A & C Auto Parts & Wrecking Co. stands as a beacon in the used auto parts industry, demonstrating how local businesses can drive economic growth, sustainability, and technological advancement. This article explores their essential role in the market, highlighting the environmental impact of their operations, contributions to their communities, innovations that enhance efficiency, and customer service strategies that set them apart. Each chapter provides insights into the multifaceted nature of A & C Auto Parts & Wrecking Co.’s operations, showcasing why they are fundamental to both the automotive landscape and local economies.

Reviving the Road: A & C Auto Parts & Wrecking Co. as a Cornerstone of the Used-Parts Economy

Located in Cleveland, Ohio, A & C Auto Parts & Wrecking Co. has worn many hats over the years, yet its core mission remains straightforward: to turn wreckage into usable parts, and to keep cars on the road without forcing customers to pay premium prices. Since its founding in 1941, the company has earned a reputation for reliability, breadth of inventory, and a practical approach to repair, maintenance, and sustainability. The site is not merely a yard of rusted shells; it is a carefully managed ecosystem designed to connect salvage with repair. In a landscape where vehicles are sometimes treated as disposable, A & C Auto Parts stands as a counterexample—proof that waste can be minimized, costs can be controlled, and communities can benefit when a local business embraces the circular economy. The story of this company mirrors a broader shift in the automotive world: treating parts as resources and viewing vehicles as collections of assets with multiple lifecycles rather than one-off commodities.

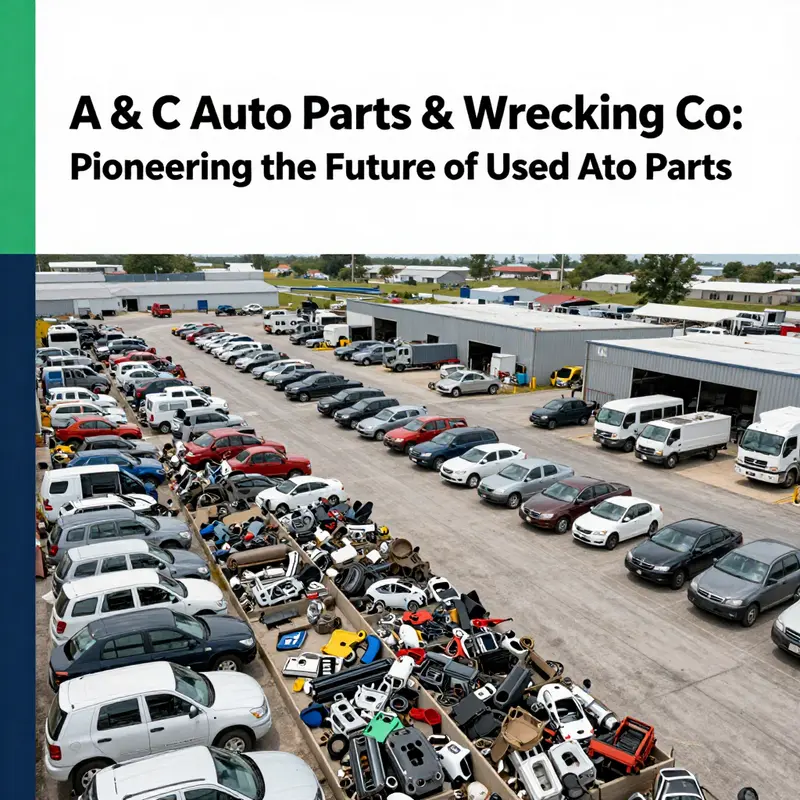

From the outside, one could assume that a wrecking operation is a chaotic warehouse of frames and fluids. Inside, it is a disciplined operation that balances procurement, inspection, and logistics. A & C Auto Parts sources salvage vehicles with a careful eye for parts viability, looking beyond obvious damage to identify components with enduring value. Engines, transmissions, brakes, steering assemblies, doors, fenders, consoles, and countless other pieces are cataloged, tested when feasible, and stored in a way that makes them accessible to customers ranging from professional repair shops to DIY enthusiasts. The breadth of the inventory matters as much as the depth; a shop working on a rare domestic model can still find a hard-to-source item at A & C, thanks to years of stocking and the ability to cross-reference compatibility across generations and makes. This is not about selling the newest gadget but about sustaining reliability through practical reuse.

