Evo 9 headlights represent a pinnacle of automotive lighting technology, appealing to both car enthusiasts and business owners. Originally designed for the Mitsubishi Lancer Evolution IX, these headlights have evolved dramatically from their stock versions into highly sought-after aftermarket upgrades. With impressive design and lighting capabilities, Evo 9 headlights not only enhance the vehicle’s look but also its performance. The following chapters will delve into the evolution of these headlights, their features and technologies, design considerations, market trends, and important installation and maintenance tips for maximizing their longevity and effectiveness.

Night’s Edge: Tracing the Evo 9 Headlights’ Journey from Halogen Staples to Aftermarket Brilliance

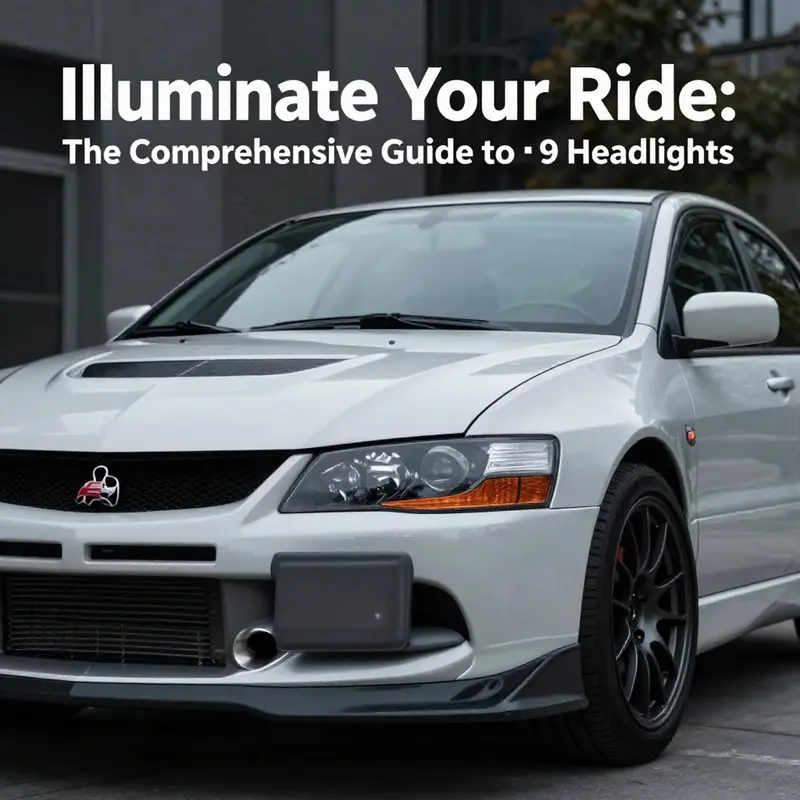

The evolution of the Evo 9 headlights unfolds like a quiet manifesto written in light. When the Mitsubishi Lancer Evolution IX rolled into showrooms and onto the streets, its front end announced performance with a crisp, aerodynamic silhouette. The headlights that framed that face were more than just illumination; they were a statement of intent. The stock units, designed around halogen bulbs, carried a distinctive twin-eye motif that framed the car’s aggressive demeanor. They were sharp, purposeful, and undeniably practical, aligned with the CT9A’s precision engineering and performance-oriented personality. The lamps completed a clean, low-drag profile that looked ready to bite into a midnight straights or carve through rain-soaked back roads. Yet within the enthusiast community, there was an unspoken truth: illumination was not enough. The car deserved light that matched its visual intensity, and that push to upgrade would gradually transform not only how the Evo 9 saw the night, but how it was perceived in the light of day as well.

