The Mitsubishi Eclipse 2G front bumper serves as both a protective barrier and a defining stylistic element for this iconic vehicle. Business owners in the automotive industry, particularly those dealing in aftermarket parts or restoration components, will find valuable insights within this article. As we delve into five critical chapters, you’ll discover various aftermarket options that can enhance the Eclipse’s sporty look, the importance of adhering to OEM quality standards, the materials that ensure durability, the aesthetic impact these bumpers have, and emerging global sourcing trends that could shape your procurement strategies. This comprehensive exploration aims to equip you with all the knowledge necessary to meet your customers’ demands effectively and elevate your business offerings in the automotive market.

Choosing and Customizing Aftermarket Front Bumpers for the Eclipse 2G

Choosing and Customizing Aftermarket Front Bumpers for the Eclipse 2G

Selecting an aftermarket front bumper for the Eclipse 2G is a decision that blends style, function, and practical planning. The right bumper transforms the car’s face, improves airflow at speed, and protects vulnerable components. Yet it also involves trade-offs: material choices affect durability, design choices influence fitment, and sourcing decisions determine cost and lead time. This chapter walks through the realistic options and the actions that turn a promising listing into a successful installation.

Begin by identifying what you want the bumper to do. If your priority is a sharper, more aggressive look, many aftermarket designs deliver larger intakes, sharper lips, and integrated aerodynamic elements. If improved cooling or high-speed stability matters, look for bumpers with ducting and splitter-ready lower sections. If daily driving and longevity are the goal, focus on materials and build quality. Each objective steers you toward different vendors and finishes.

Material matters. Three common materials appear in listings: polyurethane (PU), acrylonitrile butadiene styrene (ABS), and fiberglass. PU blends offer a balance of flexibility and impact resistance. They bend under mild stress and often resist cracking from small impacts. ABS is a rigid thermoplastic that usually fits well without much trimming and holds paint reliably. Fiberglass can deliver the sharpest, lightest designs but is prone to cracking on impact. It also often requires more prep and finishing before paint. Reinforced plastics with added fibers or proprietary blends can mimic OEM resilience while allowing bolder shapes.

Finish options affect cost and preparation time. You will find raw black, primer-ready, and painted bumpers. Raw or primer-ready parts reduce shipping marks and often cost less, but they demand professional paint and finish work. Pre-painted pieces might reduce labor but risk color mismatch if your car has faded paint. If you plan to paint yourself, choose a bumper with a smooth gelcoat or factory primer coat.

Fitment is the frequent stumbling block for buyers. Even parts advertised for the same model range may require trimming, drilling, or slight bumper bracket adjustments. Differences in year, trim, and factory options—fog light openings, tow hook covers, or parking sensors—change how easily a bumper mounts. Verify compatibility with your exact year and trim, and inspect listings for references to specific chassis codes. When in doubt, choose suppliers that state compatibility with your trim and include installation instructions. Expect to spend time test-fitting and aligning mounting points during installation.

Design features can make integration of other accessories simple. Many bumpers are pre-drilled or pre-shaped for fog lights, LED strips, or mesh inserts. If you plan to add lighting or a larger intercooler, prioritize bumpers with built-in openings or removable ducts. A bumper with a removable lower splitter or a bolt-on chin piece simplifies future swaps and repairs.

Aerodynamics are more than style. A thoughtfully designed bumper can reduce front lift and channel cool air toward the radiator and brakes. Splitters and air dams redirect airflow; ducts and scoops feed intercoolers and oil coolers. If you track the car or run sustained high speeds, choose designs that manage airflow rather than purely cosmetic shapes. Remember that adding a lower splitter may require a small ride-height change and stronger mounting points to handle added load.

Sourcing and quality control are practical considerations often overlooked. Reputable suppliers provide clear material specs, fitment notes, and return policies. Check for references to industrial standards or reinforcement details where available. If ordering from overseas suppliers, confirm shipping protections, lead times, and customs duties. For business buyers or bulk orders, request production samples and run basic dimensional checks against OEM mounting points. Quality control measures should include verifying hole locations, thicknesses at mounting points, and finish uniformity.

Installation demands patience and the right tools. Remove the old bumper and inspect brackets, clips, and foam absorbers. Replace any damaged mounting hardware. Test-fit the new bumper without fasteners to locate gaps and interference points. Minor trimming with rotary tools or adding small tab brackets often solves alignment issues. For bolt-on splitters, use stainless hardware and thread-locking compound on high-vibration points. If paint is required, mask mounting surfaces and use a two-stage paint system to improve durability.

Cost varies widely. Basic replacement bumpers aimed at correct fitment and daily driving sit at the lower end of the market. Performance or show-focused kits command higher prices for complex molds and reinforced sections. Factor in paint, mounting hardware, and possible professional fitting when comparing quotes. Remember that a cheaper part that requires extensive rework can cost more in the long run.

