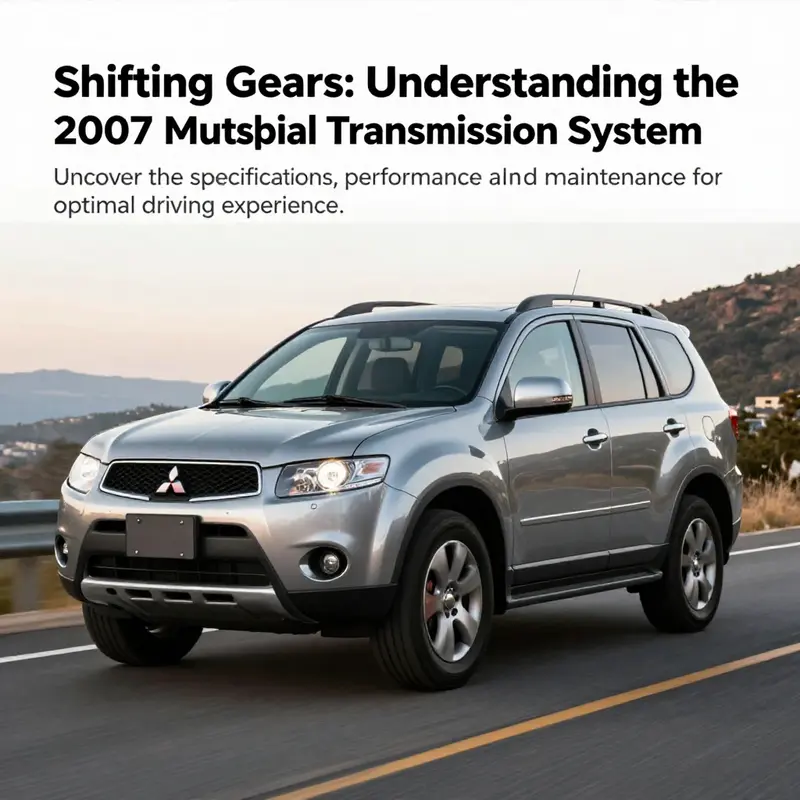

The 2007 Mitsubishi Outlander is recognized for its unique combination of versatility and efficiency, powered by a four-speed automatic transmission. For business owners, understanding the transmission system of this vehicle is crucial—not just for its performance on the road, but for its implications regarding maintenance and operational costs. This article delves into five key areas: an overview of the transmission system, detailed specifications and features, performance dynamics, a comparison with other vehicles, and common issues along with maintenance tips. Each chapter is tailored to enhance your knowledge and assist in making informed decisions regarding your fleet or personal vehicle.

Under the Hood: How the 2007 Outlander’s 4-Speed Transmission Shapes Performance and Longevity

Transmission anatomy and long-term considerations

The 2007 Mitsubishi Outlander pairs a compact crossover chassis with a four-speed automatic transmission. This gearbox, often referenced by its internal designation, was engineered to deliver a predictable mix of fuel economy and everyday performance. It was calibrated to work with two engine choices, and offered both front-wheel drive and an all-wheel drive option. Those two variables — engine and drivetrain layout — define how the transmission behaves on the road and how it ages over time.

From a mechanical perspective the transmission is straightforward. It uses a four-speed planetary gearset and a hydraulic control system to select ratios. A torque converter provides smooth engagement at low speeds and multiplies torque when needed. The system also includes a driver-activated manual shift mode that lets the driver prompt upshifts or downshifts. That mode does not turn the gearbox into a performance transmission. It does, however, give more control when passing, climbing hills, or towing a light load.

Matched to the 2.4-liter inline-four, the transmission emphasizes efficiency and smoothness. When paired with the larger 3.0-liter V6, drivers notice a slightly different character. The V6 provides more torque, which places different demands on the internal clutches and bands. In practice that means the same transmission hardware can feel firmer or more worked, depending on the engine and how the vehicle is driven.

