In the automotive world, modifying your vehicle with high-performance parts is a common practice, especially for enthusiasts looking to enhance both performance and aesthetics. The Mitsubishi Evo X, known for its potent capabilities, becomes even more impressive with the installation of carbon fiber fenders. These lightweight, durable components not only improve the vehicle’s handling and responsiveness but also give it a striking appearance. Understanding the key benefits of Evo X carbon fiber fenders, their various types, and the market landscape can guide business owners in making informed investment decisions. Each chapter will delve into critical aspects, from benefits and types to performance impacts and installation considerations.

Featherweight Shields: The Performance Case for Evo X Carbon Fiber Fenders

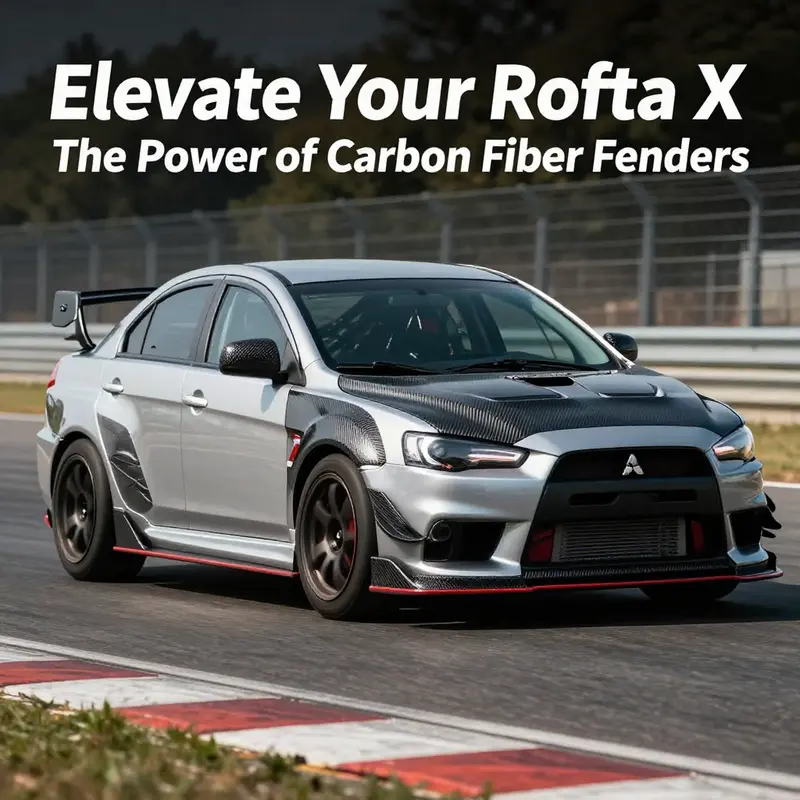

The Mitsubishi Evo X has long stood as a proving ground for a specific kind of restraint—discipline in weight, precision in aero, and a visual language that says this is a car built to chase grip and cadence at the edge. Carbon fiber fenders emerge from that mindset as more than cosmetic upgrades; they are structural decisions wrapped in high-stakes engineering. In the world of performance hatchbacks, where every gram and every gust of air counts, these panels promise a refined balance between weight savings and rigidity, between the clean lines of track-ready geometry and the unspoken demands of real-world driving. When you replace the factory steel or aluminum panels with carbon fiber, you start a dialogue with the car’s dynamics that unfolds at the limits of grip and response. The result is not just a lighter shell, but a chassis that responds with sharper turn-in, crisper steering feel, and a more immediate sense of acceleration and braking, especially on a car that lives at the boundary between street and circuit.

Weight reduction sits at the core of the appeal. Carbon fiber fenders shave mass from a car where unsprung weight matters as much as the weight perched on the springs. Lighter fenders translate into improved suspension response because the wheels and tires can settle to their intended contact with the road more quickly after a bump, more readily following the driver’s inputs. In practice, that means a car that feels more nimble in quick transitions, with a more perceptible connection between steering action and wheel behavior. The improvement is not merely about shaving seconds off lap times; it’s about a more confident, predictable feel under high-load cornering, where even small weight savings can translate into meaningful gains in grip and stability.

