Don’s Auto Parts & Machine Shop is a vital resource for business owners in need of quality automotive parts and machining services. Located in Kenosha, Wisconsin, this establishment stands out for its extensive range of products and expert knowledge in automotive repair and maintenance. In this article, we will explore the comprehensive services offered, delve into customer feedback and reviews that highlight its reputation, assess its convenient location and accessibility, analyze operating hours for optimal visits, and perform a comparative analysis against competitors to underscore its uniqueness and excellence in the market.

Revving with Purpose: A Deep Dive into Don’s Auto Parts & Machine Shop’s All-in-One Craft in Kenosha

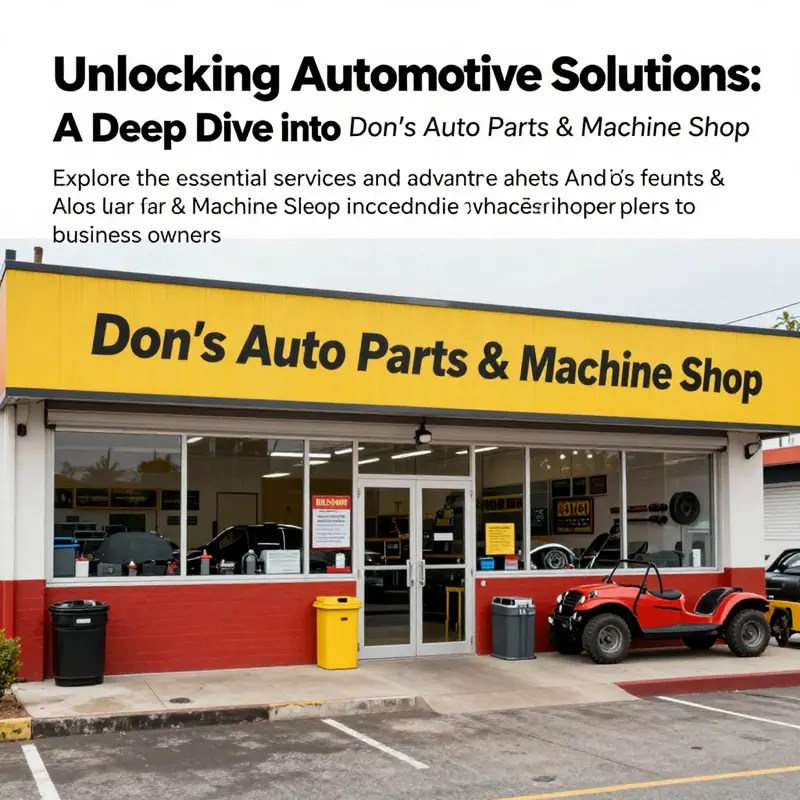

In the quiet industrial corridors of Kenosha, Don’s Auto Parts & Machine Shop stands as more than a storefront. It is a working hub where metal sings under the hands of technicians who treat every vehicle as a puzzle to be solved, not a problem to be masked. The shop sits at 6814 39th Ave, a location that has become a reliable waypoint for local drivers and fellow mechanics alike. Its doors open Monday through Thursday from 8:00 in the morning until the late afternoon, a schedule that mirrors a work ethic built on availability, responsiveness, and practical problem solving. The small but sturdy footprint of the operation conceals a breadth of capability that makes it a rare one-stop resource in a region where complex repairs can otherwise demand multiple stops. When customers walk in, they encounter a no-nonsense atmosphere that blends the texture of seasoned shop hands with the clarity of a service approach aimed at getting people back on the road without unnecessary detours. And because today’s automotive needs extend beyond simple parts or a quick fix, the shop’s reputation grows from the core idea that reliability is earned through hands-on work, accurate measurements, and a commitment to doing things right the first time.