The dismantling and stocking process is more than a sequence of pulls and labels. It is the curation of a resource that travels through the hands of technicians who understand what makes a part suitable for reuse. Each component passes through a basic quality check, a lightweight inspection that considers wear, corrosion, and any hidden damage. Parts are tagged with origin, mileage when known, and notes on compatibility, so that a repair shop can confidently match a part to a vehicle’s specific needs. The result is a refreshment of stock that mirrors demand, reducing the need to manufacture new parts whenever a salvageable alternative exists. In this way, the yard becomes a living inventory that reflects both the local vehicle mix and broader trends in repair cycles. The company’s long tenure in the region means it has observed shifts in make and model popularity, changes in how cars age, and the evolving needs of garages that depend on a stable supply of affordable components.

Beyond the visible mechanics of sorting and stacking, A & C Auto Parts cultivates relationships with salvage buyers, insurers, and repair professionals. Salvage vehicles arrive through a mix of channels—fleet turnover, insurance settlements, and regional auctions—each presenting a different profile of parts potential and risk. The evaluative step blends experience with practical testing: engines may be run during a controlled bench test, electrical harnesses are traced for continuity, and transmissions are checked for fluid condition and mechanical integrity. This careful triage is essential because it protects the customer and sustains the yard’s reputation for reliability. When parts pass these checks, they move into the catalog that repair shops rely on to keep their customers on the road. In an industry marked by volatility in demand and evolution in vehicle design, such a catalog is not a luxury but a lifeline for shops facing tight schedules and fixed budgets.

The significance of such a business extends beyond the immediate savings it affords to customers. It feeds into a larger ecological and economic logic. Recycling auto parts reduces the energy and raw material requirements of manufacturing new components, while also cutting the environmental footprint associated with disposal and leakage of fluids. By giving new life to engines that still have years of service, or brakes that can meet safety standards again, A & C Auto Parts contributes to lowering the overall footprint of vehicle maintenance. The environmental benefits are complemented by regulatory compliance that ensures safe handling of hazardous materials, proper disposal of fluids, and responsible dismantling practices. In this sense, the company is as much a steward of the local ecosystem as it is a supplier of cost-effective substitute parts. The regulations surrounding waste streams in a regional context may evolve, but the core principle remains the same: waste is a resource that can be captured and redirected, rather than discarded.

This approach also strengthens the community by enabling repair shops to operate with greater resilience. When a local garage struggles to source a particular part for an aging vehicle, it can turn to a nearby yard with a history of steady availability. The quick turnaround time and the ability to match a wide array of parts to different makes and models help minimize vehicle downtime, which in turn supports drivers who rely on their cars for daily life and work. For families and independent repair outfits alike, the availability of reused parts translates into predictable repair costs and faster service. The economic ripple effects extend to the broader local economy: a steady demand for salvage parts supports jobs, from yard staff and dismantlers to logistics personnel and shop technicians who interface with customers. In a region where vehicle dependence is high and transportation costs matter, the ability to choose affordable, sustainable options is not a luxury but a practical imperative.

The broader market context helps illuminate why A & C Auto Parts matters. The used auto parts industry is a multi-billion-dollar sector that continues to grow as vehicles last longer and repair costs rise. Consumers increasingly seek economical solutions that extend the life of a vehicle rather than replace it. This shift aligns with a growing cultural preference for sustainability and responsible consumption, where reusing components is viewed not as second best but as a viable, high-value option. For repair shops, the accessibility of a diverse inventory means fewer delays and fewer returns to vendors due to unavailable parts. Whether a shop is servicing a common family sedan or a rarer import, the ability to source a suitable component locally reduces downtime and improves customer satisfaction. In this way, A & C Auto Parts becomes a conduit through which regional demand meets a sustainable supply, reinforcing the economics of repair rather than replacement.

In navigating the challenges and opportunities of this space, the company embodies adaptability. The landscape of auto parts is increasingly digital, with cataloging, price benchmarking, and cross-vehicle compatibility often aided by databases and diagnostic tools. A & C Auto Parts has to balance its physical footprint with the needs of a modern buyer who might begin with an online inquiry and finish with a visit to the yard. The tension between offline practicality and online convenience is not a contradiction but a chance to optimize. A well-run wrecking operation tethers its inventory to a robust internal system that can track part condition, demand signals, and lead times. When models fall out of production, or a generation becomes scarce, the yard can pivot by leveraging legacy stock or repurposing similar components to meet current repair schedules. The capability to source parts from a diverse set of vehicle models further enhances resilience, ensuring that even older or less common vehicles can be serviced. That adaptability rests on decades of experience, a network of relationships with salvage buyers and repair shops, and a steady commitment to quality and reliability.