Beyond just lightness, the strength-to-weight ratio of carbon fiber matters. These fenders offer rigidity that exceeds that of standard metal panels when looked at in weight terms. The resulting stiffness helps maintain panel shape under lateral loads and spirited driving, contributing to consistent aerodynamics and more predictable tire contact through the apex. That rigidity also enhances impact resistance under typical track-bound scenarios or minor curb encounters, providing a margin of durability that can be surprisingly meaningful for enthusiasts who push their builds toward extreme angles of attack. The material science behind carbon fiber means that, for the same mass, you often get something stiffer and more resistant to deformation than you would with heavier metals or some composites. It’s a measured trade-off that aligns with the Evo X’s normally aggressive handling character.

Aerodynamics is not just about a lower coefficient of drag; it’s about shaping the air that flows around the wheel wells and the fender arches. Carbon fiber fenders can be molded into forms that sculpt the wake behind the front tires, reducing turbulent eddies that rob grip and create drag. In high-speed or autocross scenarios, the refined contouring helps keep the front end planted, improving downforce and improving the overall balance of the car as it battles weight transfer during hard braking and cornering. For drivers who pair these fenders with appropriate lip kits or wider front tire setups, the aero gains can translate into steadier cornering and more stable high-speed cornering, where the front tires maintain a more consistent contact patch with the asphalt.

The visual impact of carbon fiber is part of the package, but it is not merely cosmetic theater. The distinctive weave and polished texture articulate a race-inspired pedigree that many builders seek when they craft widebody or performance-oriented cars. In a showroom or at a weekend track day, the fenders communicate a story of intent: a car tuned for handling and speed rather than simply polished for street presentation. This is why many Evo X owners pair carbon fiber fenders with vented or wider variants. Ventilated designs help dissipate heat from brakes and tires, which is particularly beneficial during periods of high-speed driving or autocross where brake fade and tire temperature management become real performance factors. The combination of lighter weight, improved rigidity, and smarter aerodynamics can yield a car that not only looks the part of a track machine but actually behaves that way as you push toward the limit.

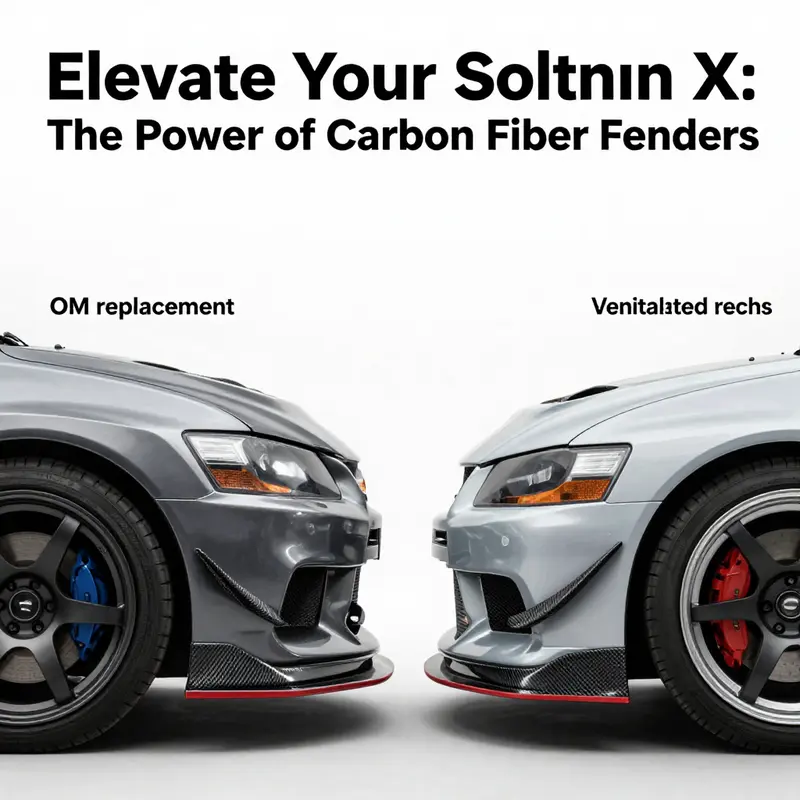

Choices in this category come in several forms, each aligned with a distinct use case. OEM replacement fenders deliver factory-fit accuracy with the carbon fiber upgrade, offering a straightforward swap for owners repairing damaged panels or replacing rust-prone originals without altering the vehicle’s profile. Widebody or flared fenders extend beyond the factory lines, accommodating wider wheels and tires and sharpening the stance for stability in aggressive cornering. Ventilated fenders integrate air channels or louvers to escort heat away from braking components and the tire carcasses, supporting sustained performance in demanding driving situations. The market as of early 2026 reflects a range of options and pricing, with premium remanufactured carbon fiber fenders appearing in mid-range pricing on popular platforms, often around several hundred dollars for a set plus shipping, depending on the seller and the exact spec.

