Upgrading your Evo X with a sequential transmission can transform your driving or racing experience, offering enhanced performance and responsiveness. This modification is particularly appealing for business owners in the automotive sector looking to provide their customers with high-end performance solutions. Each chapter of this article will delve deeper into critical aspects of sequential transmission installations in Evo X vehicles, from aftermarket options through to technical considerations, performance benefits, and the challenges faced during installation processes. Understanding these elements is key for any business aiming to cater to the increasingly performance-minded automotive market.

Seize the Shift: Navigating Aftermarket Sequential Transmissions for Evo X

The Evo X sits at a crossroads for enthusiasts who crave the fastest possible gear changes on the track while still living with a car that can be driven to the paddock and back home. The allure of a sequential transmission is simple and compelling: instantaneous, linear gear changes that keep the engine in its power band and the tires in their sweet spot. The aftermarket landscape for the Evo X mirrors a broader motorsport trend, where the goal is not just speed, but precision, repeatability, and confidence under high lateral load. In practice, this means a thoughtful marriage of mechanical hardware, electronic integration, and driver training. The path is not a plug-and-play upgrade; it is a dedicated project that reshapes how the car behaves, how it communicates with the driver, and how it fits into a race or track-day routine. A sequential setup promises faster shifts and cleaner lap times, but it also demands a rigorous approach to hardware selection, mounting geometry, and control software. The journey begins with a clear understanding of what a sequential gearbox brings to a car built around a traditional manual or semi-automatic architecture and ends with a system that feels alive in the hands of a skilled driver rather than a mere device installed for speed alone.

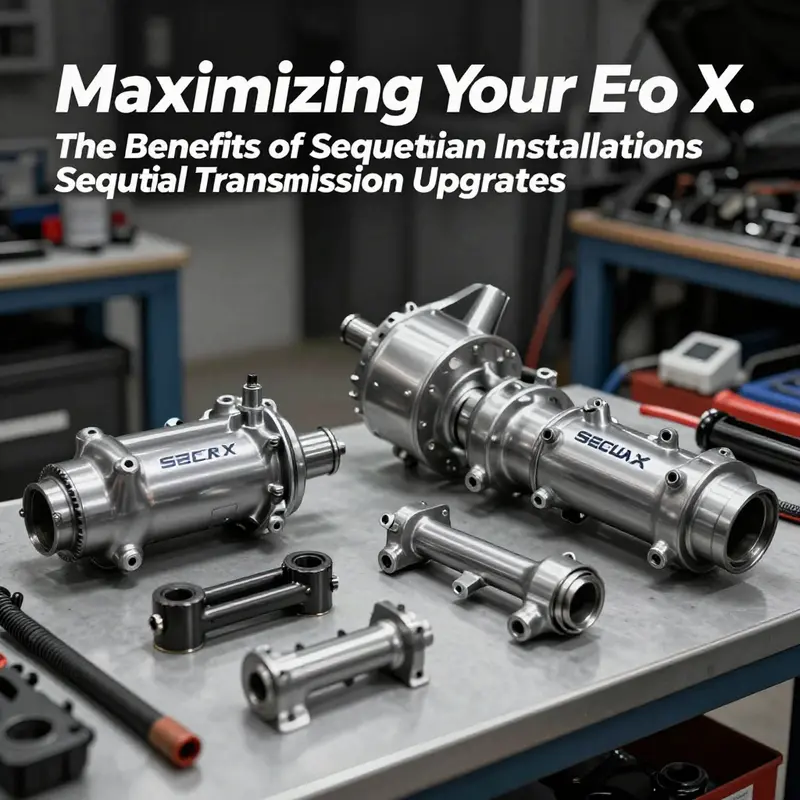

The core of any aftermarket sequential installation lies in the gearbox itself and the accompanying hardware that makes it usable in a street-legal or race-focused Evo X. In the broader practice, a popular choice centers on compact, race-proven sequential units designed for mid to high-power applications. These gearboxes are engineered for dog engagement or multiple-disc clutches that deliver rapid, repeatable shifts with minimal torque interruption. To make such a unit work in an Evo X, builders must address mounting fidelity, alignment with the driveline, and the precise mating of the shifter mechanism to the chosen transmission. Beyond the gearbox, a balanced package includes carefully matched gears, a binding-free shift linkage, a reliable clutch system, and a hydraulic or pneumatic actuation pathway that communicates cleanly with the car’s existing controls. Custom gear ratios are often part of the upgrade, calibrated to preserve the engine’s torque curve, keep wheelspin in check, and ensure the car remains harmonious with its suspension geometry and tire selection. In many builds, a dedicated shifter assembly is paired with an electronic interface that interprets paddle or lever inputs and translates them into rapid gear changes without a hiccup in the throttle or intake response. The result is a drivetrain that feels laser-focused on movement from one fixed point to the next, driven by a driver who is truly in command of the cadence of each lap.

