The Mitsubishi Lancer Evolution X stands as a pinnacle of engineering excellence in the automotive world, driven by the formidable 4B11T turbocharged engine. This introduction to the Lancer Evolution X engine encapsulates its technological innovations, performance metrics, aftermarket potential, historical significance, and how it compares in today’s market. As we delve into each chapter, business owners and automotive enthusiasts alike will discover actionable insights into what makes the Evolution X engine not just a success story in motorsports, but also a durable and adaptable powerplant for both performance and practical use.

Why the 4B11T Defines the Evo X: A Deep Look at Its Turbocharged Heart

The Lancer Evolution X’s engine is more than a power source; it is the central character in the car’s performance story. The 4B11T, a 2.0-liter, turbocharged, direct-injection inline-four, marks a deliberate shift from earlier Evolution engines. It blends modern materials, advanced valve control, and refined forced induction into a unit that balances daily drivability with serious tuning potential. Understanding what makes the 4B11T special reveals why the Evo X feels so immediate on the road and so promising on the dyno.

At the foundation is variable valve timing. The engine employs MIVEC—an adaptive valve control system that adjusts timing and lift across operating conditions. MIVEC smooths the trade-off between low-end torque and high-rpm power. At low speeds it helps fill the torque band, making the car responsive from a stop. At higher revs, it reconfigures the valves to allow freer breathing and stronger power delivery. When combined with turbocharging, this flexibility reduces the compromise usually required in a turbo engine tuned for both street and track use. The result is an engine that feels lively under light throttle and potent when pushed hard.

Turbo design matters as much as valve control. The 4B11T uses a twin-scroll turbocharger arrangement. Twin-scroll technology separates exhaust pulses into two paths before they hit the turbine. This separation reduces pulse interference and preserves exhaust energy. The immediate outcome is faster spool and less perceptible lag. Drivers notice a tighter torque curve and more linear throttle response. For a performance sedan whose driving character must be predictable, twin-scroll turbocharging gives the 4B11T composure whether accelerating out of a hairpin or merging at highway speed.

Fuel delivery is equally important. The engine’s high-pressure direct injection places fuel into the combustion chamber under pressure. Direct injection improves atomization and allows for more precise fuel metering. That precision supports higher compression and tighter ignition timing, both of which help extract power while maintaining efficiency. Compared to older port-injected setups, direct injection also reduces the likelihood of detonation under boost when paired with proper tuning and fueling upgrades. For tuners, that means a platform that can be safely pushed further with the right supporting modifications.

Material choices keep the package light. Aluminum alloy is used for both the cylinder block and head. Weight savings in the engine help the car’s overall balance and handling. A lighter front end reduces understeer tendencies and improves turn-in. This was an intentional move toward a more agile chassis. The engine’s compactness and mass reduction also aid cooling and vehicle dynamics, particularly when the car is driven hard over a variety of roads.

Cooling and charge-air management are integral to reliable power. The 4B11T pairs with a front-mounted, water-cooled intercooler that removes heat from compressed intake air before it enters the cylinders. Cooler, denser air carries more oxygen and lowers combustion temperatures. This enhances both peak power and consistency over multiple hard runs. Efficient intercooling is a key reason the 4B11T can sustain elevated boost without sacrificing detonation resistance or performance stability.

Factory output varies across years and special editions, but typical figures fall between roughly 291 and 303 horsepower, with torque around the 366 to 422 Nm range, depending on specifics. These numbers reflect a careful balance: enough factory power to meet enthusiast expectations, but conservatively tuned to ensure reliability and regulatory compliance. The final limited-run models nudged peak output upward and paired the engine with a manual transmission in certain variants, underscoring the platform’s sporting intent as the Evo series reached its last production chapter.

Beyond factory form, the 4B11T has earned a reputation in the tuning community for robustness and adaptability. Its aluminum construction and modern valvetrain are designed with performance in mind. Builders routinely fit larger intercoolers, high-flow intake systems, and upgraded turbochargers to unlock additional horsepower. Custom ECU calibration is a common step to harmonize those hardware changes. Well-executed tuning expands the engine’s power range while preserving drivability. For enthusiasts, this scalability is the 4B11T’s most compelling trait: it thrives under careful modification and rewards incremental improvements.

Some aftermarket paths focus on internal strengthening or improved cooling. Billet blocks and reinforced components are available for those planning substantial boosts in power. These parts extend the engine’s mechanical limits, enabling higher cylinder pressures and sustained performance on track. For owners who prefer bolt-on improvements, an efficient intercooler, a refined intake, and a tuned engine management system deliver significant gains without the complexity of internal work. The choice depends on goals: a balanced street build favors reliability and torque; a track-oriented conversion emphasizes cooling and internal durability.

