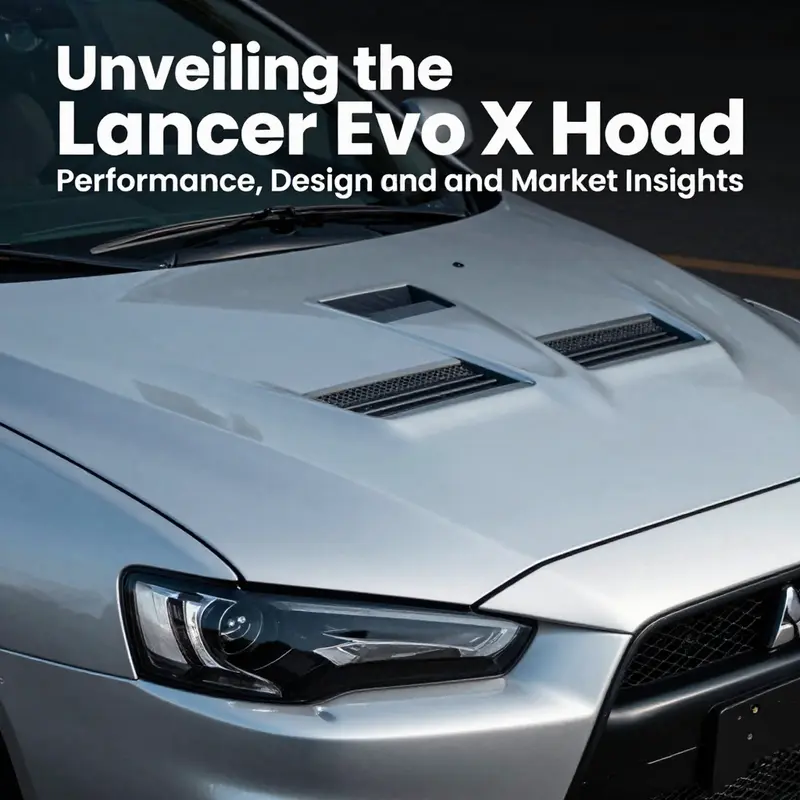

The Lancer Evo X hood serves as a significant component in enhancing both the performance and aesthetic appeal of this iconic vehicle model. Understanding its features and design, the types available, and the current market trends can provide valuable insights for business owners in the automotive industry. Each chapter in this article delves into specific aspects of the Evo X hood, offering a comprehensive overview that aids in making informed purchasing and business decisions.

Weight, Wing, and Wake: Rethinking the Evo X Hood as Performance and Identity

On a car built for rally-inspired performance, the hood is more than a cover. It is the front line of control. It marks the transition from raw power to purposeful handling. For the Lancer Evolution X, the hood is a focal point in a broader dialogue about how mass, airflow, and style intersect. The hood’s weight, its rigidity, and its vents define how quickly the engine bay can shed heat, how easily air flows across the radiator, and how confident the driver feels at the limit. In a car whose DNA is built around balance, the hood matters as much as the suspension or the brakes. This is not merely a cosmetic panel; it is a critical performance component whose design choices echo through acceleration, steering, and the ability to maintain peak power through demanding driving scenarios.

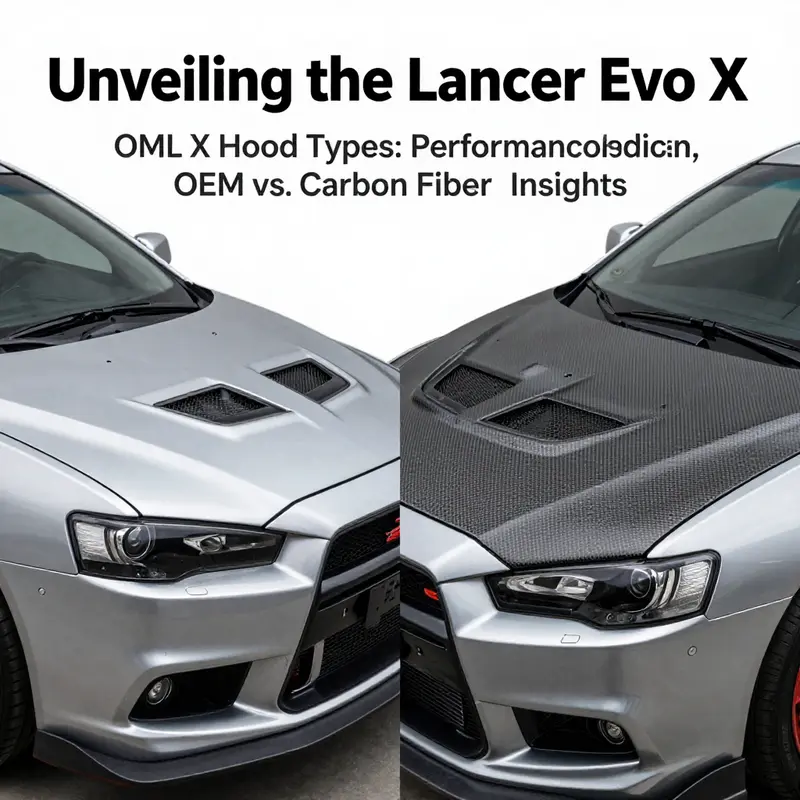

Original Equipment Manufacturer (OEM) hoods and aftermarket options sit at the heart of the Evo X hood story. OEM hoods are designed to strict safety and regulatory standards, and they emphasize precise fitment and dependable durability. In the Evolution X era, factory hoods were typically steel, with some later iterations offering aluminum as a lighter alternative. The hallmark of the OEM hood is alignment: mounting points line up with the fenders and radiator support with uncanny accuracy, ensuring consistent gaps, predictable latch behavior, and a finish that matches the rest of the sheet metal. The trade-off is weight. A stock hood adds considerable mass to the front end—roughly in the high teens to the low twenties of kilograms, depending on the exact build and era. This extra weight plausibly improves dent resistance and rigidity but comes at the expense of front-end agility and instantaneous throttle response. For a car that gains its sense of purpose from being able to shed mass around corners, that front-end heft can become a limiting factor as one pushes toward the edge of grip. Yet for a daily driver or a purity-purist build, OEM remains a compelling baseline because it preserves the original structural integrity, crash compatibility, and color-matching capabilities that make service and resale simpler and less fraught with risk.

