The EVO hood, specially designed for high-performance vehicles like the Mitsubishi Evolution series, represents a blend of cutting-edge materials and engineering excellence. With a focus on enhancing aerodynamics, reducing weight, and improving intake efficiency, EVO hoods have become essential upgrades for serious car enthusiasts. Throughout this article, we delve into the different product types and uses of EVO hoods, their core advantages, market suitability, potential limitations, and the latest industry trends that underline their significance in the automotive sector.

The Carbon Breath of Speed: How EVO Hoods Redefine Weight, Air, and Identity in the Mitsubishi Lancer Evolution

Every era of performance cars carries a signature component that becomes shorthand for speed and intent. For the Mitsubishi Lancer Evolution lineage, that signature is the EVO hood. It is more than a sheet of metal or composite; it is a deliberate engineering choice that reshapes how a car carries weight, how air moves across the engine bay, and how a driver feels the car respond to inputs at the edge of grip. The EVO hood embodies a philosophy of restraint and precision: take weight out where it weighs most, guide air with purpose, and let the unaided gaze of fans recognize that the machine in front of them is built to chase time. In the modern market, this ethos has traveled beyond the strictly automotive world, but the core ideas remain anchored in a simple truth—the hood can be a decisive lever on performance even before the engine fires to life. This chapter will trace how EVO hoods are designed, what they aim to accomplish, and why the most capable iterations feel less like cosmetic upgrades and more like fundamental rethinking of a car’s preface to speed. It is in these details—the material science, the airflow architecture, the fitment philosophy, and the regional industry ecosystems—that the EVO hood reveals its true character. And as the story unfolds, the hood becomes a narrative: a portable manifesto about lightness, cooling, and the fierce clarity of purpose that defines the Evo ethos.

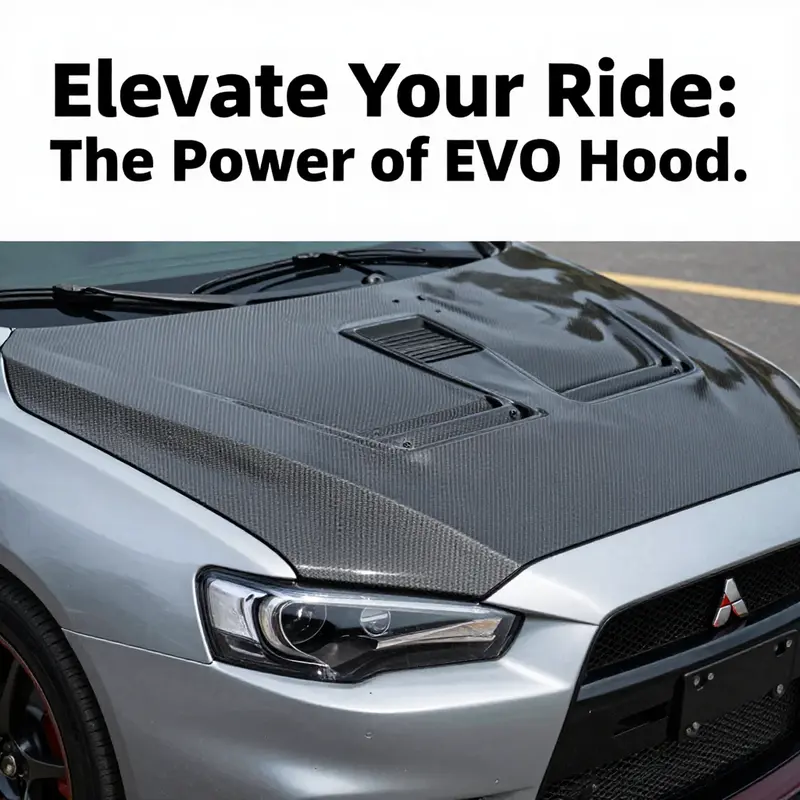

The material conversation around EVO hoods starts with weight, a constant currency in high-performance cars. Traditional iron or steel hoods carry a mass that translates directly into unsprung weight and front axle load. The shift toward composites—most notably carbon fiber—has moved the market toward an approximate 30 to 50 percent reduction in weight compared with metal alternatives. That, in turn, translates into crisper steering, quicker initial turn-in, and a reduction in the front-end pitching that can destabilize a corner entry. The immutable logic is simple: every gram shed from the hood lowers the inertia that a driver has to overcome when steering and braking under load. It is the same principle that guides the broader lightweighting push across racing and performance street vehicles. But weight savings do not come at the expense of structural integrity when the materials and layup schedules are carefully chosen. In aerospace-grade carbon, the balance of stiffness and impact resistance can be tuned to meet demanding standards while keeping the front end responsive and predictable. This is not merely a fashion statement; it is a measured engineering decision that respects the chassis dynamics of a high-performance four-wheel-drive machine.

The EVO hood’s aerodynamic and thermal ambitions are inseparable from the question of airflow. A hood can be a passive cover or an active participant in the vehicle’s breathing. Current EVO hood designs often feature ventilation channels or scooped configurations that pull cooler outside air into the engine bay or exhaust hot air more efficiently. On turbocharged or tuned setups, such as the common EVO X with turbocharged four-bangers under the hood, vented or scooped designs become a practical tool to combat heat soak and to maintain a more favorable air temperature for the intake system. When cold air flows into the plenum and the hot air is expelled more effectively, the engine sees a more favorable density of air for combustion. In performance terms, that translates to a potential gain in power and a reduction in knock risk, especially under sustained high-load conditions. The central vent or scoop can also contribute to a more even temperature distribution across the engine bay, reducing thermal gradients that can undermine sensor readings or throttle response during aggressive driving.

Designs vary widely, but certain themes recur because they address real, testable constraints. A direct-fit carbon hood that preserves factory mounting points, latch alignments, and hood hinges without requiring substantial structural modification is highly valued. This “direct-fit” ethos minimizes installation friction and preserves the integrity of the car’s original safety and crash considerations. Other options may push further with larger extractive vents, more pronounced scoops, or even active aero elements. In those cases, the hood becomes part of an integrated system, not a standalone piece. It interacts with the fenders, the bumper, the front splitter or diffuser, and even with sensor placements near the hood line. The best designs acknowledge those interactions and are engineered to avoid interference with wipers, sensors, or the hood prop mechanism. A hood that fits well and seals properly in rain is not a luxury; it is essential for maintaining the reliability expected of a high-performance street car.

