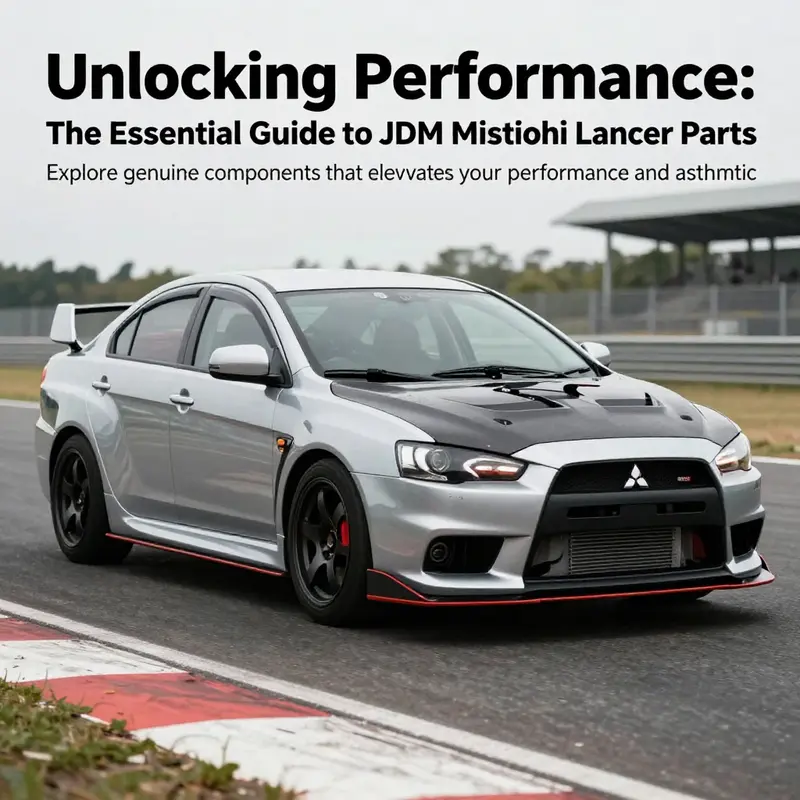

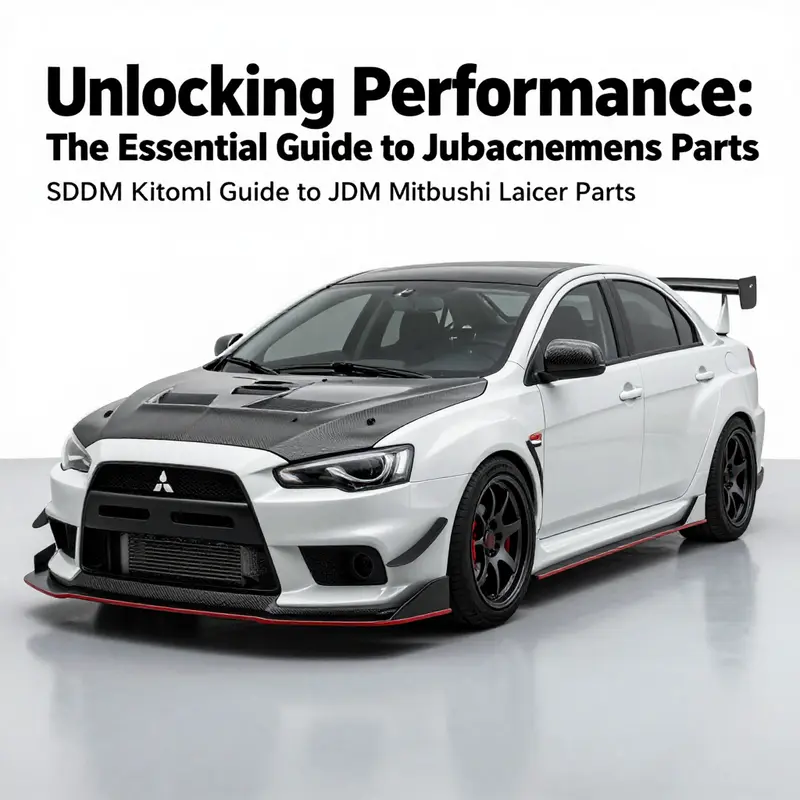

For business owners in the automotive industry, understanding the significance of JDM (Japanese Domestic Market) parts for the Mitsubishi Lancer is crucial. This comprehensive guide delves into the components that define the high-performance reputation of this iconic vehicle. Each chapter examines pivotal areas—engine components, drivetrain systems, suspension setups, body kits, and interior parts—to illuminate how authentic JDM parts enhance reliability, performance, and aesthetic appeal. In a competitive market, aligning with genuine Mitsubishi Lancer components can set you apart and attract a dedicated clientele seeking quality and authenticity.

The Pulse of Authentic Power: Engine Components in JDM Mitsubishi Lancer Parts

The engine is the beating heart of any performance-focused Lancer, and within the Japanese Domestic Market (JDM) lineage, it carries a particular pedigree of engineering that enthusiasts prize for reliability, precision, and a historically tuned sense of response. In the world of JDM Mitsubishi Lancer parts, the engine components are not merely components; they are a tightly woven system designed to endure high revolutions, maintain consistent lubrication under stress, and deliver a connected, linear throttle feel that makes track days and back-road sprints feel intimate. The Japanese approach to powertrain design emphasizes tight tolerances, robust materials, and a balance between high output and enduring durability. This balance is what keeps authentic JDM engines approachable for restoration, as well as appealing for enthusiasts who want a direct, factory-informed baseline from which to tune. The result is a powertrain that rewards precise maintenance and thoughtful upgrades with predictable behavior, rather than an off-the-shelf surge of horsepower that can become difficult to manage on the limit. In this sense, JDM engine components are not just replacements; they are a philosophy—an approach that values consistency, fitment, and the long arc of performance potential that comes from a chassis and powerplant engineered to work in concert from the factory floor to the racetrack.