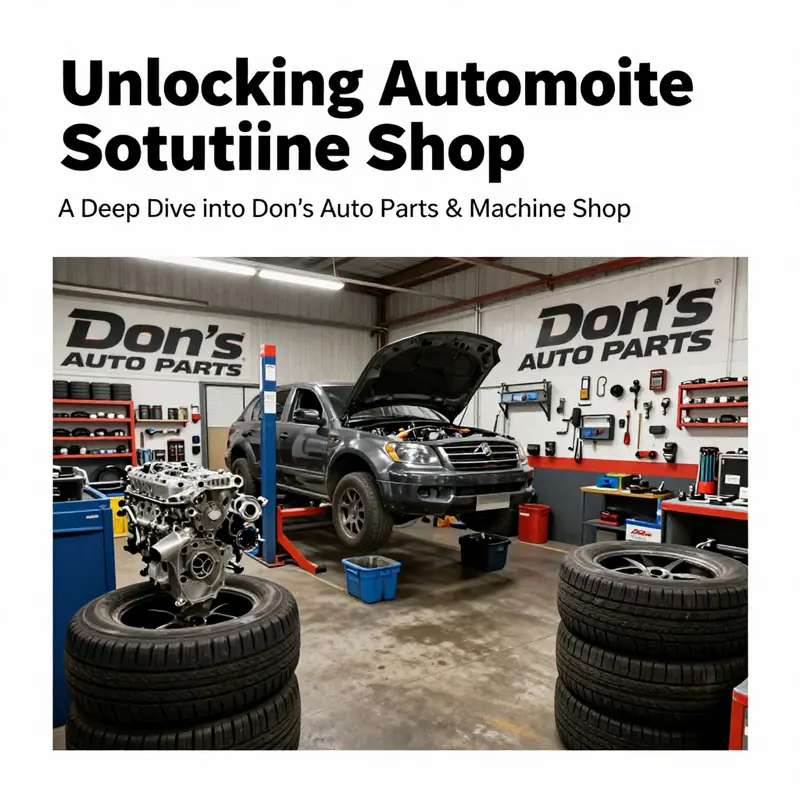

At the heart of Don’s is a full-fledged machine shop that treats engine components and other critical parts with meticulous care. Precision machining is not just a line item here; it is the language that technicians use to translate worn tolerances into smooth operation. The people who run the machines bring a blend of experience and patience, knowing that even a hundredth of an inch can change how a part performs under pressure. This isn’t about spectacle or speed alone; it’s about understanding the precise balance between material, fit, and function. The workshop atmosphere emphasizes repeatable results, with careful alignment checks, surface finishes, and deburring work that ensure parts can be installed with confidence. The result is a service that can suit routine maintenance as well as the more demanding rebuilds that come from high-mileage engines or owner-built performance projects. In this context, the machine shop becomes a backbone for the shop’s broader mission: to extend the life of vehicles while enhancing their performance in a way that’s economical and dependable for local customers who rely on their cars for work, school, and everyday life.

Drive shaft issues represent a common class of problems that Don’s addresses with both repair and rebuild options. When vibration, clunking, or driveline noise becomes a clue to internal wear, the shop’s approach blends diagnostic rigor with practical engineering. A rebuilt drive shaft is more than a fix; it’s a restoration of the power transmission path that keeps the vehicle’s momentum steady from engine to wheels. Technicians here understand the importance of balance, runout, and proper joint angles, which all contribute to smooth acceleration and predictable handling. The ability to segment a drive train issue—from a bearing shell to a U-joint or a full shaft replacement—allows Don’s to tailor its responses to the customer’s priorities, whether that means extending component life, reducing downtime, or preserving a specific driving feel that an owner has come to trust.

Electrical servicing forms another cornerstone of the operation. Starters and alternators are not simply swapped out at random; they are tested, diagnosed, and rebuilt when feasible, with an eye toward longevity and charge stability. The shop’s electrical work recognizes that modern vehicles rely on a web of sensors and controllers that demand clean, consistent electrical flow. In some cases, this means refurbishing rather than replacing, a choice that can deliver substantial cost savings while maintaining or restoring performance. The technicians approach electrical diagnostics with a methodical mindset, tracing circuits, checking voltage drops, and verifying charging system health under load. It is a reminder that the maintenance of a vehicle is not a single moment of repair but a sequence of checks that build confidence in the machine’s reliability over time.

Beyond the more traditional repair tasks, Don’s provides chassis dyno work that speaks to a different dimension of automotive care: performance testing and tuning. The chassis dynamometer serves as a controlled, repeatable environment in which a vehicle’s horsepower and torque at the wheels are measured. This data becomes valuable for both everyday drivers seeking better fuel economy and enthusiasts pursuing optimized power delivery. The dyno tests reveal how changes in mechanical condition, exhaust tuning, intake pathways, or fueling strategies translate into real-world performance. The technicians interpret these results not as a final verdict, but as a roadmap for adjustments, calibration, and, when necessary, additional service. In this way, Don’s offers a bridge between essential repair work and the sort of measured experimentation that helps a vehicle achieve its stated goals, whether they are reliability, efficiency, or a specific driving character.