To understand the practical significance, consider the EVO hood as a gateway to a broader upgrade philosophy. Lightweight panels, when properly formed and mounted, reduce the rotational mass that the engine and transmission must accelerate during each gear change and corner exit. In a car that thrives on rapid response and precise chassis feedback, that lightness translates into a more linear, more predictable relationship between pedal input, engine response, and steering behavior. The effect compounds during aggressive cornering when the front axle is already carrying a substantial load. A lighter hood reduces the moment about the front wheels, allowing the driver to modulate steering with more confidence. This is not magic; it is a carefully calibrated shift in the car’s mass distribution that complements the suspension geometry, the tires, and the drivetrain’s traction control logic.

A central theme woven through EVO hood development is the balance between performance gains and daily practicality. Carbon fiber and other composites bring not only lightness but also a distinctive visual impact. The exposed texture and weave, the high-end finish, and the tactile quality of a well-made hood contribute to the car’s identity as a performance machine. This identity is not merely about looking fast; it is about signaling, in a tangible way, that the vehicle is tuned for a specific way of moving through space. For many enthusiasts, the hood is a policy statement as much as a functional upgrade. It communicates intent—lean, purposeful, disciplined—without saying a word. Yet this aesthetic effect must be earned through durability and maintainability. In practice, carbon fiber hoods must be treated with care to avoid impact damage and to manage long-term surface integrity. The choice between a standard metal hood and a carbon alternative is often a trade-off between weight savings, cost, and the desire for a sharper visual and tactile experience.

The EVO hood also navigates market dynamics shaped by regional industry ecosystems. In regions with mature carbon fiber supply chains, including parts of China’s manufacturing landscape, vendors can offer direct-fit solutions guided by a robust network of prepregs, resin systems, and post-processing capabilities. A well-supported supply chain enables quicker iteration from concept to fully produced parts while maintaining tolerances that ensure a true fit. This is not incidental; it reflects a broader industry pattern where lightweight, high-functionality components are becoming standard options in performance tuning. The Guangzhou region, for example, has developed a suite of suppliers with the capacity to integrate pre-preg materials, CNC finishing, and coating processes that meet the discerning expectations of Evo owners who want both speed and reliability. Market reality thus reinforces the engineering logic: lighter parts that do not complicate installation and that maintain environmental sealing and weather resistance are more likely to see broad adoption among enthusiasts who also drive their cars in varied climates.

The functional breadth of EVO hoods is evident in the way different designs address heat management. Venting hoods, for instance, incorporate channels that draw heat away from critical areas such as the valve cover and intercooler, thereby lowering intake air temperatures and reducing thermal stress on charge air cooling systems. Central scoops can feed air to the intercooler or intake manifold, potentially improving turbocharger efficiency by maintaining higher air density entering the engine. The exact performance uplift depends on several variables, including engine configuration, turbo sizing, intercooler effectiveness, and the vehicle’s overall aerodynamics. In a well-balanced build, the hood’s ventilation complements the cooling system rather than working at odds with it. It is a reminder that performance is rarely about a single part but about how a series of improvements align to reduce bottlenecks along the powertrain’s path from intake to exhaust.

From a maintenance perspective, the corrosion resistance and weather sealing of composite hoods matter more than many owners anticipate. Sealing surfaces must withstand driving in rain and dust while preventing water intrusion into the engine bay. In practice, improper sealing can lead to wind-driven water ingress or debris intrusion, which may affect electronics and sensors placed near the hood line. The same emphasis applies to fitment around the windscreen area and the hood’s edge alignment with fenders. A hood that sits perfectly, seals reliably, and does not imperil wiper operation or hood latch function is more likely to be relied upon in daily driving as well as on the track. For owners who push their Evo X or earlier variants toward high-load conditions, those reliability considerations become part of the value proposition that offsets the initial price premium of carbon fiber or composite alternatives.

If the story stops at performance numbers, it would miss a crucial thread: the hood is part of a larger ecosystem of aftermarket transmission to the chassis. The market has seen a widening array of direct-fit options, created to minimize integration work and to preserve the factory geometry that so many enthusiasts prize. A well-made hood honors this philosophy by eliminating the need for messy modifications or structural alterations. It keeps the door open for future upgrades, whether a higher-flow intercooler, a more capable front diffuser, or an air-to-water intercooling loop that benefits from the hood’s venting strategy. The result is a holistic approach to car tuning where the hood does not stand alone but anchors a coordinated upgrade path. The hood becomes a confidence booster for owners who want to pursue higher speeds with a predictable sense of how the front end will respond when the throttle is planted and the tires demand grip.

The EVO hood’s significance also emerges when observing the broader cultural and technical landscape surrounding the Evo community. In markets with vibrant car culture and active modification scenes, carbon fiber parts are not merely functional upgrades; they are part of a shared language. The hood is a tangible marker of a build’s direction, signaling an owner’s commitment to reducing weight and optimizing airflow. This shared language helps sustain a feedback loop: enthusiasts test new designs, engineers refine materials and production methods, and the market rewards parts that deliver real, track-proven gains while remaining compatible with street use. The result is a living ecosystem in which a hood, carefully selected and expertly fitted, acts as a catalyst for exploring how far a machine can be tuned within the boundaries of safety, reliability, and daily practicality.