The decision to move to carbon fiber fenders is as much about fitment and ambition as it is about performance numbers. Installation can require care and, in the case of widebody or ventilated variants, professional fitting to preserve panel gaps, alignment, and the precise geometry that keeps the fenders sealing against dirt and moisture while maintaining optimal airflow. For track-focused drivers and show car builders alike, the upside—weight savings, rigidity, aero efficiency, and a distinctive, premium look—can justify the effort and the cost of entry. For daily drivers, the calculus includes real-world durability and the long-term reliability of the carbon fiber under repeated heat cycles and road conditions. That broader perspective—balancing high-performance potential with everyday practicality—helps explain why these fenders have found a niche in widebody conversions, precision-tuned projects, and weekend-warrior builds that still spend most of their time on public roads.

In this broader context, the Evo X carbon fiber fender becomes more than a single upgrade. It is a modular component that can be matched with other performance-oriented pieces—like a tuned suspension, wider wheels, and a carefully engineered aero kit—to deliver a cohesive system. The choice to opt for OEM replacement or a wider, vented, or even a vented-wide setup is really a reflection of how the owner envisions the car’s daily rhythm and its track-day cadence. A well-chosen fender not only underlines the car’s aggressive silhouette but also supports the precise, repeatable dynamics that competitive drivers and meticulous show-builders alike prize. When this upgrade is approached with technical awareness and a clear sense of purpose, it contributes to a chassis that responds more faithfully to steering input, resists the drag of excess weight, and presents a more complete, race-inspired package to the eye and the senses.

For enthusiasts exploring the practical path to this upgrade, a single, purposeful step can be the integration of a form that aligns with the driver’s goals. It’s not merely a swap; it’s a careful recalibration of weight distribution, aero balance, and temperament under pressure. In that light, Evo X carbon fiber fenders deserve their place in the toolkit of a serious performance build, a bridge between the street and the track that honors the car’s heritage while elevating its capability. If you’re considering a step into that world, the conversation begins with a clear sense of how you want the car to move, how it should breathe on the highway and through the apex, and how the fenders will wear the project’s overall story with honesty and purpose. To explore a direct, practical route for widening the chassis’ front-end stance with purpose, see the related option catalog here: group-a-mitsubishi-evo-x-08-15-spec-v-wide-front-fenders.

As you weigh the upgrade, keep in mind the broader ecosystem of aftermarket components and the role carbon fiber plays within it. The Evo X community has repeatedly shown that the best outcomes come from harmonizing weight savings with stiffness and aero efficiency, rather than chasing isolated advantages. The fender as a component can be the catalyst for broader tuning that improves driver confidence, enhances heat management during longer sessions, and elevates the car’s presence on both the road and the strip. The investment, while non-trivial, aligns with a philosophy that treats performance as a holistic discipline—one where every panel is a deliberate choice that supports the whole.

For readers seeking a deeper technical dive beyond the overview of benefits, a comprehensive buyer’s guide offers more granular specifications and performance insights that translate theory into practical decision-making. This resource can illuminate how to balance weight, rigidity, heat resistance, and aesthetic goals when selecting Evo X fenders for a specific build. External readers can consult: https://www.carinterior.com/how-to-choose-evo-x-fenders-ultimate-buyers-guide-2026