What makes the Evo X a particularly interesting case is that its factory lineage did not include a factory sequential option in the same way as some other performance platforms. This absence is not a roadblock; it is an invitation to adapt proven concepts from adjacent Evo generations and other performance applications. Tutorials and case studies drawn from the Evo 8 scene, where sequential transmissions were more widely pursued in competition and high-performance builds, provide a practical blueprint. These resources emphasize four elements: the gearbox catalog and its fitment envelope, the custom gear ratios that tailor the power delivery to the engine’s torque band, and the dog-engagement or fast-sync mechanics that shave milliseconds from each shift. They also underline the importance of a sturdy mounting framework that can resist the extra loads generated by the higher shift speeds, as well as a control strategy that coordinates the gearbox with the engine management system and the transmission hydraulics. While direct Evo X-specific installation documentation remains comparatively scarce, the shared principles across similar platforms offer a credible roadmap. The essence is to respect the car’s structural limits and electrical architecture while extracting the maximal dose of response from the gearbox.

The process of turning that roadmap into a runnable system is as much about planning as it is about parts. It begins with a candid assessment of the vehicle’s current architecture: where the OEM bellhousing, transmission tunnel, and chassis mounting points will bear the extra loads, how the engine control unit (ECU) will be reprogrammed or re-flashed to recognize the new transmission state, and how the clutch, flywheel, and hydraulics will mesh with the new geometry. A key decision point concerns the shift actuator and the shifter linkage, which must offer precise mechanical travel and repeatable action under race conditions. The swap also invites a reexamination of cooling and lubrication pathways, since the gearbox’s timing and the lubrication schedule may diverge from the stock setup under sustained high-load regimes. The drive-by-wire or mechanical throttle response needs to be harmonized with the gearbox’s shift cadence to avoid any disconnect between pedal input and the engine’s torque delivery during a shift. During planning, engineers and enthusiasts often sketch a target shift cadence, decide on the number of gears, and delineate gear ratios that preserve usable torque across the rev range while reducing the chance of surge or lug when the track requires a tight, high-load sequence.

From a practical perspective, the Evo X sequential project is as much about integration as it is about hardware. The installation workflow commonly covers four intertwined strands: the mechanical conversion, the electronic integration, the calibration, and the driving discipline. Mechanically, the car must accept the transmission’s footprint, the shift drum, and the control linkages without compromising chassis rigidity or weight distribution. Electrically, the ECU interface must translate paddle or lever commands into the gearbox’s internal sequencing logic, while staying synchronized with engine maps, throttle response, and brake systems. Calibrations must address gear tooth contact patterns, shift delay compensation, and safety interlocks that prevent mis-shifts or double-bangs from destabilizing the driveline. Finally, the driver’s role evolves—the car asks for a different rhythm, a deliberate cadence rather than the more forgiving, torque-constrained push of a conventional manual. This is not simply a faster lever; it is a new form of feedback, where a precise, tactile sequence communicates a level of control that can only be achieved through practice and adaptation.

A practical outcome of this approach is a car that can rely on very short, controlled shifts under race-day stress. Yet the reality remains that a sequential Evo X is not a universal solution for every track day. The setup requires careful balancing of weight, reliability, and daily drivability. In the broader sense, the sequential path trades some ease of daily driving for uncompromised performance on the strip or on the circuit. The drivetrain becomes less forgiving of imperfect technique, and the cockpit experience becomes more specialized. For some, that is the essence of performance: a vehicle that rewards discipline, precision, and consistent technique rather than broad, all-purpose ease. For others, the daily realities—traffic, parking, and long commutes—may tilt the decision toward more moderate applications, or at least a hybrid approach that keeps the core of the sequential system focused on track readiness while maintaining routine usability.