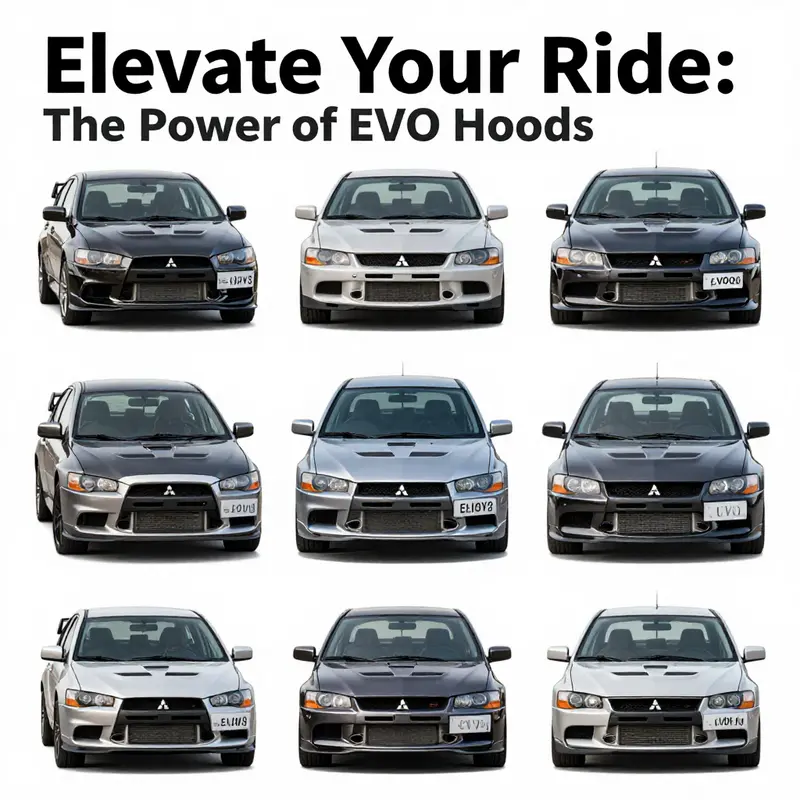

In examining the EVO hood, it is important to anchor the discussion in specific historical and technical anchors without losing sight of the broader principles. The Evo X, produced from 2008 to 2017, became a focal point for many enthusiasts exploring carbon fiber replacements, vented and scooped designs, and direct-fit engineering that preserved the car’s architecture. The academic and professional literature on this topic increasingly highlights that carbon fiber hoods can meet exacting mechanical standards while delivering meaningful weight savings and aerodynamic benefits. A comprehensive guide to hood EVO X iterations emphasizes that the material choice, weave orientation, and resin system play decisive roles in mechanical performance and long-term durability. In practice, owners who approach hood upgrades with a critical eye toward sealing, fitment, and thermal management tend to experience the most satisfying outcomes. They gain not only a lighter front end but a hood that communicates a disciplined approach to performance—an instrument, not merely an ornament, in the driver’s hands.

For readers who want to visualize a concrete pathway into this world, consider a practical example within the EVO X ecosystem. A carbon fiber bonnet for Mitsubishi Lancer Evo X demonstrates how a direct-fit panel can align with the factory chassis interfaces while offering a significant reduction in mass and a more aggressive silhouette. This kind of part typically anchors a broader upgrade strategy, where the weight savings from the hood complement lighter wheels, upgraded brakes, and a tuned suspension to deliver a more cohesive driving experience. In reviewing the broader spectrum of EVO hood options, it is clear that the most coherent builds avoid treating the hood as a stand-alone sprint but rather as the opening act in a performance narrative built on weight, cooling, and tactile feedback. The visual language of the hood matters, but the real narrative unfolds in the way it reshapes how the car moves, breathes, and responds to the driver’s intent.

To connect the reader with a concrete, practitioner-friendly reference, one can explore a direct example of the carbon fiber approach in a product that embodies the fusion of form and function. The hood’s carbon fiber subtype commonly found in Evo X builds is a vivid illustration of the design priorities sketched here. For those who wish to delve into a tangible specimen, a representative carbon fiber bonnet for Mitsubishi Lancer Evo X can be viewed through the product page linked here: carbon fiber bonnet for Mitsubishi Lancer Evo X. This link provides a concrete window into the premium category of EVO hoods and showcases how a well-executed direct-fit panel aligns with the vehicle’s structural and aerodynamic expectations while delivering the sought-after weight reduction and heat management advantages described above.

In closing, the EVO hood is a nuanced performer. It is neither solely a weight-reducing ornament nor a purely aerodynamic device; it is a carefully engineered component that interfaces with the engine bay, the cooling system, and the vehicle’s dynamic behavior at the limit. Its value emerges when weight is trimmed where it matters most, airflow is guided with intent, and the car’s personality is reinforced with a handsome, purposeful silhouette. The Evo hood stands as a reminder that performance tuning is most effective when it respects the car’s original purpose and channels that purpose through thoughtful, measurable design choices. As the Evo lineage continues to evolve, the hood remains a crucial touchpoint where material science, airflow engineering, and driver confidence converge into a single, coherent statement about speed.

External reference for further technical exploration: https://www.automotiveexpertguide.com/evox-hood-guide

EVO Hood: Core Advantages that Redefine Power, Cooling, and Handling

The hood is often overlooked, yet in high-performance machines it stands as a quiet conductor of the engine’s rhythm. An EVO hood is more than a visual upgrade; it is a carefully engineered interface between the car’s heart and the air that surrounds it. When you peek beneath the surface, you begin to understand how a single panel can influence cooling, weight distribution, and the way a car feels when you chase down a corner or slice through a straightaway. The core advantages of an EVO hood—performance improvement, thermal management, and a bolder, race-ready appearance—are not theoretical luxuries but practical gains that show up in heat-soaked dyno sessions, on the skid pad, and in everyday driving where every fraction of a second counts. In the realm of high-performance tuning, the hood is a harmonizing element that integrates air, heat, and mass into a coherent system. Its design decisions ripple through the chassis, affecting how the front axle experiences load under braking, the way the engine breathes at wide-open throttle, and even how the driver perceives the car’s response at the steering wheel.