At the core of any JDM Lancer’s engine story lies the block and cylinder head, the foundation upon which every torque figure, horsepower peak, and throttle characteristic rests. These elements are crafted with materials and machining standards that aim for reliability at elevated stresses. The block provides the rigid housing for pistons and the integral pathways of oil and coolant, while the cylinder head houses valves and the timing hardware that governs airflow and combustion. Within these structures, pistons, rings, and connecting rods form the moving trio that translates unfolding combustion into rotational energy. The pistons must withstand high thermal loads and the chamber pressures that accompany aggressive tuning. The piston rings seal the combustion chambers, maintaining compression and minimizing blow-by, while the connecting rods must tolerate forces generated at high rpm and torque levels. The crankshaft, often paired with precision-ground bearings, converts reciprocating motion into smooth rotation, and the camshafts, along with their bearings, synchronize valve opening and closing with astonishing timing accuracy. When you look at these elements in aggregate, you begin to see why JDM engineering emphasizes not just power, but repeatable, controllable power delivered in a broad and usable range. The upshot is a foundation that supports both factory performance targets and carefully orchestrated aftermarket plans without sacrificing daily drivability.

In the realm of critical internal parts, a host of components work in concert to keep the engine breathing, burning, and moving efficiently through a wide range of conditions. Pistons are engineered for high strength and thermal resilience, designed to withstand rapid heating and cooling cycles that occur during spirited driving or corner-to-corner track sessions. Piston rings provide the essential seal between the piston and the cylinder wall, balancing oil retention with effective heat transfer and minimal friction. The connecting rods are engineered to resist bending and twisting under high torque, maintaining a clean alignment as motion travels from crank to piston. The crankshaft itself reflects a meticulous emphasis on strength and durability, engineered to handle the pulsating forces generated at high rpm. Camshafts and their bearings govern valve timing with precision, ensuring that intake and exhaust openings align exactly with piston position to optimize airflow and combustion efficiency. In high-output variants of the Lancer lineage, these internal elements are often complemented by performance-oriented materials and finishes that resist wear under elevated temperatures, a key factor in long-term reliability when a build approaches or surpasses the 300-horsepower threshold. The endurance philosophy behind these components is not merely about resisting failure; it’s about maintaining predictable behavior as performance demands rise.

Beyond the bare metal of the block and head, the engine’s brain and its fuel, air, and lubrication systems play a crucial role in shaping real-world performance. Fuel injectors in a JDM engine are calibrated to deliver precise quantities of fuel at specific times, producing a clean air-fuel mixture that translates to smooth power delivery across the rev range. An efficient oil pump maintains steady lubrication pressure, protecting key surfaces from wear during high-load events. Coolant temperature sensors feed real-time data to the engine control unit, enabling rapid adaptations to engine timing and fueling as the motor warms up or cools down during a session. The valvetrain, including valve springs, lifters, and the adjusters that govern valve lash, ensures consistent timing and reliability when the engine is pushed toward its upper rpm limits. In the realm of high-performance tuning, these systems become the first levers a builder touches after establishing a solid mechanical foundation. They determine how quickly the engine breathes, how efficiently it converts air and fuel into power, and how well the fuel and ignition maps respond to rapid throttle changes on a track or a spirited canyon road.

Where the naturally aspirated core meets modern performance philosophy, forced induction models reveal a different but equally disciplined aspect of JDM engineering. Turbochargers and intercoolers are central to delivering sustained power with manageable heat, enabling higher intake pressures while controlling temperatures that would otherwise erode performance. The path of intake air, from filter to manifold and through to the combustion chamber, is designed to minimize pressure losses and thermal distortions. High-efficiency exhaust systems and appropriate headers continue this thread by improving exhaust scavenging and reducing backpressure, allowing the engine to evacuate spent gases more effectively and to sustain higher rpm operation without becoming thermally stressed. In this arena, JDM components often emphasize a balance between performance gains and emissions compliance, ensuring that the car remains usable in jurisdictions that value stringent standards. The interplay between turbocharging, intercooling, and the broader intake-exhaust architecture highlights the degree to which JDM engineering treats the engine as a system rather than a collection of discrete parts.

For enthusiasts contemplating upgrades while maintaining a coherent, authentic JDM character, the logic is clear: any internal upgrade should reinforce the engine’s structural integrity and reliable breathing at elevated power levels. Forged connecting rods and high-strength crankshafts are typical examples of internal upgrades that offer superior fatigue resistance and rigidity, maintaining piston stability and reducing flex under heavy loads. Pistons with strengthened profiles and optimized skirt design help sustain compression and reduce thermal distortion during protracted high-load runs. Pairing these with upgraded camshafts and hardened bearings can keep timing stable and consistent as boost and rpm climb. Engine mounting, too, plays a nuanced role: stiffer mounts can sharpen throttle response and reduce drivetrain movement, though they may also introduce more NVH (noise, vibration, and harshness) into the cabin. A well-considered combination of forged internals, refined valvetrain components, and careful lubrication strategy forms a cohesive upgrade path that respects the architecture of JDM powertrains while offering tangible, track-ready gains.

Tuning, in the JDM spirit, remains about more than raw horsepower. Modern ECU remapping and calibrated control units offer a refined method to optimize ignition timing, air-fuel ratios, and boost curves. The intent is to exploit the engine’s inherent precision without pushing core components beyond their designed envelope. This approach helps maintain driveability and reliability even as peak numbers rise, a hallmark of JDM engineering that favors predictable behavior under real-world conditions. In practice, a well-tuned JDM engine communicates with the driver through a linear, responsive throttle, a broad torque band, and a willing, linear surge of power when the boost comes on. When assembled with correctly matched components—block, head, pistons, rods, crank, and a balanced valvetrain—the engine not only performs but also inspires confidence on public roads and private tracks alike.

For those who want a concrete example of what a robust, authentic JDM build can look like in practice, there are dedicated resources that document the design and availability of highly engineered components. One such reference highlights the billet-block option that has become emblematic of attention to structural integrity and precision machining. This resource provides a detailed look at the manufacturing philosophy and the performance benefits of moving to a stronger block while retaining compatibility with the rest of the powertrain package. See 4b11t-billet-block for a direct exploration of how an upgraded block can influence durability under heightened loads and how it fits within a broader JDM-oriented build.

