The EVO 9 bumper stands at the intersection of innovation and performance in the automotive aftermarket. Designed specifically for the Mitsubishi Lancer Evolution IX, these bumpers transcend mere aesthetics, offering a blend of safety and enhanced aerodynamics crucial for high-performance driving. This article delves into the sophisticated materials and technology that make up the EVO 9 bumper, explores its aerodynamic design features, discusses performance enhancements it provides, and highlights current market trends and customization options for business owners. By the conclusion, you will gain comprehensive insights into what makes the EVO 9 bumper an essential component for automotive enthusiasts and a lucrative market opportunity for business owners.

Reinforced Aerodynamics: Inside the EVO 9 Bumper Materials and Engineering

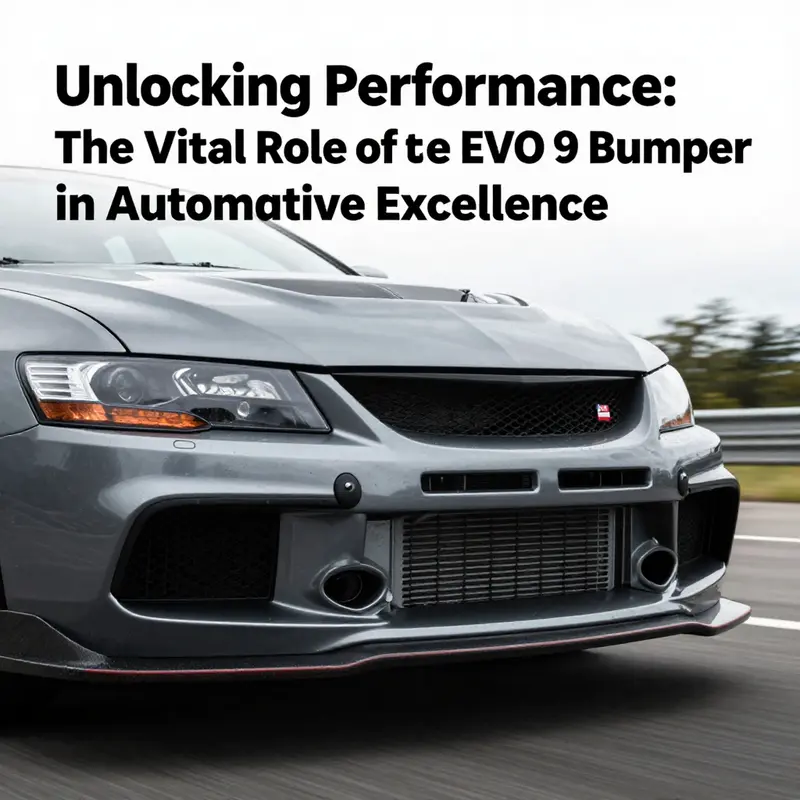

When it comes to the Mitsubishi Lancer Evolution IX, the bumpers at both front and rear are far more than cosmetic attachments. They are critical interfaces between the car and the air rushing past at high speeds, as well as sacrificial elements in the event of impact. The blend of materials and engineering that goes into an EVO 9 bumper directly shapes its performance on daily roads and on the track. From factory-installed parts to cutting-edge aftermarket upgrades, each design decision—from polymer selection to composite layup—affects weight, durability, and aerodynamic efficiency, making the bumper a silent hero of driving dynamics.

Factory bumpers for the EVO 9 rely chiefly on polypropylene (PP) reinforced with acrylonitrile butadiene styrene (ABS) plastic. This thermoplastic combination balances cost and performance by offering a lightweight shell capable of absorbing and dissipating crash energy. Engineers optimize the molecular structure to provide just enough flexibility during low-speed impacts while preserving dimensional stability under normal driving stress. The resulting assembly meets strict safety and quality standards, guaranteeing consistent fitment and finish across production runs. These OEM bumpers arrive in a blank white finish, ready for paint matching, and carry the reassurance of factory-approved crashworthiness and long-term resistance to the elements.

