In the automotive industry, understanding the components that make up vehicle structure is essential for business owners and automotive professionals. Among these, the A and C pillars are crucial in ensuring vehicle safety and integrity. This article dives into the significance of these pillars, explores the classification of automotive components, and clarifies misconceptions associated with automotive brands related to A and C auto parts. Each chapter will enhance your knowledge, guiding you in making informed decisions that can impact the quality and safety of your automotive offerings.

Guardians of the Frame: The A and C Pillars That Shape Safety, Silence, and Style in Modern Vehicles

What people sometimes call “a and c auto parts” is less a single brand or catalog than a way of talking about a family of components that are fundamental to how a car holds itself together. In the language of vehicle structure, the letters A and C designate specific pillars—the vertical members that run from the roof down toward the floor, between the windshield and the doors on the one hand, and between the rear window and the trunk on the other. These pillars are not cosmetic trim; they are load-bearing, energy-absorbing elements that define the integrity of the passenger cabin. They are the quiet sentinels that keep shape under stress, the invisible frameworks that translate the kinetic energy of a crash into controlled deformation, and the silent enforcers of comfort, visibility, and aerodynamic behavior. When we talk about the parts that support a car’s body, the A and C pillars emerge as the backbone of the structure, shaping not only how a vehicle behaves in a collision but how it feels to the driver and passengers on every ordinary drive.

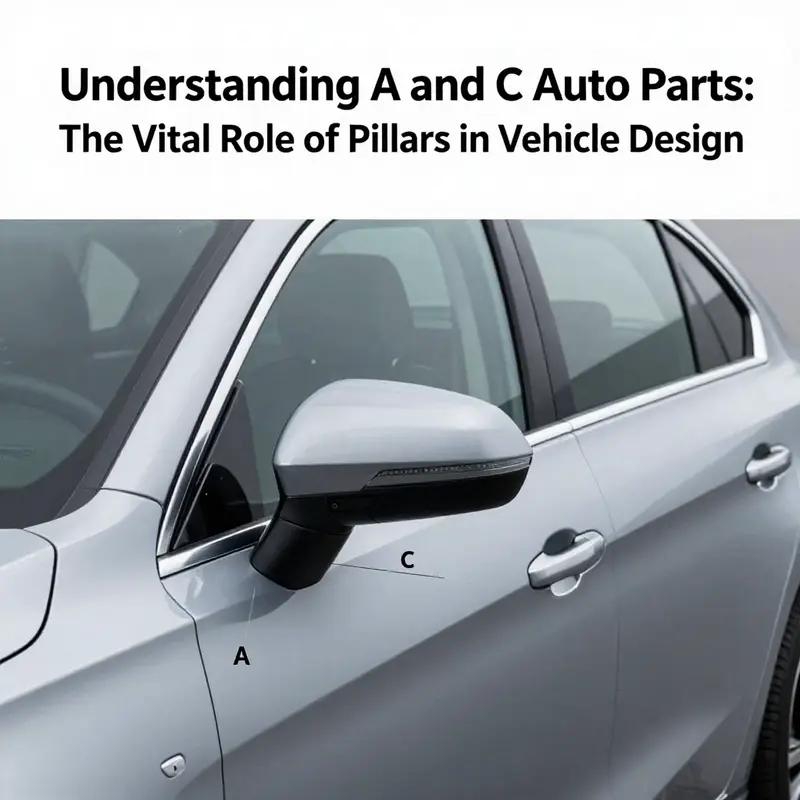

To understand their significance, start with the more obvious: location and duty. The A-pillar stands at the front edges of the roof, bracing the roof shell against the force of gravity, maintaining the windshield’s angle, and providing a pathway for the roof to transfer vertical loads into the rest of the body. In a crash, it is precisely the A-pillar that participates in maintaining the cabin’s integrity during corner impacts and rollovers. The C-pillar sits near the rear, linking the roof to the rear portion of the vehicle’s frame and helping to preserve cabin rigidity when the car’s rear experiences lateral or rearward forces. Together with the B-pillar between the front and rear doors, these pillars form a protective lattice around the occupant space. They are not mere lines on a blueprint; they are the scaffolding that keeps the cabin from collapsing inward, absorbing energy and distributing it so that occupants experience deceleration in a controlled, survivable way.