To deepen understanding of the engine architecture and its compatibility with Lancer chassis layouts, readers may consult the official engineering resources from the manufacturer, which provide authoritative specifications and service data that underpin genuine JDM components. For a broader perspective on how these systems are standardized and implemented across model years, the official engine catalog offers a comprehensive view of architecture, materials, and compatibility across generations. This connection to the factory perspective helps frame the evolution of Lancer powertrains within the larger context of Japanese automotive engineering and the emphasis on consistency, fitment, and long-term reliability that define JDM parts culture.

For readers seeking a practical entry point into exploring authentic JDM engine components, the following link provides access to a curated internal reference that aligns with the themes discussed here: 4b11t-billet-block. It offers insight into how a billet-block approach can reinforce the core structural integrity of a high-performance Lancer engine while preserving essential tolerances and fitment characteristics that matter to builders and restorers alike.

As a concluding reflection, the engine components of JDM Mitsubishi Lancer parts demonstrate that power is only as potent as the system that delivers it. The block, head, internals, fuel and lubrication systems, and the forced-induction path all contribute to a coherent performance philosophy: one that prizes precise engineering, reliable operation under stress, and the potential for controlled, meaningful upgrades. The result is a powerplant that not only delivers speed but also communicates with the driver in a precise and confident way. For those who value authenticity and long-term, track-ready reliability, the JDM engine architecture offers a blueprint that remains relevant across generations of Lancer enthusiasts, anchoring every build in a tradition of engineering discipline and performance with a distinctly Japanese sensibility. External readers can explore the broader engine architectures and model-wide specifications through the official catalog linked here for an authoritative perspective: https://www.mitsubishimotors.com/jp/engines/4b12.html

Shifting Speed and Symmetry: Inside the Transmission and Drivetrain of JDM Mitsubishi Lancer Parts

The drivetrain is the heartbeat of any performance-focused Mitsubishi Lancer, especially when viewed through the lens of JDM parts. This chapter traces power from the engine to the wheels, emphasizing components that decide how quickly a car responds and how predictably it puts that power to the pavement. In the Japanese domestic market, the engineering philosophy is clear: precision, reliability, and a direct connection between driver and machine. When the topic moves from generic components to genuine JDM parts, the drivetrain becomes a carefully tuned ensemble designed for track-focused handling, consistent drivability, and enduring performance under demanding conditions. For enthusiasts who value authenticity as much as speed, the transmission and drivetrain are the most visible evidence of that philosophy in action. They are the parts most often scrutinized, upgraded, or preserved to maintain the car’s original intent while unlocking its full potential on road or circuit.

At its core, the transmission in a JDM Lancer is more than a means of changing gears; it is a calibrated bridge between the engine’s torque and the wheels’ grip. The design favors close gear ratios that keep the engine in its sweet spot during aggressive driving, enabling rapid shifts with minimal power loss. The result is a transmission that rewards precise, confident gear changes and allows the driver to exploit the engine’s torque with minimal hesitation. A well-matched gearbox with the right spacing and rigidity helps maintain pedal feel, shift accuracy, and the stability needed for aggressive corner exits. The practical upshot is better lap times and more tangible control when the road turns twisty or the track demands quick direction changes.

Alongside the transmission, the drivetrain’s symmetry rests on a robust all-wheel-drive architecture that distributes torque with a balance suited to high-performance intent. The central differential tunes torque between front and rear axles, complemented by a differential at the axle ends that manages traction where it matters most. In the JDM context, these elements handle high torque, repeatable behavior under load, and predictable response when more grip is asked for. Drive shafts linking the gearbox to wheel hubs must transmit power cleanly with minimal torsional vibration, so joints and flanges are machined to close tolerances. The overall effect is a drivetrain that remains linear under hard acceleration, where smooth power delivery and steady grip form the foundation for precise cornering and confident power release.

A critical, sometimes overlooked, piece of the puzzle is the role of the limited-slip function within the front and rear differentials. In JDM configurations, the goal is to modulate slip to preserve torque to the wheel with the most traction. Mechanical, clutched, or progressively engaged systems offer distinct traits. Mechanical designs are rugged and track-focused, clutch-type designs self-regulate friction to adapt to grip changes, and progressive systems blend control and forgiveness for a race-informed feel as weight transfers during cornering. Regardless of mechanism, the intent is the same: maintain drive to the road where it matters, reducing one wheel’s dominance or power waste on spin. Lubrication and seals matter as much as metal, so oil quality and maintenance underpin consistent behavior.

Beyond the diffs, the central differential is the brain of the AWD system, dictating how torque is apportioned as you drive through changing speed and grip conditions. In a JDM setup, it’s tuned to deliver a bias toward high-speed stability without sacrificing turn-in precision. Front-rear balance influences mid-corner stability and throttle aggressiveness on exit. Enthusiasts who seek authentic handling prize this balance for predictable, communicative responses even when tires are pushed to the limit. The transfer of power through the system—via the transfer case, asymmetrical gear sets, and cross shafts—must be dependable, resistant to heat soak, and aligned for quiet efficiency under load. A drivetrain that holds its shape under stress earns respect on track and on winding roads alike.

Fitment and authenticity are more than fit and finish; they are the lifeblood of any JDM-spec build. Genuine, market-specific transmission and drivetrain components are designed around chassis mounting points, engine bell housing interface, and driveshaft lengths, yielding immediate improvements in pedal feel, shift quality, and rigidity. Sourcing from the JDM market preserves engineering intent: parts interact with the rest of the car as originally designed. This unity matters not just in performance but in long-term reliability. The risk of deviation rises when aftermarket parts are used without verifying compatibility. In practice, meticulous attention to torque specs, lubrication intervals, and correct installation sequences preserves the car’s original character while laying a solid upgrade foundation.

