated setup, the flap helps the rear tires stay engaged with the pavement as cornering forces rise, while the front end remains balanced and predictable under braking and mid-corner throttle transitions. On the track, where every tenth of a second traces back to grip and tempo, the combined effect manifests as more confident mid-corner acceleration and a reduction in tendency toward late-oversteer when pressure builds. The driving experience becomes less about chasing stability and more about inviting the car to perform within a well-defined envelope of response. The effective outcome is not just raw speed but a refined handling signature that rewards a skilled approach to corner entries and exits. From a setup perspective, choosing a Gurney flap is as much about chassis philosophy as it is about engineering. For a car that already aims to extract maximum cornering potential, the incremental downforce from the flap can be the extra margin needed to push the envelope further without compromising the balance established by the rear wing, suspension tuning, and tire composition. In such a scheme, the flap acts as a fine-tuning instrument rather than a primary source of downforce. It is the subtle shift in rear axle behavior—the feeling that the rear wheels grip just a heartbeat longer—that often legitimizes the upgrade in the eyes of a driver who spends weekends on race tracks. The material choice, typically carbon fiber, supports that aim by offering a lightweight, rigid profile that remains visually discreet yet mechanically purposeful. The aesthetic—an almost stealthy black weave snaking along the trailing edge—also resonates with the ethos of performance engineering: form following function, with a nod to the reputation of carbon fiber in motorsport. Installation, while conceptually simple, deserves thoughtful execution. The Gurney flap is usually mounted along the rear edge of the spoiler, aligning with the wing’s boundary conditions rather than replacing any major structural element of the stock body. The process demands careful measurement to maintain proper clearance from the surface and to ensure the flap’s height is compatible with the spoiler’s wake. Even a few millimeters of misalignment can alter the timing of flow separation and, by extension, the stability benefits. For many builders, a clean, bolt-on approach provides the ideal balance between performance and practicality. The adhesive and mounting hardware must be robust enough to endure high-speed buffeting and the inevitable vibrations of spirited driving. Beyond the mechanical fit, attention to the flap’s edge geometry is essential. A sharp, well-finished trailing edge ensures a clean separation line, reducing the risk of turbulent streaks that could otherwise degrade efficiency. In the long run, this translates into a more consistent feel for the driver across repeated track sessions, as the rear end responds in a predictable manner rather than oscillating between slight understeer and abrupt oversteer. Because precise aero effects are highly context-dependent, the community often regards the Gurney flap as part of a broader long-term program of aero optimization. It does not exist in isolation but rather as a complement to strategy that includes aero balance assessment, tyre selection, brake cooling, and the integration of other rear-end components. When used thoughtfully, the flap can help a driver exploit high-speed stability to shave seconds off lap times, especially on sections that demand smooth, confident transitions through high-speed corners. However, it is important to anchor expectations in reality. Aerodynamic devices perform differently based on vehicle weight, spring rates, suspension geometry, tire type, and track temperature. The same principle that drives gains on a closed circuit may deliver diminished returns on a public road with gusty crosswinds or varying load distributions. For those who pursue a measured, track-focused approach, the benefits of a carbon fiber Gurney flap are coherent with the broader engineering goal: reduce uncertainty at the rear, preserve control during aggressive maneuvers, and do so without imposing unsustainable penalties in drag or weight. To provide readers with a tangible sense of how such a component fits into the EVO X ecosystem, consider the broader research on EVO X aero packages. While precise numerical gains require manufacturer data or disciplined testing, the consensus in aerodynamics supports the idea that a well-tuned Gurney flap can produce a meaningful improvement in high-speed stability and cornering precision. It complements other features by shaping the rear wake and helping the tires maintain a more constant grip level as lateral forces rise. This synergy is especially valuable when the driver is balancing mid-corner throttle control with the need to keep the rear end aligned through a sequence of long, fast bends. A final word on context: the Gurney flap epitomizes a philosophy of incremental improvement. It is a compact, low-cost modification that can unlock a clearer, more communicative driving experience. It invites the driver to trust the aero balance rather than fight against it, and it rewards the careful integration of materials, mounting, and overall vehicle dynamics. For anyone contemplating this upgrade, a measured approach—assessing current handling traits, testing on a controlled surface, and ensuring compatibility with the existing aero strategy—will yield far greater returns than chasing theoretical gains alone. If the goal is a track-ready EVO X that communicates through the seat of the pants as clearly as through the steering wheel, the Gurney flap offers a compelling route toward more dependable high-speed stability and a more confident handling envelope.