This fundamental role translates into a set of material and design choices that designers balance every day. The strength of the pillars stems from materials and geometry. Modern vehicles often employ high-strength steels or advanced alloys to resist bending and puncture while keeping weight in check. In some applications, aluminum or composite materials may be used to shave away weight where the safety goals allow. The cross-sectional shape—often an optimized hollow profile or a carefully crafted box-section—is engineered to resist the specific modes of loading that pillars encounter. The result is a pillar that can bend in a controlled fashion, absorbing energy, while the adjacent passenger cell remains intact enough to protect the occupants.

Yet even with the best alloys and geometry, pillars are only as good as their integration with surrounding structures. The A and C pillars do not act in isolation; their strength is inseparable from the door skirts, rocker panels, floor pans, roof rails, and the side door structures that connect to them. In a collision, the energy path travels through a network of members that includes the pillars, reinforcing beams in the doors, and the roof structure itself. Achieving that kind of integrated safety requires an engineering mindset that treats every junction as a potential weak link worth reinforcing. Attachments like welds, adhesives, and fasteners receive equal attention to ensure that the pillar remains a single, coherent element of the frame rather than a collection of independent parts that could separate or fail under stress. This is why even what might seem like a small detail—how the pillar meets the roof line or how the pillar’s inner reinforcement ties into the A-pillar’s outer skin—can influence the car’s overall crashworthiness by a measurable margin.

The functional story of the pillars is inseparable from the daily experience of driving. A-pillar design shapes visibility. In close urban encounters, a driver’s line of sight to pedestrians, bicycles, and vehicles at intersections is partially filtered by the pillar’s thickness and the way its frame is blended with the windshield area. A well-considered A-pillar minimizes blind spots without sacrificing the structural envelope. Likewise, the C-pillar’s influence on aerodynamics and rearward visibility matters on highways and city streets alike. The pillar’s silhouette, the curvature of the glass around it, and the integration of seals and trim all contribute to wind noise, climate control efficiency, and perceived vehicle refinement. These elements remind us that while the A and C pillars are primarily about strength, they can also be about quietness and comfort—the sort of engineering that you notice only when it’s missing.

Within discussions of “A and C auto parts,” one frequently encounters a tension between rigidity and weight, safety and efficiency, form and function. The modern approach often involves using materials and manufacturing technologies that achieve a high degree of mechanical performance without unduly increasing the vehicle’s mass. High-strength steel allows slimmer, stronger profiles that resist deformation without requiring bulky members. Composite reinforcements, where used, provide energy-absorption characteristics that pure metal cannot easily replicate, contributing to crashworthiness while offering pathways to reduce weight. The choice of joining methods—welds, rivets, adhesives, and occasionally bonding agents—plays an essential role in ensuring that the pillar acts as a coherent unit. Each joining technique has its own fatigue and corrosion considerations, which engineers must anticipate across decades of expected service life. Even things as routine as repainting or re-skinning a pillar after a collision call for a careful understanding of how coatings interact with metal, how seams seal against moisture, and how the overall geometry of the pillar is preserved under repair.

Repair and replacement scenarios reveal another practical layer of the A and C pillars’ importance. When a vehicle has sustained damage to its side structure or roofline, the pillars become central to restoring safety. A-pillar damage, for instance, may necessitate not only panel work but a re-evaluation of the roof’s alignment and the windshield’s seating relationship. Similarly, C-pillar damage demands careful attention to rear window fitment, trunk integrity, and the correct perception of the car’s rear geometry in the driver’s sight lines. In such contexts, the term “A and C auto parts” can indeed cover a spectrum of components—from whole pillar assemblies to trims, insulators, and seals that affect how the pillar interfaces with glass, doors, and the body itself. These parts, while sometimes perceived as cosmetic or secondary, can have a decisive impact on how the vehicle behaves after a repair and how the cabin retains its protective concept during a subsequent impact.

There is another layer to the discussion: aesthetics and acoustics—how the pillars influence the feel of the car beyond mere safety. The pillar assemblies host a range of trim pieces, seals, and sound-dampening materials. These elements contribute to a quiet interior by reducing resonance along the roof rails and around the glass interfaces. The trim that covers the pillar—often designed to align with the door and roof aesthetics—also serves to channel water away from joints, helping to prevent corrosion and maintain a clean, dry seam. In daily driving, these seemingly small decisions accumulate into a smoother, more refined experience—less wind intrusion, fewer rattles, more consistent climate control. This is where engineering meets user experience in a quiet, almost invisible way; the pillars are doing heavy lifting while the rest of the interior remains pleasantly tranquil.