While the OEM solution emphasizes reliability and cost-effectiveness, it also carries inherent trade-offs in weight and styling freedom. At roughly 4–6 kilograms per piece, factory bumpers strike a middle ground: they are light enough to avoid overburdening a vehicle tuned for quick acceleration, yet durable enough for day-to-day use. Impact absorption takes priority over peak stiffness, a necessary compromise to meet crash regulations. For drivers seeking more aggressive profiles or sharper handling characteristics, these trade-offs are invitations to explore aftermarket alternatives that push the boundaries of material science.

In the realm of aftermarket components, advanced composites step onto the stage. Fiberglass-reinforced plastic (FRP) stands as the entry point for many enthusiasts. FRP bumpers skirt the line between affordability and performance, offering a weight reduction of roughly 10–15% compared to OEM parts. Although not as rigid as carbon fiber options, properly laid up fiberglass molds can hold their shape under moderate track use. Their porosity demands careful finishing and sealing to prevent moisture intrusion, but once prepared, they accept custom paint and bodywork modifications with ease.

One level up, wet carbon fiber bumpers employ a resin-infused fabric that yields a glossy finish and a moderate stiffness boost over FRP. This process mixes carbon weave with resin by hand, allowing craftspeople to tune resin ratios for optimal balance between strength and weight. While still pricier than fiberglass, wet carbon delivers a noticeably firmer front end feel and a weight saving of up to 20% relative to stock. Enthusiasts often favor this option for street builds that seek both head-turning looks and a tangible performance edge without the premium cost of dry carbon.

At the pinnacle of lightweight bodywork sits dry carbon fiber, molded under high pressure and vacuum to remove nearly all excess resin. The result is a component that boasts the highest strength-to-weight ratio and the lowest possible mass. Dry carbon bumpers can shave off as much as 30% of the weight of a standard plastic assembly. This translates directly into quicker turn-in response, more precise steering feel, and reduced front-end inertia during rapid direction changes. The downside is a sticker price that climbs significantly with each layer of specialized fabric and every hour spent in meticulous vacuum curing.

To bridge the gap between cost and performance, hybrid composites merge carbon fiber layers with fiberglass or even Kevlar. These blends harness carbon’s rigidity where it matters most—such as around mounting points and intake openings—while leveraging fiberglass’s impact resistance in lower-risk areas. The result is an engineered solution that maintains a balanced ride quality, stands up to low-speed scrapes, and still delivers a convincing weight advantage. Hybrid bumpers also benefit from enhanced vibration damping, reducing the risk of crack propagation along high-stress zones.

Technological progress in bumper design extends beyond sheer material choice. Modern aftermarket bumpers feature integrated airflow channels, air intakes, and sculpted diffusers molded directly into the composite layup. These aerodynamic details guide air toward the radiator, intercooler, and brakes, improving engine cooling by up to 20% under demanding conditions. The inclusion of modular mounting points makes these bumpers compatible with universal widebody kits, front splitters, and accessory lips. This flexibility allows drivers to dial in downforce levels, fine-tune air curtain effects around the wheels, and optimize balance between front and rear grip.

Brand and part certifications also play a vital role in ensuring safety and performance. Many aftermarket bumpers carry OEM-equivalent specifications, meaning they undergo comparable material testing and structural analysis. This certification process assures buyers that the lightweight composite will not compromise crash performance or mounting integrity. For Evo 9 owners who demand both track cred and street-legal compliance, these certified bumpers represent the sweet spot between radical styling and reliable engineering.

Selecting the right bumper ultimately comes down to intended use. A daily-driven Evo 9 benefits from the peace of mind and seamless fitment of a factory-style polypropylene piece, while a weekend warrior or track rat may opt for a carbon or hybrid composite shell that shaves precious pounds off the front axle. For those in between—drivers who want a sharp new look without breaking the bank—fiberglass and wet carbon fiber remain popular choices.

Customization extends beyond material: the EVO IX front bumper kit with carbon fiber lip provides a readily available platform for adding splitters, canards, and additional ducting. Enthusiasts can mix and match lips and diffusers, transforming the standard profile into a bespoke aerodynamic statement that complements suspension upgrades and wheel fitments.