All-wheel-drive models add another layer of complexity. The AWD system routes power through a transfer mechanism and a center coupling to the rear axle. That coupling interfaces with the transmission through a transfer case or center differential assembly. When AWD engages, the transmission may see fluctuating loads and torque distribution changes. These shifts are normal, but they can accelerate wear when the vehicle is frequently driven on rough roads, in deep snow, or when towing.

Owners have broadly reported reasonable reliability under typical commuting conditions. The transmission was designed with durability in mind, but it is not immune to age-related wear. As these vehicles reach and surpass the 15-year mark, some patterns emerge. Shift firmness can increase. Downshift and upshift timing may feel delayed. Occasional slipping or hesitation under load becomes more common. These are signs the hydraulic circuits, clutches, or valve body components are experiencing wear.

There are multiple causes for these symptoms. Fluid condition is the simplest and most common. Old, darkened fluid loses viscosity and friction properties. It no longer cushions and cools properly. Contaminants and degraded additives cause valves to stick and solenoids to work less predictably. Heat exacerbates wear in seals and clutches. Driving styles that include aggressive acceleration, frequent towing, or extended high-speed runs increase operating temperatures and accelerate internal wear.

Another contributor is mechanical stress. The transmission relied on friction materials, bands, and solenoids that wear gradually. In high-mileage units, reduced clutch surface area and stretched bands alter hydraulic pressure regulation. Valve bodies, with their small passages and check balls, can clog or wear, producing inconsistent shift timing. These effects are often subtle at first but grow more pronounced over tens of thousands of miles.

When a transmission begins to underperform, owners face choices. Some first steps are simple and cost-effective. A full fluid and filter change, performed with the correct fluid type and procedure, can restore operation in many cases. Cleaning the transmission pan and replacing the filter removes debris and restores flow. Resetting adaptive shift logic, when accessible through diagnostic tools, may help a transmission re-learn shift points and smooth behavior after a service.

If symptoms persist, repair paths diverge between targeted rebuilds and full replacements. Rebuilding can be economical when a few components are worn or when the problem is isolated to the valve body, solenoids, or a single clutch pack. A comprehensive rebuild replaces seals, clutches, bands, and worn bushings. It restores internal clearances and hydraulic integrity but requires labor and proper machining where needed.

For many owners, especially those with higher-mileage vehicles, buying a replacement assembly becomes attractive. Remanufactured units offer near-new internals with warranty coverage, while used transmissions can be a lower-cost choice when sourced from low-mileage donors. Compatibility matters. Transmissions differ by drivetrain (FWD vs AWD), engine pairing, and production revisions. Confirming part numbers and verifying the donor unit’s configuration is essential before purchase. Listings and seller descriptions often include the vehicle years and drivetrain to help match parts.

When sourcing a used assembly, look for units with clear mileage history and a short return window. Remanufactured units should come with a parts list and warranty. Whether rebuilding or replacing, insist on fresh fluid, a new filter, and a pan gasket during installation. Torque specifications, fluid quantity, and fill procedure affect longevity. Overfill or underfill can harm the unit quickly. A properly filled and bled transmission will operate within expected temperatures and pressure ranges.

Driving habits influence the lifespan of this gearbox more than many drivers realize. Gentle throttle application, avoiding sudden full-throttle starts, and minimizing heavy towing preserve clutch life. Regular maintenance intervals for fluid changes, particularly in severe-use scenarios, reduce the chance of mid-life failure. If the vehicle spends time in stop-and-go traffic or spends winters with heavy salt exposure, more frequent inspections and fluid changes help.

Diagnostics begin with simple checks. A clean fluid sample with a mild, non-burnt smell points to a healthy unit. Dark fluid with a burnt odor indicates overheating and potential clutch glazing. Scattered metal flakes in the pan raise immediate concern. Modern scan tools can read transmission solenoid codes and clutch apply pressures. They also provide live data for line pressure and shift timing. Those readings help differentiate between electrical faults, sensor issues, and true hydraulic or mechanical failure.

The transmission’s engineering lineage included cross-company collaboration. Shared design principles with other platforms aimed to achieve cost efficiency and durability. That shared architecture means that some replacement parts and service procedures mirror those used in other models. It also means aftermarket and remanufactured options are more available than they might be for a one-off design.