Engine management and electronics are central to extracting the 4B11T’s potential. The factory control unit coordinates MIVEC, direct injection timing, boost targets, and safety maps. Retuning the ECU is often necessary after mechanical changes. Modern tuning strategies use mapped ignition, fuel, and boost control to manage knock thresholds and air-fuel ratios. This electronic layer allows tuners to carefully expand the engine’s performance envelope while maintaining crucial protections. In many builds, software changes deliver as much practical benefit as hardware swaps.

Maintenance and cooling system health are practical considerations for longevity. Higher boost levels increase thermal and mechanical stress. Owners who increase power should prioritize oil and cooling upgrades, and ensure that intake air remains cool even during repeated full-throttle runs. Regular inspection of hoses, intercooler connections, and the turbo wastegate mechanism helps prevent failures before they occur. Simple preventive maintenance often determines whether a tuned 4B11T lives a long, productive life or encounters avoidable setbacks.

What makes the 4B11T stand out is not a single feature but the way its technologies work together. MIVEC brings flexibility to the valvetrain. Twin-scroll turbocharging sharpens response. Direct injection delivers efficient combustion. Aluminum construction improves dynamics. The cumulative effect is an engine that is both refined and eager. It suits everyday driving, yet reveals new layers when pushed. That dual nature is why the Evo X remains a favorite among drivers who want a car that is both usable and capable of serious performance work.

The 4B11T’s place in the evo lineage reflects a philosophy rather than a checklist. It is an engine that accepts compromise only where necessary and prioritizes the driving experience. For someone who values throttle feel, immediate torque, and the ability to tune without starting from scratch, the 4B11T offers a clear path forward. From factory form to fully modified builds, it is an adaptable heart that keeps the Evo X relevant for drivers and tuners alike.

For those considering upgrades, resources and components tailored to the 4B11T are available, including enhanced blocks for high-power projects. One useful reference for parts is the 4B11T billet block listings, which can help plan an internal build. https://mitsubishicars.com/en-us/technical-resources/mivec-engine-explained

Measured Might: Power, Torque and Real-World Performance of the Lancer Evolution X 4B11T

Power and Torque: How the 4B11T Defines the Evo X Driving Character

The heart of the Lancer Evolution X is the 4B11T, a 2.0‑liter, all‑aluminum, turbocharged inline‑four. Its architecture blends modern engine technologies and motorsport heritage to produce a compact, potent powerplant. On paper, the factory 4B11T delivers roughly 217 kW (about 291 horsepower) and 366 N·m (269 lb‑ft) of torque, with peak torque accessible at a modest 3500 rpm. Those figures tell part of the story. Equally important is how the 4B11T makes power across the rev range, how it pairs with transmissions, and how chassis systems turn numbers into acceleration, cornering speed, and everyday usability.

When you examine the 4B11T’s output curve, the relatively low peak torque rpm stands out. Torque arriving from 3500 rpm means the engine has strong midrange punch. That midband thrust is ideal for both quick overtakes and rapid exits from corners. Drivers seldom need to wring the engine to reach usable power. The result on the road is a car that accelerates eagerly from reasonable revs, without the lag associated with older, smaller‑turbo setups. This characteristic also helps in traffic and during spirited canyon runs, where immediate response matters.

Peak power around the top end remains accessible, though the 4B11T does not rely on an extreme, narrow powerband. Instead, it offers a broad spread of usable torque, which contributes to tractable, predictable behavior under boost. Turbocharged engines are frequently judged by their response and plateau width. The 4B11T combines a crisp transient feel with a sustained power plateau, giving drivers both snap and endurance through long, high‑speed runs.

Transmission choice changes the car’s character significantly. The Evo X shipped with two main options: a 6‑speed twin‑clutch TC‑SST automatic and a 5‑speed manual. The dual‑clutch system delivers lightning‑fast shifts and allows precise launch control strategies that exploit the engine’s torque. In track or roll‑race scenarios, the TC‑SST keeps the engine in the optimal torque band without interrupting traction. Conversely, the 5‑speed manual gives a more visceral, engaged experience. With the manual, the driver can exploit engine torque with carefully timed clutch work and gear selection. Both transmissions have tradeoffs: the TC‑SST optimizes lap times and consistency, while the manual rewards driver skill and modulation.

Measured acceleration reflects the synergy between engine, drivetrain, and AWD control. The factory 0–100 km/h (0–62 mph) time of about 5.9 seconds shows that the car’s systems work in concert. All‑wheel drive, specifically the Super All‑Wheel Control (S‑AWC) system, routes torque intelligently to preserve traction and stability. At launch, S‑AWC helps prevent wheelspin and maximizes grip, allowing the 4B11T’s thrust to be translated to forward motion efficiently. On high‑grip surfaces, the result is strong, repeatable launches. On low‑grip surfaces, the system provides stability without overly smothering the car’s dynamic edge.