For those exploring options, the market offers a range of transmission and drivetrain configurations, from standard five- and six-speed layouts to specialized gearboxes. Genuine drivetrain parts deliver clear feedback: tight shifts, controlled torque split, and even power dissemination through the drive shafts. It is this authenticity that many owners seek when restoring or preserving a JDM Lancer. Correct center-diff behavior, reliable driveshaft assemblies, and solid wheel hubs together deliver a balance between agility and grip.

Linking theory to practice, sourcing decisions carry weight. A genuine JDM drivetrain component is more than a bolt-on; it is part of a larger, calibrated system. The decision to invest in authentic parts should consider long-term reliability, correct fitment, and resale value through authenticity. With proper maintenance—regular differential lubrication, seal inspection, and correct mounting—the drivetrain remains durable and communicative. Where readers prefer to gauge the market directly, catalogs across major marketplaces show availability, price ranges, and ongoing evolution of what is standard or premium within the community of enthusiasts who celebrate JDM Lancers.

Internally, advanced drivetrain upgrades can stay true to the JDM spirit with specialized gearbox options designed for sequential operation. Such a unit offers a different cadence of shifts and can dramatically change the car’s throttle and brake responses. A deeper look is available through dedicated listings that describe full-sequential gearboxes for relevant models. These entries illustrate how a high-end transmission option can redefine the relationship between engine, drivetrain, and tires while aligning with the core JDM principle of authentic engineering and precise feedback.

As the discussion turns toward practical decision-making, it helps to ground the narrative in real-world sourcing realities. The broader market for Lancer transmission components is active, with OEM-like and carefully engineered upgrades offered and evolving with supply and demand. Enthusiasts who value the JDM drivetrain will weigh reliability, fitment, and the preservation of intended balance when choosing upgrades. The ultimate goal remains the same: a drivetrain that communicates clearly with the driver, delivering traction, stability, and confidence in every corner, throttle application, and straight line.

For readers seeking external context, reputable resources offer broad perspectives on transmission options and market availability. External reference points provide snapshots of current listings, pricing, and the type of drivetrain components discussed among enthusiasts. External resource: https://www.ebay.com/bhp/mitsubishi-lancer-transmission. This link anchors the chapter in the wider marketplace reality, illustrating how parts circulate and how buyers assess authenticity, compatibility, and value as they assemble or restore a JDM Lancer’s drivetrain.

In sum, the transmission and drivetrain in a JDM Lancer are not merely components; they are the interface between driver intent and machine response. They reflect a philosophy of engineering that emphasizes precise fitment, robust construction, and a direct, communicative relationship between pedal, shifter, and road. When correctly matched to the chassis, these parts deliver immediacy and reliability that capture the essence of driving a high-performance Japanese car. The journey from engine torque to tire grip is as much about discipline and maintenance as it is about choice of parts. The promise of authenticity—not just in nomenclature but in performance—remains the central appeal of genuine JDM drivetrain components, and it motivates many Lancer owners to seek out the best possible matches for their build and driving style.

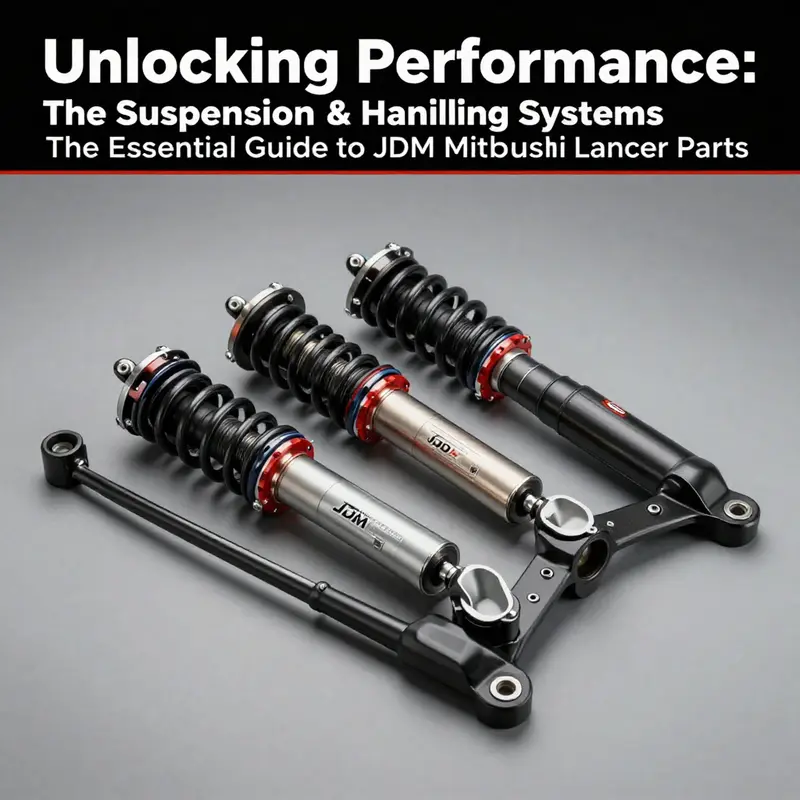

Precision Under Pressure: Suspension and Handling in JDM Mitsubishi Lancer Parts

Suspension is the quiet negotiator between power and grip. In the JDM Mitsubishi Lancer, the suspension system is not an afterthought; it’s a core expression of meticulous Japanese engineering. JDM components are designed to deliver predictable responses under track heat and the rough cadence of daily streets. The result is a chassis that communicates through the steering, the seat, and the tire’s contact with the road. Precision here underpins every turn, every lift off, and every millisecond of feedback the driver feels.

At the heart of the JDM approach are four cornerstone ideas that define the handling character of the Lancer. First, sport springs are chosen to lower the car’s center of gravity and stiffen the roll axis. The data-driven choices here translate into a reduced body lean and a more faithful transfer of cornering forces to the tires. Second, performance dampers manage how the wheel responds to pavement, with refined compression and rebound values tuned for track cadence. They damp peak loads and keep tire contact through irregularities, which translates to steadier turn-in and quicker recovery after weight transfer. Third, anti-roll bars link the left and right suspension to suppress body lean without sacrificing steering feel. A stiffer bar reduces sway during aggressive cornering, allowing the car to rotate with intention rather than float through the apex. Fourth, reinforced control arms contribute rigidity to the front and rear chassis, improving geometric consistency under high load. Together these components create a chassis that communicates through the seat of the pants and the line drawn on the asphalt, even as grip shifts between wet and dry conditions.