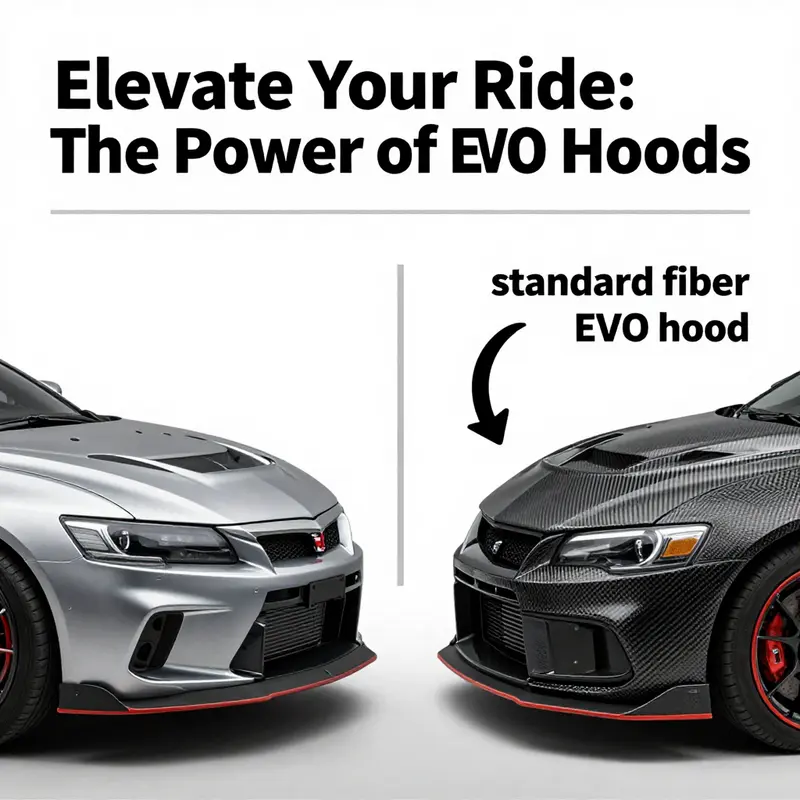

First, the most conspicuous benefit is lightweight construction. The shift from heavy steel to advanced composites, particularly carbon fiber, brings a meaningful reduction in front-end mass. In numerical terms, carbon fiber can cut weight by roughly a third to nearly half compared with traditional sheet metal, depending on the thickness and weave. That weight loss directly translates into improved front-end agility. With less mass up high at the nose, the vehicle rotates more readily, and steering input translates into quicker corner entry without the need to overcome a heavier front end. The immediate feel is a lighter, more responsive steering column and a more nimble chassis attitude that rewards precise inputs on twisting roads and demanding track sections. The front axle experiences less inertia, which helps the car settle into a corner with less pescatory understeer and more natural progression toward the intended line. This improved balance often unlocks a higher level of confidence for drivers, encouraging them to push harder without sacrificing stability.

Weight reduction is not merely about reducing the mass; it also reshapes how mass is distributed in service of dynamic performance. When the hood itself is lighter, the center of gravity moves slightly upward and forward, altering the vehicle’s polar moment. The overall effect is a more predictable front-end behavior at limit conditions. It means the driver can apply steering inputs with a clearer sense of the car’s intent, a crucial factor when chasing on-throttle grip through a demanding sequence of bends. The practical outcome is a vehicle that feels more eager to respond and less hesitant at the apex, especially when the throttle is used to modulate yaw and balance. The EVO hood’s contribution to lightness often pairs with other lightweight components in a coordinated build to create a chassis that feels more willing to dance, weaving precision into performance rather than merely adding horsepower.

But lightness is only part of the equation. The EVO hood excels by shaping the airflow in and around the engine bay. Venting and scooped designs channel hot air away from the crowded under-hood area, a move that directly impacts thermal health. In turbocharged or high-load environments, engine bay temperatures rise quickly. Heat soak can rob performance by elevating intake air temperatures and engine oil temperatures, weakening efficiency and potentially nudging knock limits. A hood with well-placed vents or a central scoop helps create a cleaner, more stable thermal profile. The surrounding air is encouraged to pass through the engine bay rather than stagnate, effectively sweeping away heat and reducing the likelihood of hot spots that can degrade performance during extended sessions on a track or during sustained aggressive driving on a hot day. The benefits to cooling are not merely about comfort for the driver or the feel of the gauge readings; they translate into real, measurable improvements in sustained power output and component longevity.

The design language of these hoods often blends functional ventilation with aerodynamic intent. A hood with vented channels or a central intake can become part of an integrated cooling strategy that also collaborates with the car’s front splitter, fenders, and bumper aerodynamics. When air is directed efficiently through specific channels, it can reduce boundary layer separation along the hood’s surface and encourage a smoother flow over the car’s profile. This is not cosmetic aerodynamics; it is a calculated approach to reducing drag while increasing downforce where it matters most. The result is a more balanced car at speed, with less lift, improved high-speed stability, and a more planted feel through sweepers and high-speed transitions. The upshot for the driver is a more consistent handling character, especially under heavy throttle and in the middle of a long straight where airspeed magnifies every aerodynamic effect.

Beyond the weight and heat benefits, the EVO hood also delivers a pronounced visual and tactile statement. The aggressive lines, exposed carbon weave in many sport-oriented versions, and the mechanical suggestion of performance create a sense of purpose. For enthusiasts who want their car to announce its intent without saying a word, the hood acts as a powerful cue. The aesthetic upgrade is not merely about style; it signals an engineering mindset that values efficiency, speed, and discipline. A hood that looks fast also encourages a driver to behave with a more disciplined approach, knowing that the hardware mirrors the intent of the machine: to perform with precision under pressure. While the eye-catching exterior draws attention, it is the underside of the hood where the true innovation resides, where lightness, rigidity, and air management converge in service of the engine’s health and the car’s overall balance.

From a compatibility and install perspective, the EVO hood is designed for direct-fit installation in many reference platforms. This design philosophy minimizes the need for structural modifications to the vehicle’s chassis or core body panels. A direct-fit hood typically aligns with factory mounting points, hinges, and latch mechanisms, allowing for a simpler, cleaner installation. For mechanics and enthusiasts, the appeal lies in turning a straightforward upgrade into a manageable maintenance task rather than a full-body rebuild. This factor broadens the accessibility of performance improvements, enabling more people to explore the benefits of lightened mass and improved cooling without the risk of unintended fitment issues.

Manufacturing and availability also shape the practicality of such upgrades. In markets known for advanced composite production, the supply chain for carbon fiber components is well established, with capabilities ranging from pre-impregnated materials to resin systems and precision CNC work. In regions that host robust carbon fiber industries, we see a more rapid translation from concept to mass production, with options that emphasize not only performance gains but also durability and consistent fit. This ecosystem matters because performance parts cannot remain isolated from reliability and serviceability. A hood that returns to its original shape after repeated heat cycles and minor impacts, that resists warping, and that can be repaired or replaced without an insolvably high price tag, is a hood that earns long-term trust from enthusiasts who push their cars to the limit.

Yet every advancement comes with trade-offs. The drive to reduce weight and improve cooling can bring challenges. Sealing becomes a particular concern when venting or scooping is involved. Water intrusion in wet climates or during rain-driven drives is a real consideration. The more complex air paths become, the more critical it is to ensure that seals and gaskets maintain integrity. Noise levels can also rise because vented pathways and open channels may carry higher wind and engine noise into the cabin at highway speeds. And while carbon fiber brings strength and stiffness, it also presents a different repair economics landscape compared with steel or aluminum. When damaged, composites often require specialized repair or replacement, which can come at a premium relative to conventional metal parts. These considerations remind builders that the EVO hood is not merely a one-off upgrade; it is an element of a broader performance plan that should be integrated with cooling expectations, intake efficiency strategies, and acoustics management.