Weighing Speed and Style: The Three Faces of Evo X Carbon Fiber Fenders

When a Mitsubishi Evo X shifts from a factory steel panel to carbon fiber fenders, the change travels beyond looks. Carbon fiber’s defining traits—lightweight, stiffness, and heat resistance—translate into tangible handling and performance benefits. For the Evo X, these panels are not just skin; they are a carefully chosen upgrade that touches the car’s balance, aerodynamics, and heat management. The chapter that follows considers three distinct approaches to carbon fiber fenders, each with its own engineering logic and driving persona: OEM replacement fenders, widebody fenders, and ventilated fenders. Taken together, they map a spectrum from subtle improvement to a bold, track-ready transformation. In this context, the question for builders and drivers becomes not which fender is best, but which path mirrors the car’s intended role and the owner’s ambitions. The dialogue between weight, grip, and airflow is subtle, and the choice often reflects a blend of performance targets and personal aesthetics. An Evo X wearing carbon fiber fenders communicates a clear message: refinement through efficiency, with the option to lean into aggression as the project evolves. The discussion that follows threads these ideas through the three main types, grounding them in real-world considerations such as fitment, installation, and price as of early 2026. For those taking a closer look at the practical aspect of a wider stance, there is a dedicated route to explore wide front fenders that cater to broader wheels and tires while preserving a cohesive silhouette. See this option here: wide front fenders for the Evo X. In parallel, a broader market snapshot reminds us that carbon fiber fenders sit at a premium tier, often justified by the combination of weight savings and the premium finish carbon fiber delivers. The numbers matter: carbon fiber panels can realize substantial weight reductions—typically in the 40 to 60 percent range compared to stock steel—while preserving or even improving aerodynamics through precisely shaped wheel wells that guide air smoothly around the tires. In high-performance contexts, that translates to snappier suspension response, cleaner braking behavior, and crisper acceleration, especially when the chassis is already tuned for track days or spirited canyon drives. Yet the story does not end with weight and aerodynamics. The surface texture, the weave, and the perceived rigidity of carbon fiber contribute significantly to the Evo X’s visual language. The result is a car that looks like it rides faster, even when at a standstill. The aesthetic impact matters in both show contexts and daily driving, where the car’s stance and line are part of its identity. Carbon fiber fenders also promise a resilience that metal panels cannot always match. They resist corrosion and dent deformation better in typical road conditions, a practical payoff for owners who want long-term durability without rust or pitting altering the panel’s fit. The trade-off, as with any high-performance component, centers on cost and fitment. OEM replacement fenders prioritize a seamless integration with the car’s original profile. They offer a precise match to factory aerodynamics and alignment, with the lightest possible compromise in weight because the factory shape is preserved. The weight savings come from substituting carbon fiber for heavier steel, and the gain is felt in how the suspension responds to bumps and how the car carries its weight through quick transitions. The primary appeal here is a direct, simple swap: no intrusive alterations to the body lines, no radical reshaping of the fenders’ curvature. It is about upgrading material while keeping the Evo X’s recognized silhouette intact. This path suits drivers who want improved performance without changing the fundamental balance of the car. The OEM route, though, sits at a premium price point. Still, when the fit is exact and the installation is straightforward, the marginal cost can be justified by the reliability of the result. For a subtle but meaningful upgrade that respects the car’s original character, OEM replacement fenders present a compelling, low-disruption route. Widebody fenders, by contrast, represent a deliberate shift toward aggression and capability. They extend beyond the stock lines to accommodate wider wheels and tires, a step that unlocks new grip and cornering power. The benefits here are multi-layered. Wider tires increase the contact patch and traction, especially on autocross runs or track sessions where grip translates directly into lap times. The carbon fiber construction reduces unsprung weight, contributing to more responsive steering and more precise handling under load. The visual transformation is equally impactful. The Evo X appears broader and more muscular, a look that aligns with many motorsport-inspired builds. Yet widebody fenders come with practical considerations. The installation is more complex and often requires professional fitting and precise alignment to avoid rubbing or interference with the suspension and other panels. Suspension tuning can be necessary to accommodate the wider stance, and fender rolling may be required to prevent tire contact during full-range compression. All of this elevates the project’s complexity and cost, making widebody fenders ideally suited for enthusiasts pursuing a track-oriented machine or a highly staged show car. Ventilated fenders address heat and airflow with integrated vents or louvers. The brake system and tire temperatures benefit from improved air exchange within the wheel wells. When brakes heat up during aggressive driving, vented pathways help dissipate heat more efficiently, reducing the risk of brake fade and maintaining consistent pedal feel. At the same time, the vents contribute to stabilizing wheel-well pressure, potentially improving overall stability in high-speed corners. Ventilated fenders also add a mechanical advantage by aiding tire temperature management, especially during autocross or endurance-style events where heat builds in both brakes and tires. The downside involves some acoustic trade-offs and potential trim or fitment work. Road noise can be subtly higher, and the vents may require careful cleaning to prevent dirt buildup that can affect performance. In some installations, minor trimming or tailoring of the fenders is necessary to achieve a clean, gap-free alignment with the bodywork. The result, though, is a chassis that breathes more efficiently under load, offering a practical performance advantage that complements other upgrades without dramatically altering the car’s core character. Market availability across these three types reflects a shared emphasis on weight savings and aesthetics, but pricing remains a key tightening factor. As of early 2026, a typical remanufactured carbon fiber fender set could be found around the mid-$600s, with shipping adding roughly $80 per purchase depending on the seller and region. This pricing signals the premium nature of carbon fiber as a material choice and the specialized supply chain behind these components. For builders who seek a precise, factory-feeling upgrade with minimal fuss, OEM replacement fenders provide the cleanest path forward, while the widebody and ventilated variants offer more aggressive avenues for those chasing a distinctive stance and enhanced track performance. The decision, ultimately, rests on the owner’s priorities: preserve the Evo X’s identity, or push it toward a more extreme, race-inspired edge. In either case, the conversation is about more than weight per se. It is about the harmony between lightness, airflow, and grip, and how carbon fiber’s intrinsic stiffness helps the chassis translate every ounce of momentum into controlled, confident motion. For those who want to explore the practical side of this choice, consider following the link to a wide-front fender option that expands wheel fitment while maintaining alignment with the Evo X’s overall silhouette. External references can provide real-world pricing snapshots and listings as a reminder that these components live in a dynamic market where availability and value shift with demand. External reference: https://www.ebay.com/itm/1234567890