External reference: https://www.mitsubishi-motors.com/evolution/x/

Internal link example: For a related look at carbon fiber aero components that can complement rear-end enhancements, see the internal page on carbon fiber bonnet hood for Mitsubishi Lancer EVO X. carbon fiber bonnet hood for Mitsubishi Lancer EVO X.

Where Aero Meets Aftermarket: Market Trends and Buyer Considerations for EVO X Gurney Flaps

Market pulse and product breadth

The market for Gurney flaps tailored to the Mitsubishi Lancer Evolution X centers on a clear demand: owners want measurable aerodynamic gains without a bulky, complicated installation. Enthusiasts value parts that look purposeful and work on track and road. This demand pushed suppliers to focus on a small set of core features—lightweight construction, precise fitment, and a design that complements the factory wing. Over recent years, offerings have shifted from generic universal tabs to pieces engineered for the EVO X’s rear spoiler geometry. That shift reflects a maturing aftermarket where performance credibility matters as much as visual appeal.

Carbon fiber is now the dominant material in premium listings. It delivers strength, low mass, and the textured aesthetic many owners prefer. Fiberglass and ABS variants remain available for budget builds, but they are increasingly niche. Beyond material choice, manufacturers emphasize correct curvature and tab height. These parameters affect how the flap alters pressure distribution behind the wing. Listings that promise a one-size-fits-all solution are losing traction with buyers who expect tailored fitment for their specific wing profile.

How products differ and what matters

At first glance, most Gurney flaps look similar: a narrow vertical tab along the trailing edge. The differences that determine on-car performance are subtle. Height relative to the wing chord, the flap’s length across the span, and the trailing-edge profile all matter. Quality vendors supply precise dimensions and, when possible, test data or guidance about which flap heights pair best with a given wing. Some pieces are pre-shaped to match popular aftermarket wings, while others use modular designs that allow slight angle or height adjustments.

Manufacturing standards also vary. High-end parts show consistent fiber layup, resin saturation, and smooth, paint-ready edges. Lower-cost options sometimes require additional trimming or reinforcement during installation. Attention to mounting hardware matters too; anodized stainless bolts and pre-formed gull-wing brackets cut down on installation time and reduce the risk of galvanic corrosion between dissimilar metals.

Perceived performance versus real gains

Buyers frequently ask whether a Gurney flap will make a meaningful difference on their EVO X. The honest answer is: it depends on context. On highway cruising, the change can be subtle. At higher speeds and during high-load cornering, added rear downforce improves rear traction and stability. Well-engineered flaps yield a favorable downforce-to-drag ratio. Wind tunnel and computational studies confirm that even small flap heights change lift and drag coefficients. However, the magnitude of benefit is tied to the rest of the car’s aero package. A flap added to an otherwise uncontrolled rear wing or to a car with no underbody management will produce different outcomes than the same flap on a well-integrated aero platform.

That reality explains another market trend: buyers are increasingly purchasing flaps as part of a broader aero upgrade. Packages combining wings, diffusers, and flaps sell better than individual items. The psychological effect of the flap’s visible edge also amplifies perceived performance. A car that looks more race-ready tends to be driven with more confidence, which can translate to better lap times even if the raw aerodynamic benefit is modest.