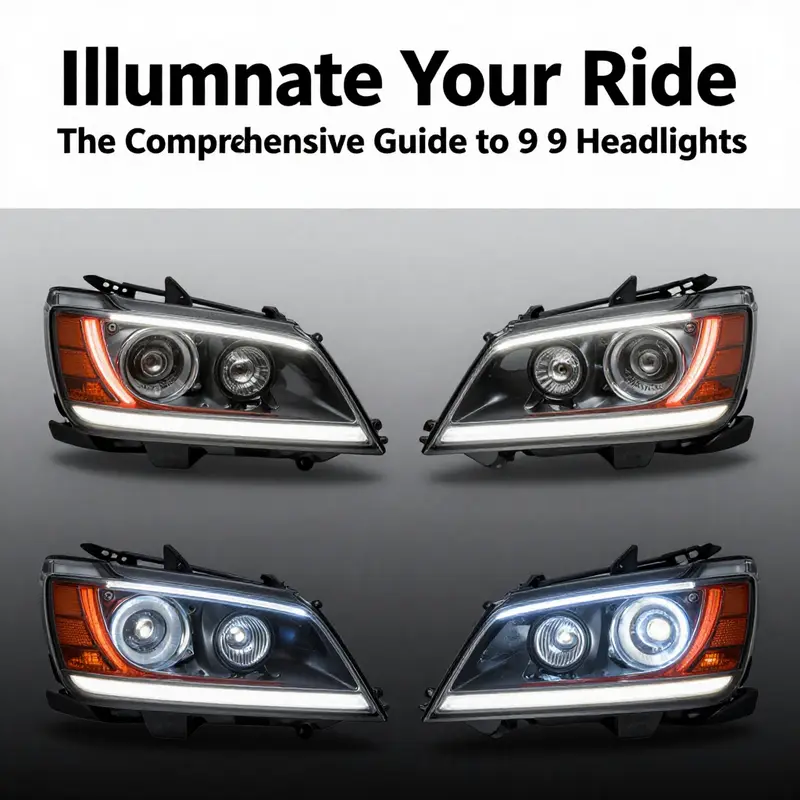

As owners began to explore aftermarket horizons, the headlight became a canvas for both aesthetic experimentation and functional improvement. The era of retrofits and upgrades arrived with the promise of brighter, crisper beams and a modern, high-tech aura without sacrificing the car’s iconic essence. LED retrofit kits emerged as a practical bridge between the stock halogen world and a newer standard of brightness. They offered higher lumens, improved color temperature, and a beam pattern that could be tuned for better night visibility while preserving the overall geometry of the front fascia. For many, a retrofit was more than a simple bulb swap; it was a refined reimagining of the light the Evo 9 would cast on the road ahead. The shift also opened doors to a broader design language. Projector-based lenses, once a feature of premium or European-sourced builds, began to appear in kits that retained OEM-fitment while elevating performance. The projection technology concentrated light into a sharper hotspot, reducing scatter and enhancing the ability to spot hazards early. In combination with updated reflector textures and carefully engineered cutoffs, the overall beam became more precise, allowing drivers to push corners with greater confidence and to engage oncoming traffic with less glare.

With the move to LED architecture—whether through retrofit kits or complete LED headlight assemblies—the car’s front end began to read as modern rather than vintage. LED light sources offered instant-on illumination, cooler color temperatures, and longer life. The visual language also shifted. The signature cues that enthusiasts often associate with the Evo 9, such as distinctive daytime running light patterns or stylized light rings, carried through into the aftermarket designs that aimed to evoke the same spirit while delivering contemporary flair. Some options emphasized a clear, almost minimalist lens aesthetic that showcased the new internals, while others embraced a more aggressive, sculpted look with carefully contoured reflectors and precise edge lighting. In either case, the goal remained constant: to enhance brightness and visibility without straying from the car’s performance-native identity.

The aftermarket landscape for these headlights reflects a balancing act between form and function. For those who want to preserve the pristine look of a stock assembly yet upgrade the light output, complete LED headlight housings have been developed to match OEM fitment while providing modern performance. These assemblies can incorporate advanced lighting components, including high-efficiency diodes, improved thermal management, and integrated drivers designed to maintain stable operation under a range of temperatures and voltage conditions. For purists who seek a more personalized appearance, there are design options that emphasize clarity and color-tinting, or that employ projector technology to craft a more theatrical beam pattern. Some enthusiasts even explore custom lens covers to alter the aesthetic without changing the core lighting mechanics. In all cases, the practical considerations are as important as the visual ones. Heat dissipation, moisture sealing, and long-term durability come into play, because a bright light is only effective if it remains consistent and reliable in real-world driving conditions.

Of course, brightness is only part of the equation. The legal and safety dimensions of headlight upgrades require careful attention. In many regions, aftermarket LED conversions must meet specific beam pattern requirements and glare standards to avoid blinding oncoming traffic. The MMNA guidelines, among other regulatory resources, remind owners to verify that any modification preserves proper alignment and does not introduce unacceptable glare. This is why installation quality matters as much as the choice of component. A retrofit or replacement headlight that is misaligned or inadequately sealed can compromise night visibility and introduce moisture, dust, or corrosion into the housing. The best practice is to approach upgrades with a methodical process: confirm compatibility with the vehicle’s electrical system, ensure the assembly’s physical fit is exact, and schedule an alignment check after installation. When done correctly, the upgrade yields safer night driving, improved color rendition, and a modern look that retains the Lancer’s distinctive silhouette.