JDM suspension parts are typically built to tighter tolerances and with higher-grade materials than many aftermarket alternatives. This translates into durability under track use and repeatable behavior lap after lap. The goal is not simply raw stiffness but a harmonious balance where steering input, tire deformation, and chassis flex all align. When a suspension set is tuned for track performance, it may feel taut on public roads. Yet for engineers and drivers who value feedback, that tautness is a language that rewards quick steering, precise lane changes, and prompt response to throttle and brake inputs. The result is a car that rotates with the driver’s intention rather than fighting the wheel. The materials also matter: high-grade steel, processed bushings, and corrosion-resistant finishes resist fatigue under high-heat cycles, maintaining alignment and dampers’ performance over time. In addition, the mounting hardware is often designed to resist shifting under load, ensuring predictable behavior during aggressive maneuvers.

Design philosophy matters as much as component choice. The Lancer’s original chassis expects a certain level of compliance and damping from its factory setup. JDM components often push toward a more direct, track-ready balance, offering enhanced precision but requiring careful maintenance of alignment, camber, and ride height. Fitment accuracy matters; when parts are sourced as part of a factory-specified system, mounting points align without forcing the body or bending subframes. However, any change in spring rate or damper valving can alter geometry subtly, so a fresh alignment and dynamic suspension check should accompany the upgrade. In many cases, enthusiasts discover that even with authentic parts, you can trip over ride height and tire clearance, so a test fit and a careful trim is essential. On the dynamic side, attention to toe and camber during setup can sharpen turn-in and reduce understeer without compromising tire wear. In the broader chassis picture, consider the fit of ancillary components like body panels and aero elements, which influence cornering balance as much as the suspension does. See how the Lancer’s silhouette gains a purpose-built edge when the lines of the bumper and bodywork speak to rigidity and control on the road.

Authenticity matters as much as the parts themselves. JDM components carry markings and part numbers that trace back to the factory process in Japan. A procurement strategy that prioritizes genuine parts reduces the risk of counterfeit or substandard items. It also supports long-term reliability because these components are engineered to Mitsubishi’s exacting standards. The best practice is to verify part numbers against official catalogs and to purchase through authorized dealers or certified suppliers who can confirm compatibility with your model year and trim. A careful buyer checks that the fasteners, bushings, and mounting points match the Lancer’s chassis specifications. That diligence protects the alignment, geometry, and handling balance you expect from authentic JDM suspension parts. In other words, the performance you feel on the road is the result of a chain of confidence that begins with sourcing. For a smoother project, keep records of every component’s origin, serial numbers, and the date of receipt; these details help with future maintenance or resale.

While genuine JDM parts promise clarity and durability, the world of performance suspension also includes aftermarket options. The most credible routes retain the same principles—preserve tire contact, maintain proper load distribution, and keep predictable steering response—while offering tunable damping, varied spring rates, or lighter construction. For many drivers, the appeal lies in customizing the balance between ride comfort and cornering sharpness. The key is to evaluate the entire system: springs, dampers, anti-roll bars, and linkages, as well as the tires and wheels that carry the load. Even with authentic components, choosing wheels with the correct offset and strength is essential to realize the intended geometry and grip. The interplay among suspension, tires, and aero is nuanced; sharper suspensions demand accurate wheel fitment and a careful look at fender clearances and underbody airflow. With tires, compound choices and tread patterns interact with suspension travel and damping; a more aggressive setup can require slower damper rates to avoid harsh impacts on rough pavement. The driver’s preference, track conditions, and intended use all shape a final balance that can be dialed in through progressive tuning rather than a single bolt-in change.

Procuring JDM suspension parts becomes a strategic exercise. Beyond price, consider availability, lead times, and the supplier’s track record for authenticity. A reliable seller will provide OEM markings, original packaging, and clear instructions for installation and alignment. The goal is a holistic upgrade that respects the Lancer’s architecture rather than a quick swap that leaves the chassis out of balance. If you need a practical reference for chassis components beyond suspension, a page on the Lancer’s broader parts ecosystem can be a helpful anchor; it illustrates how everything from aero to trim plays a role in the vehicle’s handling profile. See the example here: Lancer front and rear bumpers.

Ultimately, the JDM suspension story is about translating a nation’s engineering philosophy into road-ready performance. It is not a single magic bolt but a coordinated approach to how a car discerns surface, weight, and driver intent. The Lancer, with its track-forward heritage, rewards drivers who respect the balance between stiffness and compliance, so the tires stay in contact and the steering remains communicative through every corner. When you pair authentic JDM components with careful setup, you gain a chassis that tracks true, resists body roll, and preserves the feel of the road under dynamic loads. It is a fidelity of motion that resonates with enthusiasts who chase the sensation of a race-ready machine in a street-legal form.

External resource: https://www.mitsubishiparts.jp/jdm-lancer-suspension-technical-guide

Breath of the Wind: Aerodynamics, Aesthetics, and Authentic JDM Body Kits for the Mitsubishi Lancer

Body kits in the Mitsubishi Lancer’s JDM lineage are more than cosmetic upgrades; they are deliberate statements of engineering intent. In the high-stakes world where handling balance, cooling, and aero efficiency meet personal expression, these exterior components become a language all their own. For the Lancer, a chassis that has long carried a track-ready reputation, the aerodynamics of a well-chosen body kit translate into tangible performance gains. The front end, the sides, and the rear work in concert to shape airflow, manage turbulence, and maximize the car’s grip through corners and at speed. The beauty of a true JDM kit lies in its holistic approach: every element is designed to complement the others, ensuring that form does not outrun function, and function never becomes a simple visual flourish. As enthusiasts explore the spectrum from subtle, performance-minded modifications to full-on race-bred transformations, the kit becomes a toolkit for engineering the car’s behavior under load as much as its appearance in a photo lineup. The best kits recognize that the Lancer’s aero balance is a system, not a single part, and they respect how each piece interacts with the underbody, the radiator airflow, and the braking apparatus behind it.