For those seeking a deeper dive into available configurations, mold specifications, and cross-compatibility with universal widebody systems, refer to the official catalog of EVO 9 bumpers. Detailed listings cover both front and rear assemblies, complete with material breakdowns and finish options.

Aero-Forward: How the IX Bumper Shapes Speed, Cooling, and Confidence

A bumper is often the first thing a driver notices, yet it is rarely given full credit for its engineering inside a performance chassis. In high-speed driving, the front end acts as the throat of a breathing system, guiding air to cool, to feed, and to stabilize. The IX-generation bumper, in particular, is not just a face for the car; it is a carefully tuned aerodynamic element that intersects with the radiator, the intercooler, and the underbody to shape how a fast machine behaves when the pace rises. The design philosophy behind this bumper version is practical and precise, balancing form and function so that the vehicle remains controllable at speed while running cooler in the heat of a race or a road-legal track day. The result is a cohesive system where every contour serves a purpose, and the whole front-end assembly becomes more than the sum of its parts.

The first impression is of a low, aggressive silhouette that sits close to the ground. This stance is deliberate. A low profile reduces the lift that can build at high speeds and helps the car cut through air rather than fight it. But the visual sharpness here is more than cosmetic. The bumper’s lines guide the airflow toward the large, purpose-built intake openings that flank the center and sides. These intakes are not merely wider than stock; they are shaped to optimize the path of air as it comes under the nose and around the wheels. The goal is twofold: bring ample air into the engine bay for cooling, and manage the air that sweeps along the sides to minimize pressure buildup along the fender lines. The result is a smoother flow field around the front of the car, with less turbulent wake that would otherwise upset stability when the speeds climb.

Inside those air channels, the relationship between cooling and performance becomes especially visible. In a high-performance powerplant, the engine and its intercooler rely on a steady, high-volume supply of air. The IX bumper’s large openings act as a highway for this vital air, delivering it where it is needed most and with less resistance than a more restrictive OEM front end might allow. When airflow is efficient, the radiator and intercooler can shed heat more quickly, which translates into more reliable operation under pressure and a wider margin for tuning. It is not just about keeping temperatures in check; it is about enabling the engine to maintain power over longer periods without heat soak or knock that could force the ECU to pull timing. In practical terms, this translates to engine cooling improvements that researchers and engineers describe as up to a twenty percent enhancement over stock configurations. That gain may seem modest in a single metric, but in racing or spirited road use, it accumulates as faster laps, more consistent power delivery, and a chassis that remains predictable at the edge.

Drag reduction, another critical factor in aero performance, often travels hand in hand with cooling efficiency. A well-integrated bumper design reduces parasitic drag by shaping the stagnation zone at the front of the car. The IX bumper, with its flush lower lip and carefully contoured side intakes, works to minimize the air separation that can cause a high-drag wake. The aim is not to create a bottle of invisible air resistance but to guide the air so that the front of the car remains stable as velocity increases. In pilot terms, that translates to more deliberate steering feel when braking from high speeds and less yaw caused by winds or cornering forces. In everyday terms, it means that you can enjoy more steady acceleration on open roads while still feeling confident under track-like loads. The balance here—between cooling capacity and drag reduction—demands a precise interplay of geometry and material selection, a theme that runs through the entire design of the bumper and its supporting aero ecosystem.

Beyond the raw airflow management, material choice plays a pivotal role in achieving the promised efficiency and durability. Modern front bumpers built for performance use high-strength composites, with carbon fiber and fiberglass standing out for their weight-to-strength properties. These materials allow manufacturers to shave pounds off the front end without compromising impact resistance or rigidity. The lighter front end contributes to a more favorable weight distribution, which in turn influences handling and steering response. A lighter, better-structured nose reduces inertia during quick direction changes and enhances the car’s ability to respond to driver input with precision. Importantly, these materials also provide durability in the face of debris and minor collisions—a practical consideration for enthusiasts who push their cars on public roads, as street driving still demands robust protection.