Durability and repairability are practical priorities. PU and ABS parts tend to flex and absorb impacts; fiberglass panels often require more complex repairs. Consider how easy it will be to replace a lower lip or chin piece if you frequently encounter curbs or steep driveways. Bolt-on lips and splitters are easier and cheaper to replace than bonded or riveted pieces.

Legal and safety considerations matter. Front bumpers interact with crumple zones and pedestrian safety features. If you alter bumper structure significantly, confirm that repairs or replacements comply with local vehicle regulations. Some aftermarket bumpers keep OEM sensor and light mounts intact to preserve safety systems.

Finally, use a checklist before you buy: verify year and trim compatibility; confirm material and finish; ask about installation instructions and hardware; check return and warranty terms; and confirm shipping and customs expectations. If possible, seek examples of the exact bumper installed on the same model to evaluate real-world fitment and finish.

For readers looking to explore options for other model years or related front bumper styles, additional articles on site cover front bumpers for later Eclipse models and related parts. See the detailed page for 2006–2008 front bumpers for comparative fitment notes and installation tips.

For a curated selection of aftermarket front bumper listings and further product details, consult this external reference: https://www.aliexpress.com/item/10050057484768.html

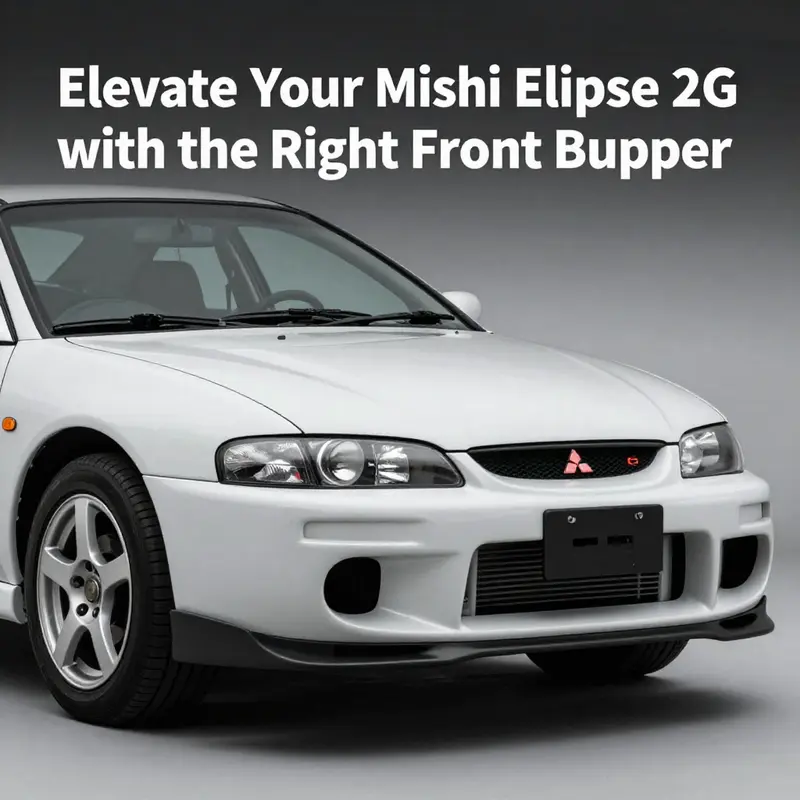

Behind the Shield: OEM Quality Standards That Shape the Eclipse 2G Front Bumper

The front bumper of the Eclipse 2G is more than a bold face for the car; it is a carefully engineered safety and performance component whose quality standards govern how the vehicle behaves in everyday driving and in the rare moments of impact. When we talk about OEM quality for the Eclipse 2G front bumper, we are tracing a lineage of design and manufacturing decisions that balance protection, fit, durability, and compatibility with the broader system of sensors, lights, and structural elements. This is not a single material choice or a single test; it is a tightly choreographed set of specifications that ensures the bumper performs as intended across decades of use and weather, while maintaining the visual character that enthusiasts associate with the Eclipse lineage.

Material composition sits at the heart of these standards. The original bumper is typically molded from high-impact resistant thermoplastics, most commonly ABS or a PC/ABS blend. These materials are chosen for their ability to absorb collision energy without cracking or shattering under low- to moderate-velocity impacts. The PC portion adds dimensional stability and heat resistance, helping the bumper maintain its shape in hot sun or freezing cold. The result is a panel that can flex enough to cushion a minor bump, yet remain rigid enough to preserve the integrity of the grille and fenders around it. The material choice also influences paint adhesion, surface hardness, and the long-term resistance to weathering, all of which are integral to OEM quality.