The front bumper and its associated air dam are the doorway to efficient cooling and controlled intake. An effectively designed front end channels air toward the radiator and brake ducts while minimizing drag. The guiding principle is simple: you want enough air for cooling and engine breathing without creating excess lift or drag that robs downforce at the rear. Front-end components often incorporate recessed channels and integrated ducts that draw cooling air to where it is needed most, keeping the engine bay and the braking system within a safe operating envelope even under sustained high-speed driving. It’s not merely about looking aggressive; it’s about shaping the air stream so the car remains stable as velocity climbs. Side skirts then take the next step. By smoothing the flow along the car’s flanks, they reduce the suction and turbulence that would otherwise creep under the chassis. The result is a more consistent pressure distribution across the undercarriage, which translates into reduced lift in the midsection and enhanced lateral stability when cornering hard. The side skirts’ effectiveness rests on their fit and how closely they align with the wheel arches and rocker panels. When they tuck neatly into the car’s lines, they work with the underbody rather than against it, guiding air rather than creating new pockets of resistance.

Rear aerodynamics complete the package. A spoiler or wing, whether in a lip form or as a larger, more pronounced element, is designed to manage separation at higher speeds. The goal is to keep the air attached to the body longer, delaying the onset of rear-end lift and preserving tire grip on the trailing axle. Even a modest lip can influence wake structure enough to improve high-speed stability and braking feel. Material choices matter here as well. Lightweight, rigid materials—such as carbon fiber or specialized composites—provide strength without adding unnecessary mass, preserving throttle response and dynamic balance. Across these exterior components, the choice of materials matters not only for weight, but for how precisely the parts can be manufactured and how well they hold their shape under load. A well-made kit avoids soft, flexing panels that can degrade aerodynamics at speed and instead relies on stiff construction and reliable mounting points that align with the Lancer’s chassis. In this sense, the art of the body kit becomes a negotiation between aesthetics and engineering, a balance between what the eye reads and what the car experiences as wind and inertia behave differently around each panel.

The culture surrounding JDM body kits adds a layer of meaning to the engineering. Rally-inspired aesthetics have long informed Lancer styling, with packages that evoke a rugged, track-ready lineage. Enthusiasts may gravitate toward designs that communicate performance intent, such as fender flares or extended overfenders that imply a broader stance and the potential for wider tires. A full-body kit can deliver a factory-like transformation, presenting a cohesive silhouette that optimizes aerodynamics and creates a show-quality finish. Fragment kits offer targeted performance upgrades, allowing builders to replace or augment a single element—such as a front lip or a rear spoiler—without overhauling the entire exterior. The cultural impact of these choices goes beyond pure styling. In many communities, a carefully selected aero package signals a car’s intent, its owner’s philosophy about balance between street usability and track capability, and a respect for the Lancer’s racing heritage.

Manufacturing and availability form the practical backbone of the JDM aero story. In today’s global market, body kits are produced in a network that blends precision engineering with scalable mass production. Regions with deep supplier ecosystems have refined processes for fabricating and finishing components that must fit the Lancer’s chassis with tight tolerances. This involves the use of digital design libraries, CNC machining, and local mold work to ensure reliable fitment across multiple generations of the model. Proximity to mold makers and a robust supply chain help ensure a consistent, high-quality product that can withstand the stresses of real-world use—whether on the street or the track. Digital accuracy also supports interchangeable options across different trim levels and generations, enabling a kit to align with the Lancer’s distinctive geometry while preserving proper ground clearance and tire clearance. The result is a market where enthusiasts can pursue an aero upgrade with confidence that the components will align with the car’s geometry, maintain consistent fitment through assembly, and perform predictably in the real world.

Material selection remains a central thread in the aero conversation. ABS plastics, fiberglass composites, and carbon fiber each offer different blends of weight, durability, and cost. The lighter the component, the more it can contribute to the car’s overall performance envelope, provided stiffness and impact resistance remain adequate. Fiberglass provides a budget-conscious path that still delivers respectable strength and formability, while carbon fiber offers the pinnacle of weight savings and rigidity at a premium. The practical decision hinges on how the Lancer is used. A daily driver might prioritize a balance of weight and everyday durability, while a track-focused build would push toward carbon fiber for critical panels and a precisely tuned aero balance that complements the car’s handling characteristics.

Beyond the physics, the fit and finish of a body kit influence both performance and perception. Accurate mounting points and robust hardware prevent distortions that can undermine aerodynamics or create rattles at speed. A well-fitted kit respects the car’s line, aligning with factory gaps and contours to preserve or enhance the car’s silhouette. The relationship between exterior aero and the rest of the chassis is iterative: as you tune downforce and airflow, you must consider suspension geometry, brake cooling, and even steering feel. A balanced aero package supports predictable behavior in high-demand driving scenarios, helping the driver maintain confidence through quick transitions and aggressive cornering. For many builders, the pursuit is not a single part but a coherent system that harmonizes with the Lancer’s powertrain, chassis stiffness, and braking performance. This holistic approach yields a vehicle that not only looks like it belongs on the raceway but behaves like it does when pushed to the limits.

From a practical standpoint, the decision to adopt a JDM body kit also involves considerations of maintenance, regulatory compliance, and resale value. Authentic JDM components, when properly installed, tend to align with the vehicle’s original design intent and can preserve or even boost resale value by signaling a thoughtful upgrade trajectory. At the same time, owners must be mindful of local emissions and noise regulations, especially with rear exhaust and certain aero elements that could affect compliance or inspection requirements. Careful selection—prioritizing fit, finish, and compatibility with existing systems—helps ensure that the aero upgrade remains a source of pride rather than a source of ongoing maintenance concerns. The aesthetic and performance benefits are most persuasive when the kit integrates with the Lancer’s driving dynamics and the owner’s goals, whether those goals revolve around club-level track days, weekend autocross, or simply standing out in a parking lot with purpose.