Another defining feature of the IX bumper is its modular, widebody-ready design. The bumper is not a rigid, one-size-fits-all piece; it is engineered with compatibility in mind, so it can be paired with various aftermarket aero kits to achieve an even more aggressive stance. This modular approach is especially valuable for builders who want to customize the front end while preserving a unified aero philosophy. By retaining OEM-spec safety and fitment standards while offering a broad canvas for aerodynamic experimentation, the bumper becomes a bridge between stock reliability and race-inspired performance. It allows the owner to preserve the essential safety margins that come with certified parts while embracing the possibilities of a broader, more expressive front end. In practice, this means you can pursue a sharper, more muscular look without sacrificing the predictable behavior that underpins safe high-speed driving. The combination of weight savings, airflow optimization, and kit compatibility creates a front end that is both practical for daily use and compelling on the track.

The integration of such a bumper into a larger aero system is not accidental. It is designed to work with other elements of the front-end aero package, including splitters, canards, and underbody diffusers. The splitter plays with the same objective as the bumper’s large vents: to channel air under the car and along the underside with minimal leakage. Canards and small vortex generators, when paired with the bumper, can help energize the boundary layer near the nose, delaying flow separation and improving high-speed stability. The diffuser, resting downstream of the bumper, further smooths the flow as air exits the undertray, reducing lift and guiding the air toward the rear of the car in a controlled manner. Together, these components create a coherent aerodynamic narrative where the bumper is not a standalone piece but a keystone in a carefully designed, holistic package. The synergy is subtle but essential: the bumper provides the air supply and the initial pressure management; the rest of the aero elements tune that flow into a stable, tractable, and endearing handling profile.

The importance of OEM specification and safety standards should not be overlooked, even as drivers chase the fantasy of maximum downforce and razor-sharp response. The IX bumper is engineered to align with the car’s baseline safety margins, crash energy absorption characteristics, and mounting geometry. This alignment means that the bumper can be installed with confidence, preserving the integrity of the car’s front structure and ensuring that European, American, or regional regulatory expectations are met where applicable. For many enthusiasts, the assurance that comes with conforming to OEM-like specs provides a crucial peace of mind. It is a practical recognition that performance upgrades must coexist with safety and reliability if they are to be used consistently and responsibly. In this frame, the bumper becomes a reliable platform for ongoing development rather than a one-off modification that could compromise the chassis’ integrity under stress.

This approach also speaks to the broader philosophy of the project: performance is a long game that benefits from engineering discipline. The bumper’s design is a testament to how small, deliberate choices—such as the size and shape of an intake, the curvature of a lip, or the stiffness of a composite panel—can ripple through the car’s behavior. A wider intake might improve cooling by a measurable margin, but if it introduces excessive turbulence or worsens curb clearance, it undermines the overall package. The IX bumper’s balance reflects countless hours of wind tunnel testing, computational fluid dynamics simulations, and practical on-track feedback. It is a product of the same ethos that underpins racing technology, translated for the tangible realities of street and track driving. The result is a front end that not only looks purposeful but also behaves predictably when the throttle is opened wide and the track invites pressure and heat to mount together.

For readers who want to explore related avenues, the modularity of the design invites cross-pollination with other components and kits. The philosophy here is that you do not need to start from scratch to realize meaningful gains. A well-chosen aftermarket kit, compatible with this bumper’s geometry, can yield a more aggressive stance, improved aero balance, and a coherent visual identity without compromising the core engineering that keeps temperatures sane and the car controllable. This is not about chasing a single spec; it is about cultivating a complete, harmonious aero character that can evolve as goals shift—from street performance to competitive lapping. The practical takeaway is straightforward: prioritize a design that respects the car’s existing safety framework, supports robust cooling and airflow, and remains adaptable to future improvements.