For owners evaluating options today, weigh cost, vehicle value, and intended use. A remanufactured unit can restore confidence for longer ownership. A careful rebuild suits those who want to control part choices. A used assembly can be an economical stopgap. Wherever you source a unit, verify compatibility and insist on correct installation. If you want to explore drivetrain component alternatives for performance-oriented vehicles, consider researching a full sequential gearbox for Mitsubishi Evo as a technical contrast to traditional automatics.

If you need a compatible used assembly for a front-wheel-drive 2007–2008 Outlander, reference listings that include full part details and vehicle fitment notes. For example, a used transmission assembly for the FWD 2007–2008 Outlander is available on an auction platform and includes specifications and part numbers useful for matching replacements: https://www.ebay.com/itm/Transmission-Assy-MITSUBISHI-OUTLANDER-07-08-FWD/133467877077

Shifting with Purpose: The 2007 Outlander’s 4-Speed Transmission and All-Weather Engineering

When the first generation of a compact SUV matures, its powertrain choices reveal how the vehicle was meant to be used. The 2007 Outlander centers on a four-speed automatic paired with either front-wheel drive or all-wheel drive, backed by a 3.0-liter V6 producing roughly 215 horsepower and 201 lb-ft of torque. This combination favors smooth, predictable progress over walloping performance, creating a stable, comfortable highway feel.

The four-speed automatic is tuned for seamless shifts rather than rapid spurts. It maps the V6 torque to a broad, usable range and shifts occur with quiet assurance that keeps the ride composed as the road demands change. A manual shift mode provides a direct link to the powertrain, allowing engine braking or a quicker throttle response when needed—useful on steep grades or winding descents. Some trims offered a five-speed manual, a choice that preserved driver involvement and potential highway efficiency for those who wanted a more connected feel.

Reliability is a central theme in this setup. The four-speed unit was designed for durability and straightforward maintenance, with fluid checks, cooling, and occasional solenoids and seals as the usual wear points. With proper care, the transmission complements the V6 torque curve and the driving manners expected of a family crossover.

Drivetrain integration matters as well. The Outlander offers AWD with a torque management philosophy that keeps the system feeling secure on slick surfaces while preserving a calm, predictable character. The drivetrain and chassis work together to deliver confident weather resilience without sacrificing everyday comfort.

In sum, the 2007 Outlander demonstrates how a modest four-speed transmission can support a versatile, all-weather crossover. It emphasizes reliability, easy operation, and quiet confidence, while still offering the option for greater driver engagement through manual shift modes and, in some markets, a traditional five-speed manual.

How the 2007 Outlander’s Transmission Shapes Its On-Road Character

The transmission in a vehicle does more than shift gears. It defines how power meets the road, how the engine feels under load, and how a driver experiences acceleration, economy, and response. For the 2007 Mitsubishi Outlander, the transmission choices and their tuning have a direct effect on daily usability and long-term ownership. This chapter examines how the Outlander’s transmission configurations influence driving dynamics, what drivers typically notice behind the wheel, and what to expect when the vehicle is asked to perform under varied conditions.

Across markets and trim levels the 2007 Outlander was offered with different transmission types. Some early descriptions point to a conventional four-speed automatic paired with the 2.4‑liter four‑cylinder engine. Other references describe a continuously variable transmission (CVT) on models aimed at maximizing smoothness and fuel economy. This variance matters because each transmission type brings distinct behavior. A four‑speed automatic has clearly defined shift points and a familiar feel. A CVT, by contrast, removes fixed gears and instead varies its ratio continuously to keep the engine in its most efficient band.

That continuous nature is at the heart of the Outlander’s smoothness. In everyday driving, the CVT keeps engine speed near the point where torque and efficiency are best. Acceleration feels steady and without the traditional upshift jolt. For many drivers this creates a calm, relaxed experience in traffic and on long highway runs. Because the transmission can maintain optimal engine rpm, fuel consumption often improves compared to older stepped automatics. This is especially noticeable where stop‑and‑go commuting or steady highway cruising dominate the mile count.