The discussion of compatibility is not merely a checklist; it is a narrative about fitment fit for purpose. The Evo 9’s headlight design is anchored by a precise curvature that mirrors the car’s air intake and fender line. Any aftermarket option that departs too far from that geometry risks creating a mismatch that can degrade sealing, trigger moisture intrusion, or alter how the beam interacts with the road surface. This is why many builders emphasize OEM-style replacements in conjunction with modern lighting technology. They offer the reassurance of proper mounting points, correct gasket profiles, and the correct beam cutoff to avoid stray glare while maintaining adequate road illumination. Yet for drivers who crave a more aggressive stance, aftermarket units that push a little beyond the factory silhouette are tempting. A bolder, more angular housing can make a strong visual impact, especially at speed, but it demands careful tuning of the light source and confirmation that the overall package will endure daily use and the occasional harsh weather cycle.

All these considerations sit within a broader owner journey: choosing, purchasing, installing, and then enjoying. The purchase environment has also shifted. Marketplaces that carry broad inventories can be convenient, offering both OEM-style replacements and more adventurous designs. A practical approach is to read seller reviews, confirm return policies, and verify that the chosen option has a proven track record with the Evo 9 platform. When possible, seek detailed product descriptions that specify mounting points, ballast compatibility, and any required adapters. The goal is to reduce guesswork and ensure that the upgrade you choose will slot into the car’s front end with minimal drama, clear instructions, and enduring performance.

In the midst of this evolution, a thread of authenticity persists. For those who want to anchor their project in a sense of history, there are sources that showcase genuine, factory-style lighting elements from the era. The idea is not to replicate the past blindly, but to honor it by aligning modern illumination with the Evo 9’s original design language. One way to explore this balance is to consider HID-style options that harken back to the late-2000s era while leveraging contemporary LED efficiency. A curated set of headlights that nod to the car’s classic twin-eye motif, yet are built for today’s performance standards, can offer a compelling middle ground between nostalgia and novelty. The narrative here is not about adopting a single path but about choosing a direction that respects the car’s character while expanding its capabilities for today’s streets and highways.

For readers who want to see concrete examples of how these principles translate into real products and options, the literature and catalogues of aftermarket lighting providers offer a useful window into how design and engineering converge. And for hands-on owners, there is an additional layer of practical insight: the installation, calibration, and long-term care of upgraded headlights. Proper sealing against moisture, period-correct mounting hardware, and thorough testing of the light output at night all contribute to a successful transformation. The relationship between the Evo 9’s identity and its illuminated face is not simply cosmetic. It is about safety, confidence, and the confident stance of a car that was born from a culture of performance. The headlights no longer merely illuminate the road; they declare the owner’s commitment to precise engineering, modern aesthetics, and the thrill of night driving without compromise.

To ground this exploration in a sense of real-world resources, consider the option to explore authentic HID options for the Lancer Evo 8 and 9, which provides a historical frame for how lighting technology evolved within this chassis family. Original HID headlights for Lancer Evo 8-9. This reference helps situate the aesthetic choices within a lineage of design intent, showing how a modern interpretation can still respect the lines of the original. On a practical level, and for broader context, many enthusiasts also turn to marketplaces that offer a spectrum of compatibility and price points. These sources can illuminate what’s possible in terms of brightness, color temperature, and beam control, while reminding buyers to verify compatibility and to read seller reviews before purchasing. External resources surrounding the Evo 9’s headlight journey can provide additional dimension to the discussion, especially when weighing the trade-offs between OEM-style reliability and aftermarket flexibility. External resource: https://www.ebay.com/itm/186372418481

null

null

Form and Function: Crafting Evo 9 Headlights That Enhance Style and Safety

Form and Function: Crafting Evo 9 Headlights That Enhance Style and Safety

Designing or choosing headlights for the Mitsubishi Lancer Evolution IX demands a careful balance. Owners want a headlight that elevates the car’s aggressive stance while delivering usable light. The Evo 9 uses a unique headlight housing that does not interchange with earlier or later models. That fact alone shapes every choice: fitment, optics, cooling, wiring and legal compliance all hinge on a design that respects the original geometry.