Precision fit and finish are the other side of the coin. Every OEM bumper is produced from CAD blueprints and tooling that mirror the vehicle’s original geometry. This is how factory lines guarantee a seamless interface with adjacent body panels, creating even gaps, consistent radii, and predictable alignment with the headlights and grille. A true fit minimizes wind noise and aerodynamic disruption, which matters not only for aesthetics but for the car’s overall efficiency and driving feel. When a bumper aligns with the fenders and hood within spec, it supports consistent door-to-panel gaps and helps preserve the vehicle’s silhouette—the kind of detail that matters when the Eclipse is viewed up close or photographed for a feature shoot.

Beyond the bare shell, OEM bumpers are designed with integrated functional features that support the car’s daily usability and safety profile. The 2G front bumper includes built-in cutouts and housings for fog lights and other lighting elements, designed to meet visibility requirements while maintaining a clean, unified look. More modern expectations for driving safety—such as sensor integration for parking aids or camera units for ADAS—have shaped bumper design to include precise mounting points and reinforcement to preserve alignment with sensors located behind the fascia. In practice, this means that an OEM bumper accommodates the factory-installed systems and leaves a clear path for aftermarket accessories that are intended to work in harmony with the vehicle’s technology stack, rather than forcing fitment compromises.

Durability under the sun and on salted roads is another central pillar of OEM quality. The bumper’s external surface is treated with UV-stabilized coatings and paints that resist fading, chalking, and color mismatch after years of sun exposure. The protective strategy extends inward as well: moisture barriers and corrosion-resistant components are incorporated to guard fasteners, reinforcements, and the internal mounting structure. For drivers in climates that see heavy rainfall, snow, or road salt, this dual-layer protection helps ensure the bumper retains its finish, mounting integrity, and structural behavior over time. The emphasis on corrosion resistance is not merely cosmetic; it preserves the bumper’s ability to hold its shape and its integrated hardware in place, preventing gradual misalignment that could affect seal integrity and aero performance.

Compliance with safety standards is non-negotiable. The Eclipse 2G bumper must meet applicable national and international regulations that govern impact absorption, pedestrian protection in relevant markets, and overall structural rigidity. In the United States, that includes FMVSS criteria, while European and other markets rely on ECE regulations and regional rules. These standards shape how the bumper behaves in a collision: its ability to deform in a controlled way, protect underlying components, and maintain a predictable retreat path for energy transfer. The OEM route usually ensures that every bumper not only looks right but behaves within the tested envelope of safety performance, both for the vehicle’s occupants and, in later considerations, for pedestrians in the event of a collision.

Quality control and testing complete the picture. OEM bumpers undergo rigorous testing that simulates real-world conditions: temperature cycling to mimic seasonal extremes, thermal stability tests to assess paint and plastic behavior under repeated heating and cooling, and impact tests that verify energy absorption and structural integrity. This testing is not a one-time step but a robust sequence that confirms consistency across production runs and part numbers. Buyers who source genuine OEM components benefit from documentation, part numbers, and traceability that confirm each bumper adheres to Mitsubishi’s engineering standards before it leaves the factory floor. In practice, this means a reliable guarantee of fit, finish, and function that aftermarket alternatives strive to rival but may not always replicate to the same degree of certainty.

For anyone weighing the choice between OEM and aftermarket routes, the story often comes down to fit, warranty, and long-term value. Aftermarket bumpers can offer cost savings or styling variety, but they frequently trade some aspects of OEM assurance for that flexibility. When OEM standards are the benchmark, a key advantage lies in the assurance that the bumper will align with factory geometries, lights, and sensor positions. It also means a smoother path to dealer support or factory-compatible documentation if the vehicle is resold or undergoes future diagnostics. In the context of the Eclipse 2G, where the front end is a prominent canvas for both performance cues and brand identity, maintaining that OEM lineage helps preserve the vehicle’s original feel and resale value.

For readers pursuing a genuine OEM option, there is value in examining dedicated compatibility pages that closely reflect the Eclipse’s mid-generation requirements. For example, a detailed reference resource on the 2006-2008 Eclipse front bumper page provides a concrete point of comparison for fitment, mounting, and finish expectations. This kind of reference can guide a buyer toward the most appropriate trim-level correspondence and help verify part numbers and documentation before purchase. You can explore that specific OEM route here: 2006-2008 Mitsubishi Eclipse front bumper. The intention is not to constrain choice but to illuminate how OEM standards translate into tangible, verifiable parts that preserve the vehicle’s integrity.

As part of a broader sourcing strategy, buyers should also consider the documentation that accompanies genuine parts. Authorized channels typically provide clear part numbers, warranty coverage, and verification of compliance with the relevant FMVSS or ECE frameworks. This documentation is more than bureaucratic detail; it is a practical safeguard that confirms the bumper’s compatibility with the Eclipse’s mounting points, fog-light housings, and any hidden sensor receptacles. For B2B buyers or those ordering in bulk for a shop or restoration project, the traceability and standardized procedures become even more valuable, reducing the risk of misfit or mismatched components that can complicate installation and prolong downtime.