However, the same trait that improves economy can reduce engagement. Without the cadence of gear changes, throttle feedback feels different. When you press the accelerator, the engine may rev to a steady pitch while the vehicle accelerates smoothly. That sustained engine note and lack of discrete shifts can make the car feel less sporty. Drivers used to the tactile rhythm of a traditional automatic sometimes describe CVT acceleration as a “rubber‑band” sensation. It works perfectly for efficiency, but it alienates those who prefer immediate, linear feedback from a gearbox.

Responsiveness under heavier demands highlights another tradeoff. The CVT tuning in the Outlander favors efficiency and comfort, not aggressive acceleration. Under hard throttle, the transmission may hold engine speed in a high rev range to build forward momentum, which can feel sluggish initially. When towing or climbing steep grades, that behavior can translate to a slower, more labored response compared to a vehicle with a more performance‑oriented automatic. Owners who frequently tow or carry heavy loads may notice the transmission reaching for more revs and staying there longer, straining the engine and producing higher cabin noise.

To address driver preference, Mitsubishi offered manual control modes on some models. This simulated manual shift feature gives the driver a choice: keep the transmission in automatic for smoothness and economy, or demand specific gear changes for sharper response. Manual mode can sharpen throttle response, reduce the feeling of slippage, and allow the driver to keep the engine at a desired rev range for overtaking or engine braking. While it does not convert a CVT into a true stepped gearbox, it gives a greater sense of involvement and control when conditions demand it.

All‑wheel drive models add another layer to the driving dynamic. The AWD system brings improved traction and composure across varied surfaces. When combined with the CVT, the result is a drivetrain that prioritizes steadiness and confidence over sporting behavior. The AWD system will modulate torque distribution in response to wheel slip, and the transmission will adapt its ratio to maintain traction and minimize abrupt torque transfers. In slippery conditions this combination instills predictability, making the Outlander feel planted during rain, light snow, or unpaved roads.

Even with the benefits, owners and reviewers have reported concerns about long‑term responsiveness and reliability perceptions. The CVT requires careful calibration and maintenance to function optimally. Under persistently heavy loads, its bias toward maintaining a specific RPM can generate heat and accelerate wear if the cooling and fluid change intervals are neglected. Regular service, thoughtful driving habits, and attention to fluid condition mitigate most issues. When planning repairs or replacement, sourcing correct parts and qualified service is important to preserve the intended behavior.

Practical ownership also ties into how the vehicle looks and is maintained. When repairing front‑end damage or refreshing the fascia after minor impacts, owners often seek genuine or high‑quality replacement pieces to retain fit and finish. For those who need replacement body components, aftermarket and OEM options exist, such as parts targeted specifically for this model. A source for exterior parts, including front bumpers designed for the Outlander, can be helpful when preserving both appearance and resale value. For example, resources listing a front bumper for Mitsubishi Outlander provide direct fit parts that keep the vehicle aligned with factory specifications.

Ultimately, the Outlander’s transmission defines a pragmatic character. It emphasizes comfort, predictability, and fuel efficiency, especially in FWD and AWD setups tuned for daily driving. Drivers who prioritize a responsive, engaging powertrain may find the feel less thrilling. Yet many owners appreciate the steady acceleration, easy cruising, and traction benefits the system provides. Where spirited performance is required, manual mode and mindful throttle control can narrow the gap between efficiency and engagement.

Understanding these dynamics helps set realistic expectations for how the vehicle will behave on the road. It also guides service choices and driving habits that preserve performance over time. Whether navigating city streets, hauling cargo, or tackling slippery surfaces, knowing how the transmission reacts allows a driver to extract the most from the Outlander’s design. For an in‑depth contemporary review and further technical observations about the transmission behavior and owner feedback, refer to the comprehensive review available from Car and Driver: https://www.caranddriver.com/mitsubishi/outlander/2007/recall-review

null

null

Shifting Through Uncertainty: Transmission Challenges and Care for the 2007 Mitsubishi Outlander