The broader industry backdrop helps explain why these hoods have gained traction. In hubs of advanced composites production, such as major manufacturing centers, the supply chain supports rapid prototyping and scalable production. The emphasis on lightweight, function-first design is no longer a niche pursuit but a mainstream approach for those seeking true performance gains. The trend toward lightweight, function-integrated, and customizable components reflects a broader shift in the industry—from simply swapping parts to engineering holistic solutions that address aerodynamics, cooling, and driveability in a coordinated package. This alignment makes the EVO hood a natural partner to other performance strategies, whether those involve tuned intake plumbing, improved intercooling, or enhanced chassis rigidity, all aimed at delivering a more communicative, more predictable vehicle.

As the field evolves, the concept of active, adjustable air management looms on the horizon. While the current generation of hoods emphasizes passive improvements—static vents, fixed scoops, and robust composites—the next wave may integrate controllable indicators of airflow and cooling. Such advancements could allow a driver to tailor the hood’s open areas to different driving modes, weather conditions, or track demands. This potential future aligns with the industry’s push toward lightweight components that do more than simply shed weight; they optimize the entire thermal and aerodynamic envelope in real time. The EVO hood, in its most effective incarnation, becomes a conduit through which heat, air, and mass collaborate to deliver measurable gains in sustained power and repeatable handling characteristics.

In sum, the EVO hood embodies a convergence of three core advantages: performance, cooling, and aesthetic aggression. It reduces front-end weight, shifts the balance toward a more agile chassis, and promotes a more disciplined, responsive driving character. It channels hot air away from critical components, lowers intake and engine temperatures under load, and supports a more consistent power delivery through longer, steadier performance on track days and spirited road sessions. It also upholds a straightforward, direct-fit installation pathway that keeps the maintenance burden reasonable while offering a tangible upgrade to the car’s personality. And while the upgrade comes with trade-offs, thoughtful integration within a broader performance strategy can maximize benefits while mitigating drawbacks. For many builders, the EVO hood is a foundational piece that unlocks a more precise, more confident driving experience—an essential companion to the rest of the performance modifications that transform a road-going car into a capable, repeatably fast machine.

For readers who want a practical snapshot of how this component can fit into a broader upgrade plan, a reference point is the carbon fiber hood variant available through reputable suppliers that emphasizes a direct-fit, bolt-on approach. carbon fiber bonnet hood offers a sense of how modern composites can deliver both the lightness and the integrated aero function that enthusiasts seek, without demanding a total rebuild of the nose structure. The broader implication is clear: when the right hood is chosen in harmony with an intended mission—be it track days, spirited canyon runs, or daily performance driving—the payoff extends beyond better lap times. It becomes a refined sense of vehicle balance, a clearer line between driver intent and road response, and a more satisfying, repeatable experience behind the wheel.

As the evolution of performance parts continues, the EVO hood stands as a representative example of how modern materials and thoughtful aerodynamics can elevate a vehicle well beyond a simple cosmetic upgrade. It is a case study in how lightweight construction, strategic ventilation, and streamlined air paths come together to support higher engine efficiency, more precise handling, and a more engaging driving experience. The hood’s advantages are not abstract; they translate into tangible benefits every time a driver pushes the pedal, every time a corner is kissed with a graceful line, and every time the car responds with a sense of eager, controlled power. The EVO hood, in its essence, invites the driver to experience a more integrated form of performance, where cooling, weight, and aerodynamics are coordinated to deliver a chassis that feels lighter, quicker, and more alive than before.