Under spirited driving, the 4B11T’s torque delivery and the Evo X’s AWD mapping create a unique balance. Corner entry can be brisk, because torque is available early. Exit is confident because S‑AWC can send torque to the wheels with the most traction. The engine’s midrange strength reduces the need to downshift drastically, letting drivers maintain momentum through linked corners. This is one reason the Evo X feels composed on a road or short circuit: power and control are synchronized.

Beyond factory tuning, the 4B11T has become a favorite for enthusiasts who want more. The stock internals and cooling layout tolerate moderate increases in boost when combined with support upgrades. Popular upgrades include larger, more efficient intercoolers, freer‑flowing intake systems, optimized wastegate and boost control, and retuned engine management. Turbocharger upgrades are a frequent path to larger gains, and many builders choose compound or larger single‑turbo setups to push output significantly higher. The engine’s aluminum block and head reduce mass and help with heat rejection, but increased power still requires upgraded cooling and fueling to maintain safe operation.

A common upgrade thread touches the physical robustness of the engine. For those planning major power increases, forged internals and strengthened blocks are logical considerations. There are aftermarket solutions that focus on reinforcing the 4B11T’s bottom end for high‑boost builds. For tuners who prefer bolt‑on improvements first, increasing intercooler capacity and optimizing airflow are high‑impact, cost‑effective steps. If you explore deeper machine work or swaps, researching options such as a dedicated billet block is a sensible step. For reference on those heavy‑duty upgrades, see the community resource on the 4B11T billet block for information about reinforced blocks and their role in high‑power builds: 4B11T billet block.

Practical performance also depends on thermal management. The turbocharged 4B11T generates significant heat under load. Upgraded intercoolers and more efficient charge piping reduce intake air temperatures. Cooling system improvements, such as higher‑capacity radiators and thermostatic controls, help maintain consistent power over extended hard runs. Keeping intake temperatures low preserves knock resistance and allows more aggressive, yet safe, ignition timing and boost levels during tuning.

In real‑world scenarios, drivability is a headline advantage. The 4B11T produces strong torque where most drivers operate. That makes daily driving easier and more enjoyable. You get brisk acceleration without excessive rev hunting, and you can extract lap‑time performance without continuous, radical inputs. Fuel efficiency, while not a primary selling point, benefits from MIVEC variable valve timing. MIVEC optimizes valve timing for different loads and speeds, smoothing power delivery and helping efficiency when outright performance isn’t required.

Reliability in everyday and performance contexts stems from careful factory engineering. The Evo X’s engine learned from rally and road car experience. Conservative thermal tolerances, modern materials, and precise factory calibration produce an engine that can endure spirited use. Still, longevity under increased power needs deliberate upgrades to cooling, fueling, and internals. Regular maintenance and attention to oil and coolant condition remain essential for any turbocharged engine, particularly when modifications raise operating stresses.

The way the 4B11T communicates through the car is important. Driver feedback comes not only from the engine but from the transmissions and the AWD system. The TC‑SST’s quick shifts and the manual’s mechanical engagement alter the perceived power. S‑AWC’s torque vectoring and stability interventions shape handling and confidence. When all systems work together, the result is a car that converts metric figures into measurable, repeatable performance on both road and track.

Numbers matter, but context is everything. A peak horsepower figure of roughly 291 and a torque peak of 366 N·m are useful benchmarks. Yet those numbers are amplified by a broad torque band, intelligent AWD control, and transmission options that let drivers choose their preferred style. The Evo X’s real strength lies in the completeness of the package: an engine that delivers power where it’s needed, chassis systems that make use of it, and a marketplace of upgrades for those who want more. For independent measurements and a deeper look at how these specifications translate into on‑road performance, consult external road test data from a reputable automotive reviewer: https://www.caranddriver.com/mitsubishi/lancer-evolution-x/reviews/a28026/mitsubishi-lancer-evolution-x-review/.