As the region’s automotive ecosystem continues to evolve, A & C Auto Parts & Wrecking Co. remains a practical anchor for those who believe in repair over replacement and in reuse over waste. The company’s legacy, coupled with its ongoing operations, demonstrates how a single local business can play a catalytic role in shaping both environmental outcomes and the economics of maintenance. News about environmental stewardship, regulatory compliance, and community partnerships rarely makes headline on a daily basis, but the cumulative effect of steady, dependable sourcing is felt by every mechanic who can complete a job quickly, the car owner who pays a fair price, and the neighborhood that benefits from lower waste streams. In this light, the Cleveland operation is more than a business—it is a model of how the automotive sector can thrive when it treats parts as resources with ongoing value, and when a community recognizes the quiet power of reuse in keeping people on the road.

External resource: https://www.acautoparts.com

Reclaiming Value: How A & C Auto Parts Drives Sustainability Through Salvage and Recycling

Sustainability Woven into Salvage Operations

A & C Auto Parts & Wrecking Co. occupies a unique position where commerce and environmental stewardship meet. By dismantling end-of-life vehicles and finding reuse for components, the company reduces waste and diverts materials from landfills. This chapter explores the practical pathways that turn wrecked vehicles into resources, and how those pathways shape local sustainability. The aim is to describe how typical wrecking-yard practices translate into measurable environmental benefits, and where such operations can further improve.

At the heart of the operation is component reuse. Engines, transmissions, doors, and many other parts retain useful life after a crash. Recovering these parts prevents the energy- and resource-intensive process of manufacturing replacements. Reuse also lowers costs for vehicle owners and repair shops. For communities, that translates to more affordable maintenance and longer vehicle lifespans, reducing the total number of vehicles produced and discarded over time.

Metal recycling is another major contributor to sustainability. Steel and aluminum reclaimed from vehicle bodies feed back into metal markets. Recycling metals uses far less energy than producing new metal from ore. That energy delta reduces greenhouse gas emissions and lowers demand for virgin mining. A & C’s sorting and baling of scrap metal streamlines this process, enabling higher recycling rates and more efficient transportation to processing facilities.

Environmental risk management is a central operational concern. Vehicles contain fluids and components that can harm soil and water if mishandled. Proper draining and containment of oil, coolant, brake fluid, and refrigerants prevents contamination. Batteries and airbag modules receive special handling to avoid chemical release or hazardous reactions. A & C likely follows industry protocols for fluid reclamation and component isolation, which reduces liability and protects local ecosystems.

Regulatory compliance plays a dual role. It ensures adherence to environmental protection rules, and it helps standardize best practices across the industry. Permits and inspections require wrecking yards to maintain records and meet disposal standards. Those controls create accountability and encourage continuous improvement in site operations. For customers and neighbors, compliance also communicates a commitment to safety and responsible stewardship.

Operational choices influence sustainability outcomes. Layout and workflow design can minimize soil exposure to hazards. Covered work areas and proper drainage systems limit runoff. Dedicated containment zones reduce cross-contamination between salvaged parts and hazardous materials. Staging parts on pallets or racks also helps prevent accidental spills and simplifies inventory tracking. These relatively simple measures make a large difference when implemented consistently.

Inventory management supports both environmental and business objectives. Accurately cataloging parts reduces redundant dismantling. It also speeds repairs for local shops, cutting vehicle downtime and lowering the need for new part orders. Clear documentation of part condition and provenance increases buyer confidence. Digital inventories and photos further reduce unnecessary trips and phone calls, saving fuel and time. By improving matching between supply and demand, the yard maximizes reuse and minimizes leftover scrap.

Community partnerships multiply the impact of salvage operations. Repair shops, fleet managers, and salvage buyers rely on quick access to parts. By cooperating with local technicians, A & C helps reduce vehicle idling time in driveways, shops, and on tow trucks. Repair shops benefit from lower parts costs. Drivers keep older vehicles on the road longer, which delays the environmental costs tied to producing new cars. Educational outreach to local mechanics about available salvage parts also strengthens the circular economy.

Material recovery extends beyond metals and major components. Wiring harnesses, sensors, trim pieces, glass, and interior materials can often be reused or repurposed. Even small recoveries add up across thousands of vehicles. Recovering these items reduces the volume of mixed waste that would otherwise require energy-intensive sorting at municipal facilities. Creative reuse also opens secondary markets for refurbished parts and accessories.