EVO Hood 的适配之路:从车型边界到市场格局

在高性能改装的世界里,引擎盖不仅是保护发动机的覆板,更是一块能改变空气动力学与热管理格局的关键部件。EVO Hood 的理念源自一个简单而极具挑战性的目标:用更轻的材料和更精确的空气流动设计,提升发动机在高负荷下的工作效率,同时让车身前部的气流向循环保送,最终转化为更直接的响应与更稳定的高速表现。走进这一领域,我们会发现,所谓的EVO Hood,往往并非单一的件体,而是一整套将重量、散热、进气与外观风格有机组合的工程实践。它把“减重”与“空气动力学优化”并置,通过材料选择与通风开孔的组合,构筑一个中枢区域的热-气流管理系统。碳纤维材料在这里扮演着核心角色。相比传统金属板,碳纤维的密度更低,强度与刚度却能在薄厚相同的条件下保持甚至提升。这种材料的普及,使得车头前段的前缘重量下降,前轴负荷随之减轻,进而改善转向响应和加速性能。这种重量减轻的直接效果,往往在日常驾驶中的转向灵活性和刹车前后响应上体现得更为明显。与此同时,碳纤维并非只是减重的代名词。通过专业的复合工艺,设计师可以在引擎盖上集成进气口、导流槽、以及必要的排热通道,形成“进气+排热”的双重功能。对使用涡轮增压或高压缩发动机的性能车型而言,这样的设计尤为重要。涡轮增压发动机在高转速处通常需要清晰且稳定的进气流程,任何气流扰动和温度上升都会削弱呼吸效率。带有通风口或中央导流槽的EVO Hood,可以将外部冷空气更直接地引入发动机舱,降低进气温度,抑制热衰,提升燃烧效率与功率输出的潜力。将热管理与空气动力整合的思路,与整车的动力学目标相互呼应,形成一个围绕前段区域的“气-热-力”三位一体的协同系统。为了实现这一目标,制造端的工艺链条也在不断完善。碳纤维部件的生产通常涉及高端预浸料、树脂系统以及数控加工等环节,广州等地的碳纤维产业集群为这一链条提供了较为完整的底层支撑。这里不仅有材料供应,还有设计验证、模具开发、以及快速打样与量产的能力。市场的意义在于,它把“可定制化”和“直接装配”的需求落地为现实的选项。直接装配(Direct Fit)的理念,指向的是尽量减少车身结构改装、避免二次加工以保持整车的原有强度与安全性。这一点对于改装爱好者尤其重要,因为在追求性能的同时,稳定性与安全性仍然是评估改装成败的关键。与此同时,设计并非仅仅追求极致的轻量化与空气动力效果。外观的格调同样的重要。碳纤维材质本身就具备强烈的赛车气质,能够瞬间赋予车辆更具攻击性的视觉效果,满足那些以“视觉冲击力”来表达自我风格的车主的诉求。对于大多数市场而言,这些碳纤维件的供应并非局限于高端改装店。国际电商平台和本地生产基地共同构成了一个较为丰富的供应网络,消费者和车主群体可以在不同的预算水平上找到合适的选项。就供应链而言,广州及周边区域的碳纤维产业链具备从材料预处理到后期加工的完整闭环,这使得小批量定制与快速周转成为可能,也支持“可定制化”的行业趋势。与之相关的市场动向,是从单纯的替换件,逐步转向功能性更强的集合件。这类件体往往不仅提供减重和外观效果,还将散热、进气通道、以及空气动力学导流等多种功能并行集成,从而提升发动机在高强度工况下的耐久性与稳定性。为避免理解上的误区,需要强调的是,EVO Hood 类产品的核心价值并非仅仅追求“更轻”,而是通过材料与结构的再设计,来实现更高效的热管理和更有力的气流利用。若仅以重量作为唯一指标,往往会忽视热积聚和气流阻力带来的潜在问题,最终导致性能提升未能真正转化为可感知的驾驶体验。市场层面的理解应当是:在广泛的车型平台中,核心适配件通常以“Direct Fit”为导向,确保不同年份和版本的机舱结构具有尽量一致的衔接点,以减少安装难度和二次改装的需要。对于不同车型群体的扩展适配,厂商与改装商往往会以“功能性设计”作为切入口,比如前部进气勺、通风口、以及带有导风槽的结构件。这些设计并非简单的视觉改造,而是通过对发动机舱热流场和进气路径的重新塑造,来达到更优的温度分布和更高效的进气压差。正是这种“工程驱动的外观升级”理念,使得EVO Hood 相关产品在全球市场中呈现出较强的生命周期特征。为了帮助读者将理论与市场感知联系起来,值得关注的一点是,相关渠道的价格区间与可用性呈现出明显的区域分化。国际电商平台通常提供较广的选择和对比,价格波动与产地差异使得预算层级的车主都能找到合适的方案。在中国市场,批量化的供应与价格竞争,使得入门级选项更加亲民,但这也带来对安装质量与售后服务的更高关注。对改装者而言,除了材料本身的评估,安装工艺与后续的维护也占据重要位置。密封性是通风设计中不可忽视的要素之一。为了避免雨水倒灌和异物进入,专业的密封处理以及与原厂密封线的兼容性,往往成为实际使用中的关键点。另一方面,噪音与振动也需要被评估。高速行驶时,风噪和进入发动机舱的声音可能因通风口设计而被放大。对于追求极致安静声学体验的用户,这样的副作用需要通过封闭式风道、降噪材料或二次密封来缓解。维修成本则是长期考量的一部分。碳纤维部件的修复或替换成本通常高于传统金属件,因此在购买前做好材料耐久性与保养方案的评估,显得尤为重要。市场趋势方面,行业普遍倡导的“轻量化 + 功能集成 + 可定制化”愿景,正在推动向主动空气动力学设计的融合发展。未来可预见的方向包括可调进气口、可动态调节的导流结构,以及在不同车速范围内自动优化的气流路径。这些设想在理论上能带来更稳定的前悬与更高效的发动机热管理,但在实际应用中,需要跨学科的协作与严格的测试验证。EVO Hood 的市场正在从“简单替换”走向“工程化集成”的阶段,车型生态与产业链的协同也在逐步成熟。广州等区域的制造与研发能力,为这一转型提供了现实基础:从材料获取、到模具设计,再到量产交付,形成了一个可持续的产业生态。正是在这样的生态中,改装文化得以与工程学的严谨性并行,消费者在获得性能提升的同时,也更容易获得可解释的、可持续的维护路径。对于未来章节的展开,可以从两个维度继续深入:一是具体车型平台的定制化设计与验证流程,二是如何在不同法规环境中实现合规改装,以及如何通过可选组件的组合实现可控的空气动力学和散热性能。若要了解实际的产品信息与技术要点,读者可以参照某些相关的线下或线上案例资源,在其中一个专门页面中查看与车型匹配的碳纤维前盖与导流件的组合效益。参阅链接可在以下页面中找到具体的产品描述与安装要点:brand-new-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x 。此外,关于全球市场的参考信息也可在专业零部件电商平台找到大量同类产品的搭配案例。外部参考资源包括对这种改装件在电商环境中的认知与应用的分析,以及对热管理与气流优化的实证研究,具体可参考以下外部链接:https://www.amazon.com/dp/B07XQJZ5KZ。通过这些渠道,读者不仅能看到不同价格区间和材质选择的对比,还能理解安装与维护对长期使用体验的影响。正因如此,EVO Hood 的适用车型与市场并非孤立的一隅;它是一个在全球化供应链、区域制造能力与改装文化共同作用下形成的复杂生态。对车迷而言,这是一种表现自我、追求技术边界的方式;对工程师而言,则是一次对材料、气流与热管理之间关系的持续探索。未来的章节将继续揭示不同车型在这种设计语言下的具体适配路径,以及在各类赛道与街道场景中如何通过组合件实现可视化与性能的双重收益。