What makes Don’s Auto Parts & Machine Shop stand out in Kenosha is less a single specialty and more a cohesive capability. The shop operates as a one-stop center in a region where drivers appreciate speed and quality without having to shuttle between multiple specialists. The team’s approach reflects a philosophy: everyday vehicles deserve the same attention to precision and safety that enthusiasts reserve for their showpieces. This is not about chasing every latest trend in automotive technology but about applying robust, time-tested methods to problems that arise in the field. The practical, hands-on culture is complemented by a careful understanding of what works within the local ecosystem—from the climate and road conditions to the typical maintenance cycles and repair hours that fit the busy schedules of local families and tradespeople.

The breadth of service at Don’s is anchored by a respect for the chaining of systems that keep a car safe and dependable. A machine shop program feeds into drivetrain work, which then connects to electrical diagnostics and performance testing. It’s a sequence that mirrors how modern vehicles function as integrated systems rather than a loose collection of parts. The technicians recognize that addressing one area can uncover secondary needs in another, and they are careful to communicate the implications of their findings in clear, practical terms. In this light, the shop becomes more than a set of tools; it becomes a partner in stewardship of a customer’s investment. Customers often come with a problem that began as a concern about a noise, vibration, or warning light and leave with a clearer sense of what it will take to restore or enhance the vehicle’s condition. The human element—friendly, transparent, and patient—contributes as much to trust as the specialized equipment.

On the topic of community and connection, it’s worth noting how Don’s supports a broader network of information and learning. For customers who want to explore related topics or understand the kinds of technical decisions that might accompany a repair or upgrade, the shop is a gateway to resources that illuminate complex concepts without overwhelming the layperson. This is part of the shop’s value proposition: it helps people make informed choices about their vehicles, balancing immediate needs with long-term reliability. The environment is one where questions are welcomed, and answers are grounded in hands-on experience rather than glossy marketing. In short, Don’s Auto Parts & Machine Shop in Kenosha blends the craft of traditional repair with the responsiveness required by today’s varied driving needs, creating a dependable hub that local motorists can rely on in both ordinary days and extraordinary projects.

For readers who wish to explore related topics beyond the shop’s walls, one can trace a connective thread to industry resources that discuss engine components and performance-oriented builds. A practical example is a deeper dive into engine options and compatibility for specific platforms. The reference point 4g15-engine-mitsubishi-lancer-cedia-2001-ta-cs2a offers a perspective on how engine choices interact with the broader work of a machine shop when owners pursue rebuilds or upgrades. Engaging with such content helps illuminate the kind of decision-making that happens when a shop owner or mechanic weighs performance goals against budget, time, and vehicle usage. This is not to imply that Don’s operates within any single niche, but rather to underscore the spectrum of technical considerations that a facility like this can navigate.

The ability to balance practical repair with informed exploration is what ultimately makes Don’s Auto Parts & Machine Shop a meaningful fixture in Kenosha. It is a place where skilled hands translate technical knowledge into tangible mobility, where the rustle of cutting tools is a daily rhythm, and where a customer can walk away feeling that a problem has been understood, planned, and solved with a clear path forward. The shop’s hours reflect a commitment to accessibility, and its integrated suite of services reflects a belief in the value of consolidation—saving customers time, reducing downtime, and delivering results that stand up to the test of real-world use. In this sense, Don’s embodies a pragmatic philosophy of automotive service: keep the wheels turning, keep the mechanics honest, and build trust one repair at a time. External resources and community networks naturally extend that trust, offering additional layers of information for those who want to learn more while keeping the primary experience grounded in the reliable, hands-on work that defines Kenosha’s own Don’s Auto Parts & Machine Shop.

External resource: https://www.mapquest.com/business/dons-auto-parts-machine-shop-kenosha-wi

Trust on the Shop Floor: How Don’s Auto Parts & Machine Shop Builds Loyalty in Kenosha

Don’s Auto Parts & Machine Shop sits along a practical strip of Kenosha, Wisconsin, where a steady rhythm of tools, conversation, and the hum of machines keeps pace with daily life. The building at 6814 39th Ave houses more than a storefront; it embodies a working philosophy: parts, machining, and problem solving do not have to be distant, abstract services. The space is organized for hands-on work and practical outcomes, a place where someone with a summer project and a professional mechanic with a time-crunched schedule can both find what they need. The shop keeps regular hours from Monday through Thursday, eight in the morning to five in the afternoon, which is more than a convenience; it is a signal that this is a dependable local resource crafted for the realities of work and repair. There is a clear sense from the moment a customer steps inside that this is a place that has learned to balance accessibility with capability, a crossroads where people come seeking both guidance and tangible progress on their vehicles. In such a setting, trust isn’t advertised; it accrues through steady performance and straightforward communication, day after day, visitor after visitor.