Meanwhile, the aftermarket landscape offers a spectrum of materials and philosophies designed to alter the Evo X’s front-end dynamics. Carbon fiber hood options have become a focal point for those chasing the ultimate balance of weight savings and stiffness. The benefits of carbon fiber are well documented in performance circles: weight reductions often exceed 40 percent relative to steel, bringing front-end mass down into a range of roughly six to nine kilograms depending on the construction and whether ventilation is included. The immediate consequence is a tangible shift in weight distribution and inertia. With less weight atop the front wheels, steering feel sharpens, turn-in accelerates, and suspension dynamics respond with greater immediacy. In practice, that lighter nose translates into crisper corner entry and improved rotational balance through midcorner transitions, especially when the chassis is already tuned to accentuate lightness and balance. The gains do not stop at the scale. Carbon fiber hoods frequently incorporate large air intakes or vent patterns designed to channel hot air away from the engine bay. These vents can help sustain higher power outputs by reducing heat soak, particularly in spirited driving or track conditions where repeated acceleration tests the cooling system. The aesthetic is unmistakable too. The visible weave, the gloss or matte finish, and the sculpted forms project a performance stance that signals intent even when the car is stationary.

Another material option in the Evo X hood ecosystem is fiberglass. Fiberglass hoods offer a meaningful weight reduction over factory steel while typically maintaining a price point more accessible than carbon fiber. They present a practical middle ground for enthusiasts who want a performance edge without the premium cost of carbon fiber. Yet fiberglass carries its own caveats. It can be more vulnerable to cracking under impact than carbon fiber when not properly supported, and it sometimes exhibits less consistent rigidity across the entire panel. Fitment tolerances can also vary, underscoring the importance of choosing a reputable supplier and verifying warpage, alignment with the hood’s edge lines, and the quality of mounting hardware. For many, fiberglass serves as a stepping stone—an affordable route to experience the dynamic benefits of lighter front-end mass while preparing for a future upgrade to carbon fiber.

Design and function are interwoven in the Evo X hood beyond material choice. Modern hoods in this lineage emphasize airflow management as a core function. Prominent front openings, vent channels, and contoured hood surfaces help manage the engine bay’s thermal load during aggressive driving. This is not only about cooling a turbocharged engine but also about controlling the intake and intercooler geometry to sustain performance without heat soak. The vent shapes—whether bold scoops, slender channels, or integrated diffusers—are engineered to influence boundary layer behavior and direct cooling air where it is most needed. The result is not simply a cooler engine; it is a more repeatable power delivery, a more linear throttle response, and a chassis that remains predictable when pushed through fast corners or long straights.

If you are contemplating a hood swap, the installation narrative matters as much as the design narrative. A well-made carbon or fiberglass hood will typically mount to the OE hinge points, avoiding the need for drilling or structural modification. This is a significant advantage for owners who want the benefits of weight reduction without introducing a cascade of compatibility issues in the grille, fenders, or hood latch. The latch mechanism has to function precisely; the panel must close evenly along all edges, and the paint must align to prevent chafing and misalignment. Paint finish and edge sealing are not mere cosmetic concerns but essential for long-term durability, especially in climates with moisture or road salt. Steel hoods can be more prone to rust at edges if the paint layer is damaged, whereas aluminum or carbon fiber models shift the corrosion risk toward fastener compatibility and resin-rich edge properties. In all cases, care with surface preparation before installation, along with correct torque for fasteners and an appropriate latch setting, preserves both function and longevity.

The Evo X hood also interacts with the broader chassis philosophy. The car’s handling balance benefits from a lighter front end, but the weight distribution must remain harmonious with the rest of the vehicle. A hood that is too light without corresponding adjustments in springs, dampers, and anti-roll stiffness can increase front-end jitter or reduce feedback. Conversely, a hood that remains stubbornly heavy may mask the car’s agile intent. For the enthusiastic driver, the ideal hood choice aligns with a full system plan: a lighter front-end panel, carefully tuned suspension, and a cooling strategy that supports peak output without inducing instability. That is the essence of the Evo X hood conversation: it is not a single upgrade, but a spectrum of choices that redefine the car’s response to throttle input, cornering forces, and aerodynamic load.

The supplier landscape for Evo X hoods in 2026 reflects a broader shift toward commoditized performance composites while preserving bespoke options for enthusiasts. The most mature production hubs lie in southern China, with Guangzhou standing out as a major center for carbon fiber production and post-processing. This region benefits from an integrated supply chain: prepregs, resin systems, and CNC tooling can be sourced locally, enabling rapid prototyping and tighter feedback loops between development and real-world testing. Zhejiang follows as another node in this ecosystem, supporting finishes, trims, and ancillary components that complete the hood upgrade package. The geographic clustering reduces lead times, making it easier for individuals and small shops to pursue iterations. For buyers, there are platforms that link buyers directly to manufacturers, offering various levels of customization—from basic vent patterns to fully customized layups. For business buyers, relationships with specialized manufacturers can unlock larger runs, consistent quality, and controlled testing to verify fit across Evo X variants in different markets.