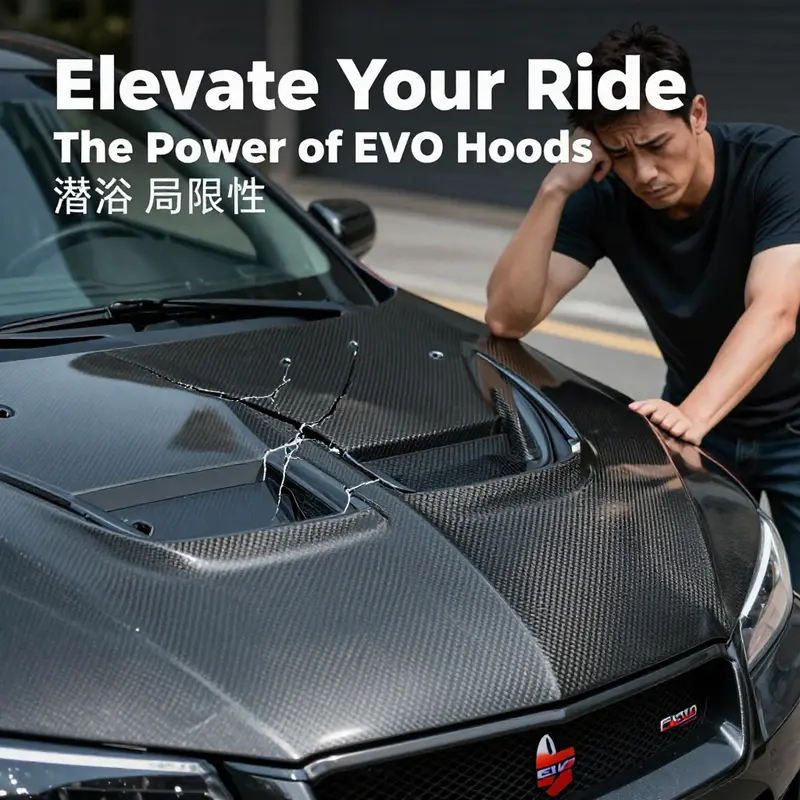

The Hidden Limits of the EVO Hood: Weighing Performance, Weather, and Structural Truths

The EVO hood has become a focal point for enthusiasts chasing a balance between lightness, airflow, and the aggressive silhouette that signals seriousness on the road and track alike. Yet beneath the gloss of a lighter, more aerodynamically tuned piece lies a set of practical limits that demand careful consideration. This chapter moves through those limitations in a flowing, integrated narrative, showing how a performance hood can transform driving experience while simultaneously reshaping heat management, weather resilience, structural integrity, and daily usability. It is not a cautionary tale about danger or failure, but a sober map of trade-offs that must be understood before committing to a modification that sounds simple in theory and acts complex in practice.

The most immediate draw of an EVO hood is weight reduction. Carbon fiber, a common material in these upgrades, promises a front end that feels more agile, with lighter steering responses and a lower moment of inertia when the car corners or shifts weight during mid-casten acceleration. Weight savings translate into tangible gains in performance metrics: improved braking stability, quicker turn-in, and a perceived improvement in overall chassis behavior. Those benefits, however, are not universal or uniform across all driving conditions. In everyday use, the front of the car carries less mass, but the hood also becomes a different kind of thermal and acoustic barrier. The engine bay, now with a different thermal path, may respond to heat loads in ways that require rethinking cooling strategies. In some cases, the reduction is accompanied by a slightly stiffer, more exposed feel at the leading edge of the car. The tactile sensation of a stiffer sheet metal sharing the load with a carbon composite can contribute to a sharper ride geometry—an effect some drivers interpret as a direct connection to the car’s intent when pushed hard, while others may notice a more abrupt transfer of road texture through the hood structure at high speeds.

Alongside weight savings, airflow optimization is the second pillar of the EVO hood narrative. Venting designs and central scoops are engineered to manage a delicate balance: they must extract heat efficiently at higher engine speeds while not becoming a source of unwanted aerodynamic complications at highway speeds. In the most optimized configurations, vented channels and scoops create a low-pressure region that pulls hot air away from the engine bay, directing it toward exhaust routes or out of the front of the vehicle. In turbocharged or high-boost engines, this can contribute to cooler intake temperatures and a modestly improved volumetric efficiency. But there is also a caveat: not all vented designs produce meaningful gains at low speed or during idle when airflow is subdued. In those conditions, the hood’s effectiveness is reduced, and the supposed dual benefit of inflow cooling and outflow exhaust may become a narrow corridor that only reveals its advantages when the engine is working hard. In practice, this means drivers may experience a disparity between the hood’s theoretical performance gains and the real-world feel at mild to moderate throttle. The incremental improvements can be meaningful on a track or during spirited drives, yet they may be less perceptible in daily commuting.

Weather resilience is another axis where the EVO hood reveals its truth. The appeal of a premium, highly engineered hood often sits atop an expectation of a perfect seal and reliable operation in all conditions. In reality, the vented or scooped hood introduces new sealing challenges. Rainwater, leaves, and debris can find their way into the engine bay through openings designed to facilitate airflow. Even when a hood is designed with drains and protective flaps, the reality of a downpour or a flood-prone stretch of road means some water ingress risk will persist. The consequences range from minor moisture exposure to more serious ones, such as corrosion on connectors or short trips in wet weather that dose electrical components with moisture. Car owners who drive in rain-heavy climates or who live in flood-prone regions should plan for additional protective measures. This might include enhanced grommets, improved rain shields, and a more stringent cleaning and inspection routine for the electrical harnesses that weave through the engine bay. The result is a practical lesson: performance upgrades often require complementary weather sealing and maintenance practices. Without them, the very airflow improvements intended to cool the engine can be undermined by moisture infiltration and related corrosion risk.

The hood’s structural integrity—how it behaves as a component within the vehicle’s overall safety envelope—also demands attention. A vented design, if improperly sized or misaligned, can reduce the stiffness of the forward body structure. The hood doesn’t just seal the engine bay; it participates in the front-end crash performance and contributes to occupant protection. If the hood’s mounting points shift or if the material lacks the rigidity of the original steel, there can be a subtle but real impact on how the hood deforms in a crash or how it interacts with the latch mechanism over time. Owners who pursue direct-fit options—those marketed as “direct replacement” or “factory-size” without substantial modification—generally experience the best results in terms of integration with existing hinges, alignment tolerances, and latch integrity. Yet even among direct-fit products, installation demands exacting attention to mounting holes, gasket sealing, and the alignment of vents with surrounding body panels. A misaligned hood can produce wind noise, uneven gaps, or even reduced safety margins in a collision scenario. The lesson here is practical: a high-performance hood should be viewed as a paired system where installation precision, hardware quality, and panel alignment matter as much as the material’s lightness or venting design.

Material choice amplifies or moderates these effects. Carbon fiber’s primary advantage is its weight-to-strength ratio, but the cost and maintenance implications are real. Carbon fiber often requires careful handling to avoid impact-induced Delamination and surface abrasion. The cost of replacement or repair can be significantly higher than that of a traditional steel hood, making a damaged hood a longer-term investment decision rather than a simple curable nuisance. The maintenance routine for a carbon fiber hood includes more vigilant inspection for micro-cracks and impact marks, particularly along the edges and vent openings where thermal expansion and contraction can create stress concentrations. The aesthetic benefits—an immediately sharper, more aggressive silhouette—are not merely cosmetic; they can influence owner confidence and perceived vehicle performance. Still, the value equation depends on how much weight the owner is prepared to trade for cost, upkeep, and the potential minor increase in wind noise that sometimes accompanies performance venting at speed.