What helps bridge these realities are the available learning resources and community experiences. Video tutorials, long-form builds, and teardown analyses give aspiring builders a sense of the practical steps involved—from how the shift mechanism is wired into the chassis to the way the system’s electronics are tuned to real-world operating conditions. They also highlight the common pitfalls: misaligned mounting points that create binding, gear lash that produces noisy engagement, or ECU miscommunication that yields unpredictable shift timing. The wisdom here is not simply about swapping parts; it is about building a holistic system where mechanical precision, electrical reliability, and driver confidence move in harmony. Even as the Evo X community borrows from related platforms, the core discipline remains constant: respect the limits of the car, plan for the integration with the car’s electronics, and test relentlessly under controlled conditions before pushing toward high-speed performance.

To support this approach, practitioners often reference a flexible repository of knowledge that transcends a single model year. A representative pathway is the comprehensive guidance that outlines an adaptable framework for the Evo family—covering unit selection, gear ratio customization, and the nature of the engagement system. This framework helps a builder decide where to apply constraints and where to push for performance gains. It also serves as a reminder that the journey toward a seamless sequential setup is iterative: you prototype, verify, adjust, and repeat until the system behaves predictably at the limits of the track. The process becomes as much about discipline and planning as about the thrill of a quick shift.

For readers seeking a narrow, concrete touchpoint that mirrors the Evo X experience, consider exploring a dedicated install guide that demonstrates how the overall architecture can be adapted across generations. full sequential gearbox for Mitsubishi Evo 4-9 and X offers a compact snapshot of the integration philosophy, including how a sequential gearbox can be slotted into a platform with a shared lineage. While this resource is outside the Evo X’s direct documentation, its emphasis on mounting accuracy, electronic compatibility, and drive-system reliability resonates with the Evo X ethos and the broader practice of sequential upgrades. For enthusiasts who want to see the concept translated into hands-on steps, the combination of such guides with video walkthroughs provides a practical, multi-angle approach to learning.

As the Evo X community continues to explore these upgrades, the conversation remains anchored in a balanced understanding of what sequential transmission brings and what it requires. The shift is not merely a faster lever; it is a new standard of precision, a more demanding interface between driver and machine, and a commitment to track-focused performance that may trade some day-to-day convenience for a level of control and speed that only a properly engineered sequential system can deliver. The dialogue across forums, workshops, and garages reveals a shared respect for the engineering challenges and the satisfaction of seeing a car respond with the immediacy that a great driver can coax from it. The result is a car that does not merely accelerate more quickly; it communicates more clearly, shifts with greater authority, and rewards patience and practice with a tangible feel that is hard to replicate with any other upgrade. The Evo X, with the right preparation, becomes a platform capable of translating that disciplined rhythm into competitive advantage on the track while retaining its character as a nuanced road car for those rare, well-planned occasions that call for a performance-focused, sequential experience. For readers who want to dive deeper into the procedural side of this journey, the evolving body of tutorials and project logs offers an invaluable, practical lens on how such a complex integration unfolds in real-world builds.

External resources and demonstrations remain a helpful reality check. For real-world demonstrations and communities sharing their day-to-day progress, see the broader online landscape where builders post their sequential swap journeys and the insights they gain from on-car testing. For an example of the kind of hands-on, in-motion learning that often accompanies these projects, you can explore the following external reference: https://www.tiktok.com/@carlifestyle/videos/123456789.

Sequential Transmission Upgrades for Evo X: Technical Realities and Practicalities

A sequential transmission offers faster, more deliberate shifts and a stronger driving sensation for high performance Evo X builds. Implementing such an upgrade on a modern, road-going chassis demands more than a bolt-in box; it requires a cohesive integration of mechanical hardware, electronics, cooling, and driver training. The Evo X platform rewards precision and planning, and a well-executed upgrade can deliver race-bred response without sacrificing daily usability.

Clutch and flywheel choice sits at the heart of a reliable upgrade. The sequential unit transmits torque in rapid bursts and places elevated loads on input components. A lighter flywheel reduces inertia and speeds response, but it also changes engagement and heat management. Multi-plate clutches are commonly selected for their higher torque capacity and smoother engagement, but they must be matched to the transmission’s input geometry and the engine’s torque profile at the target power level. Mismatches manifest as uneven engagement, slip under load, or accelerated wear that undermines reliability over a race weekend.