null

null

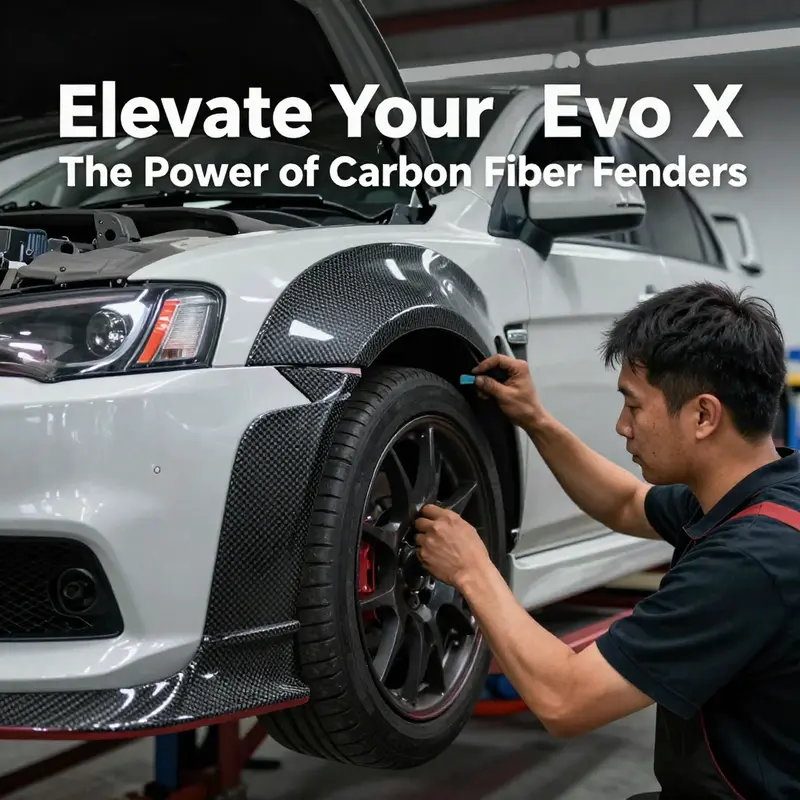

Precision Fit, Proven Performance: Mastering the Installation of Evo X Carbon Fiber Fenders