Begin with the core purpose: light. Modern HID and LED technologies have transformed what a headlight should do. They deliver brighter, whiter light and sharper beam cutoffs than older halogen bulbs. That improves peripheral illumination and contrast, helping drivers see road edges and hazards earlier. But raw brightness is not the only metric. The headlight has to shape light into a controlled pattern that illuminates the road without blinding oncoming traffic. Good optics and a properly aimed assembly are essential. Poorly designed LED arrays or misaligned projectors can create glare or scatter useful light away from the pavement.

Lens quality and optical engineering are central to that problem. A clear, distortion-free lens preserves beam shape and maximizes output. Lenses with low-haze, UV-resistant coatings maintain clarity over years of exposure. Inside, reflectors or projector housings must be matched to the chosen light source. Projectors concentrate light into a tight beam, which makes them ideal when upgrading to HID or high-power LED modules. Reflector-based designs can work well too, but they need careful shaping and surface finishing to avoid hot spots.

Functionality also requires thermal and electrical design. LED elements generate heat at their base, and HIDs require ballasts that must be housed safely. Headlight assemblies for the Evo 9 often include dedicated heat sinks, vents and quality seals to channel heat away and keep water out. Overheating can reduce LED lifespan and shift color temperature. Similarly, poor seals invite condensation that scatters light and risks corrosion. A headlight that looks impressive on a bench but fails to manage heat or moisture will degrade quickly on the road.

Aesthetic choices must respect the car’s lines. The Evo 9’s front end carries a purposeful, muscular language. Headlights that echo that language—sharp internal elements, clear lenses, and defined DRL signatures—reinforce the car’s identity. Many modern designs incorporate distinctive running lights. A subtle C-shaped or linear signature can give the Evo 9 a modern presence at day and night. But styling should not compromise the lens surface or optics. Overly decorative inserts that block the light source or rely on cheap chrome finishes tend to degrade both appearance and function over time.

Customization is where enthusiasts find personality. Color accents, smoked lenses and sequential indicators offer unique looks. These features can transform the car’s face from original to bespoke. Yet customization carries trade-offs. Colored LEDs for indicators and DRLs must still meet visibility standards and should not reduce the effectiveness of the main beam. Smoked lenses alter light transmission and may necessitate brighter output to achieve the same road illumination. When customizing, choose options engineered for the housing, not generic parts that only approximate fit.

Fitment is a practical constraint that shapes design decisions. The Evo 9’s housing dimensions and mounting points are specific. Aftermarket assemblies must mirror those attachment points precisely. When they do, installation is straightforward and factory alignment is retained. When they do not, installers must modify the bumper or inner supports. That increases labor, risk of poor alignment, and the chance of unwanted vibrations.

Wiring and controls must be addressed alongside mechanical fit. Many modern headlights include features like DRLs and sequential turn signals. These features need clean wiring, relays or CAN-bus compatible modules to avoid flicker and error codes. A headlight that integrates neatly into the vehicle’s electrical system reduces headaches. Look for assemblies that provide clear wiring harnesses and plug-and-play connectors where possible. If adapters are necessary, they should be high quality to prevent voltage drops and poor ground connections.

Regulatory compliance matters. Bright, stylish lights can quickly run afoul of local laws. Headlights should use bulbs and beam patterns that comply with regulations in the region of use. This includes correct colors for indicators and DRLs, appropriate beam cutoff lines and approved intensity levels. Non-compliant lights may fail inspection or lead to fines. Moreover, improper beam patterns can blind other drivers, creating real safety issues.

Durability and maintenance deserve equal attention. Good headlight design anticipates the environment. Salt, gravel, UV exposure and temperature extremes all take a toll. Materials like impact-resistant polycarbonate and durable coatings extend life. Replaceable bulbs and accessible ballasts make service easier. Seals should be replaceable without removing the entire assembly. Owners who plan to modify or upgrade should choose headlights designed with modularity in mind. That lets them swap bulbs or DRL modules without cutting wires or removing trim.

Thermal management returns once more in the context of long-term reliability. LEDs lose efficiency as they heat. A well-vented assembly, with dedicated thermal paths and quality heat sinks, maintains brightness and color stability. HIDs require stable ballasts and ventilation to avoid premature failures. Designers increasingly use active cooling where space allows, but passive solutions often strike a better balance between reliability and cost.