The 2007 Mitsubishi Outlander sits at an interesting crossroads of compact-SUV practicality and drivetrain experimentation. While many owners recall a straightforward four-speed automatic paired with a 2.4-liter engine, the broader dialogue around this model often centers on transmission behavior that can feel uncertain or inconsistent. The historical record shows two threads running side by side: the official specification of a conventional automatic transmission and the real-world chatter about CVT behavior in certain market variants or later discussions of Outlander transmissions. This chapter threads those threads together, focusing on the transmission landscape some owners encountered, the common symptoms they reported, and the practical care that can help preserve shifting quality and long-term reliability. By centering on what tends to go wrong, and how to respond, readers gain a practical framework for diagnosing and addressing transmission concerns without losing sight of everyday driving realities.

Among the most frequently discussed issues are paddle shifter problems, slipping, grinding noises, and erratic shifting. Paddle shifters, when present, offer a way to manually select gears or emulate stepping through ratios for a sportier feel. In practice, these shifters can become unresponsive or fail to communicate correctly with the transmission control system. When the signal chain between the paddle inputs and the transmission fails to register changes promptly, drivers can experience a lag between a commanded shift and the actual gear engagement. This disconnect may feel like a loss of control during a maneuver that depends on timely gear changes, especially in cornering or when merging into faster traffic. In some cases, the symptom is intermittent, which complicates diagnosis and can lull a driver into thinking the issue is momentary or cosmetic rather than structural.

Transmission slipping is another recurrent topic in discussions about the Outlander’s powertrain. Slipping can manifest as a delay in acceleration, a sudden surge, or a sensation of the engine revving higher without a proportional increase in vehicle speed. In some instances, slipping is subtle and slow to escalate, which makes it easy to ignore until the performance gap becomes noticeable. The root causes behind slipping in this context often point to deeper factors—wear within the transmission’s internal components, or issues within the transmission control circuit that fail to maintain the correct torque-holding or ratio-mapping under load. When slipping occurs, it is not just a nuisance; it can accelerate wear and lead to further degradation if left unchecked, particularly in models that rely on adjustable torque and progressively engaging bands.

Grinding noises during acceleration are another red flag that many owners report. A harsh or metallic grind heard under load can indicate internal wear or misalignment within the CVT’s bearings, pulleys, or belt interfaces, or it can signal a misfire in the transmission’s engagement sequence. While some grinding can be transient—associated with cold start conditions or occasional fluid issues—recurrent sounds demand a diagnostic evaluation. In this space, the distinction between a mechanical wear pattern and a control-system interpretation is crucial. The transmission control unit (TCU) or the CVT’s electronic logic drives how gears are selected and how smoothly the belt and pulley assembly are engaged. When the control signals drift from expected parameters, the mechanical presentation may appear as grinding, even if the core components have not yet reached critical failure.

Erratic shifting behavior is perhaps the most challenging symptom to interpret. Shifts that occur out of sequence, or that hesitate before engaging, can arise from a few linked sources. A faulty TCU, age-related wear within the CVT system, or degraded fluid can all contribute to nonuniform shifting. The transmission’s climate under varying temperatures and loads can also reveal reliability gaps. Diagnostic evaluation becomes essential in this setting, because erratic shifting is rarely the result of a single failing part. Instead, it often reflects an interplay between electronic signaling, hydraulic response, and mechanical wear that requires a technician to map out the fault tree and confirm the exact locus of the problem.

Understanding the likely causes helps frame the maintenance approach. Many of the issues noted above tie back to transmission control unit concerns or to wear within the belt-and-pulley CVT architecture, where timing, belt tension, and pulley ratios are coordinated by electronic signals. Fluid condition and quality are a recurring theme in maintenance discussions. CVT fluids are formulated for precise friction and heat characteristics that differ from conventional automatic transmission fluids. Over time, fluid degradation or contamination can alter frictional properties, reduce cooling efficiency, and change hydraulic pressure, all of which can magnify the symptoms described. A lifelike maintenance mindset is to treat fluid health as a leading indicator: if the fluid is dark, smells burnt, or shows metallic contamination on a dipstick, those signs warrant more than a simple top-off.