For readers curious about specific examples of JDM-style body kits, one practical path is to explore product pages that demonstrate how a carbon lip front bumper or similar aero elements integrate with the vehicle’s lines. The front bumper with carbon lip for Lancer Evo 8/9 is a tangible reference point for how a single component can influence airflow, alignment, and visual identity. While such pages reflect a particular design philosophy, the underlying principles—airflow management, weight considerations, and fitment accuracy—remain universal across the spectrum of JDM aero parts. The broader lesson is clear: the most satisfying aero upgrades respect the Lancer’s chassis, the driver’s intent, and the car’s ongoing development arc.

As the chapter on body kits closes in on its center, the takeaway is not simply about adding a new panel or lip. It is about understanding aero as a system and about choosing pieces that reinforce the car’s balance rather than simply adding surface speed. It is about acknowledging the cultural threads that link rally heritage to modern street performance. It is about recognizing how regional manufacturing capabilities shape the availability and quality of components that fit the Lancer with precision. And it is about crafting a vehicle that communicates purpose—from first glance to the last mile of a corner exit. In this sense, the JDM body kit is a careful negotiation: it is a tool for shaping behavior under load, a vehicle for self-expression, and a bridge between the car’s established history and a personalized future on the road or the track.

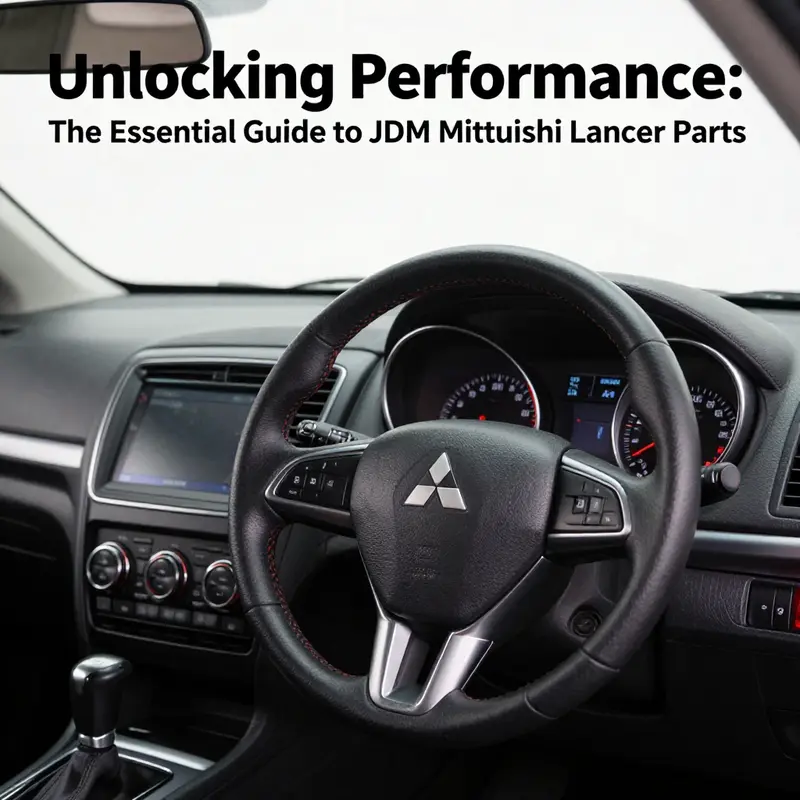

Cabin Craft: The Subtle Precision and Authenticity of JDM Mitsubishi Lancer Interior and Dashboard