The chapter of pillars is not merely a hymn to structure. It unfolds as a narrative about how a vehicle’s identity can hinge on the very architecture that most cannot see. The choice of pillar geometry, the materials that reinforce them, and the way they are integrated into the roof and floor structure all feed into the car’s stiffness, its crashworthiness, and its acoustic signature. In high-performance or luxury applications, designers push the envelope further by optimizing the pillar profile to reduce weight while increasing protective energy absorption, or by blending the pillar into the glass architecture so that visibility, light, and air flow feel natural rather than engineered. This delicate optimization—finding the sweet spot where safety, efficiency, and experience converge—illustrates why A and C pillars deserve careful attention from engineers, technicians, and curious drivers alike. They are, in a real sense, the quiet custodians of a car’s form and function, the parts that allow the vehicle to stand up to the demands of modern mobility without betraying its passengers to the elements of energy in a crash or the noise of a windy highway.

For readers who are navigating the practical world of repairs or aftermarket choices, the broader lesson is simple: treat A and C pillars as more than their outer appearance might suggest. When assessing a vehicle’s body integrity, consider how the pillars connect with the rest of the structure, how the joints and seals have aged, and how coatings have responded to wear and road chemicals. If you are evaluating replacement options or contemplating retrofits, remember that the goal is not just to restore a surface but to restore the pillar’s role in the car’s comprehensive crash envelope. In that sense, the right “A and C auto parts” are not merely components to swap in but carefully selected elements that preserve the car’s designed balance of rigidity, energy management, and occupant protection. The best choices respect the vehicle’s original engineering philosophy, ensuring that after maintenance or modification, the structure behaves the same way it did when it left the factory—protective, predictable, and reassuring.

As you move through the ongoing conversation about vehicle safety and design, keep in mind that pillars are not static. They evolve with new materials, new joining techniques, and new strategies for energy management in crashes. The push toward ever-tighter tolerances, improved corrosion resistance, and smarter integration with electronic systems means that the A and C pillars will continue to be a focal point for engineers aiming to improve occupant protection while also enhancing comfort and efficiency. In this sense, the pillars are a microcosm of automotive progress: a blend of resilience, precision, and quiet sophistication that underpins the entire driving experience. If you ever wonder where the line is drawn between structural necessity and everyday usability, look no further than the pillars at the core of the cabin—these are the quiet engineers, the unseen guardians, the anchors that keep motion safe and confidence intact for every mile traveled.

For readers seeking a broader, more technical dive into why car pillars matter, the following external resource offers a thorough explanation of pillar function and the role they play in crashworthiness and occupant protection: Pillars and Their Functions Explained. https://www.carinterior.com/what-are-car-pillars-and-their-functions-explained

And in the spirit of connecting theory with practice, an internal reference that situates discussion in the context of real-world parts access can be helpful when considering maintenance or repairs. See the internal page Front Bumper page for Outlander 2019 as a practical example of how body components are accessed and coordinated within the broader structural system: front-bumper-mitsubishi-outlander-19.

A-Pillars and C-Pillars in Focus: How A and C Auto Parts Shape Safety, Structure, and Service

When readers encounter the phrase “a and c auto parts” outside of a brand name, it typically surfaces as a shorthand for two pillars in the car’s body that endure long after the engine has cooled and the tires have rolled. In practical terms, A-pillar and C-pillar components are not stand-alone accessories but essential elements of a vehicle’s skeleton. They anchor the roof, help preserve cabin integrity, and define how a car behaves in the real world—during a corner, in a rollover risk, or in a routine repair. In that sense, these parts illuminate a broader truth about automotive maintenance: the most vital parts are often the ones we cannot see directly, yet they govern how a vehicle protects its occupants, how it remains rigid in the face of wind and weight, and how easily a repair can restore safety and function after damage. To understand A and C auto parts, one must appreciate their place in a system rather than isolate them as decorative trim or merely a cosmetic cover. The conversation begins with what these pillars actually do, and then expands to how they are classified within the larger universe of automotive parts, how they are treated in logistics and packaging, and how professionals approach replacement and refurbishment when the pillars themselves show wear or compromise structural performance.