Ultimately, OEM quality standards for the Eclipse 2G front bumper weave together material science, precision engineering, and rigorous testing to deliver a product that feels right from the moment the hood is opened. The result is a bumper that protects the front end, supports lighting and sensor systems, resists weathering, and preserves the vehicle’s iconic stance. The choice between OEM and aftermarket options is more than a price equation; it is a decision about the long arc of fit, durability, and confidence in the vehicle’s safety profile. For enthusiasts who value fidelity to the original engineering intent, pursuing OEM-grade components—backed by documentation and authorized sourcing—offers a practical path to maintaining the Eclipse’s performance and personality for years to come. In the end, the bumper is not merely a piece of plastic; it is a carefully engineered shield that carries the car’s identity forward, ride after ride, season after season.

External resources for further verification of OEM standards and part documentation can be found on official manufacturer pages that provide part information and compliance details for Eclipse components. These references help clarify the expectations for fitment, finish, and safety, ensuring that any replacement aligns with the vehicle’s original engineering intent.

How Materials Shape Longevity and Performance of the Eclipse 2G Front Bumper

Material choices determine how a front bumper performs over time. For owners of the Eclipse 2G, the bumper is more than a styling element. It protects the front end from minor impacts. It also affects repairability, paint adhesion, and resistance to weather. Understanding the materials and how manufacturers reinforce them helps you choose a replacement that lasts and fits properly.

Most second-generation Eclipse front bumpers are molded from ABS plastic. ABS is chosen for its balance of strength, impact resistance, and formability. It resists cracking under small collisions and bends enough to absorb energy. The material holds mounting points and attachment features well. That stability keeps panel gaps tight and reduces rattles over time. In practice, ABS preserves both appearance and function under everyday driving conditions.

Beyond generic ABS, modern aftermarket producers often use enhanced formulations. These can include higher-impact ABS blends or polymer compounds with added flexibilizers to reduce brittleness in cold climates. Some replacements integrate polyurethane (PU) or reinforced thermoplastics in high-stress areas. The goal is to improve toughness without adding excessive weight. Reinforced sections around tow hooks, fog light mounts, and lower chin areas reduce deformation and help the bumper recover from small scrapes.

Manufacturers also add structural stiffeners. These are ribs or thicker sections molded into the backside of the bumper. Stiffeners stabilize the face of the bumper and protect thin regions from warping under heat. They matter most where the bumper interfaces with the subframe, energy absorbers, and fasteners. A bumper that lacks adequate stiffening will flex under aerodynamic loads at speed. It may also stress mounting tabs, leading to cracks or prematurely loose fittings. When inspecting a replacement, look for visible ribs, thicker mounting bosses, and reinforced fog light housings.

Environmental durability is another critical factor. UV exposure, road salts, solvents, and repeated wash cycles degrade polymers over time. ABS has decent UV resistance, but untreated surfaces can become chalky and brittle after years in sun. Quality replacements often include UV-stable additives or are delivered primed to accept paint. Proper priming and painting after installation significantly extend service life. For cars in coastal or winter climates, choose materials rated for chemical resistance and verify corrosion protection for any embedded metal brackets.

Heat cycling and temperature extremes also affect performance. In hot climates, poor-quality plastics can soften, leading to sagging or loss of tight fitment. In freezing conditions, brittle polymers can snap during minor impacts. Manufacturers counter these issues by selecting polymers with broader operating temperature ranges and by designing thicker sections where heat buildup is likely. For example, bumpers with integrated lower diffusers or vents often use reinforced edges to prevent the formation of stress cracks around openings.

Fitment precision is closely tied to material stability. OEM bumpers are engineered to strict tolerances. Aftermarket pieces vary. Well-made replacements match factory mounting points and thicknesses carefully. They maintain correct gap lines and align with headlight and fender edges without modification. Cheaper parts sometimes require trimming or shimming to achieve the same result. When material quality is higher, the need for modification drops significantly. This saves time and prevents damage from ill-fitting trims or adhesives.

Repairability and post-impact behavior matter for everyday owners. ABS panels can often be repaired with plastic welding, epoxy fillers, or reinforcement patches. Repair methods work best when the bumper has adequate thickness and consistent polymer composition. Very thin or mixed-material bumpers are harder to repair cleanly and may need complete replacement after a moderate impact. Consider how visible a repair will be and whether the replacement material accepts fillers and paint similarly to OEM plastic.

Surface finish and paint adhesion are practical concerns. Smooth, consistent polymer surfaces accept primer and topcoat more reliably. Manufacturers that mold in a black, raw finish provide a base that sands and primes well. The recommended process is light scuffing, plastic-specific primer, and a flexible topcoat. Flexible paints help the finish expand and contract with the bumper as temperature changes. Proper painting reduces the risk of cracking or peeling and maintains a factory-quality appearance for years.