As the chapter closes, the bigger takeaway is that the IX bumper embodies a philosophy of integrated performance. It demonstrates that a front-end component can simultaneously improve cooling, reduce drag, lighten the nose, and cooperate with a wider aero strategy. The allure is in how these pieces come together—hot air is cooled more efficiently, air is directed with less resistance, weight is shaved without compromising rigidity, and the front end nods to a broader vision of speed as a controlled experience rather than a reckless surge. In that sense, the bumper is both a technical instrument and a statement of intent. It invites the driver to experience speed as something that can be managed, refined, and enjoyed without sacrificing safety or reliability. The IX bumper, with its emphasis on aerodynamics, materials, and modular adaptability, stands as a key piece in a larger conversation about how modern performance cars are built to perform under pressure—on the road, on the track, and in the hands of drivers who value both confidence and constraint.

For readers who wish to glimpse a related approach to front-end aerodynamics in a similar platform, a related option can be found here: mitsubishi evo 7-8-9 ct9a spec vrs2 front bumper.

External resource: a comprehensive overview of front and rear bumper options for this family of vehicles is available here: Alibaba listing for Mitsubishi EVO 9 Front and Rear Bumpers.

Aerodynamics in Motion: How the EVO 9 Bumper Shapes Speed, Cooling, and Stability

The EVO 9 bumper is more than a front or rear faceplate for the Mitsubishi Lancer Evolution IX; it is a carefully engineered system where materials, geometry, and safety standards converge to define how the car behaves at the edge of grip. This bumper is a deliberate statement about performance through restraint: a component that pares weight without surrendering strength, channels air with precision, and aligns with a broader aero philosophy that seeks to balance aggression with control. In the broader narrative of performance upgrades, it represents an approach that treats bodywork as an active contributor to performance, not just a cosmetic shell. Its development reflects a shift toward high-strength composites and modular design that honors both road use and track discipline.

At the heart of its performance story is the choice of materials. Modern bumpers for this platform leverage high-strength composites, predominantly carbon fiber and glass-reinforced polymers, to trim mass while retaining the ability to absorb and deflect energy under impact. The lightness of these materials translates to meaningful gains in acceleration, braking, and steering response. More importantly, the reduced inertial footprint of the bumper means the suspension and tires can work more efficiently, allowing the vehicle to change directions more readily and with less effort. This is not cosmetic weight savings; it is a functional reduction that improves steering wheel feel and corner entry behavior, especially when the chassis is loaded heavily in dynamic corners.

From a design perspective, the bumper embodies a modular universal widebody concept. Rather than a single rigid shell that dictates the rest of the aero package, the bumper is designed to play nicely with a range of fender extensions, air flows, and underbody elements. The modularity means enthusiasts can tailor an aero scheme that fits their goals—whether a street-oriented look with a hint of aggression or a full-track-ready stance that requires tight tolerances and predictable handling. This adaptability is crucial because it allows the front-end aero to work in harmony with the rest of the car’s profile, rather than fighting against it. When a vehicle’s front end breathes well, everything behind it benefits.

Airflow management emerges as a central theme in the EVO 9 bumper’s performance equation. The front bumper houses integrated air intakes and vents that direct cooling air precisely where it’s needed. Radiator and intercooler cooling is enhanced by steering cool air toward high-heat zones, reducing thermal load during high-rev runs or sustained downhill runs on a hot day. The result is more stable engine temperatures, which translates into reliable long-run performance and less heat soak during aggressive acceleration. In practical terms, this means the engine can maintain strong power delivery for longer periods without the thermal penalties that can plague a high-performance motor. The materials themselves resist corrosion and wear, supporting long-term durability in harsh environments and off-road exposures that might occur during spirited weekend drives.

Beyond cooling, the bumper’s geometry is tuned to tame aerodynamic drag and introduce controlled downforce at speed. By shaping the airflow across the leading edge and around the wheel wells, the bumper helps reduce front-end lift, a crucial factor at highway speeds and on track straights where even small lift can undermine stability. The interaction with a front splitter and side skirts—elements that often accompany a broader aero package—creates a coordinated pressure field that minimizes turbulent wake and supports tire grip. In essence, the bumper works as part of a broader system designed to keep the car planted, predictable, and responsive as speeds rise. The downforce generated, while modest on a street setup, is meaningful for chassis balance; it keeps the nose from wandering under braking and early throttle application, allowing the driver to place the car with confidence through complex corners.