The A-pillar sits at the forward edge of the passenger compartment, flanking the windshield as it rises to meet the roofline. It is the left and right vertical boundary that frames the driver and the passenger’s view, but its significance extends far beyond sightlines. In a collision, the A-pillar is a primary load path; it transfers energy from the roof to the vehicle’s side structures, supporting the frame where most of the front energy concentrates during a side impact or a rollover. The A-pillar houses critical components as well, often integrating weather seals, trim, and, in modern designs, side-curtain airbags that thread their protective role between the roof and the cabin space. A damaged A-pillar can distort the cabin’s geometry and, in turn, alter airbag timing, door alignment, and even the way the windshield bears against the roof. These realities explain why professional repairwork rarely treats the A-pillar as a simple replacement part; it is tackled with a structural mindset that considers reinforcement, alignment, and the long-term integrity of the passenger cell.

The C-pillar, by contrast, sits toward the rear of the passenger area, where the roof connects to the rear window and the rear quarter panel. It is perhaps less visually imposing than the A-pillar from a driver’s seat perspective, yet it plays a parallel role in maintaining roof rigidity and controlling the vehicle’s aerodynamics. The C-pillar’s influence extends to rear visibility and overall body stiffness, factors that influence how a vehicle behaves in high-speed maneuvers and how it behaves in a crash. In repair scenarios, C-pillar components—trim, weatherseals, and sometimes structural reinforcement—must be resurrected with careful attention to the surrounding panels, glass interfaces, and roof line. The interplay between A-pillar and C-pillar sections forms a continuous spine that defines how the vehicle distributes forces and absorbs energy, which is why technicians approach both areas with a shared appreciation for chassis geometry and alignment tolerances.

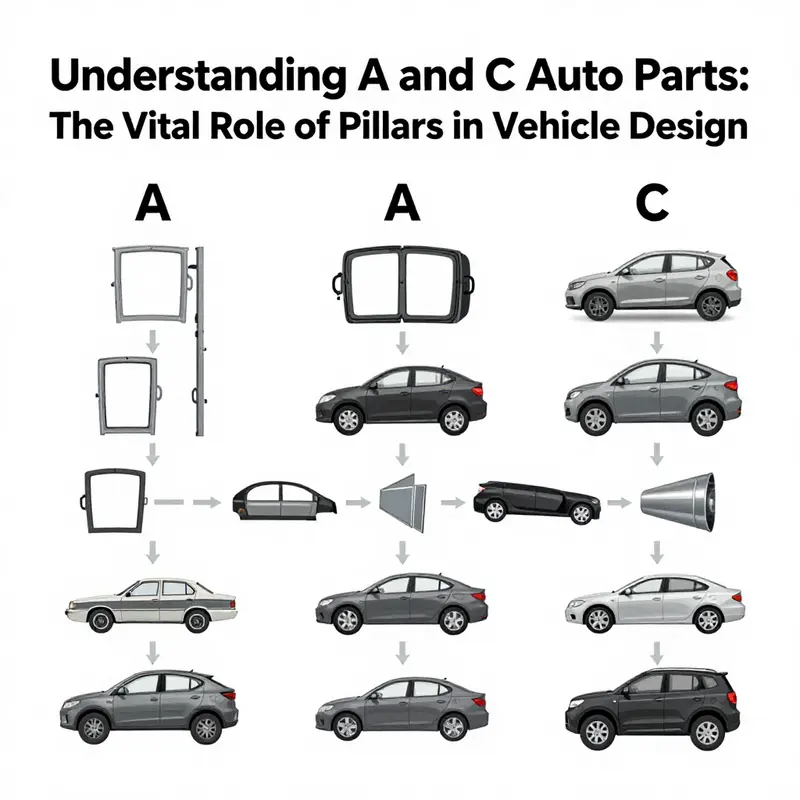

In the broader taxonomy of automotive parts, the moment a technician or a parts professional starts to categorize an A-pillar or a C-pillar accessory, the categories feel both familiar and a little abstract. Vehicle parts are typically organized into systems that describe function: engine, powertrain, electrical, braking, wheels and tires, and body parts. Within this framework, A-pillar and C-pillar components are most closely aligned with body parts, yet they are inseparable from structural integrity. They belong to a family of components that define a vehicle’s silhouette, protect its occupants, and influence aerodynamic performance. The classification is neither arbitrary nor merely academic. It underpins maintenance planning, parts sourcing, and repair guidelines that technicians rely on every day. When a shop or a DIY enthusiast asks for “A-pillar trim” or “C-pillar weatherstripping,” the inquiry sits squarely at the intersection of aesthetic restoration, weather sealing, and structural compatibility. This duality—that a trim piece can be both cosmetic and functionally linked to crash safety—highlights why precise terminology matters and why the Vehicle Parts Classification Guide becomes a practical tool rather than a dusty reference on a shelf.