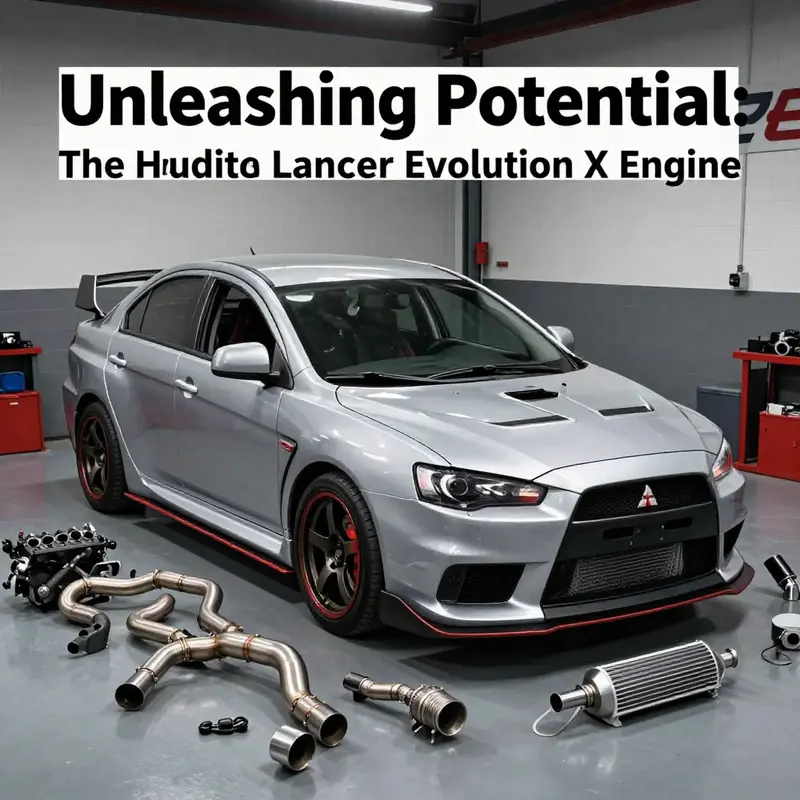

Unlocking the 4B11T: Practical Tuning Paths and Real-World Upgrades for the Evo X Engine

Tuning the 4B11T: Pathways, Pitfalls, and Priorities

The 4B11T at the heart of the Lancer Evolution X is a compelling mix of lightweight engineering and rally-bred performance. Its all-aluminum block and MIVEC variable valve timing provide a modern baseline that responds well to measured modification. For enthusiasts and professional builders alike, the question is not whether the engine can be tuned, but how to do it in a way that balances power, drivability, and longevity. This chapter walks through practical upgrade paths, critical supporting systems, and common mistakes to avoid when turning Evo X potential into repeatable performance.

Start with goals. A street-friendly increase in power requires a different plan than a track-focused 500+ horsepower build. For modest gains, bolt-ons and a calibrated tune are efficient. For serious outputs, internal strength, fueling, and cooling must be addressed first. Across both approaches, the turbocharger sits at the center. Swapping to a larger, more efficient turbo will unlock the greatest gains, but it changes the engine’s breathing and thermal profile. Matching turbine and compressor choices to your target powerband matters more than picking the biggest unit available. A properly matched turbo improves spool, reduces turbo lag, and gives predictable boost control.

When the turbo is upgraded, the intercooling system becomes more than a convenience. Upgrading to a higher-capacity intercooler lowers intake air temperatures under load. Cooler, denser air reduces detonation risk and increases consistent power through long pulls. Likewise, the intake and exhaust systems should be optimized to remove restrictions. High-flow intake plumbing, a larger front-mount intercooler, and a free-flowing exhaust reduce backpressure and improve turbo efficiency. But airflow without precise fueling and timing invites danger. That is where a custom ECU program becomes indispensable. Proper engine management adjusts fuel delivery, ignition timing, and boost control to suit the new hardware.

Fueling is the invisible backbone of any high-output build. Upgrading injectors and fuel pumps ensures consistent fuel delivery under boost. Inadequate fuel supply leads to lean conditions and catastrophic failures. Add a fuel pressure regulator and a return-style setup if your build crosses factory fueling limits. On builds that significantly increase power, switching to larger injectors and a higher-flow pump is non-negotiable. Monitoring fuel trims and using a wideband oxygen sensor during tuning helps verify safe air-fuel ratios across the rev range.

Internals define the ceiling. For builds that target outputs beyond the mid-400s horsepower, forged pistons and stronger connecting rods become essential. The stock bottom end handles a surprising amount, but it is not an unlimited platform. Upgrading to forged components reduces risk of piston failure and rod stretch under high boost. Consider also crank and main bearing upgrades for high-mileage or high-stress applications. For teams pursuing extreme power goals, aftermarket block options and reinforcement techniques exist. One such route is replacing or modifying the block with a billet or reinforced unit when chasing reliability under very high cylinder pressures. If exploring that path, research reputable sources and machining practices carefully; poor fits or improper clearances cause worse outcomes than stock parts.

Compression ratio and engine geometry matter for tuning choices. When installing a larger turbo, many tuners lower static compression to avoid detonation under increased boost. That can be achieved with different pistons or careful tuning. Cylinder head work, including porting and upgraded valves, improves flow at the top end and smooths the transition to larger turbo setups. Valve springs and retainers are cheap insurance when lift increases or steady high-rpm operation is expected. MIVEC complicates matters slightly because its variable timing benefits blending drivability with peak power. A good tune accounts for the timing map and optimizes midrange torque without sacrificing peak output.