Waste minimization requires deliberate disposal practices for unrecoverable materials. Non-recyclable plastics, contaminated absorbents, and certain composites must be handled according to hazardous-waste rules. Contracting licensed waste haulers and using certified recycling vendors ensures proper end-of-life treatment. It also reduces the risk of illegal dumping and fines. A & C’s reputation depends on responsible disposal practices that prioritize environmental safety.

Measuring impact helps guide improvements. Tracking metrics such as weight of metals recycled, number of parts resold, volume of fluids reclaimed, and gallons of hazardous waste properly disposed provides a data-driven picture. These metrics identify bottlenecks and opportunities. They also create transparency for regulators, partners, and customers. Over time, benchmarking against regional peers can highlight best practices and growth areas.

Technology adoption accelerates sustainability gains. Fluid reclamation units and refrigerant recovery machines reduce emissions and improve safety. Hydraulic lifts, efficient compressors, and pneumatic tools speed dismantling while lowering fuel use and labor hours. Digital platforms for inventory and sales reduce inefficiencies. Even simple tools, like mobile cameras and barcode systems, increase part traceability and lower the chance of duplicate dismantling.

There are opportunities to expand environmental leadership further. Investing in solar panels for lot lighting or shop operations reduces grid dependence. Rainwater harvesting for non-hazardous cleaning tasks lowers potable water use. Onsite training programs focused on spill response and recycling best practices strengthen staff skills and reduce incidents. Partnerships with academic institutions and nonprofit groups can also bring fresh ideas and grant opportunities.

Customer education is part of the sustainability story. When buyers understand the lifecycle benefits of used parts, demand grows. Clear labeling of part condition and expected lifespan helps consumers make informed choices. Demonstrating the environmental savings of reuse, such as estimated greenhouse gas reductions from buying a used engine, resonates with increasingly eco-conscious customers. Such transparency builds trust and encourages repeat business.

Finally, the role of wrecking yards in the circular economy is strategic. By keeping materials and components in use, A & C reduces pressure on raw material extraction and manufacturing. The yard acts as a local hub in a wider network of reuse and recycling. Strengthening that network through reliable service, environmental diligence, and proactive partnerships enhances both community resilience and environmental outcomes.

For readers seeking practical guidance on vehicle disposal and maintenance that minimizes environmental impact, the U.S. Environmental Protection Agency offers resources and best practices. These materials provide helpful technical guidance and regulatory context for businesses and consumers alike. evo-x halfcut

More in-depth guidance is available from the EPA: https://www.epa.gov/vehiclesandfuels

Local Engines of Value: A & C Auto Parts’ Role in Community Prosperity and Sustainability

A & C Auto Parts & Wrecking Co. has long served as more than a parts supplier. Its activities generate steady local income, conserve resources, and strengthen the regional automotive ecosystem. Operating since 1941 in Cleveland, the company offers stable jobs that ripple through households, local businesses, and municipal services. Jobs at the yard range from dismantling technicians to parts specialists and administrative staff. Each role supports a paycheck, and those paychecks pay for groceries, rent, school supplies, and services. The predictable employment the company provides helps families plan and invest locally. That financial stability sustains other small businesses and stabilizes demand for community services. In neighborhoods where manufacturing declined, businesses like A & C create dependable work that keeps experienced hands employed and skills circulating in the local labor market.

The firm’s inventory strategy deepens this economic impact. By maintaining broad stocks of reusable components, the company reduces repair costs across the area. Affordable replacement parts keep older vehicles on the road longer, lowering ownership costs for individuals and small fleets. Independent mechanics rely on used parts to meet tight margins and quick turnaround times. When a local repair shop can source a transmission or door panel quickly, it avoids customer delays and protects reputation. That efficiency keeps repair shops competitive and viable. The result is a local automotive services network that retains spending within the community rather than outsourcing it to distant suppliers.

Beyond immediate commerce, A & C’s operations feed a small but resilient circular economy. Salvaging engines, transmissions, body panels, and electronics converts potential waste into valuable inventory. This reuse reduces demand for newly manufactured components. It also saves energy and raw materials otherwise required to make new parts. Each part reclaimed represents avoided emissions and conserved resources. The cumulative effect matters: tens of thousands of pounds of metal, plastics, and glass diverted from landfills translates into measurable environmental and fiscal benefits. For municipal systems, reduced waste volumes lower disposal costs. For the manufacturing chain, slower replacement demand can ease pressure on supply lines and raw material extraction.