Beyond the shop floor, the way these pillars are packaged for transport and distribution reveals another layer of complexity. Packaging designers recognize that A-pillar and C-pillar components encompass both rigid structural elements and fine-seal or trim details. Cardboard packaging has long been a critical material in the auto parts supply chain because it offers cost-efficiency, recyclability, and moldable protection through clever geometry. For heavy or structural sections, corrugated cardboard boxes with die-cut inserts or partitions help stabilize the parts, absorb minor impacts, and prevent shifting during transit. Lighter trims or weather seals may be grouped in paperboard cartons that protect against scuffs while providing a surface suitable for branding and barcoding. The packaging design must respect the part’s tolerance stackups—the small gaps and fitments that ensure a panel aligns correctly with adjacent components during installation. In other words, good packaging does not just reduce damage; it reduces the risk of misalignment when a technician installs a replacement part, which directly relates to safety and uptime.

Effective packaging goes hand in hand with robust classification. When manufacturers and distributors define a part’s identity—A-pillar trim, A-pillar reinforcement, C-pillar trim, C-pillar reinforcement, and related weather seals—they create a predictable language for ordering, stocking, and refurbishing. This is especially important in markets where repair and customization are common, and where the supply chain must accommodate both new-old-stock and modern, crash-compatible designs. The broad significance of classification extends to the research and publishing sphere as well. Industry publications, such as the Vehicle Parts Classification Guide, distill the complexity of component families into an accessible framework that technicians and engineers can adopt without re-articulating the basics every time a part is needed. In practice, this means that a repair shop in any country—whether it is a mature market or a developing one—can align with a common standard, reducing confusion and increasing the odds of a correct, safe repair.

To put these ideas into a practical frame, consider how a service professional navigates the reality that A- and C-pillar components might require a combination of new structural pieces and refurbished trims. A common scenario is the replacement of a damaged door opening area or a compromised roof line following a collision. The technician will assess not just the visible damage but the implications for the pillar’s inner reinforcement and how the roof will seat after installation. The process may involve removing interior panels, inspecting reinforced sections, and ensuring that the pillar-to-body joints maintain their original geometry. The goal is not merely to restore a cosmetic appearance but to reestablish the original design intent: a cabin that remains rigid, a roof that does not sag, and a front or rear structure that can efficiently absorb energy in the event of another impact. In a sense, A-pillar and C-pillar components are among the most consequential parts that survive a crash because their condition often dictates whether the vehicle will protect its occupants in subsequent events.

This guiding role in safety and structure also frames the practical avenues for sourcing and evaluating replacement parts. The search strategy for A-pillar and C-pillar related components tends to converge on terms like pillar trim, weather seals, pillar reinforcement, and sometimes even on the more generic umbrella term body parts for structural reference. The challenge for many buyers—especially those who engage in frequent repairs or restorations—is to sift through a wide field of options while avoiding misinterpretation of fitment for a given model. Even among the same vehicle family, differences in roof design, pillar geometry, and even trim thickness can lead to incompatibilities that show up only after the parts are painted or fitted. These nuances reinforce the value of reliable catalogs and crisp part descriptions, which again circles back to the broader theme of classification: clear language and precise grouping underpin quality outcomes.

A broader market lens adds another layer to this discussion. In markets with strong repair cultures and robust aftermarket ecosystems, A-pillar and C-pillar components may be refurbished, reinforced, or replaced with a spectrum of options. The goal in these contexts is to balance safety, vehicle identity, and cost. The classification system helps practitioners decide whether a part is a direct repair or an adaptable fit, and it guides decisions about whether a damaged pillar should be restored in its original configuration or whether a more modern reinforcement solution is warranted to meet current safety standards. It also shapes the way a shop schedules maintenance tasks, how it budgets for parts, and how it times the repair within a vehicle’s overall recovery plan. All of this happens within the time-sensitive, safety-critical frame that governs modern automotive service.

In the global supply chain, this coherence matters for more than repair shops. It informs manufacturers who design new pillar geometries and reinforcement strategies, suppliers who engineer trim and seal systems, and distributors who bridge factories with repair bays. The clarity of classification translates into predictable lead times, clearer warranty expectations, and more reliable service experiences for customers. Even the act of packaging—carefully protecting a pillar reinforcement during shipment, ensuring trim pieces arrive undented, and that weather seals are not dried out or torn—becomes part of a quality narrative that begins long before installation and ends only after a vehicle returns to the road with the original safety margins intact.