Compatibility with sensors and trims is increasingly important. Some second-generation vehicles were retrofitted with sensors or aftermarket lighting. The bumper material must accommodate mounts and wiring without tearing or stressing the components. Look for pre-cut locations, reinforced brackets, and enough internal space for wiring harnesses. A durable polymer helps the bumper retain threaded inserts or clip bosses used by sensors.

For buyers weighing OEM versus aftermarket, consider the trade-offs. OEM parts provide predictable fit and material consistency. High-quality aftermarket options can match or exceed OEM durability. They sometimes include improved polymers and reinforced areas designed for modern driving demands. The key is to verify material specs, check for stiffening, and examine the finish before purchase. If sourcing multiple units or buying for a shop, request material data sheets and sample pieces to confirm thickness and reinforcement.

Installation stresses also influence longevity. Fastening torque, bumper-to-chassis clearance, and reinforcement support must be correct. Over-tightened clips can crack mounting bosses, while loose bolts allow vibration and wear. Use torque specifications where available and inspect the bumper after initial road miles. Adjustments are normal as clips seat and adhesives cure.

Finally, realistic lifespan expectations help with maintenance planning. A well-made, painted ABS bumper properly installed and cared for can last a decade or more in normal conditions. Exposure to repeated impacts, extreme climates, or poor painting practices shortens that span. Routine washing, UV protection when possible, and gentle handling during winter months prolong service life.

For those researching replacements or upgrades, learning to read material cues is valuable. Look for uniform wall thickness, visible stiffening ribs, cleanly finished mounting bosses, and a primed or raw surface ready for paint. When available, review supplier documentation on polymer blends and temperature ratings. If you want to compare options or sourcing channels, the shop page for a later-generation Eclipse bumper provides useful reference details about fitment and finish: 2006-2008 Mitsubishi Eclipse front bumper.

For a sample product listing and additional specifics on materials and reinforcement details, see this external product listing: https://www.ebay.com/itm/404876512382

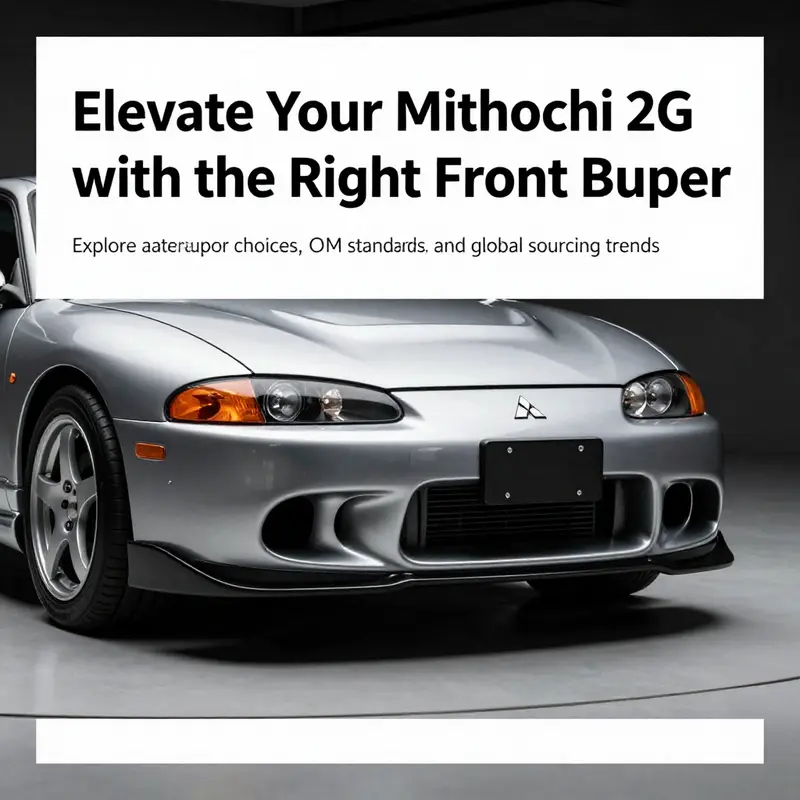

Sharper Front, Stronger Presence: Redefining the Eclipse 2G’s Aesthetic through its Front Bumper

The front bumper is more than a shield for the Eclipse 2G; it is a defining edge of its personality. In the late 1990s, when the 2G Eclipse arrived, its design language already spoke in a language of speed and agility. The bumper, in particular, became the primary canvas on which the car’s athletic intention could be read at a standstill. Its lines, its relationship to the grille, and the way it meets the ground all contribute to a perception of stance that can transform a modest coupe into a bold statement. This is not simply about protection; it is about crafting a first impression that carries through the rest of the silhouette, from fender curves to headlight treatment, and from color to texture. When a bumper is designed with performance in mind, it signals to the eye that the car behind it is ready for action, even when it is parked on a street corner or captured in a showroom photograph.