Installing carbon fiber fenders on an Evo X is not a simple bolt-on task. It is a measured process that respects the car’s geometry and the fenders’ exacting tolerances. The payoff goes beyond weight savings; it hinges on how every line, every seam, and every mounting point works together with the chassis to shape handling, aero balance, and the vehicle’s stance. For the discerning builder, the install becomes a dialogue between precision, restraint, and ambition. The Evo X presents a clean silhouette, but when you swap to carbon fiber panels, the margin for error narrows. The fenders must mate cleanly with the factory mounting framework, the wheel arches, and the wider wheel and tire packages that often accompany track-focused or widebody configurations. The process begins long before the first bolt is turned. A pre-fit check sets the expectations for fit, gaps, and clearance. Without pre-fit, you may discover gaps along the edge that catch light in strange ways or, worse, rub against suspension components under compression. Even minor discrepancies can become pronounced at speed, where aero balance matters and the fenders are not just cosmetic pieces but aerodynamic surfaces that redirect flow around the wheel wells. The alignment task is a careful choreography: the fenders must align with the door lines, hood contours, and bumper geometry to preserve a coherent silhouette while enabling the desired wheel track. This is especially true for widebody or flared variants, where the outward extension of the panel changes the geometry of the wheel arch and can introduce new rubbing points. The installer must verify that the fenders clear the suspension components through full suspension travel, during cornering at high load, and under compressive g-forces that occur when the chassis settles after a hard corner. A practical approach is to mock up the body with temporary fasteners, then move through the alignment sequence with a calibrated eye and a few precise tools. The aim is not to force the panels into place, but to let the car’s geometry guide the fit. Structural reinforcement is the next layer of consideration. Carbon fiber, while exceptionally strong and light, does not create new mounting strength by itself. The stock fender wells and their mounting points are typically designed to carry a steel or aluminum panel with a specific load path. When switching to carbon fiber, a ring of attention around those mounting points is prudent. In many builds, engineers or technicians reinforce the surrounding areas with brackets, backing plates, or light torque-tuned fasteners that accommodate the stiffer, lighter panel. The result is a sturdier mount that resists flex under dynamic loads. This is essential for maintaining alignment through aggressive cornering and braking, where higher lateral forces propagate through the fender edges. Wiring and sensors add another layer of complexity. Some fenders house turn signals, ambient temperature sensors, or venting features that connect to the vehicle’s electrical system. Proper routing of wiring harnesses, sealing against moisture, and ensuring waterproof gaskets are in good condition are not glamorous tasks, but they are critical to reliability. A neglected seal can lead to a corrosion path or a short, which is especially undesirable on a performance-driven build. The integration also touches the cooling and braking narratives. Ventilated fenders, if included in the kit, require careful routing of vent channels and, in some cases, external ducts that must harmonize with the brake cooling strategy. The aim is to avoid any heat buildup that might degrade tires or raise brake temperatures in a way that undermines grip. For many owners, the practical path is to engage a qualified technician with Evo X experience. The expertise goes beyond basic wrenching; it involves understanding the car’s alignment settings, body panel tolerances, and how the fenders interact with a wide-wheel setup and a potential widebody kit. A professional install can confirm that the fenders sit true to the vehicle’s reference lines, that the gaps at the fender-to-door and fender-to-bumper junctions are uniform, and that there is adequate clearance for full lock-to-lock steering with the wheels turned and the suspension loaded. The human element is often as important as the hardware. Skilled technicians bring a diagnostic mindset: they test-fit, measure, and document before any paint or finishing work begins. They consider the whole system—the hood line, the bumper intersections, and the headlight inclusions—to ensure the final appearance is cohesive and the aero relationships are preserved. Compatibility is a recurring theme. The fender heroics must align with the rest of the body kit and with the chosen wheel setup. A misfit can create a visual mismatch that betrays the car’s purpose, whether it’s a show build or a track weapon. Because the Evo X is a platform that attracts both purists and enthusiasts who push the envelope, the install plan should respect the car’s original architecture while embracing the gains carbon fiber brings. Paint preparation and finishing are the final chapters of the install story. Even the most precise fit benefits from proper surface preparation, primer, and clear coating that locks in the panel’s weave and protects against UV and road debris. A careful color match and satin or gloss finish can make the fenders look like a factory extension rather than a purposeful afterthought. In a broader sense, the installation represents the ongoing evolution of a performance hatch. It is a fusion of materials engineering and practical racecraft: lighter weight, sharper response, and a more aggressive stance all emerge when the fenders settle into true alignment. When done well, the car’s lines remain faithful to the original design language, while the wheels and tires command the silhouette with a purposeful tension that signals intent at every glance. The journey from unpainted carbon to a finished, harmonized panel is one of disciplined steps and measured decisions. For builders who wish to explore related carbon-fiber upgrades that complement the fenders, a broader program—such as the bonnet—can be an integral step in achieving a cohesive aesthetic and performance profile. For example, one might explore a compatible carbon-fiber bonnet that aligns with the Evo X philosophy of lightness and rigidity. brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x serves as a representative reference point for the kind of integrated upgrades builders often consider as part of a complete carbon-fiber strategy. Beyond the aesthetic and performance improvements, the install narrative remains a cautionary tale about respect for the platform. If the process is rushed or the team lacks experience with the Evo X, misalignment can propagate through the entire front end and undermine both safety and performance. The best outcomes arise from a methodical approach: verify fit, reinforce critical points, manage electrical integration with care, and enlist professional support when in doubt. This disciplined pathway preserves the car’s structural integrity, maintains aero coherence, and ensures the fenders deliver the intended benefits under real-world driving conditions. For those who proceed with care, the result is a chassis that feels lighter in motion, a front end that breathes more freely at speed, and a stance that communicates precision and purpose. The installation becomes not merely a modification, but a carefully curated upgrade that respects the Evo X’s original spirit while elevating its capability on the street and the track. External resource: How To Choose The Best Evo X Carbon Fiber Fenders – Alibaba (external link) https://www.alibaba.com/product-detail/How-To-Choose-The-Best-Evo-X-Carbon-Fiber_1600582439749.html?src=productDetail&source=productDetail