Electronics are equally critical. The Evo X’s stock shift logic relies on tightly integrated ECU and transmission control, with driver inputs through paddles. A standalone sequential box often requires reprogramming or replacement of the ECU/TCM to synchronize timing, rev-matching strategies, fault handling, and safety interlocks. Without a coherent control strategy, shifts can become erratic or uncommanded. In practice, teams implement a dedicated control strategy or a carefully calibrated interface that maps paddle inputs to precise gear commands while preserving interlocks and diagnostic feedback.

Cooling and lubrication cannot be neglected. Rapid shifts and sustained track sessions generate significant heat, stressing factory cooling paths designed for conventional transmissions. External oil cooling, appropriate synthetic transmission fluid, and a validated thermal loop are essential to maintain consistent shifts and prevent heat soak that damages gears, bearings, and seals. The objective is to keep oil temperatures stable across the full range of operating conditions and to ensure lubrication remains effective under high shear.

Mounting and drivetrain alignment also demand meticulous attention. A sequential swap often requires redesigned mounts, brackets, and possibly restructuring of subframes and crossmembers. Misalignment can produce vibration, elevated bearing loads, gear whine, and accelerated wear. Precision with alignment tools, fixtures, and careful re-verification after heat cycles reduces risk and preserves long-term reliability.

Driver adaptation and safety are fundamental. The cadence and feel of a sequential system change the driver’s interaction, from pedal feel to shift timing. Proper training, data logging, and defined fault handling help the team monitor shifts, protect the engine, and keep the car stable through corners and at the limit. The upgrade is as much about software calibration and driver coaching as it is about hardware.

In summary, a thoughtful architecture—matched clutch/flywheel, aligned electronics, robust cooling, careful mounting, and disciplined driver integration—is essential to a successful Evo X sequential upgrade. It is a demanding project that can yield race-car responsiveness and reliable operation when executed with a clear plan, validated on a dyno and a controlled track environment.

Shifting Gears, Elevating Pace: Performance Gains from Sequential Transmissions on Evo X Upgrades

On the race tightrope where milliseconds decide outcomes, shifting becomes a skill unto itself. A sequential transmission changes that skill from a learned habit into a precise, repeatable action. In high performance platforms designed for speed, the driver’s intention is translated into a gear change with minimal delay and maximum throttle continuity. The appeal is simple and compelling: faster shifts, fewer opportunities for a missed gear, and a drivetrain that stays connected to the torque flow even as acceleration stacks through the gears. This is especially impactful on a platform built for aggressive handling and all wheel drive gripping power, where every fraction of a second counts in how the car translates track momentum into forward pace. The sequential setup, with its dedicated shift path and streamlined engagement, allows the driver to walk a steady line between torque, grip, and momentum, turning shift timing into a controllable dial rather than a variable to contend with. The result is not merely a perception of speed; it is a measurable uplift in consistency and lap pace that can transform a track session from a series of good moments into a sustained performance rhythm.

The core advantage begins with shift speed. A sequential gearbox is engineered for rapid gear exchanges that occur in a narrow window, often without lifting off the throttle. The driver commands the change with a single action that engages the next ratio while the engine remains under load. In practice, this means the engine does not lose precious rpm, the tires do not experience a torque lull, and acceleration remains more linear through the transition. For cars built to exploit corner exit traction and mid-corner drive, that continuity matters. The throttle remains planted, the drivetrain remains engaged, and the subtle cadence of power delivery becomes a controllable attribute rather than a byproduct of the driver’s precision. It is this throttle-preserving shift that translates into faster exits and more uniform lap times, particularly when the driver is hunting peak grip across a sequence of tight corners.

Power handling is another realm where sequential systems shine. In builds aiming well into the higher horsepower range, the gearbox must cope with torque peaks that stress or even overwhelm a stock arrangement. A properly designed sequential setup distributes torque through robust internals and a packed lubrication regime that is optimized for rapid, repeated shifts under sustained load. The design intention is to keep gear teeth, synchronizers, and shafts operating within safe margins even as the engine breathes aggressively. For enthusiasts chasing substantial torque without compromising reliability, this translates into a wider operating envelope: more power, more consistently delivered through the same gear, and less risk of a skipped or misapplied shift that could spike heat or trigger instability. The result is confidence that the car can sustain intense track sessions without incremental failures, a meaningful difference when every lap time is a data point and every data point matters for setup decisions.