Thermal management cannot be an afterthought. High-power sessions, whether on track or in spirited street driving, generate sustained heat. Upgrading the cooling system, adding an oil cooler, and improving radiator capacity maintain stability. Oil temperature control is particularly critical; high oil temps degrade lubrication and accelerate wear. A robust oil supply, a competent oil cooler, and careful routing of oil lines will protect bearings and turbo bearings under sustained stress.

The transmission and drivetrain must match the engine’s ambitions. The Evo X platform features capable gearboxes, but clutches, flywheels, and differentials will need upgrading as torque climbs. For AWD systems, differential tuning and clutch packs are often necessary to distribute the extra torque reliably. Gear ratios play a role too; taller or shorter ratios change the way power is used on track or street. A drivetrain built to handle the new torque curve prevents drivetrain lash and catastrophic failures under load.

Electronics and data acquisition turn guesswork into repeatable results. A standalone or piggyback engine management strategy allows precise control over boost, fueling, timing, and safety parameters. Log everything during the tuning process: intake temperatures, exhaust gas temperatures, knock events, air-fuel ratios, and boost targets. Use the data to refine maps and to detect early signs of stress. Good data reduces risk and shortens development cycles.

Sourcing parts and choosing suppliers is a practical concern. The Evo X enjoys a vast aftermarket ecosystem, so reputable suppliers for 4B11T-specific components are plentiful. For high-risk components like forged internals or a billet block, choose manufacturers with proven tolerances and clear warranty or support policies. For those buying parts wholesale or building inventory for customers, relationships with trusted distributors offer steady supply and better lead times. Even when building on a budget, spending on critical components such as fuel delivery, cooling, and forged internals yields better long-term value than cutting corners on these items.

Installation quality matters as much as parts selection. Proper torque sequences, fresh gaskets, and correct clearances ensure the work lasts. For turbo installations, pay attention to oil feed and return lines, thermal shielding, and wastegate control. When machining heads or blocks, follow established best practices. Small errors in assembly translate into large failures under boost.

Finally, plan for progressive upgrades. Stage your build to allow testing and validation between major changes. Start with intake, exhaust, and a tune. Then move to a larger intercooler and improved fueling. Upgrade the turbo and internals as needed. This stepped approach reduces risk and keeps the car usable throughout the build.

The 4B11T offers a combination of adaptability and performance that rewards thoughtful, methodical tuning. Whether you aim for a streetable Evo X with sharper throttle response or a competition car pushed to four-figure outputs, success depends on balancing airflow, fueling, thermal control, and mechanical strength. For those considering extreme block work, a reinforced or billet option is available within the community; research and vet that route thoroughly before committing. For a practical resource on the engine’s variable valve timing architecture and its design principles, consult this technical guide on MIVEC for deeper insight: https://www.mitsubishi-motors.com/en/technical/mivec-engine-explained.

For parts that specifically address block reinforcement and high-stress builds, the 4B11T billet block offering is a common search term among builders and can be a starting point when planning an all-out build: 4B11T billet block.

Careful planning, sensible staging, and attention to supporting systems turn the Evo X from a fast car into a durable, tunable platform. With the right approach, the 4B11T rewards patience with both reliable performance and a broad spectrum of tuning paths.

From Rally Roots to a New Chapter: The Evolution X Engine’s Place in Mitsubishi’s Legacy

The story of the Lancer Evolution X engine is not just a tale of cylinders and boost. It is a narrative about lineage, transition, and technical choices that reflect decades of motorsport experience. For enthusiasts, the name evokes rally stages, late-night tuning sessions, and the unmistakable feeling of a well-balanced all-wheel-drive performance sedan. To understand the Evolution X’s engine in context, you must see it as both a culmination and a turning point: the point where a storied powerplant’s legacy met a modern, aluminum-engine philosophy.

Across the Evolution line, one engine achieved iconic status. That unit, a 2.0-liter turbocharged inline-four, built its reputation on robust internals, straightforward architecture, and an ease of modification that made it a tuner’s favorite. It powered early rally-born models and proved itself durable in both competition and road use. Because of its proven track record, the engine became synonymous with the brand’s performance identity. Owners and racers learned how the block responded to increased boost, how its head reacted to higher compression, and what changes yielded predictable gains. Over the years, this engine matured. Refinements in fueling, turbochargers, and engine management pushed its limits in production and aftermarket contexts. As a cultural touchstone, it connected generations of drivers to a shared mechanical heritage.