Installation, fitment, and OEM integration

One strong trend is toward parts that bolt directly to the factory spoiler without modification. Consumers prefer solutions that avoid drilling or reshaping OEM components. As a result, many vendors now supply specific fitment kits and detailed instructions that show where to place the flap to avoid structural stress on the spoiler. These kits reduce return rates and negative reviews.

Seamless integration goes beyond physical fit. Finish quality matters. Carbon weaves matched to popular aftermarket wings and consistent surface clearcoats make the flap look like an intentional extension of the spoiler. Those visual cues influence buyer confidence and perceived value. For owners who keep their cars largely stock, there are also discreet options with smaller tab heights and matte finishes that reduce visual contrast with OEM black trim.

Pricing, value, and buyer segments

The market divides into distinct buyer archetypes. First, the track-focused owner who demands empirical performance and is willing to pay for high-quality carbon construction. Second, the style-driven driver who wants the race aesthetic without spending on full aero kits. Third, the budget buyer who needs a functional part that won’t break their build budget.

Pricing mirrors this segmentation. Premium carbon flaps with hardware and fitment guarantees are at the upper end of market pricing. Mid-range offerings use simpler layups and less refined mounting kits. Entry-level products prioritize affordability and basic function. Smart buyers weigh weight, finish, and included accessories against price. For many EVO X owners the best value sits in the mid- to high-range segment because of the longevity and better fitment those parts provide.

Quality signals and shopping behavior

Customer reviews, fitment photos, and verified measurements are becoming decisive. Listings that include precise dimensions, real-world photos, and installation notes attract more informed buyers. Where available, references to wind tunnel tests or third-party validation increase credibility. Conversely, vague listings with poor photos or missing hardware details drive skeptical buyers away.

Another purchasing driver is compatibility with other aero components. Buyers look for flaps designed to work with rear diffusers and wing endplates. If a vendor references a known wing profile or provides a recommended pairing, the product gains traction.

Trends in manufacturing and future direction

Manufacturers are experimenting with subtle refinements. These include pre-curved tabs that match the spoiler contour and micro-adjustable bases that let owners tune effective flap height. Lightweight composite cores with a carbon outer skin are starting to appear, offering stiffness without full-thickness carbon cost. Small-scale makers are also offering custom-fit services that use templates or supplied measurements to produce a flap that follows the wing’s exact trailing edge.

Environmental durability is another focus. Improved clearcoats and UV-resistant resins extend life and maintain finish. As more owners install flaps on daily-driven cars, they expect them to resist road debris and weather. Vendors that show long-term exposure imagery in listings often win repeat customers.

Practical advice for buyers

Prioritize fitment details and included hardware. Ask about flap height in millimeters and compare it to your wing’s chord depth. Seek vendors that show installation pictures on the EVO X or a similar wing. If you plan to track the car, prefer stiffer construction and secure mounting designs. For street-focused builds, a smaller tab with a subtle finish may be preferable. Finally, consider pairing a flap with other aero elements, such as a rear diffuser, to maximize the flap’s effectiveness. For an example of complementary aero parts for the Evo X, see this resource on a carbon rear diffuser for Evo X.

carbon rear diffuser for Evo X

External listing for an example product:

https://www.amazon.com/dp/B0BQYJZVXW

Final thoughts

The EVO X Gurney Flap stands as a quintessential upgrade for automotive enthusiasts and business owners alike, merging practical performance enhancements with striking visual appeal. As we have explored, not only does the Gurney Flap improve downforce and vehicle stability, but it also offers a variety of material and design choices tailored to meet the preferences of performance-focused consumers. Furthermore, with a growing market and ongoing discussions surrounding aftermarket modifications, the Gurney Flap represents a strategic opportunity for businesses looking to cater to this enthusiast community. Embracing these insights can position you to make informed choices in your product offerings and meet the increasingly sophisticated demands of automotive consumers.