Environmental compliance is a practical and economic dimension of the company’s value. Dismantling vehicles generates hazardous byproducts and recyclable streams. Proper handling of fluids, batteries, and electronics prevents contamination and costly cleanup for public spaces. By adhering to regulations, the company prevents negative externalities that could otherwise burden local taxpayers. Safe recycling of materials also creates salvageable secondary markets. Scrap metal, recovered batteries, and reusable electronics move into specialized recycler channels. Those channels support additional local jobs in collection and processing, expanding the employment footprint beyond the yard itself.

The circular model also fosters entrepreneurship and skill development. Workers at the wrecking yard acquire practical mechanical and inventory skills, such as diagnosing salvageable components, cataloging parts, and reconditioning items for resale. These skills translate to many roles across automotive services and manufacturing. The company often partners informally with nearby vocational programs and independent mechanics. These relationships produce training opportunities and faster knowledge transfer. Local students and apprentices gain hands-on exposure to older and newer vehicle systems, which strengthens the region’s technical talent pipeline. That talent helps attract service-oriented businesses, which in turn demand more parts and services, forming a feedback loop that bolsters the local economy.

Community resilience also appears in how the company supports low-cost mobility. For many residents, access to an affordable, reliable vehicle can mean the difference between steady employment and sporadic work. When repair costs spike, people must choose between costly new parts or giving up a vehicle. A dependable source of salvage parts extends vehicle lifespans affordably. This accessibility contributes to stable employment, consistent school attendance, and regular healthcare visits. Reliable transportation supports economic participation across the community, reinforcing social mobility and reducing strain on public transit for certain trips.

The firm’s local procurement and partnerships further concentrate economic benefit. Working with tow operators, insurers, and dismantling contractors puts money into small local firms. Parts sales to neighborhood shops and individual buyers keep transactions close to home. Even when components move beyond the region, the initial economic activity begins locally. Tax contributions from business operations and payroll add to municipal budgets. These funds support roads, emergency services, and other civic infrastructure that, ironically, sustain the very automotive economy the company serves.

A & C also influences market fairness and consumer choice. By offering economical alternatives to costly new parts, the company exerts downward pressure on repair prices. That keeps vehicle maintenance accessible to a broader set of consumers. When repair costs remain reasonable, owners are more likely to invest in proper maintenance. This tendency improves overall road safety and reduces the likelihood of vehicles being abandoned or improperly scrapped. The availability of diverse parts for varied makes and models ensures repair shops can serve a wide customer base, which amplifies competition among service providers and encourages better service quality.

On occasion, A & C supplies larger assemblies and specialty packages popular among enthusiasts and small rebuilders. These offerings include complex half-cut assemblies that combine engine, transmission, and wiring into a single, reusable unit. Such packages can significantly reduce labor time for extensive repairs. For those interested in compact, comprehensive solutions, resources like the Evo X halfcut provide practical case points on how dismantled vehicles supply high-value components and systems.

This economic and environmental symbiosis positions the company as a local steward of sustainable commerce. Its activities conserve materials, create jobs, and maintain affordable mobility. The model supports local repair shops, enables workforce development, and contributes municipal revenue. At the same time, adherence to environmental standards minimizes harmful impacts and preserves public spaces. The company’s approach demonstrates how a seemingly simple business—salvage and parts resale—can weave into a community’s social and economic fabric.

For readers who want additional specifics about operations, inventory, or community programs, the company posts details and contact information on its official site: https://www.acautopartsandwrecking.com

Digitizing the Salvage Floor: Technology, Transparency, and the Circular Economy at A & C Auto Parts & Wrecking Co.