A final practical layer is resale and perceived value. High-quality headlight upgrades that fit precisely and function reliably often increase the car’s appeal. Conversely, poorly designed lights can diminish resale value. For collectors or buyers who value originality, OEM-style replacements that restore factory performance are often preferable. For those seeking bespoke looks, choose upgrades that complement other well-executed modifications. Cohesion across bumper, grille and lighting defines a thoughtful build.

When deciding between OEM-style replacements and custom units, weigh performance, aesthetics and long-term costs. OEM-style assemblies prioritize fit and factory optics. Custom units offer styling and modern features, but require careful selection and sometimes additional installation work. Read product descriptions carefully and verify that assemblies are engineered for the Evo 9’s housing and mounts. Pay attention to lens coatings, ingress protection ratings, and whether the unit includes properly aimed projectors or reflectors.

One practical advantage for buyers is the availability of model-specific HID units developed for the Evo platform. These often mirror factory mounting points while bringing improved illumination. For a direct source of OEM-like HID assemblies for the Evo 8/9 platform, see the detailed parts listing available here: OEM HID headlights for Evo 8/9. That kind of product bridges the gap between factory fit and improved performance.

The ideal Evo 9 headlight is a synthesis. It respects the car’s original engineering while adding meaningful improvements in light quality, durability and style. It manages heat, keeps water out, integrates with vehicle systems and avoids glare. In practice, that means choosing units with quality optics, clear lenses, robust seals and thoughtful wiring. When aesthetics are desired, prioritize designs that enhance the Evo 9’s lines without impairing illumination. The result is a headlight that looks purposeful and makes night driving safer and more confident.

For reference on model-specific aftermarket assemblies that balance form and function, visit the external product listing below:

https://www.alibaba.com/product-detail/Evolution-9-Mitsubishi-Headlights-For-2006-2010_1600375428765.html?spm=a2700.1.xcx.2.1a1b6d5cXWQvSx

Hunting the Perfect Glow: Pricing and Availability Trends for Evo 9 Headlights

Market snapshot and what’s driving prices

The market for Evo 9 headlights remains strong years after the model left production. Enthusiasts keep demand steady. Collectors seek original parts. Tuners look for modern upgrades. That mix creates a market where both OEM replacements and custom aftermarket units trade hands regularly.

At the core of pricing are a few simple truths. Quality parts cost more. Units with advanced lighting technology command premiums. Rare or authentic OEM pieces fetch higher resale values. As a result, shoppers encounter a broad price band that reflects these differences. For a reliable pair of replacement headlights, expect to see prices that generally fall between roughly $150 and $400. Lower-cost options exist. So do top-tier builds that exceed that range when you add adaptive modules, high-output LEDs, or unique finishes.

Several factors determine where a given headlight assembly will land in that spectrum. The first is whether a unit is OEM or aftermarket. Original-equipment parts often carry a higher price tag. They are sought after for fitment and authenticity. Aftermarket units vary widely. Some reproduce stock fit and function closely. Others add design cues and new lighting tech. Components matter too. Lenses, reflectors, and housing materials affect longevity and clarity. The inclusion of LEDs, daytime running lights, or integrated fog lamps raises costs further. Electronics such as adaptive driving beams or dynamic cornering add complexity and price.

Geography and supply chain shape costs and access as well. Suppliers and manufacturers are concentrated in Asia, Europe, and North America. Wholesale and B2B platforms provide abundant inventory from Asian manufacturers. Specialist retailers and resellers in Europe and North America stock units tailored to regional regulations. Shipping speed and import logistics influence final price. Fast shipping options reduce wait times but increase cost. Conversely, long lead times can lower upfront prices but lengthen the wait for installation.

Recent market trends illustrate how technology and taste shift pricing dynamics. There is a broad movement toward LED lighting. LEDs offer brighter illumination and increased efficiency. They also enable new styling elements, like signature running lights. As LEDs become standard, older halogen-style units decline in appeal for some buyers. Aftermarket designers respond with aerodynamic housings and sleeker lenses. Those design improvements can affect pricing because they require different molds and production processes. Custom finishes and integrated packages are also more common. Buyers now ask for matching fog light assemblies or tailored trims as part of headlight kits. Such bundled options raise average sale prices.

Demand for customization has a clear effect on availability. Popular styling themes are produced in higher numbers. Niche or exotic designs are rarer. When a particular look captures the community’s imagination, supply can tighten. Limited runs of boutique units sell quickly and hold value. Conversely, mass-produced OEM-style replacements are easier to find and often cheaper.