Reliability and durability are not afterthoughts in this equation. The mechanical stiffness of a sequential box is designed to resist the fatigue that accumulates in a high-strain environment. Stronger gear trains, hardened materials, and improved lubrication paths work together to reduce the wear and tear that plague high-output manual systems. In charting the potential gains, one often sees a reduction in maintenance interruptions and a greater tolerance for sustained high-load operation. A reliable shift machine supports long track days and rapid test-and-tune cycles with less downtime, which is exactly the kind of operational advantage that endurance racers and club racers alike seek. The reliability gains are complemented by electronic sophistication that modern sequential systems bring to the table. Advanced controls orchestrate shift timing with precision, leveraging data from the engine, transmission, and vehicle dynamics to optimize when the next ratio is engaged. This level of electronic integration not only tunes performance but also improves drivability, helping a driver to maintain control across varied surfaces and temperatures. The sophistication reduces the cognitive load on the driver, turning shift strategy into a programmable aspect of vehicle behavior rather than a trial-and-error skill executed under pressure.

The day-to-day experience of driving a car with a sequential upgrade is another compelling dimension. The absence of a clutch pedal and the streamlining of the shift lever can simplify operation, especially under track-focused use where fatigue, repetition, and precision all play a critical role. Yet the appeal is not purely convenience. The predictable and repeatable shift pattern enhances consistency, which translates into more predictable vehicle behavior at the limit. For many drivers, that predictability is the essence of confidence when they push toward the edge of grip through a corner sequence. The crispness of the engagement, the feel of a well-timed cadence, and the assurance of staying on the power band through gear changes contribute to a more intuitive sense of control. This is not a replacement for driver engagement; it is an amplifier of it. It allows the driver to focus on line, apex, and staging for the next run rather than micro-engineering each upcoming shift.

From a dynamics perspective, sequential gearing improves overall vehicle responsiveness. With shorter shift intervals, the car’s behavior aligns more closely with the driver’s intent, particularly when managing transitions between corners or adopting aggressive throttle application during late braking. The control logic that accompanies the gearbox often includes programming to synchronize shifts with differential lock strategies and traction control parameters, ensuring the chassis responds coherently to the intent expressed by the driver. The net effect is a more coherent, composed, and aggressive acceleration profile that can translate into faster lap times as line accuracy improves and the car remains more balanced during the shift itself. In high-speed corridor sections, where every moment of power transfer matters, the ability to maintain momentum through shifts is a tangible performance lever that teams and enthusiasts pursue with enthusiasm.

The path to these benefits, however, is not without its caveats. Upgrading to a sequential transmission requires a substantial integration effort. It is not simply swapping a gearbox; it is reconfiguring the drivetrain’s interaction with the engine, the differential, and the control electronics. The installation typically demands careful alignment of mounting points, reinforcement of the transmission tunnel, and a rethinking of the shifter mechanism—often tailored to a paddle-style interface or a specialized lever geometry. The electronic ecosystem must be harmonized with the ECU so that shift maps, speed sensor data, and throttle input all communicate in a coherent loop. In practice, this means a comprehensive engineering approach that accounts for the vehicle’s weight distribution, cooling capacity, and the durability of downstream components like driveshafts and mounts under elevated loads. Such work is best executed in collaboration with specialists who understand how to preserve reliability while extracting the speed gains that sequential gearboxes promise.

Heat management remains a practical concern. The gearset, hydraulic actuation, and electronic control can generate additional heat in both the gearbox and surrounding subsystems. Effective cooling strategies, including targeted oil cooling and strategic chassis airflow, are essential to maintain performance over long sessions. The higher the power and the more aggressive the use profile, the more the heat equation matters. A well-integrated system will often incorporate cooling loops tuned specifically for the sequential setup, along with robust lubrication strategies to sustain mid-range operating temperatures during repeated upshifts and downshifts. This is not merely a hardware upgrade; it is a holistic performance program that requires attention to how the upgrade interacts with the vehicle’s aero balance, weight distribution, and overall cooling capacity.