For readers who are building a mental map of where A-pillar and C-pillar components sit within the larger ecosystem, it can help to think of their role as a bridge: between the structure that keeps a car upright and the functional details that make a cabin livable and safe. They are not flashy, and they rarely win design awards, but their performance under stress, their fit during repair, and their resilience in daily use determine, in a real sense, how a car protects its passengers. When a vehicle is designed, built, and maintained with that understanding in mind, the A-pillar and C-pillar components are treated as living parts of a complex system rather than as static surfaces. This perspective aligns with the approach of professionals who rely on consistent classification, robust packaging, and precise part descriptions to keep vehicles safe and roadworthy across diverse markets.

The narrative here naturally invites a practical takeaway: if you are replacing or refurbishing pillar components, seek parts that acknowledge their structural role while offering compatible trims and seals that restore the original geometry. Do not assume that a visually similar piece will fit or perform equivalently. Take advantage of catalogs and classification guides to confirm fitment, reference compatible reinforcement options, and assess how the restored pillar will stand up to future stresses. And when you are planning logistics or discussing parts with a supplier, remember that the journey from the workshop to the road is as much about the reliability of packaging and the clarity of descriptions as it is about the metal, the seals, or the trim.

In closing, A-pillar and C-pillar components illustrate how a seemingly narrow topic—one or two parts—can illuminate the intersection of safety, design, logistics, and repair practice. They remind us that a vehicle’s integrity is a tapestry woven from many threads, and that the strength of the whole depends on attention to the parts that hold it together in the strongest sense. The materials science behind the pillar reinforcements, the aerodynamic considerations of the roof line, and the practical realities of the repair shop all converge when a technician studies a pillar. The result is not merely a restored panel, but a return to the vehicle’s designed safety envelope, a restored sense of structural faith, and a repaired line of sight that keeps occupants protected under the most demanding conditions. For anyone who wants to understand how a car remains safe, comfortable, and repairable, following the story of A-pillar and C-pillar components is a revealing entry point.

As you explore this topic further, you will encounter a wealth of related resources and references that elaborate on how classification, packaging, and field practice align to produce consistent, reliable outcomes. The Vehicle Parts Classification Guide and related industry materials offer structured frameworks that help practitioners navigate complex choices with confidence. For additional reading, you can consult external resources that discuss these classifications and their practical applications in the field: https://www.scribd.com/document/589473256/Vehicle-Parts-Classification-Guide-PDF. And on the practical side, a real-world example that connects to ongoing maintenance considerations can be found in targeted content that details how to address days of service, installation challenges, and compatibility checks, including pages that cover the Lancer/ Evolution family’s pillar-related components, which you may explore through this internal reference as you prepare to source and fit the relevant parts Lancer Evo X headlights.

The shaping of A-pillar and C-pillar components through classification, packaging, and disciplined repair practices demonstrates how modern automotive service thrives on an integrated approach. It shows that even parts out of the spotlight—hidden in plain sight along the vehicle’s silhouette—carry the responsibility of safety, performance, and longevity. In that sense, these pillars are not just structural features; they are testaments to how meticulous attention to detail in design, logistics, and refurbishment sustains the roadworthiness of cars across oceans and years.

Beyond the Name: Decoding ‘A and C Auto Parts’ and Finding A‑ and C‑Pillar Components

Understanding the label and what it actually points to

The phrase “A and C auto parts” rarely identifies a single, established company. It more commonly points to two separate things: the A‑pillar and the C‑pillar on a vehicle, or a shorthand confusion born from abbreviated brand names. In practice, when someone searches for “A and C auto parts,” they usually seek parts that belong to those two pillars. The A‑pillar sits on either side of the windshield. It supports the roof and contributes to frontal crash protection. The C‑pillar sits beside the rear window and helps support the roof and the rear structure. Both pillars host trim, seals, wiring, and attachment points for safety components. Treating the phrase as a directional hint, rather than a corporate name, helps focus the search and ensures proper fitment.

Pillars are structural, and their associated parts vary from cosmetic trim pieces to integral safety components. The visible items are often plastic or fabric covers, weather seals, and clips. Beneath those covers lie brackets, reinforcements, and channels for wiring and airbags. Some parts are purely decorative. Others directly affect occupant safety or roof integrity. That mix explains why the same generic phrase can hide very different needs. A trim clip costs little. A welded reinforcement panel and headliner stitching can be expensive and labor intensive.