The engineering story here is not just about drag reduction; it is about stability and predictability at the limit. Reducing drag while increasing downforce requires a delicate balance. The bumper’s sculpted surfaces direct air into regions that energize the boundary layer in beneficial ways and avoid creating dangerous flow separation. This equilibrium translates to more confident high-speed behavior, where the car maintains its line through fast corners and requires less correction from the steering wheel. The effect is subtle in everyday driving, but it becomes tangible on a road course where suspension, tires, and aero interact as a system. Enthusiasts often report smoother transitions between throttle-on and throttle-off states, a sign that the aero package is working as intended rather than fighting against the car’s momentum.

Safety and compliance remain foundational to these performance gains. The EVO 9 bumper adheres to OEM specifications and safety standards, so the modification preserves the car’s crashworthiness and the integrity of front-end safety structures. This means mounting points align with reinforcement zones, sensors remain within tolerance, and the energy-absorbing behavior of the bumper is preserved to protect occupants in the unlikely event of a collision. The careful attention to safety standards provides peace of mind for enthusiasts who want a track-ready aero presence without compromising everyday safety. The result is a product that supports performance goals while staying true to the car’s original engineering philosophy.

From a compatibility standpoint, the bumper is designed to be part of a broader aero ecosystem without forcing a complete rework of the vehicle’s architecture. It plays well with additional aero elements and optional fabrications that extend the same reliability and fitment aesthetics that buyers expect from OEM-aligned upgrades. The modular design helps ensure that adding a lip, canards, or fender extensions can be accomplished without intrusive modifications to the base structure. In practical terms, this translates to a more straightforward installation process, predictable alignment, and a consistent look across the entire front end. When enthusiasts go to the trouble of upgrading to a more aggressive aero stance, they want assurance that the package will hold its shape, not develop cracks or deformations after a few track days. The EVO 9 bumper is designed to be resilient under load, resisting flex that would otherwise dilute aero performance or alter sensor alignment.

In real-world scenarios, these design choices translate to tangible performance benefits. Cooler engine bays mean that power can be sustained for longer periods without de-rating, a crucial advantage on longer track sessions or during aggressive driving where heat builds quickly. The car maintains a more stable aerodynamic profile, which helps with predictable steering—particularly under late braking and mid-corner throttle modulation. The weight savings from carbon fiber and glass-reinforced polymers contribute to quicker turn-in and improved mid-corner balance, enabling the driver to manage weight transfer more precisely. In this sense, the EVO 9 bumper serves as a bridge between aesthetic intent and measurable performance outcomes, turning airflow into usable grip and confidence.

Practical maintenance considerations also factor into the engineering approach. Composite bumpers tend to handle road debris and minor impacts with a durability that outperforms simpler plastics, and their resistance to UV exposure helps maintain cosmetic appeal far longer in sunny climates. Long-term value accrues not only from fuel efficiency or lap times but from reduced touch-ups and a more consistent appearance that remains faithful to the car’s performance spirit. The combination of lightness, resilience, and safe energy absorption translates into a practical solution for owners who demand more from their car without a steep price in reliability.

The EVO 9 bumper’s role in shaping the vehicle’s identity is as important as its mechanical impact. While it communicates intent through a sharper silhouette and a more aggressive stance, it also conveys a disciplined approach to aerodynamics. The integration with the overall body, including the potential pairing with a wider body kit, signals that performance is a system-level concern rather than a collection of isolated upgrades. The visual language aligns with functional goals: a front end that breathes easily, a chassis that remains planted under stress, and a silhouette that speaks to track readiness while still serving daily driving needs. In that sense, the bumper embodies a philosophy of performance that respects safety, reliability, and the enduring appeal of a clean, purposeful design.

For readers curious about a specific kit, see the evo-ix-front-bumper-kit-front-lip-white-evo-ix-mr-ralliart-carbon-fibre-front-lip-evo-ix.