Central to the Eclipse 2G aesthetic is the way the bumper negotiates the front fascia’s geometry. A recurring design cue is the Evo-inspired grille treatment, a grille that reads as a deliberate shout of performance without saying a word. This cue does more than just add visual interest; it compels the eye to trace a sharper, more aerodynamic line across the car’s face. The result is a front end that appears narrower, more focused, and more ready to cut through air. The Evo-inspired detail helps align the Eclipse with a lineage of high-performance Mitsubishi models, creating a visual shorthand that resonates with enthusiasts who prize a blend of street legality and track-ready attitude. The improvement is not purely cosmetic. The grille’s opening, its proportions, and how it sits within the bumper influence perceived airflow and the car’s overall stance, turning a flat front into a visually dynamic plane that catches the light and holds attention from every angle.

The bumper’s impact extends beyond the grille. The 2G front end often benefits from a carefully sculpted lower lip and diffuser combination that subtly widens the impression of the car’s width. When integrated with a lip spoiler or a low splitter, the effect is a front that looks more planted, as if the Eclipse has learned to ride lower without sacrificing comfort. This visual aggressiveness is not about aggression for its own sake; it signals precision and purpose. The lines flow from the upper edge of the bumper, down along the corners, and into the fenders, creating a cohesive rhythm that guides the eye along the car’s profile. The result is a front end that reads as fast even when the vehicle is stationary, a quality prized by the 2G community that values both performance heritage and personalized expression.

Materials and build quality play a subtle but essential role in this visual transformation. Front bumpers for 2G Eclipse models are commonly constructed from durable polyurethane or reinforced plastics. These materials balance impact resistance with weight and fatigue resistance, ensuring that the bumper holds its shape under sun, rain, and the occasional curb encounter. The finish options further shape the aesthetic. A raw or matte black finish emphasizes a rugged, track-ready vibe, while a glossy surface can reflect street lighting in a way that accentuates the bumper’s contours. The choice of material and finish directly influences perceived quality. It is not just about how the bumper looks when new; it is about how it ages, how it wears, and how its lines remain crisp after miles of driving and exposure to weather. Industrial standards help ensure that these components meet safety and durability requirements, so the bumper remains a reliable element of the car’s identity as much as its protection.

Enthusiasts often pursue a cohesive look by pairing the bumper with other body-mod elements. A GT-style lip, for instance, can be added to extend the lower edge and emphasize a forward-stancing angle that echoes the car’s performance aspirations. While the lip spoiler adds a more aggressive silhouette, it also influences airflow at the car’s periphery, contributing to a perception of speed even when the Eclipse is at rest. In practice, many builders view the bumper as a central piece that must harmonize with the rest of the kit, including side skirts, a rear diffuser, and sometimes wider fenders. The careful assembly of these parts matters as much as any single piece in achieving a balanced, tasteful upgrade. The goal is not to overwhelm the eye with busy details but to craft a front end whose every line has a reason, from the crest of the hood line to the tip of the lip and the curve of the lower air dam.

For those who prioritize authenticity alongside customization, compatibility becomes a guiding principle. The Eclipse 2G’s bumper is not a one-size-fits-all component; it must fit the specific model year and trim level to avoid gaps, misalignment, or compromised aerodynamics. The landscape of aftermarket options is broad, but informed buyers look for pieces that respect the car’s original geometry while offering modern construction and finish quality. In this sense, the 2G bumper becomes a bridge between eras: it preserves the car’s early, era-defining silhouette while enabling modern finishes and precise assembly. The result is a front end that remains true to the Eclipse’s spirit while appearing refreshed and purposeful. When evaluating potential replacements or upgrades, it is helpful to consult catalogs or repositories that catalog the evolution of Eclipse bumpers across model years, such as the classic entries that detail the 2006-2008 front bumper variations and their mounting considerations; these references help ensure a proper fit and a visually coherent result.

From an ownership perspective, the bumpers’ aesthetic contributions are often realized in daily life as well. A bumper that maintains its shape, finish, and alignment across seasons helps preserve the car’s curb appeal and resale value. The 2G Eclipse draws attention for its clean, purposeful front end, and a well-chosen bumper can preserve that impact well into later years. The lighting treatment, the headlamp housings, and even paint color interplay with the bumper’s surface to influence perceived depth and brightness. A bumper with well-defined edges can catch the light in ways that make the car appear more dynamic when viewed from oblique angles. Similarly, a bumper that wears unevenly, or that is contrasted with a mismatched hood or fender line, can break the visual flow and soften the performance-inspired intent. Maintaining a consistent aesthetic requires careful attention to fitment, finish, and weather exposure, especially in climates that spare the bumper neither sun nor salt.