The aesthetics of the build are not incidental to performance either. In many race-inspired configurations, functional upgrades are complemented by structural refinements and lightweight panels that improve chassis rigidity and heat management. A well-chosen enhancement, such as a carbon fiber bonnet or other aero elements, can influence airflow and cooling efficiency while reducing unsprung mass. In one practical example of how these pieces fit together, consider a carbon fiber hood upgrade, which can help manage under-hood temperatures and contribute to the car’s structural stiffness. For readers exploring this aspect of the build, a detailed example of a carbon fiber bonnet hood option is available here: carbon fiber bonnet hood for the Evo X. The integration of such components is not purely cosmetic; it supports the thermal and mechanical demands of a high-performance, track-oriented setup, enabling the sequential system to perform as designed without compromising everyday usability.

As the hobby and the sport have matured, the community surrounding high-performance builds has become attuned to how a sequential upgrade fits into a broader program. Enthusiasts who pursue competitive track results often approach the upgrade as a phased project: establish the core mechanical reliability and shift performance, then enhance data acquisition and drive-by-wire compatibility, followed by refinements to cooling, chassis rigidity, and aero balance. This staged approach allows teams to quantify gains, validate reliability, and tune the vehicle’s personality to match the driver’s preferences. It also helps in balancing the inevitable tradeoffs—cost, weight, complexity—against the upside of faster shifts and improved traction under load. The consolidated effect is a vehicle that is easier to drive at the edge, more forgiving when pushed, and capable of sustaining aggressive pace across a full session rather than at isolated moments.

In closing, the pursuit of speed through a sequential upgrade is a synthesis of engineering discipline and driver-centric design. The gains in shift speed, power handling, reliability, and electronic integration converge to deliver a vehicle that responds with heightened immediacy to a driver’s intent. The experience is not just about faster times; it is about a more consistent, confident, and engaging feel on the track. For builders and drivers who value a purpose-built, race-informed approach to performance, the sequential transmission represents a coherent pathway to unlock the next tier of capability from a high-performance platform. If a broader vehicle program emphasizes heat management, chassis rigidity, and aero efficiency as the scaffolding for speed, the gearbox becomes a central lever rather than a standalone upgrade. The journey toward faster laps, higher reliability, and more intuitive control is, at its core, a craft—the art of making every shift count while preserving the harmony of the whole car.

External resource: Understanding Legacy Transmission: Key Specifications, Industrial Applications, and Performance Benefits. https://www.autoblog.com/2026/01/23/understanding-legacy-transmission/

Racing Against the Clock: Engineering the Evo X Sequential Transmission Upgrade

The Evo X stands as a paradox in performance engineering. On one hand, its chassis and suspension have a track-focused immediacy that invites bold experimentation; on the other, its factory drivetrain is tuned for reliability and a familiar manual-shift cadence. When the goal is to push into a race-bred shifting paradigm—where fraction-of-a-second gear changes can decide a lap—the idea of a sequential transmission becomes seductive. Yet the path from concept to road-ready installation is not a straight line. It is a careful negotiation between mechanical compatibility, electronic harmony, and metals and fluids that must endure the demands of high-speed, high-stress driving. The journey is less about swapping a gearset and more about orchestrating a system where every moving part, from the clutch to the ECU to the cooling system, speaks the same language of precision under pressure. This chapter traces that orchestration, highlighting the core challenges that arise when a purposes-built sequential unit is grafted onto an Evo X, and the practical routes through which builders have answered them. It is a narrative of iteration, of learning to respect the limits of a platform while relentlessly pursuing the improvements that a true sequential can deliver on the track and, with care, on the street as well.

Mechanical compatibility forms the first, stubborn veil. The Evo X was designed around a traditional manual transmission with a bellhousing that aligns with a set of mounting points, a tail that meets a particular driveshaft length, and a differential geometry matched to the axial load profile of its initial gear ratios. Introduce a sequential gearbox, and suddenly the geometry matters more than ever. The new box demands custom mounting brackets and often a modified bellhousing to clear surrounding components and fit within the existing tunnel silhouette. The driveshaft must be re-measured and rebalanced for correct anti-squat behavior and proper angular velocity transfer, while the differential casing and flange pattern may require reengineering to maintain the correct drive ratio and torque distribution. The result, if these alignments are not exact, is a cascade of micro-mismatches: slight misalignment can ripple into shaft vibrations, unsteady torque delivery, and, at worst, mechanical failure under launch loads. Engineers combat this by developing tailored adapter kits and pre-engineered mounts that address the Evo X’s unique cradle and crossmember geometry, alongside precise bellhousing alterations that preserve bell-to-gear alignment while enabling the sequential unit to mate with the existing clutch actuation and input shaft interfaces. Even with these systems in place, the risk of misalignment remains a constant companion. In practice, a successful swap demands meticulous measurement, finite-element validation of mounts, and a long sequence of test fits and real-world validations on a dyno and then on the track. The goal is not simply to insert a gearbox but to harmonize the new drivetrain’s centerlines, driveshaft angles, and torque path so that every shift under load is predictable rather than an unplanned mechanical audition.