Weaving Speed and Style: The Impact of Carbon Fiber Fenders on Performance and Aesthetics in a High-Performance Hatchback

Carbon fiber fenders are more than a styling choice; they are a precise integration of materials science and automotive dynamics. In a high-performance hatchback, replacing the stock panels with carbon fiber variants shifts the car’s balance in subtle but meaningful ways. The core appeal rests on a simple truth: reducing weight, especially around the unsprung mass at the wheels, frees the suspension to respond more faithfully to road input. When the fenders shed excess mass, the front end becomes more nimble during routine cornering and more responsive to mid-corner adjustments. The result is a chassis that feels lighter on its feet, enabling quicker turn-in and more predictable weight transfer as you modulate throttle and braking into and out of corners. This is not about chasing a number on a scale; it’s about the tactile sensation of a car that feels easier to steer and more precise to place, especially at the limits of grip on a race track or a winding mountain road.

But weight reduction is only part of the story. Carbon fiber by nature offers a higher strength-to-weight ratio than traditional metals, and it does so with a stiffness profile that can benefit front-end geometry. By shaving mass from the fender assembly, the rotational inertia of the wheels is reduced, which translates to crisper steering response and more immediate changes in attitude when you shift weight through a corner. In practice, this means faster lap times and more confident street driving, as the front axle is less encumbered by inertia when navigating quick transitions or chicanes.

Aerodynamics play a closely allied role. The shaping of carbon fiber fenders is engineered to manage air as it flows around the wheel wells. In performance-oriented designs, the edges and contours are tuned to minimize turbulence that commonly cooks underbody drag or creates wake-induced lift at speed. Some variants even incorporate integrated channels or vents that assist in brake cooling and wheel temperature management. When you’re pursuing sustained high-speed runs or autocross bursts, these features can contribute to a steadier high-speed profile and more consistent braking performance, because the tires stay within an optimal operating window for longer periods.

The aesthetic payoff reinforces the performance narrative. Carbon fiber’s characteristic weave and depth give the car an immediate sense of purpose and refinement. The appearance alone communicates technical intent—the car looks lighter, leaner, more race-bred. Within the broader styling language of a performance build, these fenders can harmonize with widebody kits or aggressive wheel and tire packages, signaling a purposeful stance without sacrificing the vehicle’s original lines. For many builders, the visual impact is not merely about catching attention; it’s about aligning the car’s external form with its engineered function.