Within this market reality, choosing the right hood becomes a question of goals and constraints. If the priority is a faithful reproduction of factory aesthetics, an OEM-style hood remains compelling. It preserves the stock look, color match potential, and the safety margins of the original design. If performance is the primary objective, carbon fiber options with vented designs stand out, offering a clear performance delta in weight and cooling efficiency. For budget-conscious projects or educational build threads, fiberglass alternatives can deliver meaningful improvements in mass savings without the premium of carbon fiber. The key is to assess how each material interacts with the car’s overall tuning, including cooling capacity, sheet metal tolerances, and the risk profile of corner-case conditions such as heavy rain or gravel exposure. In a well-planned build, the hood becomes a strategic element rather than a simple bolt-on: a component that communicates intent, shapes behavior, and elevates the whole car from a baseline Evo X to a purpose-driven machine.

An essential practical step in this journey is recognizing available sourcing channels and how they shape outcomes. For individuals seeking OEM fidelity and predictable serviceability, a vetted OEM-compatible hood offers a seamless path. The internal ecosystem for Evo X parts can also support color-matched finishes that require minimal repainting, reducing risk and preserving resale value. To illustrate the OEM path, consider a specific Evo X hood option that preserves fitment and color accuracy: 08-15-mitsubishi-lancer-evolution-evo-x-hood-phantom-black-oem-u02. This option demonstrates how OEM-grade components continue to be relevant even as enthusiasts chase lighter, more aggressive alternatives. The choice here is not merely about weight; it is about a cohesive approach to maintenance, aesthetics, and reliability within a familiar platform geometry.

From a broader perspective, the Evo X hood is part of a larger dialogue about how high-performance cars balance weight, heat, and airflow without sacrificing reliability. The hood’s venting patterns are not decorative; they shape how quickly air moves through the engine bay when the car is loaded with torque and speed. In hot weather or with track use, vents guide hot air away from the intake and intercooler pathways, lowering the risk of heat soak that can sap horsepower and throttle response. The hood’s surface geometry—its curves, creases, and edge radii—also influences aerodynamic behavior at speed. A hood that directs air cleanly toward the sides of the car reduces lift and helps keep the front tires planted on the road. All these relationships matter, and they become even more nuanced when the hood is replaced with a lighter panel that alters the mass moment of inertia and the front-end load transfer during aggressive cornering.

When considering the practicalities of procurement and installation, it is useful to keep a clear sense of the owner’s environment and maintenance habits. If the car lives predominantly on public roads and only visits the track on weekends, a balanced approach—perhaps a fiberglass hood with a tasteful vent pattern—may offer a satisfying combination of weight reduction, cost efficiency, and durability. If the car is regularly tracked, carbon fiber with a robust weave and well-engineered venting can deliver repeatable performance and a cooler engine bay, helping maintain engine power under sustained loads. For those who prize a clean, stock-like appearance with some weight savings, a carbon fiber hood with a minimal vent configuration can deliver both performance and discretion. In all cases, choosing a hood is a matter of aligning the metal and composite choices with the driver’s passion, the car’s mission, and the budget allocated for ongoing upgrades and maintenance.

In closing, the Evo X hood is a layered decision point. It sits at the intersection of engineering and expression, where every gram saved or gained can shift the balance of handling, cooling, and the vehicle’s perceived speed. It is a choice that communicates intent to the world: this car is designed to go fast, to corner tightly, and to endure high-stress driving with poise. The path from OEM steel to a carbon fiber vented panel is not merely a swap of parts; it is a reimagining of how the Evo X carries its power and how it presents itself on the street and the strip. Whether you aim for a quiet, understated upgrade or a dramatic, track-focused transformation, the hood remains one of the most consequential and revealing parts of the Evo X chassis.

Internal linking and performance identity: For OEM fidelity, there is a hood option that preserves the original fit and color matching, offering seamless integration with the car’s stock lines. The anchor text for this option reflects the URL slug and provides a direct path to the OEM hood variant: 08-15-mitsubishi-lancer-evolution-evo-x-hood-phantom-black-oem-u02. This choice demonstrates how an OEM-grade part can still play a meaningful role for owners who want a straightforward, reliable upgrade that doesn’t introduce new fitment risks or paint compatibility concerns. It is a reminder that performance is not solely about weight reduction; it is about sustaining the car’s original character while enabling a controlled evolution in capability and response.

External resource: For a broader view of carbon fiber hood options and the trade-offs between stiffness, weight, and cost, an external reference offers insights into material choices, layups, and real-world performance implications. See this external resource for additional context: https://www.alibaba.com/product-detail/Carbon-Fiber-Hood-Evo-X-Engine-Cover_1600553254677.html

Frontline of Performance: Weighing OEM Steel, Aluminum, and Carbon Fiber Hoods on the Evo X

The hood is often the first piece of a car that a spectator notices in motion, and for the Evo X it is more than a mere cover for the engine bay. It is a statement of intent. In a machine built to blend rally-derived engineering with street manners, the hood embodies a philosophy that prioritizes either factory reliability and seamless integration or radical lightness and aggressive airflow. When you stand in front of a car in motion, the hood’s silhouette, its surface finish, and even the way light glints off a vent are all part of how the vehicle communicates its purpose. This is especially true for a model like the Evo X, where performance parameters are finely balanced: traction, weight distribution, cooling, and aerodynamics all hinge on front-end design. The choice between an OEM hood and a carbon fiber alternative circles back to the broader theme of how a single component can influence a chassis’s behavior as much as a set of tires or a suspension tune. Yet the decision is not only about physics. It is also about authenticity versus experimentation, about preserving a sense of original intent or reimagining it with new materials that shift the car’s character, sometimes quite dramatically, at the moment it crosses the line from daily transport to track-ready menace.