On the business front line of Cleveland, A & C Auto Parts & Wrecking Co. stands as more than a salvage yard. It sits at the intersection where waste reduction becomes value creation. The yard has long prided itself on turning ruined or end-of-life vehicles into a catalog of reusable components. The story now extends beyond the yard gates into a spectrum of digital practices that recalibrate how reclaimed parts flow from wrecking to repair bays across the region. Even when public sources spotlight the breadth of their inventory and the quality of their customer service, the underlying technology that powers these outcomes remains largely unadvertised. That silence, however, does not diminish the central truth: modern salvage operations increasingly rely on a carefully orchestrated tech backbone to deliver speed, reliability, and sustainability to customers who count on affordable, responsible repairs. Technology in a salvage operation begins with visibility. A & C’s inventory isn’t merely a list of parts on a rack; it is a dynamically managed dataset that reflects pending dismantling, tested functionality, and the provenance of each component. The shift toward digital inventory management enables the business to track where a part sits in the workflow—from the moment a salvage vehicle arrives to the moment a customer takes possession of a refurbished engine or a door panel. Real-time stock updates reduce the friction between demand and supply. For repair shops and individual customers alike, this means a lower risk of order delays and a higher probability that a needed part is available when it is most needed. In practice, such systems translate to shorter downtimes for repair work and, by extension, to less time a customer sits without a vehicle. Beyond stock visibility, the operational core is subtly reshaped by the use of part-matching logic. AI-assisted matching algorithms, even in their early stages, can compare thousands of attributes—year, model, trim, engine code, and compatibility notes—to surface the best possible reuse option. This is not about replacing human judgment but augmenting it. A technician or parts specialist can confirm a suggested match with an eye toward condition, compatibility, and warranty terms. The dialogue between human expertise and machine-assisted suggestion speeds up the process while preserving safety and reliability. Even if public documentation does not trumpet a proprietary algorithm, the pattern is clear: efficiency scales when the system can learn from past assemblies and forecast future needs. The practical outcome is that a repair shop, pulsing with demand for a specific component across diverse makes and models, experiences a tighter, more predictable fulfillment cycle. The customer experience is equally shaped by digital tools that connect the yard with the street. An online storefront or catalog—whether hosted by the company’s own domain or integrated with a broader marketplace—gives customers a window into what is available. In many respects, this is an evolutionary step from a traditional yard where knowledge lived in the heads of long-tenured staff. With a robust digital layer, the yard’s knowledge becomes shareable, audit-able, and more scalable. A customer can search for a part, compare options, read notes about condition or history, and place an order with confidence. The result is not just convenience; it is trust. Transparent information about a part’s history and its compatibility turns a salvage transaction into a responsible choice that aligns with the growing consumer demand for sustainable maintenance options. To maintain integrity across the process, the use of digital tagging and barcoding becomes essential. Each component carries its own identifier, linking it to the vehicle it came from, its dismantling history, and any tests it has passed. This traceability matters not only for quality assurance but also for regulatory compliance. In an era when environmental safeguards govern how fluids are drained, engines are tested, and metals are recycled, a precise digital record reduces the risk of missteps and surfaces the data regulators may request during inspections. The environmental dimension is not incidental. It is a measurable outcome of disciplined data capture and process discipline. By correlating parts with their test results and disposal notes, the yard can demonstrate adherence to waste handling standards and recycling targets—an important narrative for customers who want to support sustainable practices as part of their repair strategy. A & C Auto Parts & Wrecking Co.’s emphasis on sustainability also translates into a more resilient supply chain. Digital systems enable better forecasting: by analyzing patterns in salvage arrivals, maintenance cycles, and repair shop demand, the business can anticipate which parts will trend in the coming months. This anticipatory capability reduces the need for sudden, expensive purchases and curbs the impulse to overstock on items that do not move. It also supports a more diversified sourcing strategy. When one salvage stream slows, another may accelerate, and a well-tuned data ecosystem helps the business reallocate space, labor, and capital accordingly. The upshot is a broader, steadier readiness to serve a variety of repair contexts—essential in a market where vehicle longevity continues to outpace new-car sales and where repairs remain the most cost-effective path for many drivers. The social value of technology in this setting cannot be overlooked. Local repair shops, small businesses, and individual customers all rely on timely access to affordable parts. The tech layer helps keep downtime to a minimum, which in turn supports the broader community by enabling more reliable transportation for families and workers. Moreover, a data-driven approach makes it easier to document environmental stewardship. When a yard demonstrates accuracy in parts provenance and compliance with waste-disposal standards, it helps bolster the ethical backbone of the regional auto-recycling ecosystem. In this sense, the tech investments are not isolated improvements but part of a holistic strategy that links economic viability with ecological responsibility. The result is a model in which recycling and reuse become a competitive advantage rather than a peripheral duty. While the public record provides a snapshot, it is important to acknowledge that the precise nature of A & C’s internal technologies remains largely private. The available materials point to robust operational routines and a reputation for dependable service, but they stop short of detailing every digital tool in use. That gap invites thoughtful speculation about the pathways other salvage operators have pursued. It is reasonable to imagine platforms that integrate with local vehicle databases to streamline vehicle identification, mobile apps that empower technicians on the yard floor, and analytics dashboards that translate raw data into actionable decisions. What matters most is not the exact brand of software but the outcome: faster, more accurate parts fulfillment; stronger traceability; and a sustainable approach that aligns with customers’ values and budgets. The absence of public specifics also underscores a broader industry truth. Small, regional salvage operations often adopt customized, low-profile tech stacks that fit their workflows and budget constraints. The result is a tailored solution that delivers impact without sacrificing flexibility. In this sense, the chapter of A & C Auto Parts & Wrecking Co. reads as a case study in pragmatic modernization. It is not a tale of high-budget, showpiece systems, but a narrative about incremental adoption—where digitized workflows, data-driven decision making, and customer-centric online access converge with the tangible, hands-on expertise that marks the salvage trade. The technology acts as an amplifier: it makes the yard’s core competencies—inventory management, quality control, and sustainable dismantling—more precise and scalable. It also elevates the relationship with customers from transactional to collaborative. By providing clearer information, faster fulfillment, and transparent environmental practices, the business creates a platform on which repair shops and individual motorists can trust in a reused component to deliver reliable performance. For readers seeking a tangible example of how digital catalogs shape access to used parts, consider the online listings that catalog specific Mitsubishi Evolution components. The catalog approach illustrates how a single part family can be visible across a broad audience, with filters, compatibility notes, and test histories that help buyers move confidently from decision to purchase. This example is a microcosm of the broader digital transition underway at A & C, one that aligns with the company’s stated mission to promote sustainability while offering economical replacements for aging vehicles. As technology continues to mature within salvage operations, the potential for further integration grows. More sophisticated data models could enable predictive maintenance recommendations to customers ordering from used- parts catalogs. Real-time environmental monitoring on the yard could feed directly into compliance dashboards, ensuring every disposal step is auditable. The eventual convergence of these tools promises not only operational efficiency but a traceable, transparent pathway from salvage to service. The broader implication for the region is clear: when local dismantlers embrace digital transformation, they contribute to a more resilient, sustainable automotive ecosystem. The vehicles that once ended their days at the edge of the road can, through careful innovation, re-enter the lanes of daily life with performances that honor both affordability and ecological stewardship. External resource: MapQuest offers a ground-level, practical view of A & C Auto Parts & Wrecking Co.’s presence in Cleveland, situating the business within the local urban fabric and illustrating how proximity supports rapid service and community engagement. https://www.mapquest.com/business/a-c-auto-parts-and-wrecking-salvage-cleveland-oh-3805-ridge-rd-216-961-6840