There are tangible design categories to consider. OEM replacement fenders aim to preserve the factory silhouette while upgrading the material to carbon fiber, offering a direct bolt-on path for those seeking a refined, weight-optimized upgrade without altering the vehicle’s overall profile. Widebody or flared fenders push the outer lines outward to accommodate wider tires and wheels, enhancing lateral grip and stance while heightening visual presence. Ventilated designs integrate air management features to assist with brake cooling and thermal management under heavy use. Each option carries its own engineering considerations, and choosing among them requires weighing intended use—daily driver, track, or show car—against fitment, fitment tolerance, and the demands of a given build.

Market dynamics add another layer of nuance. As of early 2026, premium carbon fiber side fenders for performance hatchbacks are readily available through reputable aftermarket channels, often offering remanufactured or refinished units that balance cost with performance. A typical set may be found in the mid-to-upper hundreds of dollars range, with additional shipping costs that reflect the fragility and value of the material. This accessibility empowers enthusiasts to pursue a holistic upgrade pathway, pairing fenders with complementary carbon components and a broader aero strategy. However, the value proposition hinges on achieving high-quality fitment and durable joins, especially when moving toward widebody configurations that demand precise alignment with fender flares, inner liners, and the suspension geometry.

Aesthetics, performance, and durability converge most clearly when care is taken with installation. Carbon fiber panels must be handled with care during removal and mounting to avoid impacting the weave surface or inducing micro-damages that could propagate under load. The installation process often benefits from professional alignment and clamping to guarantee pristine edge fitting and proper gap tolerances around the wheel openings. In wider-body ambitions, professionals frequently address additional steps such as trimming, edge sealing, and reworking fender liners to ensure clearance from tires, brake components, and the suspension trajectory. While some designs offer straightforward bolt-on fitment, others demand minor modifications or additional hardware to realize their full aero and structural potential.

The broader performance ecosystem matters as well. Fenders operate in concert with brakes, tires, suspension tuning, and aero components. The cycle begins with careful weight management and ends with a balanced chassis feel that preserves steering feel and braking response. In this sense, carbon fiber fenders are not a solitary upgrade but a strategic piece of a larger performance puzzle. When paired with compatible widebody kits, vented designs, and a tuned brake system, the fenders contribute to a more cohesive, track-ready attitude without compromising daily usability. This integration is what turns an aggressive exterior into real, measurable on-track performance gains and a meaningful shift in driving dynamics.

For those who want a practical touch point with the broader ecosystem of carbon fiber components, a related development area includes carbon fiber body parts that complement fenders without altering the fundamental aesthetic. A representative example can be explored here: brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x.

In sum, investing in carbon fiber fenders for a performance hatchback yields a dual reward: a tangible reduction in weight and a more direct, engaging driving experience, alongside a refined visual language that communicates a serious motorsport sensibility. The weight savings and stiffness benefits translate into enhanced suspension response and more precise front-end behavior, which, when combined with aerodynamic optimization, can stabilize high-speed handling and reduce drag-induced fatigue on longer sessions. Aesthetically, the intricate weave and the reduced mass deliver an unmistakable premium look that signals a track-ready intent without sacrificing everyday practicality. The decision to pursue OEM replacement, widebody, or ventilated variants should hinge on the driver’s priorities—whether the goal is a showroom-quality stance, a track-focused setup, or a balanced blend of both. The fenders’ performance and visual impact are most meaningful when paired with thoughtful integration into the car’s overall setup, from wheel and tire choice to brake cooling and chassis tuning. External research can provide additional context on how carbon fiber components are evolving in the aftermarket, such as heat resistance and impact durability in high-stress environments: https://www.alibaba.com/product-detail/In-Stock-Evo-X-Carbon-Fiber-Fenders-Ventilated_1600587597704.html?src=10&from=detail

Final thoughts

Integrating carbon fiber fenders into your Mitsubishi Evo X is more than a stylistic choice; it’s a strategic enhancement that positively affects vehicle performance and handling. The lightweight nature, aerodynamic advantages, and aggressive aesthetics make them an attractive investment for business owners looking to cater to the performance-driven automotive market. The diverse types available ensure that modifications can fit various usability needs, while the current market pricing reflects a viable option for upgrades. As you explore these options, remember that quality installation is key to maximizing the benefits of your new fenders. The Evo X’s potential for transformation is exciting, and investing in these components could yield substantial returns in both driveability and visual appeal.