OEM hoods, as factory replacements, are designed to be a faithful echo of the car’s original front-end. They are constructed to match mounting points with exactitude, to preserve the safety margins built into the vehicle’s structural design, and to satisfy regulatory expectations that cover impact behavior and pedestrian protection. The most common material for these hoods is high-strength steel, with aluminum appearing in later iterations as a response to the weight crisis that often follows a high-performance chassis across ages and markets. The weight of an OEM Evo X hood sits in a region around eighteen to twenty-two kilograms, a mass that subtly but noticeably affects front-end load, steering feel, and the inertia the front tires must overcome under braking and cornering. When you replace a hood with a genuine factory part, you gain the comfort of a perfect fit and the warmth of factory-grade paint-matching options. In practical terms, this means fewer alignment headaches, a more predictable engagement with the fenders and body lines, and a restoration-friendly route if the car is kept in a near-stock state for daily driving or occasional competition events.]

The advantages of sticking with an OEM hood go beyond fit and finish. They extend to warranties and long-term dealer support, which can be a decisive factor for owners who prioritize continuity and coverage. In a car that is already tuned with precision, maintaining a stock front end helps ensure that other modifications—whether a larger intercooler, a re-tuned engine management system, or upgraded brake components—remain compatible with the original safety and regulatory baselines. The downside, however, becomes evident when activity beyond the showroom floor takes shape. The steel construction, while robust against minor impacts and daily knocks, tends to be heavier than aftermarket alternatives. The weight contributes to a higher front axle load, which in turn can influence how the car brakes, steers, and aero-stabilizes at elevated speeds. This is not just a theoretical observation; it translates into predictable, repeatable behavior that is the bedrock of many street-driven Evo Xs. Yet the weight penalty is real. In environments where speed and agility are the daily pursuit, the extra mass of an OEM hood can feel like carrying a small anchor in the front of the car, slightly dampening acceleration responsiveness and front-end quickness. And while corrosion and paint chipping are less common with properly cared-for factory parts, any hood is still subject to wear. The risk of rust, especially in climates with salted roads or high humidity, is not negligible if the surface protection is compromised or if the underlying metal is exposed to the elements, causing long-term durability concerns that a meticulous owner can mitigate but never entirely eliminate.

Above all, the decision to use an OEM hood rests on a desire for authenticity and reliability. If the goal is a car that remains visually faithful to its original blueprint, with a front end that can be restored to factory condition with standard parts and service procedures, the OEM hood is a natural fit. For owners who prize a pristine showroom look or who intend to preserve the vehicle in a state that matches a specific historical or collector standard, the OEM path often makes the most sense. It preserves the lines that tuned engineers designed around the car’s mass distribution and cooling requirements. Yet for enthusiasts where the objective leans toward stripped weight and enhanced heat management, the story shifts quickly toward carbon fiber—an option that brings a different set of benefits and trade-offs.

Carbon fiber hoods offer a confluence of lightness, stiffness, and aggressive styling that aligns with a track-focused mindset. Carbon fiber, particularly when fabricated as CFRP (carbon fiber-reinforced polymer) or in advanced composite constructions, can reduce hood weight dramatically—typically by more than forty percent in many cases. Where the OEM hood might hover in the high-teens or low-twenties in kilograms, a carbon fiber hood often lands in a six- to nine-kilogram range. That kind of weight reduction matters. It lowers the front-end inertia, sharpening steering response and reducing the load on the front subframe during rapid weight transfer in cornering. In a chassis that already rewards precise handling and balanced weight, shaving several kilograms at the front can translate into quicker turn-in, more immediate throttle response, and a more eager sensation as you rotate the car into apexes. Weight savings also contribute to better acceleration characteristics, as less mass must be moved when changing speed, particularly in a car where the engine breathes through turbocharged pathways and where the cooling system must manage heat with the engine bay’s airflow dynamics in mind.

The design language of carbon fiber hoods often emphasizes performance-driven airflow. A hood designed for performance may incorporate a raised vent or a built-in intake channel that guides air through the engine bay to assist with cooling, or more subtly, to reduce intake air temperatures by pumping a small amount of cool outside air into the bay under load. The engineering logic is that turbocharged or high-load operation creates heat that can degrade power output or exacerbate detonation risk. Efficient ventilation in the hood area helps keep the turbocharger and intercooler working within their ideal temperature envelope, which is especially important in a car where the engine management system can push beyond stock parameters when tuned for more aggressive power delivery. The visual impact is equally potent. A carbon fiber hood often showcases a distinctive weave pattern, a raw or clear-coated surface, or a color-matched finish that reveals or conceals the weave depending on the owner’s taste. The aesthetic is not merely superficial; it signals a philosophy of performance and lightness that many enthusiasts find both compelling and authentic to the spirit of the car.