Where to look and how availability plays out depends on the buyer’s priorities. If you want a plug-and-play replacement that replicates factory fit, mainstream marketplaces and specialist retailers usually provide steady options. If you want a high-quality upgrade with advanced lighting, boutique manufacturers and direct suppliers are the likely sources. Salvage yards and low-mileage used markets remain viable for authentic OEM parts, especially for collectors restoring vehicles to original spec. When shopping internationally, factor in compatibility with local lighting regulations. Some units are designed to meet specific regional standards and may not be legal in others without modification.

A few practical buying strategies help navigate the market and manage cost. First, verify compatibility before purchasing. Check mounting points, electrical connectors, and bulb types. Ask sellers for part numbers or fitment guides. Second, read reviews and inspect seller ratings. Real-world feedback highlights recurring issues like condensation, misalignment, or premature LED failure. Third, consider warranty and return policies. A longer warranty often indicates manufacturer confidence. Free or easy returns reduce risk, especially for cross-border purchases.

Another cost factor is installation. Some aftermarket headlights are true plug-and-play units requiring no modification. Others mandate wiring adapters, programming, or small bodywork adjustments. Factor installation labor into total cost, unless you plan to do the work yourself. For electronic upgrades such as adaptive beams, professional installation is often required to ensure correct calibration.

Import considerations matter too. Customs duties, taxes, and shipping insurance add to landed cost. Choose sellers that provide clear documentation and transparent shipping estimates. When buying from overseas, be mindful of lead times and communication channels. Reputable suppliers usually offer tracking and responsive support.

Price negotiation is possible in several contexts. Bulk purchases or purchases by shops can yield discounts. Seasonal promotions and industry cycles sometimes produce temporary price drops. For rare OEM items, patience often pays; persistent searching across forums, classifieds, and salvage listings can reveal underpriced gems. For aftermarket upgrades, new model releases or overstock events may reduce prices for previous designs.

Quality assessment should guide purchasing decisions. Inspect product photos closely. Look for uniform lens clarity and secure mounting tabs. Ask about thermal management for LED units. Poor heat dissipation shortens LED life. Check whether assemblies use separate bulbs for high and low beams or rely on integrated LEDs. The former can ease future repairs, while the latter may require replacing an entire assembly when one element fails.

Resale and long-term value are part of the calculus for many Evo 9 owners. High-quality headlights that maintain performance and appearance tend to retain value. Authentic OEM units and limited-run aftermarket models often resell well. Conversely, cheaper knockoffs can degrade quickly and reduce a car’s appeal at resale. Investing in quality can protect both safety and asset value.

Legal compliance and safety must never be overlooked. Headlight beam patterns and intensity must meet local regulations. Noncompliant units may be illegal to use on public roads, and they can pose safety risks. Verify certifications and ask sellers for documentation when necessary.

For buyers who prefer a middle ground, there are many options that balance price, quality, and modern features. Mid-range aftermarket units often mimic factory fit while upgrading illumination and styling. They are widely available and generally well priced. At the high end, custom shops and boutique manufacturers deliver bespoke finishes and advanced electronics. Those options suit enthusiasts seeking a standout look.

If you want immediate market access, check dedicated listings that specialize in Evo parts. For those open to wholesale channels or bulk sourcing, B2B platforms offer a wide selection and competitive pricing. For authentic OEM or low-mileage used parts, search specialized salvage inventories and collector networks. When you evaluate sellers, look for clear photos, honest defect descriptions, and a straightforward return process.

Finally, consider the long view. Headlights serve form and function. They influence safety, visibility, and the car’s aesthetic. Market trends show a steady shift toward brighter, more efficient lighting and cleaner designs. That shift affects pricing and availability in predictable ways. Buyers who understand those forces can make informed choices that balance cost, performance, and style.

For up-to-date supplier listings and distributor details, consult wholesale product pages that list current inventory and minimum order information. One example of a wholesale listing can be found here: https://www.alibaba.com/product-detail/EVO-9-Headlight-Distributor_1600387822757.html

For an example of an alternative retail option focused on custom HID replacements for these models, see the brand resource titled brand-new OEM customized HID headlights for Lancer Evo 8-9.