In the broader context of the Eclipse 2G’s design ecosystem, the bumper is a critical link between performance cues and street-ready practicality. It embodies the dual demands of enthusiasts: to evoke speed through visual drama while preserving daily usability. The Evo-inspired grille, the sculpted lower edge, and the decision to use durable materials together create a front end that communicates a clear message—this car is ready for action, even when it is idling at a traffic light. This chapter’s exploration of the bumper’s aesthetic power underscores a simple truth: small changes in the front can ripple through the entire silhouette, altering how the Eclipse is perceived, driven, and imagined by both drivers and onlookers.

For readers who want to see how these ideas translate into real-world options, consider exploring the Eclipse bumper catalog to understand how different years and trims present unique fitment considerations. You can reference a catalog entry for the early 2000s Eclipse front bumper here: 2006-2008 Mitsubishi Eclipse front bumper. This resource provides a practical sense of how the front-end geometry is negotiated in production and aftermarket contexts, and how a well-chosen component preserves the car’s archetypal look while letting owners tailor it to their tastes. External inspiration for the visual direction discussed here can be found in dedicated mood boards and design references that showcase Evo-inspired grilles and sharp front ends, such as visual explorations on Pinterest that highlight the clean, aggressive lines of the Eclipse 2G with an Evo-style grille. See this visual reference for a quick context: https://www.pinterest.com/pin/1234567890/.

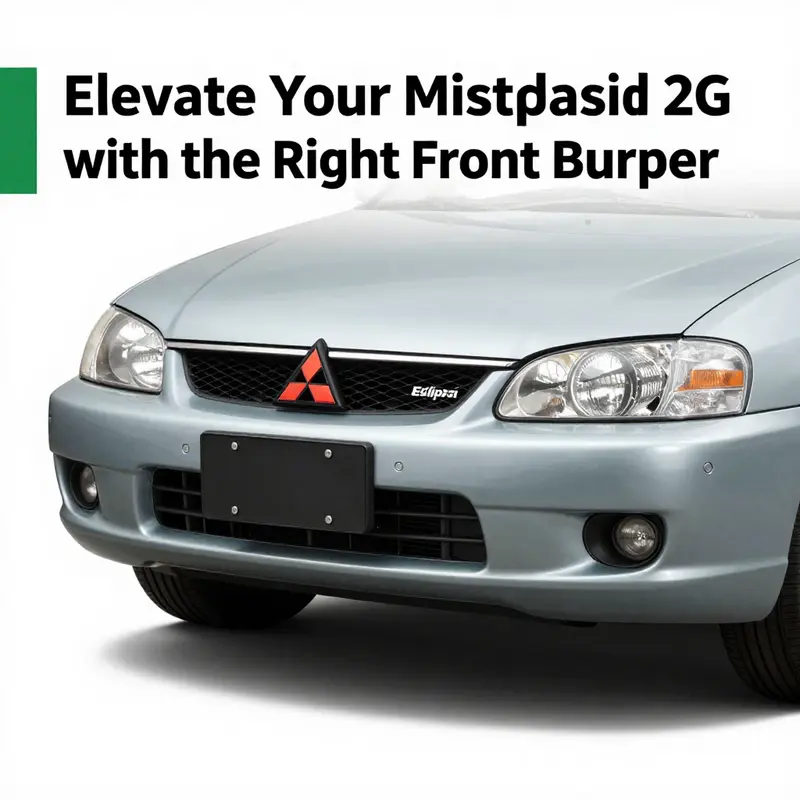

Sourcing the Eclipse 2G Front Bumper: Global Hubs, Materials, and Procurement Strategy

Sourcing the 2G front bumper requires more than price comparison. Successful procurement blends an understanding of regional manufacturing strengths, material choices, quality systems, and logistics realities. For buyers who care about fitment, durability, and finish, that blend determines whether a replacement bumper will look factory-original, deliver on impact resistance, and arrive on time.

China remains the primary production base for front bumpers compatible with the second-generation Eclipse. Within China, two clusters dominate: the southern coastal cluster centered on Guangzhou, and the eastern cluster in Zhejiang Province. Guangzhou benefits from mature injection-molding, painting, and thermoplastics ecosystems. Its industrial districts have long supplied exterior components with consistent cycle times. The proximity to large export terminals reduces transit delays, which keeps lead times predictable for international buyers. Zhejiang’s cities emphasize lean manufacturing and tight process control. Suppliers there often offer flexible order quantities and efficient prototyping, which suits buyers who need small-run runs or fast iterations.

Material choice shapes both supplier selection and final performance. Standard thermoplastics such as ABS and polypropylene are common for OEM-replacement bumpers. They strike a balance between cost, rigidity, and finishability. For buyers who require higher flexibility and resistance to cracking, polyurethane (PU) remains popular. PU bumpers bend under minor impacts and return to shape more readily, reducing repair bills for urban drivers. For aesthetic or performance-focused projects, composite materials, including carbon fiber overlays or grilles, are an option. These parts require different manufacturing processes and typically come from specialized workshops rather than mass-plastic factories. Choosing a material early in sourcing narrows qualified suppliers and speeds evaluation.