When the tenth generation arrived, engineers made deliberate choices. The platform was all-new, designed for improved torsional rigidity, modern suspension geometry, and advanced electronic control systems. The engine bay, weight distribution, and systems like torque vectoring received fresh thinking. Under this contemporary approach, the new powerplant embraced an aluminum alloy block and head, variable valve timing, and a focus on mass reduction without sacrificing strength. These choices reflected a broader industry shift toward lighter, more efficient engines that could still deliver high specific output. The new engine adopted technologies intended to optimize torque delivery across a wider band. That trait fit the character of a car built to be nimble, responsive, and tractable in everyday driving, as well as quick on a closed course.

This transition did not erase the influence of the earlier engine. Instead, the earlier design’s philosophy—simplicity, strength, and tunability—continued to inform development decisions. The new engine was engineered with serviceability and upgrade potential in mind. While internal geometry and materials changed, the idea that a compact, high-output turbocharged four could be both reliable and highly tunable persisted. The tuning community embraced the new architecture with familiar vigor, adapting intercooling, intake, and turbo solutions to extract extra power. The same hunger that once modified the older engine now studied fueling maps, cam timing, and boost control for the new unit. That continuity of aftermarket energy helped ensure the new engine would be judged not only by factory figures, but by what it could become.

On the chassis side, the tenth generation introduced advanced stability and traction systems that merged with engine control to change how power got to the road. Electronic torque distribution, yaw management, and precision ABS calibration meant the engine no longer had to produce power in isolation. Instead, its character became part of a larger integrated driving system. Peak torque and horsepower became components in a broader equation that included steering feedback, suspension compliance, and electronic assistance. For drivers, that resulted in an experience that felt modern yet evocative. The new engine’s torque curve and response were tuned to play well with these systems, providing strong midrange thrust and usable delivery that encouraged confidence in corners.

The final special editions of the series offered a distilled expression of the engine’s potential. Tuned outputs, revised gearing, and manual transmission pairings were gestures toward the enthusiast base. These models demonstrated that engineering could balance factory refinement with a rawer, more analog driving feel. The limited-run variants celebrated the lineage while recognizing the need to evolve. Part of that celebration was the recognition that legacy engines had earned their place through decades of competition, but the brand’s engineers had to meet modern standards for emissions, safety, and packaging. The end result was an engine that honored heritage through intent rather than replication.

Historically, this chapter matters because it reframed what the brand’s performance identity could be. The classic engine was more than metal and spark timing; it represented an era where mechanical sympathy and bolt-on upgrades defined community. The newer engine signaled a move toward systems integration, material science, and electronic control. Yet it did so without abandoning tunability. That balancing act—retaining enthusiast appeal while embracing modern engineering—was central to the Evolution X story.

For the aftermarket, the transition opened new avenues. The older engine’s parts and knowledge base remained valuable. Low-mileage examples continued to circulate among collectors and rebuilders. At the same time, the new engine’s architecture inspired bespoke upgrades: intercoolers scaled for improved thermal management, high-flow intake systems shaped for the revised manifold, and carefully calibrated ECU strategies. Turbocharger enhancement kits and intake manifolds designed for the aluminum head allowed meaningful gains while respecting component limits. In short, the aftermarket adapted, blending old-school performance goals with contemporary engineering approaches.

Within motorsport and enthusiast circles, the Evolution X engine’s significance extends beyond figures and components. It symbolizes a brand’s attempt to reconcile two demands: remain true to a rally-bred past while meeting the future’s engineering constraints. That reconciliation required compromises and innovations. Engineers preserved the spirit of the earlier powerplants—focused power delivery, robustness, and tuning potential—while adopting materials and systems that reduced weight and improved thermal efficiency. The result was an engine that could handle the stresses of spirited driving while integrating seamlessly with modern chassis dynamics.

The narrative of the Evolution X engine also highlights how technological shifts change community practices. Where once a cam swap and a turbo upgrade sufficed, tuners increasingly consider software, airflow, and cooling as integrated systems. This systems-level thinking led to more reliable high-power builds. It also spread knowledge about how different materials and manufacturing techniques influence reliability at high output levels. Enthusiasts who prized legacy engines began to appreciate the advantages of lighter components and variable valve timing. Meanwhile, younger tuners, entering the scene with a modern engine as a starting point, benefited from a vast archive of collective know-how passed down from the earlier era.

Viewed over time, the Evolution X engine stands as both an endpoint and a bridge. It marked a decisive technical shift and served as a conduit between generations of drivers and builders. The engine’s legacy is therefore twofold: it honors the mechanical lineage through shared tuning culture, and it pushes that culture forward through improved materials and control systems. That dual role explains why it remains a subject of fascination and debate among enthusiasts. It represents a moment when tradition and progress met under the hood, each informing the other.