However, carbon fiber hoods bring their own set of considerations. Price is a primary factor. While an OEM hood is a straightforward replacement with a known cost and predictable availability, carbon fiber alternatives carry a premium that reflects materials, manufacturing complexity, and the lower production volumes common in high-performance aftermarket parts. The material itself—whether a prepreg carbon fiber system or a dry-weave composite—has implications for durability and maintenance. The lighter mass makes the hood more susceptible to certain risks if the mounting or sealing is not perfectly executed. For instance, sealing against water intrusion can require extra attention when the hood is replaced with a ventilated or vented carbon fiber model. The air channeling that aids cooling can also alter acoustics; many drivers notice a perceptible increase in engine howl or intake-driven sound at high speed when a hood with optimized ventilation is installed. The UV exposure that carbon fiber endures over time demands protective coatings—clear finishes or UV-stabilized resins—to prevent yellowing or micro-cracking in sun-exposed climates. These considerations underscore that a carbon fiber hood is not simply a lighter replica of the factory piece; it is a thoughtfully engineered upgrade with performance incentives and maintenance responsibilities that must be respected.

The installation story for carbon fiber hoods is generally favorable in terms of compatibility. Most reputable aftermarket options are designed to align with the factory hinge points and latch mechanisms, and many maintain the same outer dimensions as the OEM hood to preserve alignment with fenders and headlight assemblies. In practice, this means a straightforward swap that does not require structural modifications or welding. Still, the nuance matters. If a hood is not precisely aligned, the risk of water ingress or wind noise can rise. The closure tension and latch engagement must be checked to ensure that the hood remains properly secured at speed, and additional sealing or water management considerations may be warranted depending on the design and climate. The tensioning of hood hinges and the overall panel fit should be assessed after installation, and a careful owner will verify that the hood lines up with the hood gaps along the fenders, bumper, and radiator cover—elements that influence both function and aesthetic harmony.

Beyond the engineering specifics, the market context for these components in 2026 paints a picture of a robust, dynamic ecosystem. The strongest supply clusters for high-performance composites are found in regions with established carbon fiber ecosystems, notably in parts of southern China and the broader manufacturing landscape that includes Zhejiang and Guangdong. This regional concentration has shaped a well-developed local supply chain: from prepregs and resin systems to precision CNC tooling and surface finishing, vendors in these hubs offer rapid prototyping, consistent quality control, and the capacity to deliver both mass-market and bespoke, small-batch runs. For the individual buyer, the path to acquiring carbon fiber hoods often traverses popular online marketplaces and regional distributors that provide on-demand customization options—color, finish, ventilation layout, and weave pattern. For business buyers, the selection typically centers on established manufacturers who can fulfill bulk orders with consistent tolerances and warranties. It is in this convergence of supply chain maturity and engineering specialization that the Evo X hood landscape has become so mature and diverse. The ecosystem supports both the street-oriented user who wants a subtle upgrade and the race-oriented enthusiast who seeks a full performance upgrade with visible, tangible aerodynamic gains.

When it comes to choosing between a factory-style hood and a carbon fiber performance hood, several practical decision points emerge. For owners prioritizing daily reliability, ease of ownership, and a restoration-friendly approach, the OEM hood remains a solid default. It preserves the sense of continuity that many owners value, including compatibility with stock under-hood components and less need for additional sealing or weatherproofing considerations. For those whose priorities center on chassis agility, throttle responsiveness, and front-end balance under track-like conditions, carbon fiber represents a compelling route. The weight reduction can meaningfully affect cornering dynamics, approach and exit speeds, and the car’s overall behavior when transitioning between tires and aero loads. The decision is rarely about a single dimension; it is a negotiation between weight, stiffness, heat management, and the intended usage scenario. The best path often hinges on how the car is used most of the time. A weekend warrior who spends hours chasing track laps and hot-lapping days will likely appreciate the vented carbon fiber hood’s cooling and weight advantages. A daily driver who values consistency and cost efficiency may prefer the OEM option for its predictable performance and serviceability.

In the broader cultural language of the Evo X community, the hood is also a conversation piece. It signals the owner’s approach to car building: an emphasis on original lines and factory integrity or a bold statement of engineering ambition through material science and aerodynamic nuance. The aesthetics of carbon fiber—its exposed weave or its color-coded coating—can become an integral part of how the car is perceived by peers and spectators, especially at car shows or on the street where a quick glance may reveal a crosshair of performance intention. The hood, then, is not merely a component but a platform for personal storytelling about a vehicle that blends rally heritage with modern high-performance engineering. The choice flows naturally into related decisions—radiator and intercooler sizing, intake routing, exhaust heat management, and even the paint strategy—that together define the car’s street presence and track readiness.

For owners who want to explore the technical and practical implications in a structured way, a closer look at the available options reveals a spectrum of possibilities that can align with almost any budget or objective. The OEM hood remains a staple for those who value reliable compatibility and a preservation-minded approach. The carbon fiber hood, by contrast, is a choice that rewards those who are prepared to invest in careful installation, thoughtful sealing, and ongoing maintenance to maximize the performance and longevity of the lightweight construction. The market continues to respond to demand with more nuanced products, including variants that blend venting with reinforced panels, or that pair a dark, stealthy appearance with a high-tech, high-performance ethos. As production and supply tighten around high-quality composites, the availability of options that maintain file-level tolerances and finish quality increases, allowing more Evo X owners to tailor their front-end experience to their precise aims.

Ultimately, the hood decision on the Evo X is a decision about balance: balance between authenticity and evolution, between front-end weight and steering agility, between cooling capability and weather resistance, and between the visual narrative the car carries and the mechanical story it tells under the hood. The choice should reflect not only what the car can do in a controlled environment but what the owner expects it to do in everyday life and on the occasional weekend track session. The hood is a single component, yet it stands at the threshold where engineering meets identity, where form bends to function, and where a car that began as a rally-bred sedan can redefine its personality with a single, carefully chosen upgrade. For those who are ready to weigh the options, the path forward is clear: either stay with the proven reliability and seamless integration of an OEM hood or embrace the bold efficiency and aggressive stance of a carbon fiber hood that promises lighter weight, improved cooling, and a visually compelling statement that signals a shift from stock to specialized performance. The decision, in essence, is a negotiation with gravity, speed, heat, and style—and a negotiation that defines how the Evo X meets the road in the modern era.