Another layer of complexity arises from the reality of market availability and manufacturing realities. In markets with deep carbon fiber supply chains, such as areas with established aerospace or high-end automotive composites ecosystems, there is a broad spectrum of options regarding weave patterns, resin systems, and surface finishes. Those choices influence not only the hood’s appearance but its longevity under UV exposure and its resistance to micro-cracking from thermal cycles. The supply chain’s maturity can also affect lead times and confidence in fitment, which matters for enthusiasts who plan seasonal builds or who rely on a car as a daily driver. The regional production landscape matters as well. In hubs where carbon fiber sits alongside a robust aftermarket ecosystem, a hood can be sourced in a relatively short time with a predictable path to installation, including direct-fit provisions and a suite of compatible mounting hardware. For a careful buyer, the choice becomes more nuanced than “lighter is better” and shifts to a more holistic evaluation: weight reduction, heat management, weather resilience, structural integrity, cost, and the practicalities of installation.

Compatibility is not a mere footnote. The EVO hood family spans a spectrum of designs tailored to different engine configurations and performance goals. A hood with aggressive venting may pair well with a specific turbocharged setup, while a scooped hood might better suit another configuration focused on ram air effects. Each pairing has implications for sealing, moisture management, and heat extraction paths. This is where the concept of a “system” becomes critical. The hood does not operate in isolation; it forms part of a front-end ecosystem that includes the radiator shroud, grille, headlights, and front bumper geometry. In practice, a successful upgrade keeps the overall airflow coherent, ensuring that the cooling system’s capacity is not undermined by a change in the hood’s exit paths or intake routes. When contemplating any hood replacement, owners should consider whether their cooling plan includes upgraded fans, radiators, or intercoolers to maintain a balanced thermal profile under sustained performance, rather than relying solely on the hood for heat management.

The broader market context also shapes how a modification like this is perceived and adopted. In regions with strict vehicle inspection or with weather patterns that include heavy rainfall and dusty climates, the reliability of a venting front-end becomes a defining factor. A hood that is perceived as a performance novelty may struggle to gain acceptance if it introduces persistent maintenance burdens, compromises sealing, or increases wind noise beyond a comfortable threshold. Conversely, for the performance-focused driver who uses the car primarily on weekends or on track days, the hood represents a line in the sand between compromise and capability. It marks a clear signal of intent: the vehicle is optimized for track-ready heat management and aggressive aero cues. This variance in user needs explains why the EVO hood market thrives on a mix of direct-fit options, customization shops, and small-scale manufacturers who can tailor designs to a specific engine setup and climate.

From a design and engineering standpoint, the EVO hood embodies a philosophy of lightweight, functional integration. The most durable and satisfying implementations tend to be those that treat venting as active management rather than a purely cosmetic feature. In practice, this means ensuring that vent sizes correspond to actual thermal loads, that seals meet environmental challenges head-on, and that the latch and hinge assemblies are upgraded or reinforced to maintain safety margins. It is precisely this blend of performance goals with practical safeguards that distinguishes a well-executed hood upgrade from a well-lit but underperforming after-market addition. Enthusiasts who approach the hood as part of a broader program—improving intake, turbocharging, cooling, and chassis dynamics in tandem—almost always arrive at a more satisfying, cohesive driving experience. They describe a car that feels more connected, with a front-end presence that communicates intent without compromising reliability.

For readers seeking a tangible way to translate these considerations into a decision, a practical takeaway is to treat the hood upgrade as a modular step in a larger plan. Start with a clear assessment of heat management needs for your engine and driving style. If you anticipate frequent high-load use, prioritize venting designs and sealing strategies that minimize both ingress risk and needless heat accumulation at lower speeds. At the same time, commit to a precise installation process, using a trusted installer who understands vibration, airflow, and sealing dynamics across the entire front-end assembly. Material selection should be guided not only by weight but by total cost of ownership, including potential repair costs and repainting needs after maintenance or impacts. And finally, keep a long-term view on maintenance: carbon fiber demands care, seals require attention, and the overall system benefits from periodic inspection and service in a way that mirrors the diligence applied to other high-performance parts.

If you are curious to explore a concrete example of how a hood’s material and finish can align with performance aims while respecting the realities described above, a widely accessible reference point is a carbon-fiber bonnet hood option designed specifically for the Evo X. See the linked example that demonstrates how designers balance fit, finish, and function in a package that remains true to the car’s engineering spirit while pushing toward lighter weight and improved airflow. carbon-fiber bonnet hood for evo-x. This serves as a practical case in point: the hood’s design language, its mounting tolerances, and its venting geometry all reflect a broader philosophy of thoughtful, integrated performance upgrades rather than a mere swap of materials. Even when one chooses a different path—another carbon fiber variant, a different vent arrangement, or a distinct resin system—the core considerations described here remain constant: weigh the real gains against maintenance costs, weather resilience, and structural safety, and embrace a plan that treats the hood as a strategic component rather than a one-off upgrade.

In the end, the EVO hood can deliver meaningful performance gains if chosen and installed with a holistic perspective. It offers the allure of weight reduction, the promise of cooler air and accelerated heat dispersion, and the visual drama of a vehicle that communicates its intent with authority. Yet those benefits are always balanced by tangible constraints: the risk of water ingress, the necessity for precise installation, the premium cost of materials, and the potential for increased wind noise or reduced rigidity if not properly integrated. Awareness of these factors empowers a driver to decide when a hood replacement makes sense, and how to approach the upgrade in a way that preserves daily usability while elevating track-ready capability. The chapter’s throughline is simple but essential: performance enhancements thrive when they are part of a deliberate system design, not an isolated tweak. The more thoughtfully a hood upgrade is aligned with a vehicle’s cooling architecture, chassis balance, and climate realities, the more likely it is to deliver lasting satisfaction rather than brief, expensive excitement.

null

null

Final thoughts

EVO hoods represent a significant advancement in automotive design and engineering, offering numerous advantages for performance-focused vehicles. Their lightweight construction, enhanced aerodynamics, and striking appearance make them a worthy investment for car enthusiasts. While they come with some potential drawbacks, the evolving technology and expanding market promise greater accessibility and improved designs. For businesses in the automotive sector, embracing the evolution of these components can lead to new opportunities in performance upgrades and customization.