External resource: https://www.alibaba.com/product-detail/Mingyang-EVO9-Body-Kit-PP-Plastic-New_1601027854345.html?spm=a2700.galleryofferlist.normal.1.1a6e7d69RgQsYl&urlFrom=gallery

Aerodynamic Edge and Style: EVO 9 Bumper Market Trends and Customization

Market Momentum Meets Custom Flair

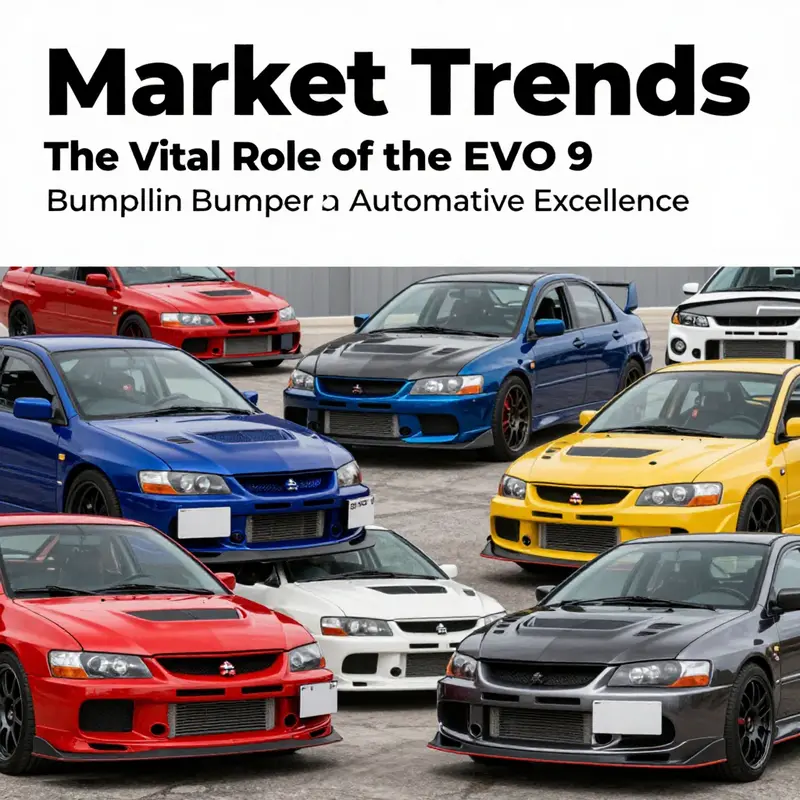

Enthusiasts and tuners continue to propel the Mitsubishi Lancer Evolution IX bumper market into a realm where performance engineering and visual personalization converge. The enduring reputation of the EVO 9 platform shapes a vibrant demand for components that deliver more than cosmetic flair. Front and rear bumpers are no longer just protective shells; they’ve become critical aerodynamic devices that channel airflow, optimize engine cooling and minimize drag while offering a canvas for individual expression. Across street, rally and track environments, drivers seek a balance of OEM+ fitment and race-inspired function to maintain factory reliability without sacrificing aggressive styling.

Material innovation sits at the heart of this market evolution. Gone are the days when standard plastic bumpers prevailed; today glass fiber and hybrid composites such as carbon fiber–fiberglass blends lead the pack. These advanced materials deliver a 20% improvement in engine cooling and reduced drag relative to stock components, thanks to thinner wall sections and precisely engineered vents. Their superior impact resistance and high-temperature durability handle the rigors of spirited driving and frequent track use while trimming unsprung weight by up to 30%. Products listed on leading global platforms illustrate how tuners leverage these composites to unlock both aerodynamic gains and a dramatic visual upgrade. Source

Beyond raw materials, a performance orientation defines buyer priorities. Whether carving mountain roads or launching off gravel rally stages, EVO 9 drivers recognize that a well-designed bumper can improve high-speed stability by smoothing airflow under the car and around the front end. Strategic grille openings and integrated air ducts enhance thermal management for turbochargers and intercoolers, extending component life under prolonged load. Even on daily commutes, optimized airflow to the radiator and brake ducts reduces stress during heavy traffic and spirited weekend runs. These performance gains dovetail with the car’s AWD architecture to deliver consistent handling feedback and traction balance, fueling the EVO 9’s reputation as a true driver’s car.