The practical maintenance steps that follow are designed to address both the symptoms and their root causes. Regular fluid check and replacement emerge as a foundational best practice. CVT fluid cycles through the system to keep belt wear and heat under control, and timing is a critical factor. Following the manufacturer’s recommended service intervals helps prevent fluid degradation from accelerating wear patterns. When symptoms first appear—whether it is a hesitant paddle response, a slipping sensation, or a grinding sound—a diagnostic evaluation should be pursued promptly. Modern transmissions rely on sophisticated control algorithms, and the feedback loop between sensors, the TCU, and the CVT’s hydraulic system must be accurate. If a technician identifies a discrepancy in the control unit’s data, reprogramming or even replacing the TCU can restore proper communication with the transmission. The goal is to restore clean, predictable signals that translate into smooth, confident shifts.

Fluid quality remains a central pillar of reliability. The emphasis is on using fluids that are appropriate for CVT architectures and that meet the vehicle’s specifications. Fluid compatibility matters as much as fluid level. Old or mismatched fluids can alter frictional coefficients and hydraulic responses, causing the very symptoms we’ve described: slipping, inconsistent engagement, and shifting irregularities. In practice, owners should seek diagnostic confirmation that the fluid is within specification and that the coolant and filtration systems associated with the CVT are functioning as designed. In many situations, a simple drain-and-fill procedure with the correct grade of fluid, followed by a careful drive cycle, can resolve minor irregularities. In more persistent cases, a full service that includes fluid replacement, filter checks, and, if needed, TCU calibration can be required.

Beyond fluids and electronics, the reliability equation includes ongoing performance monitoring. Quiet operation and smooth shifts should be the baseline. If warning lights illuminate, or if the vehicle exhibits unexpected behavior during a routine drive, it is prudent to perform a diagnostic scan with equipment calibrated for transmission control logic. The result may reveal an out-of-range sensor value, a need for software reprogramming, or a failing solenoid that governs flow and pressure in the CVT system. In each case, early diagnosis saves both time and expense and reduces the risk of collateral damage to the belt or pulleys.

An additional practical note concerns maintenance tangents tied to the Outlander’s drivetrain. For owners who care about a broader maintenance strategy, consider how exterior parts accessory pages might intersect with overall vehicle upkeep. For example, if you are addressing exterior wear and tear or pursuing aesthetic repairs, you could explore related parts pages such as the front bumper listing for Outlander models. This page, accessed through the link front-bumper-mitsubishi-outlander-19, can serve as a reminder that good maintenance is a holistic habit. Keeping the vehicle in sound mechanical condition supports safe driving and contributes to long-term value, even as individual components like the CVT age and evolve with the car’s mileage.

In closing, the essence of care for the 2007 Outlander transmission—whether in the form of a conventional automatic or a CVT-equipped variant observed by some market-specific discussions—rests on vigilance, timely diagnosis, and disciplined fluid management. When signs suggest transmission distress, a structured diagnostic approach guided by professional technicians is the most reliable path. Regular fluid checks and precisely specified fluid changes help preserve frictional and hydraulic characteristics that ensure smooth engagement. Addressing a miscommunication within the control unit or correcting sensor feedback can restore confident shifting. Above all, maintaining a habit of attentive observation, prompt response to warning indicators, and adherence to service intervals keeps the Outlander’s transmission in a healthier, more predictable state over the miles ahead. External resources provide further diagnostic context and practical workflows for owners and technicians alike. For a detailed, model-specific diagnostic framework, consult the Mitsubishi Outlander CVT Troubleshooting Guide: https://www.mitsubishimotors.com/support/technical-bulletins/2007-outlander-cvt-troubleshooting.

Final thoughts

Understanding the transmission system of the 2007 Mitsubishi Outlander is vital for ensuring its longevity and performance. By familiarizing yourself with its specifications, driving dynamics, and potential issues, as well as how to maintain it effectively, you can make informed decisions that enhance your ownership experience. This knowledge is not just for personal insight; it scales to impact business decisions, particularly for fleet management, where efficiency and reliability are paramount.