For anyone tracing the lineage of high-performance, turbocharged four-cylinder engines from rally stages to today’s street builds, the Evolution X’s engine chapter is essential. It is not the end of a story, but a hinge. Through it, legacy knowledge found new expression, and a modern powerplant earned its place in a long-running performance narrative. For deeper context on the model’s evolution and historical milestones, see the official archive on the brand’s evolution history: https://www.mitsubishi-motors.com/en/evolution/history.html

Explore a tangible connection to that legacy with a listing for an original low-mileage engine from the earlier generation, available as an example of the enduring appeal of these designs: genuine JDM 4G63T low-mileage engine listing.

Heartbeat of a Rally-Bred Shape: Placing the Lancer Evolution X’s 4B11T Engine in the Performance Sedan Landscape

The Lancer Evolution X stands as the final chapter in a lineage built on rally-bred resolve, and at its core sits a powertrain that has become almost legendary among enthusiasts: a 2.0-liter, all-aluminum inline-four turbocharged engine. The 4B11T is more than a simple displacement on a spec sheet; it is a coordinated ensemble designed to deliver peak performance with a measured approach to reliability. In factory form it produces power in the high two-hundred horsepower range and torque in the mid-range, numbers that place the Evo X in the upper echelon of its class. But those numbers only hint at the engine’s true personality. What makes it compelling is how Mitsubishi integrated timing, materials, and cooling to create a compact powerplant that can sustain punch through a demanding driving cycle while remaining approachable for daily use. The 4B11T’s aluminum block and head reduce unsprung and overall weight, a design choice that pays dividends in agility and throttle response. MIVEC, Mitsubishi’s variable valve timing system, adds a layer of adaptability, optimizing flow and combustion across a broad engine map, which translates into crisp midrange response and efficient operation when the car is driven with restraint. Twin-scroll turbocharging further sharpens the throttle feel, reducing lag and delivering a more immediate surge as boost builds. The engine’s cooling architecture is a model of efficiency, with a multi-waterway cooling system that reduces heat soak during extended sessions on track days or spirited highway runs. All of these elements come together to form an engine that is not just strong on paper but coherent in practice, where smooth torque delivery and progressive power build contribute to a sense of confidence that drivers can rely on after extended periods of high-load use.

The Evo X’s power figures reflect a carefully tuned balance. In its standard configuration, the engine produces horsepower in the close-to-300 mark and peak torque that remains plentiful across the RPM band. This balance is essential for a car that relies on precise chassis dynamics as much as raw output. The turbocharged inline-four is paired, in some variants, with a five-speed manual transmission that emphasizes driver engagement; in other editions, different drivetrain configurations offered variations in feel and response. The Final Edition, a notable milestone within the lineup, pushed peak output to a higher ceiling while preserving the familiar, communicative driving experience that has become the Evo X’s calling card. Beyond raw numbers, the 4B11T’s reputation rests on how a well-tuned engine can be both exhilarating on a twisting road and dependable in routine use, a dual reputation that has helped the Evo X endure in a market that often shifts toward new technology or different propulsion philosophies.

What makes the Evo X unique within the performance sedan segment is the way its engineering philosophy extends beyond the engine itself. The car’s drivetrain architecture is designed to exploit the engine’s strengths through a holistic approach to handling and traction. The suspension and steering system work in concert with the engine’s throttle response to produce a cohesive chassis dynamic. The all-wheel-drive system—paired with a sophisticated torque-vectoring setup—translates that engine personality into controllable grip and selective power delivery. The result is a sedan that can change character between a tractable daily car and a precise, almost go-kart-like machine on a back road. The braking system, featuring high-performance components, ensures that the chassis remains predictable under heavy use, complementing the engine’s power delivery with control and fade resistance. In this sense, the Evo X embodies a philosophy where engine tuning, chassis engineering, and electronic governance are not separate boxes to tick but parts of a single, integrated system that seeks to maximize a driver’s expressive capabilities behind the wheel.

From a market perspective, the Evo X has always lived in a space where enthusiasts value driver involvement as a core virtue. In a class that also includes rivals armed with turbocharged four-cylinders of various displacements and turbo schemas, the Evo X emphasizes a holistic proposition: potent power coupled with a chassis that communicates mechanically and audibly with the driver. A rival hatch with a larger-displacement turbo engine might offer stronger mid-range torque and a broader powerband, while another competitor could lean on refinement, interior packaging, or infotainment integration to broaden appeal. Yet what often tilts the balance in favor of the Evo X is the way its powertrain interacts with the chassis in real-world driving. The engine’s torque peak may arrive at a different RPM than a competitor’s, but the way the torque is delivered—its rate of rise, the immediacy of response, and the way boost builds into a clean, progressive surge—creates a sensation that a driver can read and anticipate. And in a segment where steering feel, throttle response, and cornering grip determine track-day performance as much as peak horsepower, the Evo X presents a compelling, driver-centric equation.