As you consider the leap into carbon fiber, you may meet a few practical questions that help anchor the decision. How will the lighter mass alter front-end dynamics in typical driving scenarios? Will the vented design noticeably improve cooling under high load, or will it simply contribute to a louder engine note? If you lean toward authenticity and budget-conscious ownership, can the factory-style replacement deliver a satisfying drive experience that remains faithful to the model’s original temperament? The answers depend on your driving profile, your local climate, and how far you plan to push the car’s performance envelope. In shaping your approach, it can be helpful to engage with the broader community of enthusiasts who have walked this path before, comparing notes on fitment, durability, and daily usability. The road to a well-chosen hood is, in many ways, the road to understanding what you want your Evo X to say about you every time you park it—and what it can do the next time you drop the hammer at the end of the straight.

To bring this discussion full circle, consider that a product selection is not merely a function of weight or air flow, but of how the car’s entire architecture interacts with front-end mass, cooling, and aero balance. A lighter hood can free up chassis dynamics to help the driver modulate entry and exit from corners with more immediacy, while a precisely matched OEM hood preserves the car’s original ergonomics and tolerances. The decision is always a balance: speed versus sovereignty, a race-inspired impulse tempered by practical maintenance considerations. In the end, the Evo X hood landscape is a testament to how a single part can anchor a broader engineering philosophy: one that honors the heritage of rally-influenced performance while embracing the ongoing evolution of materials science and manufacturing capabilities. Those who explore both options with an eye on reliability, cost, and long-term ownership will find a path that suits their ambitions—whether that path leads toward a showroom-perfect restoration, a lightweight track-stripper ethos, or a blend of the two that keeps the car both usable on weekday commutes and terrifyingly rapid on weekend laps.

For those who want to dive deeper into the practical and technical standards behind carbon fiber hood design and how it translates to real-world Evo X performance, a dedicated guide offers a thorough exploration of the subject. This resource provides a rigorous look at how venting, weave orientation, resin systems, and surface finishing come together to deliver a hood that is not only lighter but also durable and heat-tolerant under race conditions. The guide also discusses maintenance practices to maximize longevity and protect against environmental exposure, which can be critical in regions with harsh weather or long sun exposure. As always, real-world experiences from owners who have swapped to carbon fiber hoods can provide invaluable perspective on fitment, sealing, and long-term behavior under load. And for those who prefer a hands-on approach to procurement and installation, the latest supplier catalogues and community feedback can illuminate practical pathways to finding a hood that meets your exact performance and aesthetic goals. In summarizing the essence of this chapter, it is clear that the Evo X hood decision is a microcosm of how modern performance cars are navigated: by balancing heritage with innovation, and by choosing a front-end solution that harmonizes with the rest of the build while remaining faithful to the spirit of the model.

Internal link reference: To explore a representative carbon fiber hood option in greater depth, you can review a detailed product page here: brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x.

External resource: For a comprehensive, technical overview of Evo X hood types and their implications for performance and reliability, see the detailed guide at https://www.mitsubishi-evolution.com/guide-to-evo-x-hood-types/.

Lightweight Gatekeepers: How the Evo X Hood Shapes Performance, Heat, and Street Presence

Every performance car carries its own quiet manifesto in the design of its front end, and the hood is a central paragraph in that manifesto. It is easy to overlook how such a seemingly simple panel influences weight distribution, aerodynamics, and the tactile relationship between driver, chassis, and ambient air. Yet in a high-performance four-door born from a lineage of rally-inspired engineering, the hood is not merely a cover for the engine bay. It is a critical component that can tilt the balance between street comfort and track-ready rigor. From the factory-specified steel or aluminum variants to the aftermarket carbon fiber options that promise significant gains in mass reduction, the hood embodies a practical philosophy: every gram saved up front can translate into crisper steering, a more responsive throttle, and a colder heart under the hood when pushing into the upper reaches of power and speed.

At the core of the Evo X hood discussion sits a simple, utilitarian truth: weight matters. The original steel hood, with its broad surface area and integrated structure, offers dependable strength and precise fitment, the kind of predictability manufacturers prize for everyday use and public road compliance. In a practical sense, the OEM hood is designed to withstand the rigors of daily driving across varying climates, while preserving the structural integrity of the vehicle’s front end. It typically sits in a weight range that, while not negligible, maintains a balanced front-to-rear mass distribution suitable for the car’s overall dynamics. In many markets, the steel variant is the standard, with selective trims offering a lighter aluminum alternative. The heft of the factory hood—often in the neighborhood of a dozen or more kilograms—translates into a front axle load that drivers feel in steering effort, particularly when navigating quick transitions or entering a high-speed corner where every ounce of inertia matters.

For enthusiasts seeking a more aggressive stance without abandoning reliability, the aluminum hood presents a compelling compromise. Aluminum’s superior strength-to-weight ratio can shave valuable mass while preserving the line and safety margins that the OEM design guarantees. Yet even with aluminum, the hood remains a sizeable component; its weight reduction, though meaningful, is often incremental rather than transformational. The result is a hood that maintains factory-level fit and function while delivering a perceptible lift in nimbleness and front-end precision. For daily drivers, this is often the sweet spot: a visible, tactile upgrade that does not demand heavy modifications to hinges, latch points, or under-hood hardware.