Crafting Loyalty in a Salvage Ecosystem: Customer Engagement and Service at A & C Auto Parts & Wrecking Co.

A & C Auto Parts & Wrecking Co. stands as a quiet centerpiece in a larger conversation about sustainability, repair, and community resilience. Since 1941, the shop at 3805 Ridge Rd in Cleveland has earned a reputation not just for stock or price but for something more enduring: honesty, integrity, and a level of service that treats every customer, whether a DIY enthusiast or a professional technician, as a partner. In a world that often moves too quickly to proper guidance, A & C has built a culture where engagement is not a tactic but a practice—an approach that turns a simple transaction into a durable relationship and, in the process, helps keep vehicles on the road longer through smart, sustainable choices. The backbone of this approach is a clear, cohesive understanding of what customers need and how best to meet those needs in a way that respects both their time and their budget.

The first pillar of their engagement model centers on inventory management. A huge stock of both new and used parts means that customers are far less likely to encounter a frustrating dead end. Availability matters as much as price in the salvage economy, and the assurance that the right part is likely to be found—whether it’s a common curb part or a more elusive component—reduces downtime and elevates trust. This reliability does more than satisfy immediate repair goals; it reinforces a longer arc of loyalty. When a customer knows they can call, walk in, or check a live inventory, the feeling of certainty becomes a differentiator. In practice, that translates into fewer broken plans, fewer rushed substitutions, and a sense that the shop is a dependable ally in vehicle maintenance rather than a quick stop on a price-driven circuit.

Complementing the breadth of the inventory is the shop’s emphasis on personalized service. Staff at A & C Auto Parts are not just check-out clerks; they are guides who help customers identify the correct parts through careful listening to vehicle information and the application of technical knowledge. This is where a transactional moment becomes a collaborative one. A customer might arrive with limited certainty about fitment or compatibility, or they might be returning to a long-term project with shifting needs. In those moments, a trained associate can translate vague symptoms or vague memories into precise part numbers and workable options. The transformation from “I think this is right” to “Yes, this matches your vehicle and your repair plan” is the heart of their service philosophy. It is this capability to interpret vehicle details—D.O.B., model nuances, trim differences, and sometimes even the VIN history—that helps convert a quick shopping trip into a productive repair strategy. By making the process approachable yet technically rigorous, the shop elevates a routine purchase into a confident solution.