Yet raw performance is only half the story. Customization options now rival high-end body shops in scope. Most aftermarket bumper kits arrive in a blank white finish, ready for custom paint, vinyl wraps or dramatic two-tone schemes. Enthusiasts mix and match lower lips, central splitter extensions and accent trim pieces to craft unique profiles that mirror personal style or brand identity. The modular nature of modern widebody kits allows each element to snap together without extensive modification. For those who want to blend subtle OEM cues with track-focused aggression, tailored kits—like those found in specialized galleries of EVO IX front bumper kits—offer factory-grade mounting points alongside carbon-fiber accents, achieving a seamless transition from stock appearance to race-inspired stance. EVO IX front bumper kits

This modular approach extends to integration with complementary components. Widebody bumpers are engineered to align perfectly with side skirts, rear spoilers and diffusers, resulting in a unified aerodynamic package. Careful attention to mounting flange placement and panel gaps ensures that each interface tightens within OEM tolerances, eliminating the need for hasty filler work or improvisational trimming. Bolted-on splitter brackets and pre-cut vent channels let owners fine-tune front downforce in minutes rather than days. Such cohesion benefits tuners who juggle multiple aftermarket upgrades, enabling them to stack performance mods—like upgraded intercoolers and oil coolers—without compromising the exterior silhouette.

For a segment of owners who value a near-factory upgrade, OEM-certified bumpers bridge the gap between stock elegance and tuned aggression. These solutions adhere to original impact-absorption standards, maintain crashworthiness and preserve airbag deployment calibration. Precision compatibility with factory sensors and tow-hook mounts saves installation time and eliminates error-prone workarounds. Attractive to enthusiasts who want an understated aesthetic, these certified parts offer subtle diffuser fins and integrated fog lamp surrounds that echo the styling of limited-edition Evolution models. By balancing the look and feel of genuine OEM pieces with enhanced aerodynamics, certified bumpers cater to drivers who demand reliable performance without overtly signaling competition readiness.

Meeting this complex demand profile requires wholesalers and suppliers to adapt swiftly. Technical precision in tooling translates to consistent fitment across production runs. Quality consistency hinges on strict inspection protocols and well-documented material certifications. Forward-thinking distributors maintain flexible production schedules that accommodate small-batch custom colors or exclusive design runs. They anticipate regional preferences—matte black finishes for urban tuners, vibrant color-matching for show circuits and reinforced lower cores for rally enthusiasts. Digital ordering systems with integrated CAD previews let customers visualize bumper contours on their exact chassis before committing. This responsiveness to market flux cements long-term partnerships and positions suppliers at the forefront of the EVO 9 aftermarket.

Looking ahead, the EVO 9 bumper landscape will continue to embrace cutting-edge processes. 3D scanning and additive manufacturing promise rapid prototyping of bespoke grille patterns and personalized vent layouts. New composite formulas infused with natural fibers and recycled polymers aim to reduce environmental impact without sacrificing strength. Virtual reality configurators will let drivers tweak bumper angles, vent sizes and grab-handle reinforcements in real time. As the tuning community demands ever-faster lead times and deeper personalization, the synergy between performance engineering and visual artistry will define the next generation of EVO 9 bumpers.

Across performance halls, garage workshops and online forums, the convergence of aerodynamic refinement and customizable styling fuels a market that is as much about individual identity as it is about horsepower and handling. The EVO 9 bumper has evolved from a protective panel to a strategic performance asset and personal signature piece—proof that even the smallest exterior component can carry a big statement.

Final thoughts

As we have explored, the EVO 9 bumper is not merely an aesthetic upgrade but a critical component that enhances performance and safety. Through advanced materials like carbon fiber and fiberglass, and innovative aerodynamic designs, this bumper significantly contributes to vehicle efficiency and driving experience. Additionally, understanding current market trends and customization options can empower business owners to meet the demands of automotive enthusiasts. By keeping abreast of these insights, you can better position your offerings within the competitive aftermarket landscape.