Electrical and electronic integration presents a second, equally rigorous barrier. A sequential transmission relies on a sophisticated control strategy: shift logic that knows precisely when to liberate the clutch, a clutch management profile that matches the engine torque curve, and a communications backbone that synchronizes gearbox state with engine management, traction control, and data logging. The Evo X’s original electronics ecosystem—especially older models lacking modern CAN bus capabilities—often lacks the plug-and-play readiness a modern sequential package expects. In such cases, the signal highway must be rebuilt: wiring harnesses are redesigned, sensors are relocated or renamed, and a standalone controller becomes the central conductor. This can mean reprogramming the ECU to maintain idle stability, to safeguard misfire protection while the gearbox engages, and to ensure that thrust limitations during high-torque launches do not trip the engine management into protective modes. The risk here is as much about reliability as it is about performance. If the shift logic runs out of sync with engine torque, the result is erratic shifting, premature wear, or even a loss of engine control under critical conditions. Standalone ECUs or highly adaptable engine-management systems offer the flexibility to host the new shift logic while preserving essential engine functions, but they require careful mapping, sensor calibration, and a disciplined testing protocol. The electronic discipline must extend to the shifter mechanism itself, where a smooth, repeatable pull-or-push action must translate into crisp gear engagement at the gearbox, even when the driver is working the controls at the edge of the rev range.

Thermal and durability considerations add a third line of scrutiny that often surfaces only after the first two are negotiated. Racing gearboxes are designed for short, intense bursts of power and rapid heat dissipation under controlled conditions. A street-legal Evo X with a sequential unit, however, experiences a broader duty cycle, including repeated hot starts, city traffic micro-bursts, and lengthy sessions on track days where sustained high torque is the norm rather than the exception. The sheer thermal load on a high-torque sequential transmission can produce oil temperatures that climb quickly, especially if the cooling provisions were designed for a conventional gearbox rather than a high-demand race spec unit. Without robust oil cooling—be it through cooler lines, larger reservoirs, or enhanced heat exchangers—the clutch packs and gearsets can suffer from accelerated wear, creeping drag, and lubrication breakdown. The result is a reliability profile that becomes the central question of any build that wants to run reliably at track speed for multiple hot laps. Builders address this by integrating high-capacity oil cooling, designing oil-feed strategies that maintain lubrication pressure during aggressive launches, and selecting clutch packs known for repeatable performance at high temperatures and sustained torque. These choices have ripple effects across the rest of the drivetrain—the bellhousing clearance, the layout of the oil lines, and even the design of the transmission tunnel to accommodate larger components. The engineering mind in the room must constantly weigh the benefits of faster shifts against the heat you invite into the system and the accompanying maintenance burden.

Cost and expertise. If the mechanical, electrical, and thermal arguments above were fully mastered, the project would still require financial and human resources that are seldom trivial. A sequential swap for a performance-oriented platform is a high-value, long-cycle project. The gearbox itself represents a substantial capital outlay, even before the cost of custom fabrication, sensors, controllers, and the labor needed to assemble, install, and calibrate the system. Then there is the time cost: the iterative testing, the data logging, the parameter tuning, and the eventual road- and track-testing that converts a concept into a dependable performance feature. The broader shop ecosystem matters as well. Achieving reliable integration across the mechanical, electrical, and thermal domains requires a team with deep, cross-disciplinary experience—engineers who can validate fitment with precision, write and tune control strategies, and verify durability through simulated and real-world stress tests. This is not a one-man job; it is a small, dedicated project team that treats the Evo X not as a generic chassis but as a living platform whose particular geometry and electronic architecture demand bespoke solutions. All of this underscores a practical truth: the appeal of a sequential system must be weighed against the budget, the tolerance for risk, and the willingness to support a high-maintenance, high-performance machine over its entire lifecycle.