In the conversation about performance-oriented upgrades, carbon fiber hoods frequently take center stage. The allure is not only reduced mass but also a dramatic shift in the car’s behavior and its on-road persona. A carbon fiber hood can reduce weight by roughly 40 percent or more, depending on the thickness, layup, and whether it incorporates reinforced sections for rigidity. In practice, a typical carbon fiber hood can weigh as little as six to nine kilograms, a stark contrast to the steel or even the aluminum OEM counterparts. This reduction reshapes the front-end moment of inertia, lowering the vehicle’s overall polar moment and loosening the weight that the suspension must contend with in rapid dynamic changes. The result is a more responsive steering feel, quicker turn-in, and a chassis that can respond to steering inputs with a more immediate sense of lightness, especially when the vehicle is pushed beyond everyday tempo on winding roads or a closed-track environment.

A carbon fiber hood is more than a mass reducer; it is a performance amplifier in terms of heat management and aerodynamics. Many carbon fiber designs incorporate intentional venting, scoops, or ducts that facilitate heat extraction from the engine bay and direct the airflow away from or across critical components. Where a stock hood might rely on under-hood pathways and a contribution from the radiator fan to manage heat, a hood with integrated vents or channels can complement the car’s cooling system by expelling hot air and reducing thermal buildup during sustained high-performance driving. The hood’s surface geometry—the subtle curvature, the vent placement, the aerodynamically tuned edges—also interacts with the car’s front fender geometry to influence boundary layer behavior and front-end downforce. In practical terms, carbon fiber hoods with venting can contribute to more consistent intake temperatures and steadier power delivery when ambient temperatures climb or the tires and brakes begin to work hard on a hot track.

Installation of carbon fiber hoods is designed to be straightforward for those who wish to retain factory mounting points. The hood is typically compatible with the original hinges, latch, and support structure, avoiding the need for extensive alterations to the car’s front end. This preserve-the-skeleton approach is a major appeal for enthusiasts who want the race-ready aesthetic and the performance gains without introducing new points of failure or compromising safety certifications. The surface finish is another area where carbon fiber shines. While the raw carbon look has its own appeal, many owners opt for a clear coat or a satin, matte, or gloss finish that harmonizes with the vehicle’s overall color story. In a sense, the carbon fiber hood becomes a canvas upon which performance identity is painted, signaling a willingness to push the envelope while preserving the continuity of the car’s original design language.

Choosing between OEM steel, aluminum, or carbon fiber involves weighing several practical factors beyond weight alone. The OEM hood offers familiarity, known fitment, and regulatory compliance that come with factory standards. It is a reliable choice for a daily driver or for someone who wants a straightforward upgrade that minimizes risk. An aluminum hood can strike a balance between weight savings and cost, keeping the daily-driver durability while still delivering a noticeable boost in front-end feel. For those pursuing peak performance, the carbon fiber hood is often the centerpiece of a broader strategy to re-balance mass distribution toward the middle and rear of the vehicle, where handling and rotation truly live. The carbon fiber option also introduces a design philosophy rooted in race-derived engineering: every opening and contour is deliberate, designed to optimize airflow and heat dispersion while granting the driver a direct, visceral sense of the car’s stance and attitude.

From a market perspective in 2026, the ecosystem surrounding these hoods has evolved to support both the casual weekend modifier and the professional-grade performance shop. The supply ecosystem has matured around a cluster of manufacturing hubs that specialize in advanced composites, with a well-developed chain that spans material prep, resin chemistry, layup processes, curing, and final finishing. For individual buyers, the landscape includes a spectrum of options—from fully finished, color-mmatched finishes to raw or faux-textured finishes that can be painted to suit a particular aesthetic. For teams and shops, the opportunity lies in scalable, customized solutions that can accommodate unique vent patterns, logo placements, or limited-run colorways that align with a vehicle’s broader branding and performance suite. In this environment, the hood becomes part of a broader dialogue about how a car is configured to perform, both on the road and in the context of a competition-ready build.

The decision-making process for an Evo X hood upgrade also intersects with financial and logistical considerations. The cost gap between OEM and carbon fiber options is readily apparent in the upfront price, but the total cost of ownership can tell a different story. A carbon fiber hood can offer weight savings that translate into better acceleration response, sharper steering, and a more favorable front-rear weight distribution, with the potential to reduce tire load during cornering and lower front-end braking demands. The incremental fuel and tire wear benefits may be modest, but in a high-performance context, they are part of an integrated performance envelope. In addition, carbon fiber components demand careful handling and storage, especially in regions with high humidity or where UV exposure can affect surface finish over time. The finish, whether matte or glossy, can require periodic maintenance to preserve its appearance and structural integrity, especially if a vented hood is used extensively in daily driving where road debris and exposure to the elements can become a factor.

From a practical standpoint, the hood is a gateway to a broader performance philosophy. It invites a reassessment of front-end mass, cooling strategy, and aero balance, which in turn speaks to the car’s overall dynamics. It also speaks to a broader trend in the car culture around 2026: the fusion of raw speed with visible craftsmanship. Enthusiasts no longer consider performance simply in terms of horsepower and torque; they weigh the entire front-end package—the hood, the vents, the air dam lines, and the way the metal, resin, and fibers talk to the wind. The hood is a visual cue to everyone watching that the vehicle is intended to perform, not merely to commute. In this sense, the Evo X hood functions as an ambassador for a broader ethos: engineering that respects both the science of speed and the art of automotive presence.