Recognize the two main interpretations early. One interpretation treats “A and C” as lettered categories in a parts list. The other reads it as shorthand for A‑pillar and C‑pillar. Knowing this clears confusion and prevents wasted time buying the wrong item.

How the A‑pillar and C‑pillar differ in design and function

The A‑pillar handles windshield loads and helps maintain the roof’s shape during a rollover. It also forms a critical blind spot beside the driver. Manufacturers often hollow the pillar to route wiring for microphones, sensors, or curtain airbags. A trimmed A‑pillar may conceal clips, foam, and a thin metal reinforcement. Many modern vehicles integrate side curtain airbags into or near the A‑pillar. That placement makes correct replacement critical.

The C‑pillar does less to protect from frontal impact. It helps stabilize the rear roof and can alter aerodynamics. It frequently contains parts of the rear window seal, rear interior trim, and sometimes speaker mounts. On hatchbacks and wagons, the C‑pillar may also house wiring for rear lights. C‑pillars often see rust at the base where water collects. They may also become bent or crushed in rear collisions.

Parts associated with these pillars fall into discrete categories. Trim panels and garnish pieces are cosmetic and simple to replace. Weatherstrips, seals, and channel liners affect water management and noise control. Internal reinforcements and brackets influence safety and alignment. Electrical harnesses and mounting clips make reinstallation exacting. Recognizing which category your replacement falls into guides sourcing and pricing decisions.

Common misconceptions that lead buyers astray

Many searches assume a company called exactly “A and C Auto Parts” exists. That assumption leads to confusion. The real sources for pillar components range widely. There are large national retailers, dealership parts departments, specialized suppliers, small local stores, and salvage yards. Each source offers different guarantees, prices, and availability.

Another misconception treats pillar trim as purely cosmetic. Replacing a trim clip is easy. Replacing a structural reinforcement is not. A poorly installed pillar part can leave an airbag unable to deploy properly. It can also create unwanted wind noise or permit water intrusion. Some buyers assume that any part labeled as a pillar component will interchange across models. That rarely holds true. Pillar shapes vary by roofline, body style, and trim package. An A‑pillar trim from one year may not fit another year of the same model.

People also mix up label abbreviations. A search term might mix initial letters from two brand names or abbreviations. Misreadings of corporate tickers or shorthand notations can create phantom brand names. The result: time spent chasing a name that lacks a unique catalog entry.

Practical guidance for finding the exact part you need

Begin with the vehicle identification number. The VIN gives exact build details. Use it whenever possible. If you lack the VIN, collect make, model, year, body style, and any distinctive trim options. Note the side of the vehicle when ordering left or right pieces.

Use precise part names. Search for “A‑pillar trim,” “A‑pillar weatherstrip,” “A‑pillar reinforcement,” or “C‑pillar garnish.” Avoid vague searches that include only letters. Pair these search terms with your vehicle details and the VIN. When a listing provides a part number, compare it to factory diagrams or exploded views. Pictures help confirm details like clip patterns, visible fastener locations, and upholstery texture.

Inspect any used part photos closely. Look for intact clip mounts, undamaged mounting holes, and color match. Photos should show both the visible face and the rear structure. For trim, check for upholstery wear. For seals, ensure the cross‑section looks complete and not flattened. For reinforcements, inspect for rust or welding repairs.

For structural parts, ask for a part history. Did it come from a crash vehicle? Was it heat repaired? Even a straight-looking reinforcement might hide fatigue or prior repairs. When in doubt, buy new from an authorized source or have a qualified body shop inspect the used item before installation.

Fitment, compatibility, and fit-first habits

Treat fitment as a nontrivial issue. Pillar parts often interlock with the headliner, door seals, or dash. Misaligned clips can pull the headliner out of place or allow water to run in. When possible, test fit cosmetic panels before final reinstallation. Keep original fasteners if they are still serviceable. Many trim clips are single‑use; replacing them prevents rattles.

Cross‑reference part numbers. Aftermarket suppliers may offer a part that matches visually but not dimensionally. Compare measurements. Confirm the clip pattern and any hidden brackets. If buying from a general parts marketplace, read questions and answers to learn common fitment pitfalls.

When a pillar houses an airbag or sensor, treat the entire assembly with caution. Disconnect the battery per manufacturer guidance before removing the trim. Avoid cutting or altering airbag mounting tabs. Reinstallation must meet factory torque and clip retention specifications.