The interior of a Mitsubishi Lancer, particularly one born from the Japanese Domestic Market, is more than a convenience space. It is a disciplined manifest of how Japanese engineers translate thorough usability into a cockpit that remains legible, durable, and ergonomically focused under the most demanding conditions. When enthusiasts seek genuine JDM interior components, they are chasing a tactile memory as much as a functional upgrade. The panels, the textures, the layout of gauges, and the quiet confidence of the controls all carry the imprint of a market that prioritized reliability and driver connection over fleeting cosmetic trends. In this light, the interior is not a backdrop for horsepower but a vital partner to it, shaping how performance feels and how long it endures on the road or the track. The journey into authentic JDM interior parts begins with the instrument cluster, a centerpiece of any Lancer’s cockpit that communicates the car’s life-digesting details: RPM growth, fuel state, engine temperature, and sometimes boost pressure, all presented with a precision that reflects Japanese engineering standards. In many JDM Lancers, the cluster not only tells time and speed but also carries the philosophy of compact efficiency. The tachometer, often with a prominent arc, sits at the eye line of the driver and is flanked by gauges that prioritize the essentials of the drive. The dash is kept reined in, avoiding gratuitous chrome or busy graphics; instead, it relies on legible typography, strong illumination, and a layout that respects the driver’s quick glance, a feature that remains valuable whether the car is pressed into a daily roll or a weekend sprint. The instrumentation in genuine JDM Lancer parts is more than a function; it is a statement about how information should be delivered when time and attention are at a premium. Beneath the glass, the materials choice is telling. Textured plastics with a restrained gloss, soft-touch surfaces in the upper trims, and carefully molded bezels that cradle the gauges all convey a sense of durability. This orchestration of materials supports long-term reliability, a hallmark of OEM parts from Japan. The interior panels, the dash’s edge treatments, and the way each gauge face wears over the years all reflect that meticulous factory standard. The center console, a bridge between the driver and the cabin, anchors an efficient control zone that includes the audio, climate controls, and a storage pocket that’s thoughtfully placed for accessibility. In JDM Lancers, the console often remains compact and purpose-driven, avoiding bulky accoutrements that might intrude on legroom or arm reach. The design ensures the driver’s posture remains comfortable across miles, a subtle but important factor in performance-oriented variants where the cockpit is as much a tool as the engine. The climate system controls, seating, and the gear selector area all align with a philosophy of tactile feedback. The feedback from a well-made center console, the click of a climate control dial, the smooth operation of the shifter, and the resistance of a well-built gear lever all contribute to the long-term enjoyment of a vehicle as much as to its immediate usability. For restorers and collectors, genuine JDM interior components offer a route back to the car’s original intent, preserving not only the look but the feel of the ownership experience. A reclamation project that uses authentic parts can recapture a cabin’s original ergonomics, ensuring the driver and passenger experiences remain true to the model’s Japanese lineage. The steering wheel is more than a symbol of control; it is a direct conduit to the car’s character. In JDM Lancers, especially the Evolutions, the steering wheel is often sized to balance precision with comfort, providing a confident grip during aggressive cornering while still offering the subtle softness required for daily driving. The wheel’s diameter, texture, and the placement of any integrated controls are all calibrated for a cockpit that rewards the driver’s tactile sense. The wheel, the center console, and the instrument cluster form a coherent trio that defines the cabin’s identity. Door panels, too, are an essential element of the JDM interior equation. They house window controls, storage pockets, and the mounting points for switches that may differ between RHD and LHD configurations. In Japan’s market, the driver sits on the right side of the car, which means the driver’s door and the window controls are positioned with this orientation in mind. When importing or restoring a JDM interior into a different market, a restorer must acknowledge that fitment and ergonomic alignment matter just as much as aesthetics. The trim pieces—those finishing accents that catch the eye and the touch—are another quietly decisive factor. The way a dash trim cap meets the instrument cluster, the contour of a door panel edge, and the subtle grain of the surface under a glovebox shelf all contribute to a cabin that feels crafted rather than assembled. The interior’s premium feel in JDM Lancer parts is not the result of high-gloss surfaces alone; rather, it emerges from a careful balance of texture, color, and contour that reduces glare, enhances grip, and improves acoustics inside the cabin. What makes genuine JDM interior components especially valuable to collectors and restorers is their tight fitment and robust construction. OEM parts from Japan adhere to strict standards that translate into precise mounting points and consistent tolerances. This predictability matters when you are replacing worn panels or upgrading an entire cockpit to its original configuration. Replacing a center console plate, a dash trim piece, or even a floor console can be an exercise in authenticity as much as one of restoration. For those who want to preserve a Lancer’s character, opting for genuine JDM interior components can maintain the cabin’s original soundproofing, tactile feedback, and the overall sense that the vehicle was built with a particular, almost surgical, attention to detail. In practice, sourcing authentic interior parts means navigating a landscape where a part number or a compatibility note is more than a catalog entry. It becomes a map of if this is the right piece for a specific Lancer Evolution or a particular year’s trim level. Enthusiasts often seek original instrument clusters, center console covers, steering wheel trims, and door panels that match the vehicle’s era and market. The effort pays off in a cabin that not only looks correct but feels correct to the touch and to the driving experience. Replacing worn or damaged components does more than restore a brand-new appearance. It preserves the ergonomics that drivers rely on, ensuring that the seat height, the footwell clearance, and the reach to the controls remain consistent with the vehicle’s intended design. In the broader context of the Lancer’s cabin, the interior and dashboard carry a distinct aura of the JDM approach: clarity over clutter, function over show, and durability that stands up to the demands of performance driving. A genuine JDM dashboard, for instance, is more than a gauge panel; it is a compact opera of instrumentation, lighting, and accessibility engineered to minimize distraction and maximize focus on the road. A remarkable example can be found in Evo-era designs where the dashboard layout prioritizes the driver’s line of sight and the order of operations for quick, repeated actions. For anyone exploring authentic JDM interior parts, a deeper look at dash configurations—such as the Evo-9 cockpit layout—offers insights into how Japanese manufacturers tuned the instruments to deliver instant feedback under demanding conditions. To explore authentic dashboard configurations and related interior components, you can reference detailed Evo-9 dashboard options here: dashboard evo-9. This internal resource demonstrates how a genuine JDM layout preserves the balance between visibility, accessibility, and aesthetic coherence that defines the Lancer’s cabin. The interior’s integrity is not merely about nostalgia; it’s a practical commitment to comfort, reliability, and ongoing value. When a cabin remains faithful to its original engineering, it sustains its appeal to collectors while continuing to deliver a satisfying driving experience for owners who seek an authentic connection with the road. Regular maintenance of these parts—careful cleaning, avoidance of harsh chemicals on sensitive plastics, and timely inspection of mounting points—helps maintain the feel that JDM interiors promise. It’s also worth noting that some interior upgrades offered in the market lean toward performance aesthetics, such as Alcantara-trimmed surfaces or sport seats. While these improvements can heighten the cabin’s appeal, they should be approached with care to preserve the authenticity that JDM interiors embody. Authentic replacement panels, instrument clusters, and trim pieces keep the Lancer’s cabin cohesive, ensuring that the touch and sightlines remain consistent with the model’s Japanese design intent. In the end, the interior and dashboard components of JDM Mitsubishi Lancer parts crystallize a philosophy: a cabin is a tool built to last, but it’s also a space that invites the driver to feel at home with the machine. The pursuit of genuine parts is about more than matching aesthetics; it’s about preserving the exact engineering intent—the ergonomics, the tactile feedback, and the dashboard’s quiet confidence—that made the Lancer’s cabin a trusted companion on both road and race. For builders and restorers, the path through the interior is a careful balance of authenticity, fitment, and durability. It’s a reminder that the Lancer’s interior is not just a component of a car but a testament to a culture of precision and a reflection of the way Japanese automotive design translates into real-world driving joy. External resources and further reading can deepen this understanding; for instance, a current reference for floor console components offers a practical look at genuine interior elements and their compatibility with various Lancer models: https://www.ebay.com/itm/394895374295.

Final thoughts

Authentic JDM Mitsubishi Lancer parts not only enhance vehicle performance but also contribute significantly to the car’s aesthetic appeal and overall value. As this guide illustrates, each component—from the engine to the interior details—plays a vital role in meeting the demanding performance standards set by enthusiasts and everyday drivers alike. For business owners in the automotive sector, aligning with genuine parts can foster customer loyalty and elevate your expertise in the market.