Quality assurance has risen up procurement agendas. Verified suppliers that share documentation on material composition, test reports, and production controls are preferred. Look for suppliers who provide basic certificates indicating compliance with polymer material standards and environmental controls. In many cases, third-party testing—impact resistance, paint adhesion, and UV stability—adds confidence. For business buyers, insisting on pre-shipment inspection (PSI) and factory audits reduces the risk of costly returns. A sampling phase with clear acceptance criteria should be part of any order. When buyers need cosmetic consistency across color-matched bumpers, request color cards and production samples before full production.

Logistics and export infrastructure influence supplier choice as much as factory capability. Suppliers near major ports offer quicker access to ocean freight and simplification of export procedures. This is particularly relevant for bulky items like bumpers, where freight cost becomes material to total landed cost. Suppliers with experience exporting to target markets can handle packaging that prevents deformation and finish damage. They can also advise on efficient palletization and protective crating. For buyers evaluating landed cost, consider transit time, freight mode, and potential demurrage risk at destination ports.

Strategic sourcing balances cost, quality, and lead time. For small and medium enterprises, partnering with a supplier that offers prototyping and low minimum order quantities is valuable. For larger buyers, economies of scale favor suppliers who can lock in production runs and competitive unit pricing. Dual sourcing is a practical risk-mitigation tactic. Maintain a primary supplier for volume and a secondary vendor for contingency supply. This ensures continuity in case of capacity constraints or shipping disruptions.

Supplier credibility is measurable and actionable. Ask for production photos, batch traceability, and references from other buyers. Factory visits remain the most effective verification method, but when visits are infeasible, secure virtual audits. Request evidence of consistent tooling maintenance, injection-molding parameters, and paint booths with controlled environments. For composite parts, validate layup procedures and cure cycles. Include specific acceptance criteria in contracts, covering paint thickness, gap tolerances, and attachment point integrity.

Regulatory and environmental compliance matter more than ever. Buyers should review local regulations in their destination markets for materials and emissions. Suppliers that maintain records of volatile organic compound (VOC) controls and waste-management practices reduce compliance headaches. Certifications and declared compliance statements help during customs clearance and reduce hold-ups in markets sensitive to environmental standards.

Customization and aftermarket demand have changed procurement dynamics. Many buyers now order slight design tweaks to accommodate additional components or sensors. Suppliers that offer in-house tooling and rapid prototyping services shorten time to market. For projects requiring an integrated look across multiple components, such as matching a front bumper to side skirts, look for suppliers experienced in coordinated body-kit production. When exploring cross-year fitment needs, consult reference guides and parts lists; insights from adjacent model years can simplify sourcing. For example, parts pages covering later Eclipse models can provide fitment clues and help buyers identify compatible patterns, such as the 2006–2008 Mitsubishi Eclipse front bumper.

Cost control strategies should be pragmatic. Negotiate based on total cost of ownership, not just unit price. Factor in warranty claims, rework rates, and potential losses from late deliveries. Build clauses into agreements that allocate responsibility for defective parts discovered during initial fitment. Consider staggered shipments and buffer stock to smooth supply variability. For larger orders, negotiate tooling amortization into the unit price to lower per-piece costs over time.

Communication cadence and clear technical documentation prevent misunderstandings. Use annotated drawings, dimensional tolerances, and finish sheets. Specify fastener types, foam supports, and paint codes. When colors must match factory shades, request sample panels and agree on acceptable light conditions for sign-off. Keep a clear change-control process for design iterations during pre-production and full production runs.

Finally, buyers should plan for disruptions. Contingency planning includes alternate freight routes, holding safety stock, and maintaining strong relationships with customs brokers. Regularly review supplier capacity and financial health. Long-term partnerships with a small set of vetted suppliers reduce transaction overhead and improve responsiveness.

Sourcing a front bumper for the Eclipse 2G is not a one-dimensional task. It requires mapping regional expertise, selecting the right materials, enforcing quality gates, and aligning logistics. A disciplined procurement process results in parts that fit well, finish reliably, and support your vehicle’s visual and functional goals.

External resource for a related carbon fiber grille option:

https://www.alibaba.com/product-detail/Carbon-Fiber-Front-Bumper-Grille-Cover-for-Mitsubishi-Eclipse-Spyder-2009-2012_1600843624527.html

Final thoughts

The Mitsubishi Eclipse 2G front bumper is more than just a cosmetic feature; it is a vital part of vehicle safety, durability, and aesthetics. For businesses involved in sourcing, selling, or installing these bumpers, understanding the varied aftermarket options, complying with OEM quality standards, and recognizing the significance of materials can lead to better products and happier customers. As the automotive industry continues to adapt globally, being aware of emerging sourcing trends will position your business favorably within the market. Embrace these insights to elevate your offerings and ensure your clients drive stylishly and safely.