In pursuit of this balance, the market has also grown more attentive to the sourcing story behind a hood. The conversation around high-performance composites has matured beyond the simplistic notion of “lighter is better.” It now includes questions about material chemistry, process controls, and environmental considerations. The materials that form the core of a carbon fiber hood—pre-preg or dry cloth carbon, resin systems, and the method of consolidation—carry implications for heat resistance, stiffness, and long-term durability. Reputable suppliers emphasize tooling precision, quality control, and traceability, with third-party testing and certification that reassure buyers about performance under load and in crash-related scenarios. As buyers become more discerning, the emphasis shifts from “looks fast” to “engineered to endure.”

The practical implications of this trend are evident in how a hood can influence the vehicle’s integration with other performance components. A lighter front end can alter ride height, suspension tuning, and even how braking bias feels under track conditions. A hood with optimized venting can complement the cooling capacity of the radiator and intercooler, reducing thermal soak that would otherwise erode power delivery. And a hood with a carefully staged curvature can harmonize with the body lines, reducing wind lift at high speed while enhancing the sense of speed conveyed by the car’s silhouette. The net effect is a cohesive performance identity that the driver experiences every time the vehicle is on the road or in the bend of a racetrack.

For the curious buyer who wants a tangible example of how a carbon fiber hood can become a focal point of a broader upgrade strategy, consider the practical implications of a single upgrade choice. The carbon fiber hood acts like a hinge between performance and style. It is a high-visibility modification that signals intent, but it also quietly contributes to the car’s handling balance, heat management, and aerodynamics. It invites a thinking person to ask not only how the hood looks, but how it behaves. The hood becomes a case study in how the interplay between weight, stiffness, airflow, and thermal management coalesces into a single, coherent performance philosophy.

In the end, the Evo X hood is a lens through which to view a broader automotive culture that respects lightweight design, precision engineering, and the aesthetics of speed. Whether preserving the OEM feel with a steel or aluminum panel, shaving weight with a high-strength alternative, or pushing the upper limits with a carbon fiber piece that adds both mass savings and race-inspired airflow, the hood remains indispensable. It is the part of the car that cannot be ignored when discussing how a vehicle communicates with the road—the way it breathes, how it steers into a corner, and how its driver experiences speed as a sensation rather than merely as a number on a gauge. The hood, then, is not only a component; it is a philosophy of performance.

For enthusiasts who want a closer look at a particular carbon fiber option, there is a compelling example that demonstrates how form and function can align. A carbon fiber hood—crafted to fit the Evo X’s dimensions and to work with the factory mounting points—offers a vivid illustration of how contemporary composite engineering translates into tangible on-car benefits. If you are curious about a specific carbon fiber hood that emphasizes the visual appeal of the raw material while delivering enhanced rigidity and airflow management, you can explore a practical reference here: carbon fiber bonnet for Evo X. This link provides a window into how a hood can be finished and presented, allowing buyers to understand the aesthetic and the mechanical expectations embedded in a high-performance composite panel.

As the market continues to mature, buyers also gain access to a broader set of procurement options. The evolution of supply chains in major production hubs has made it possible for individual buyers to source from manufacturers with robust quality-control practices and strong after-sales support, while teams and shops can engage in more sophisticated collaborations that involve design customization, prototyping, and rapid iteration. The shift toward composite components is not solely about weight savings; it is about the confidence to push a vehicle to its limits, knowing that every front-end interaction—how the hood meets the hood line, how it seals against the fender, and how it carries heat away from the engine bay—has been engineered to perform under pressure. In this sense, the hood becomes a catalyst for a broader performance program, one that values repeatable results, safety, and a distinct, road-credible sense of aggression that remains practical for daily use.

The Evo X hood, in its various incarnations, embodies a pragmatic approach to performance. It invites buyers to weigh structural integrity, thermal management, aerodynamics, and visual impact as a single, interconnected system. Whether you opt for the reliability of an OEM panel, the weight-shedding benefits of aluminum, or the race-inspired efficiency of carbon fiber, the hood remains the gateway to a more confident, quicker, and more engaging driving experience. And while the choice ultimately rests with the owner’s goals, budget, and tolerance for maintenance, the consensus across the evolving ecosystem is clear: high-quality carbon fiber hoods have established a meaningful baseline for performance-oriented builds. They represent a balance of lightness, stiffness, and airflow enhancement that aligns with a modern philosophy of speed where every component earns its seat at the table.

In sum, the hood is not a mere accessory. It is a strategic component that can redefine how the Evo X communicates with the road. It is a testament to engineering that respects mass, aerodynamics, and heat, while also celebrating the artistry of automotive design. The decision to upgrade—whether to preserve the factory look, to embrace lighter alloys, or to adopt a carbon fiber solution with venting and a tailored surface finish—reflects a broader commitment to performance without compromise. It is the kind of upgrade that quietly delivers measurable returns in handling, response, and driving enjoyment, even when observed by only the most discerning enthusiasts. The hood, in short, is the silent accelerant of a car that seeks to blend street credibility with track-ready confidence, and that is precisely why it remains such a central topic in the Evo X’s ongoing evolution.

External resource for further reading: For insights into strategic sourcing and supplier evaluations in this space, see the Evolution X hood supplier guide, which discusses sourcing considerations, supplier qualifications, and how to balance cost with quality in a way that supports long-term performance objectives. https://www.industryweek.com/automotive/evolution-x-hood-supplier-guide-strategic-sourcing-b2b-buyers

Final thoughts

Understanding the Lancer Evo X hood is vital for business owners in the automotive industry, as it represents an important intersection of design, performance, and marketability. By familiarizing themselves with the features, types, and current market trends, businesses can make strategic decisions that resonate with enthusiasts and customers alike. Ultimately, choosing the right hood not only enhances the vehicle’s performance but also contributes to its aesthetic appeal, a critical consideration in the highly competitive automotive aftermarket landscape.