When to choose new, refurbished, or salvage parts

Choose new parts for structural components and for safety‑critical locations. New parts have known histories and fitment. Choose refurbished or used parts for nonstructural pieces to save money. Trim panels, noncritical brackets, and decorative elements often work well when used.

Salvage yards can be good sources for rare parts. They can supply OEM pieces that are otherwise discontinued. However, salvage parts need careful inspection. Ask sellers to remove and ship parts intact. Avoid parts cut from flood vehicles. If a salvage part requires repainting, plan for color match and labor.

Refurbished parts sometimes offer a middle ground. They may be reconditioned by a specialist who replaces clips and rewraps trim. Ensure the refurbisher provides photos and a warranty. A short return window often accompanies refurbished items, so act quickly if a fitment issue appears.

Installation realities and small but critical steps

Removing trim requires the right tools. Plastic pry tools and panel levers reduce damage risk. Work slowly at clip locations and along seams. Keep removed clips organized so you can replace them in the same spots.

Document the wiring path before removal. Take photos or mark harnesses. Pillar areas often contain speaker wires, antenna leads, or sensor cables. Replacing the panel without routing wires properly can strain connectors and cause intermittent faults.

Seal and weatherstrip installation matters. A new seal often needs a small bead of adhesive or primer. Follow manufacturer instructions for adhesives and curing times. Properly seated seals prevent wind noise, water leaks, and corrosion.

If a pillar has rust, address it before reinstalling trim. Surface treatment is often insufficient for structural rust. In such cases, a repair panel or welded replacement may be required. Corrosion can hide under seals and trim, so remove those pieces during inspection.

How to verify sellers and avoid common traps

Look for clear return policies and part‑specific guarantees. Sellers should list part numbers and provide multiple photos. Read reviews for reliability and shipping times. Ask questions about fitment and history before purchase.

Beware of listings that use only stock photos. Request pictures of the actual item. Avoid listings without measurements or closeups of mounting points. For international purchases, verify customs and duties and expect longer lead times.

When using forums and community groups, treat advice as anecdotal. Use member photos and build threads as references, not definitive proof of fit. Large community threads demonstrate common solutions and often list alternative part numbers that fit.

The role of diagrams, OEM literature, and VIN lookups

Factory parts diagrams remove much of the guesswork. They show how parts interlock and provide OEM part numbers. Those numbers are the best reference when searching for exact fitment. A VIN lookup with a dealer or a parts portal can produce the correct part numbers for the pillar sections.

If an OEM number is missing, some online catalogs allow lookup by year and trim. Compare listed diagrams to your vehicle visually. Even when the nomenclature differs, diagrams often reveal clip patterns and bracket placements.

Local installers, specialty shops, and when to call a professional

Simple trim swaps suit do‑it‑yourselfers. Structural repairs, airbag work, and corrosion repairs need professionals. A skilled installer ensures alignment, proper torque, and reliable trim retention. Body shops manage welded repairs and replace reinforcements to factory standards. Electrical shops handle sensors and wiring harness routing.

If you suspect that a pillar problem affects safety, do not delay a professional inspection. Small misalignments can worsen over time. A trained technician can spot stress signs that a layperson might miss.

Search tips and sample queries that get results

Use precise queries like “A‑pillar trim [make] [model] [year]” or “C‑pillar weatherstrip [VIN].” Add terms like “garnish,” “reinforcement,” or “trim clip set” to refine results. When in doubt, attach clear photos to a seller inquiry. A short set of images showing interior view, clip locations, and part numbers speeds identification.

For interior trim and dashboards on similar models, community posts and specialist parts pages often show compatible pieces. For a visual reference and interior trim details, see this Evo 9 dashboard and interior trim resource.

For authoritative parts lookup and dealer catalogs, consult the linked industry portal for fitment verification: https://www.advanceautoparts.com/

This guidance helps turn an ambiguous search phrase into a precise parts order. With the right identifiers and inspections, you can source the correct A‑pillar and C‑pillar components. Clear photos, part numbers, and VIN checks reduce returns and ensure safety. That clarity moves the discussion from a vague name to a confident repair plan.

Final thoughts

In conclusion, understanding the role of A and C auto parts is vital for anyone involved in the automotive industry. Not only do these pillars contribute significantly to vehicle safety, but they also highlight the importance of proper classification in auto components. By addressing common misconceptions regarding A and C brands, business owners can ensure they are making informed decisions when sourcing and marketing automotive parts. As you consider how these components impact your business, remember the vital role they play in safeguarding both vehicles and their occupants.