An equally important facet of engagement is the community role the business plays. The Cleveland storefront is more than a place to buy parts; it is a local hub that sustains relationships with independent repair shops, DIYers, and neighborhood residents who rely on trustworthy access to components. Face-to-face engagement matters here because it creates a human context that digital channels alone cannot replicate. Customers can discuss their project details in real time, lay out constraints, and receive nuanced feedback about the best route to take. This face-to-face rapport is reinforced by the store’s consistent presence in the community—the kind of visibility that makes a repair emptying a shop’s queue into a smoother, more predictable day. In a sector where supply concerns and miscommunications can derail a repair, having a reliable partner nearby reduces downtime, builds goodwill, and strengthens the ecosystem of local automotive work.

The modernization of service is another key thread in the narrative of customer engagement at A & C. While the shop respects traditional, personal service, it also leverages contemporary tools to enhance efficiency and accuracy. Up-to-date inventory databases, clear product information, and accessible consultations—whether in person or through digital touchpoints—streamline decision-making for customers who are juggling time, budget, and vehicle reliability. The fusion of old-fashioned neighborhood trust with the clarity and speed of modern information systems creates a service experience that feels both solid and current. Customers can move through the purchasing journey with less friction, guided by transparent data about part fitment, compatibility, and the status of stock. The outcome is not only a smoother checkout but also an increased sense of partnership; customers feel supported as they pursue repairs that extend the life of their vehicles rather than replace them at every turn.

Beyond the mechanics of service delivery, the sustainability imperative casts a long shadow over engagement strategies. Salvage operations, informed by environmental regulations and responsible waste disposal practices, position A & C as stewards of a circular economy in the auto repair space. Reclaiming engines, transmissions, doors, and other components reduces waste and provides cost-effective options for vehicle owners. This alignment with ecological responsibility resonates with customers who are increasingly mindful of the environmental footprint of their repairs. It also reinforces the organization’s credibility: when a business can demonstrate both practical utility and environmental accountability, customers are more likely to return, knowing their choices contribute to broader societal goals rather than merely satisfy a quick fix. Protection of the environment thus becomes an integral part of the service narrative, not an afterthought or a separate policy.

The interplay between sales, guidance, and sustainability shapes a distinctive customer experience. The engagement model is not about upselling or aggressive sales tactics; it is about empowering decisions. When customers feel understood and supported, they are more inclined to trust the process, accept guidance on the best components for their particular repair, and return with future projects. The result is a loyalty loop: repeat visits, steady referrals, and a reputation that extends beyond price and speed to include reliability, integrity, and a shared sense of responsibility for the community and environment. In this sense, A & C Auto Parts & Wrecking Co. illustrates a broader principle for local auto parts businesses: durable customer relationships emerge when stocking decisions, advisory interactions, and community presence converge with a principled commitment to sustainability.

Ultimately, the chapter’s themes point to a simple but powerful insight. Engaged customers do not merely purchase parts; they gain confidence in repair outcomes. They feel supported by a business that knows its stock, respects their time, and stands by the values that matter to them—honesty, practicality, and stewardship. The store’s long-standing legacy, grounded in decades of reliable service, offers a blueprint for how salvage-oriented businesses can thrive in a competitive market by prioritizing people as much as parts. As the auto repair landscape continues to evolve—with increased vehicle complexity, tighter budgets, and heightened environmental expectations—the A & C model suggests a sustainable path forward: combine transparent inventory, expert guidance, and community rootedness, and you build not just a customer base but a resilient, enduring ecosystem of repair and renewal.

External reference for local context and accessibility of the storefront can be found at the listing for the business: https://www.google.com/maps/place/A+%26+C+Auto+Parts+%26+Wrecking+Co./@41.5229765,-81.6776794,17z/data=!3m1!4b1!4m6!3m5!1s0x8834d3a7c8f7e23d:0x8e12c88795d2996e!2sA+%26+C+Auto+Parts+%26+Wrecking+Co.!3m2!1d41.5229765!2d-81.6776794!5m1!1e1?hl=en

Final thoughts

A & C Auto Parts & Wrecking Co. exemplifies what it means to be a responsible and community-focused business in the used auto parts industry. Their commitment not only enhances vehicle longevity through affordable solutions but also fosters economic growth and sustainability efforts that benefit both local communities and the environment. By embracing technology and engaging effectively with customers, they continue to set the standard for excellence in the sector, proving that businesses can thrive while making a positive impact.