Bright Boundaries: Installing and Maintaining Evo 9 Headlights for Longevity and Peak Performance

Headlights are more than a lighting package on a high-performance hatch; they fuse form and function, signaling the car’s intent while guiding the driver through the dark and unpredictable edges of the road. On the Evo 9, the headlights carry a distinct presence that mirrors the car’s aggressive stance and precise engineering. Upgrading or refreshing these assemblies is about more than chasing a brighter beam; it is about preserving the car’s character, ensuring reliable visibility, and maintaining road legality as the components age and environments take their toll. A thoughtful approach to installation and ongoing care can transform nighttime driving from a routine necessity into a controlled, confident experience where the road ahead feels almost guided by a steady, trustworthy glow. In this light, the process becomes a blend of careful workmanship and practical maintenance—a continuity that honors the decay and renewal cycle every performance vehicle endures. The Evo 9’s headlights demand attention that begins with the right parts and ends with an alignment that respects both your line of sight and the safety of others on the road. When done well, the lights illuminate a path that reveals road texture, curb edges, and changing weather conditions with clarity, while the distinctive shape of the assemblies preserves the vehicle’s signature silhouette. The goal is not merely to replace worn or mismatched units; it is to restore the car’s night presence so it remains as expressive at midnight as it is at dusk on a sunlit street.

The installation journey starts with respect for the vehicle’s design intent and the clarity that OEM specifications provide. It is tempting to reach for quick, off-brand replacements or add-ons that promise “plug-and-play” convenience, yet the best outcomes come from parts that match the original electrical load, mounting geometry, and lens curvature. Compatibility is not a hypothetical concern but a practical necessity that ensures the new headlights sit correctly in their housings and synchronize with the car’s existing electrical system. The process begins with a precise assessment of the replacement unit’s compatibility with the Evo 9’s mounting points, adjusters, and harness connectors. As with any serious upgrade, confirming that the replacement unit preserves the correct beam pattern is essential; misalignment can cause glare for oncoming drivers and reduced roadway illumination for you.

From there, the physical steps unfold in a sequence that respects the vehicle’s electrical architecture and structural tolerances. Begin by safely disconnecting the battery to prevent short circuits or unexpected activation during the swap. Next, access the headlight housing by removing the surrounding trim and, if necessary, loosening or removing mounting components so the old unit can be pulled free without jarring the bodywork. Detach the wiring harness with care, noting how each connector is oriented and clipped, so it can be reattached without forcing pins or damaging seals. When the new assembly is aligned with the mounting studs and guides, slide it into place and secure it with the original fasteners, replacing any worn hardware. The moment of truth arrives with the electrical connections reestablished and the battery reconnected. A quick circuit check ensures there are no flickers, dimming, or error codes from the vehicle’s computer system. If a fault appears, revisit the connectors and ensure that the seals around the housing are intact and that the ballast or driver units, if present, are seated correctly.

Alignment is the hinge on which successful headlight performance pivots. A correct aim ensures the beam is distributed down the roadway rather than into the faces of oncoming drivers. The typical approach involves phasing the vehicle at a suitable distance from a flat wall or garage door and then adjusting the horizontal and vertical aim using the built-in screws on the back of the headlight housing. The goal is a clean, even pattern with a distinct cutoff line. The horizontal alignment should be centered so that the brightest part of the beam tracks along the lane line without spilling excessive light onto the shoulder or opposing lanes. The vertical aim should place the brightest portion of the beam at a point a short distance down the wall, often a few feet below the centerline mark, ensuring that the beam is high enough to illuminate farther ahead without blinding other road users. These adjustments are subtle yet vital; a miscalibration may be invisible in daylight but becomes glaring the moment you drive into a dim, wet, or curving road.

Mounting integrity follows alignment. The headlight housings must be secured against vibration, heat cycling, and road disturbances that would gradually loosen fasteners or distort the lens. If the original mounting hardware shows signs of wear or corrosion, replace it with components that meet the original geometry and strength specifications. Gaskets and seals around the housing protect the interior from moisture and dust; their integrity matters as much as the beam itself. A compromised seal invites fogging, which scatters light and reduces contrast on the road. When you replace seals, apply them evenly and avoid lifting or pinching the gasket, which can create premature leaks. This diligence safeguards against moisture that can cloud lenses, promote corrosion on reflector surfaces, and degrade the color temperature of the light over time.