Yet even as challenges accumulate, a pathway through them exists. Builders have begun to segment the problem into modular, repeatable steps. The early phase focuses on the mechanical interface—developing mounts and adapters that lock the gearbox in a fixed, precise position with respect to the engine and driveshaft while preserving safe clearance margins for the exhaust, cooling lines, and other components that skirt the transaxle. The next phase centers on the control architecture. A standalone management system can host the shift logic and clutch control while providing a clean, predictable interface to the engine ECU and the car’s CAN networking where applicable. This approach reduces the risk that the gearbox will disrupt engine management or safety systems and offers a stable platform for calibration and data analysis. In parallel, the cooling strategy is designed to be resilient under repeated launches and lengthy track sessions. High-capacity oil reservoirs and carefully routed cooling circuits reduce the likelihood of thermal fatigue in the gearbox and clutch system, thereby extending life and maintaining shift integrity under load. The final phase binds the whole system together with rigorous testing. A disciplined testing protocol—comprising static measurements, dyno validations, and progressive track testing with data logging—allows engineers to observe how the sequential system behaves under different loads, temperatures, and driver inputs. The objective is not merely to achieve faster gears but to secure a behavior profile that remains consistent, controllable, and predictable across the entire operating envelope.

Within this practical framework, one can see how the Evo X sequential transmission upgrade becomes less a single part swap and more a carefully choreographed program. The modular conversion kits that increasingly appear in the aftermarket space provide pre-engineered mounts, adapters, and harnesses that reduce development time and improve reliability. By pairing these hardware foundations with standalone ECU systems, builders unlock the ability to tune shift timing, manage clutch engagement, and ensure that engine management remains cohesive with the new gearbox. For those who pursue high-performance results, this combination—rigid mechanical interfaces, flexible electronic control, and robust thermal management—defines a credible path to real, track-ready performance gains. The choreography of fitment, control, and cooling is not just about speed. It is about repeatability and safety, two attributes that matter every time the shift pedal is pressed at the apex of a corner or the start line of a sprint race. While the pursuit may appear niche, its underlying philosophy resonates with any engineering challenge that seeks to replace a legacy system with a more capable, albeit more complex, successor. It is a reminder that progress in performance is as much about disciplined integration as it is about horsepower on paper.

For those who want a concrete sense of how these elements come together in practice, refer to the detailed discussion on full-sequential gearboxes for Evo-family platforms. A practical, design-oriented overview can be found in the community-driven technical resources that outline mounting strategies, adapter considerations, and wiring harness approaches tailored to the Evo X platform. See the guide at full-sequential-gearbox-for-mitsubishi-evo-4-9-and-x for a compact synthesis of the components and steps involved in a credible installation. This resource, while not a panacea, illustrates how modular solutions can sharply reduce development time and improve reliability when the goal is a competitive, race-oriented Evo X.

As the field evolves, the promise of a robust, track-worthy sequential experience grows more tangible. The Evo X remains a platform that rewards thoughtful engineering more than dramatic, untested improvisation. The path forward is not a shortcut but a series of informed choices—mechanical alignment, electronic integration, thermal resilience, and a careful calculus of cost versus benefit. When these elements align, a sequential transmission upgrade transforms from a theoretical upgrade into a dependable performance feature. It is a transformation born of precision, discipline, and a willingness to iterate—traits that power not only the fastest Evo X builds but any rigorous pursuit of performance: the art of making a machine do precisely what the driver intends, every time the gearbox is commanded to shift.

External resource note: For broader context on high-horsepower sequential builds and the hands-on realities of these conversions, a detailed, widely viewed reference is available online at this external resource: https://www.tiktok.com/@racingevolution/video/7465123456789012345.

Final thoughts

Adopting a sequential transmission for your Evo X can yield significant performance advantages, appealing to both enthusiasts and those in the automotive business. While the journey involves careful consideration of aftermarket options, technical complexities, and overcoming various challenges, the end result offers an exhilarating driving experience defined by rapid gear shifts and improved handling. By understanding these critical factors, business owners can cater effectively to a growing market segment eager for high-octane performance modifications.