It is here that the story of the 4B11T transcends simple comparison. The engine’s architecture—aluminum construction, MIVEC timing, twin-scroll turbo, and a cooling system designed for sustained pressure—contributes to a package that handles well even under repeated performance demands. This reliability and predictability, especially when paired with OEM components that honor the engine’s original balance, has helped cultivate a loyal after-market following. The tuning landscape around the 4B11T has flourished precisely because the engine responds well to upgrades that expand airflow, improve heat management, or reflect more aggressive fueling maps, while still preserving the fundamental character that makes the Evo X engaging to drive. The community’s enthusiasm for upgrades like larger intercoolers, high-flow intake systems, and ECU programs underscores a broader point: the Evo X engine is not a finicky, one-note performer. It is a platform with a robust foundation that invites thoughtful modification without compromising the essential harmony between engine, drivetrain, and chassis.

Within this ecosystem, a strengthened bottom end—such as a purpose-built billet block—has become a focal point for enthusiasts seeking higher power thresholds while maintaining reliability. The practical appeal of such a component lies in enabling elevated boost pressures and sustained high-rpm operation without compromising durability. This line of thought is not simply about chasing peak numbers; it is about preserving the engine’s liveliness and pressure-ready torque while expanding the envelope of what the car can do on a track or a spirited road session. In discussing the 4B11T, it is impossible to ignore the community’s practical wisdom: engines designed with a robust core, well-managed cooling, and precise electronic control can evolve into genuinely formidable performance platforms without losing their composure under the demands of daily driving. This philosophy parallels the Evo X’s broader market narrative, where enthusiasts value a transparent link between performance, reliability, and the thrill of driving.

For readers curious about the engineering specifics that underpin this balance, there is a practical thread worth following. The bottom end strength and a design that accommodates both lightweight construction and rigidity play a central role in enabling higher power goals. The idea is to provide a foundation that can resist the additional stresses of upgraded boost and airflow while preserving the engine’s characteristic responsiveness. In this sense, the 4B11T becomes more than a power unit; it is a platform that embodies a philosophy of efficiency, resilience, and driver engagement. It is precisely this combination that has helped the Evo X maintain its identity in a rapidly evolving market where electrification, SUV prevalence, and increasingly sophisticated digital conveniences shape consumer expectations. The Evo X remains a beacon for the art of the traditional internal combustion performance sedan, where mechanical feedback, linear torque, and a chassis tuned to amplify driver input deliver a compelling driving experience.

Within the tuning community, the 4B11T’s strength is widely explored in configurations that push the engine toward higher power while preserving bottom-end liveliness and high-speed stability. The possibility of upgrading the block and refining the internals complements the stock architecture, enabling a broader range of setups that can be tailored to track days or weekend fun. This adaptability is a hallmark of the Evo X platform, confirming that a well-engineered turbocharged inline-four can stay relevant even as automotive trends shift toward new propulsion philosophies. In sum, the Evo X engine is not merely an artifact of its era; it remains a conduit for driver-focused enjoyment, a benchmark of how a compact, turbocharged four can deliver exhilarating performance through a refined orchestration of power delivery, chassis balance, and purposeful engineering. The result is a car that speaks to enthusiasts with a clear, confident voice, inviting them to explore its limits with the same precision that Mitsubishi engineers embedded in its design.

For readers seeking more technical depth on the engine and drivetrain, official Mitsubishi technical documentation offers a detailed reference point that complements this chapter’s narrative. The 4b11t billet block is a tangible example of how engineers and builders think about strengthening the essential core to unlock higher performance while preserving reliability. This kind of specification-oriented exploration underscores the Evo X’s enduring status as a benchmark in the compact performance sedan category. In the end, the Lancer Evolution X’s engine is remembered not only for its numbers but for the way it harmonized power, response, and chassis communication into a driving experience that remains both immediate and precise.

External reference for deeper technical insight into the engine and drivetrain architecture can be found through official Mitsubishi technical resources, which offer comprehensive diagrams, specifications, and calibration notes that illuminate how this powertrain operates under a variety of conditions and configurations: https://www.mitsubishi-motors.com/global/support/technical-documents

Final thoughts

The Mitsubishi Lancer Evolution X with its 4B11T engine exemplifies the perfect fusion of technological advancement, unyielding performance, and remarkable potential for adaptation in the aftermarket scene. Understanding its specifications, tuning possibilities, and historical significance illuminates why it remains a celebrated choice among automotive enthusiasts and business owners alike. Its legacy in racing and personal vehicle applications reflects the ongoing desire for innovation in the automotive sector and highlights the vital role that engines like the 4B11T play in shaping the future of performance vehicles.