Beyond the mechanical and optical considerations, the electrical side of headlight upgrades merits careful attention. Modern headlights, whether LED or HID-based, rely on drivers, ballasts, and wiring that tolerate specific loads and voltage ranges. A mismatch can manifest as dim output, intermittent flicker, or even fault codes that illuminate dashboard warnings. If your upgrade introduces new drivers or LEDs, verify the system’s compatibility with the Evo’s electrical architecture. In some cases, higher-lumen units demand upgraded power management or relay wiring to prevent voltage dips that can trip fuses or cause the lights to briefly black out during heavy engine load. The principle is simple: honor the electrical circuit as a designed ecosystem where each component has a role, rather than treating the upgrade as a plug-and-play accessory that operates in isolation. This careful approach keeps the headlight system reliable across cold starts, idling heat, and the cumulative fatigue of long drives.

As you consider cross-generation designs or aesthetic cues, exploring related lighting options for other Evo generations can illuminate why certain shapes, day-running light signatures, and lens coatings endure as popular motifs. For readers curious about how design language evolves across generations while maintaining lighting performance, a look at headlights for Lancer Evo X offers useful context about how modern styling cues can integrate with robust illumination. Headlights for Lancer Evo X (2007-2017) Audi Design Version 2. This reference can help frame the balance between aggressive styling and dependable beam performance, even as the specific mounting geometries and electrical interfaces differ between generations.

Maintenance emerges as the quieter, ongoing counterpart to installation. A regular inspection routine catches small problems before they escalate. Periodic checks should accompany the wash and polish schedule already common to a performance vehicle. Look for cracks in the lens, condensation inside the housing, loose clips, or detaching seals. Fogging is not merely an aesthetic concern; it reduces light output and scatters the beam. Some drivers notice yellowing or clouding that develops after UV exposure and exposure to road grit. A straightforward DIY restoration can help, especially if the fogging remains mild. A practical restoration method uses a simple baking soda and water paste to scour the lens surface gently, followed by a thorough rinse and a polishing compound to bring back the clarity. This approach can restore some of the original transparency and improve light output without replacing the entire assembly. Yet, if the lens is deeply etched or the internal layer has deteriorated, replacement is the more effective route.

Moisture ingress deserves particular attention. Seals are the primary defense against water intrusion, but a compromised seal can also permit dust and moisture to accumulate inside the housing. If moisture appears after a wash or a drive through rain, inspect the gasket location and test the seal by pressing gently around the housing edge to feel for any movement or leaks. Replacing damaged seals promptly can prevent corrosion on reflector surfaces and moisture-related fogging. In some cases, resealing with a high-quality automotive-grade sealant is a reliable interim measure, but replacing a damaged seal remains the most durable solution. Even with flawless exterior seals, the interior components demand occasional checks. Dashed or degraded wiring insulation, loose connectors, or frayed harnesses can create intermittent losses that undermine performance. A clean, orderly harness layout with proper routing away from high-heat sources reduces the risk of future failures.

What follows is a reminder that installation and maintenance are not isolated tasks but a continuum. If you plan additional electrical enhancements or interior upgrades, proceed with a comprehensive plan that considers how new wiring, triggers, or modules might interact with headlight controls and ignition sequencing. In this regard, the project benefits from a measured approach rather than a sprint. When in doubt, consult professional installers who can verify compatibility, adjust beam patterns to local regulations, and ensure that all safety-critical aspects of the headlight system are addressed. The best outcome is a headlight setup that remains dependable under all driving conditions, preserves the Evo’s aggressive identity, and supports safe, confident night driving for years to come.

For readers seeking additional, visually guided restoration techniques, a modern short-form resource demonstrates the baking soda method for reviving foggy headlights. It is a practical complement to this chapter’s guidance and offers a quick, repeatable procedure for your at-home toolkit: https://www.tiktok.com/@carfixer/video/7412345678901234567. The combination of careful installation, ongoing maintenance, and informed, cautious upgrades creates a headlight system that stands up to the rigors of performance driving and the demands of daily use alike. And with the right approach, Evo 9 headlights remain a defining feature—bright, precise, and resilient—so the car can deliver its signature presence on every road you choose to travel.

Final thoughts

Evo 9 headlights have transformed from basic factory units to highly desirable aftermarket options, enhancing both appearance and performance. Understanding the evolution and technology behind these headlights is crucial for business owners in the automotive sector looking to meet customer demands. By considering design elements, keeping an eye on market trends, and ensuring proper installation and maintenance, business owners can navigate the Evo 9 headlight landscape effectively. Embracing these upgrades can lead to increased customer satisfaction and boost sales.