Customers repeatedly describe an atmosphere that feels welcoming without being pushy. The tone of conversations here is practical and respectful, and the staff’s approach to questions—no matter how basic or complex—reflects a culture of helpfulness rather than hurry. A pattern emerges in the town’s chatter about the shop: residents value not just the breadth of inventory but the attitude with which that inventory is approached. The feedback often highlights affordability alongside genuine assistance, a combination that matters when a budget and a timeline have to live in the same conversation. In a world where some parts stores feel like traffic through a warehouse, Don’s Auto Parts & Machine Shop stands out as a place where a customer can feel heard and guided toward a solution that fits both need and means. This consistency matters because trust, once earned, becomes a kind of currency that reduces friction during a repair or restoration project and invites customers to return when new questions arise.

The narrative of expertise runs as a thread through the shop’s reputation. It isn’t enough to stock a broad range of parts; the real value shows up when a staff member can translate a buyer’s description into precise, workable action. A telling anecdote from a classic-car aficionado underscores this blend of listening and doing. The customer recalls a session with a staff member named Tony, whose demeanor balances friendliness with precise technical knowledge. The project involved engine work on a vintage vehicle and the integration of a modern control feature into an older chassis—a combination that demands careful planning and careful execution. The appreciation centers not only on the successful outcome but on the process: clear explanations of options, honest assessments of risk, and a willingness to roll up sleeves and participate in the actual fit and installation when complications arise. In other words, the shop demonstrates a partnership approach that many DIY enthusiasts crave but seldom find at other suppliers. The effect is not merely the satisfaction of completing a task; it is the built confidence that when an unexpected snag appears, there is a local team that understands both the problem and the project’s longer arc.

What makes Don’s Auto Parts & Machine Shop especially resilient is the way it combines inventory with capability. The business handles a spectrum of needs—from quick replacements to more involved machine work—creating a one-stop experience that reduces back-and-forth and speeds up resolution. The machine side of the operation is not a separate department but an integrated resource that can craft or modify components to meet specific tolerances or fit unique configurations. This capability is particularly valuable for projects that involve older vehicles or custom builds, where off-the-shelf parts may need adaptation. The Kenosha community benefits from this synergy because it means repairs can progress without long delays while maintaining a standard of workmanship that local customers recognize and trust. The practical benefits cascade: fewer trips to multiple suppliers, faster turnaround on custom pieces, and a clearer sense of ownership over the repair journey. In this environment, the customer’s plan—whether it’s a daily driver needing dependable maintenance or a hobbyist pushing a build toward completion—has a realistic pathway to realization.

It would be easy to define the shop by its parts catalog alone, but the lived experience of customers reveals a deeper pattern. When a challenge arises, staff members do not default to suggesting the most expensive or fastest option; they explore alternatives, compare timelines, and help the customer map a route that aligns with both budget and ambition. The courtesy of a patient explanation matters as much as the availability of a rare component. This approach creates a broader sense of reliability in the marketplace: a place where a customer can anticipate honest conversations about feasibility, a clear sense of expected results, and a realistic timeline. In practice, that means customers leave with more than just a receipt; they leave with a plan and a confidence that comes from a transparent, collaborative process. The business’s willingness to discuss tradeoffs openly is a quiet strength, especially when tackling projects that require precise tolerances or custom fabrication. It is here that the shop earns the trust that turns occasional visits into ongoing relationships, with customers returning when a new question arises or a fresh project begins.

The broader impact of this approach becomes evident in the way the shop is perceived within Kenosha’s repair ecosystem. The combination of accessible hours, knowledgeable staff, and practical, affordable service creates a frictionless experience that supports both professional technicians and amateur enthusiasts. This is not about a single sale or a one-off fix; it is about nurturing a collaborative environment where people feel encouraged to pursue their automotive goals. The effect on local routines is subtle but meaningful: vehicles stay safer longer, projects are more likely to reach completion, and the sense that a capable, nearby partner stands at the ready reinforces a community’s capacity to maintain and improve its own mobility. In a region where people balance work, family, and a passion for cars, having a dependable local resource can be as important as the parts themselves.

As automotive technology continues to evolve, the value proposition embedded in this shop remains anchored in two constants: depth of knowledge within reach and a genuine willingness to invest time in a customer’s aims. The practical synthesis of parts access with machining know-how positions Don’s Auto Parts & Machine Shop as more than a marketplace; it is a conduit for turning intentions into realized outcomes. The feedback loop—driven by customer stories, word-of-mouth recommendations, and public reviews—helps keep the operation aligned with the needs of its patrons. In this sense, the shop serves as a quiet anchor in a world of rapid change, a place where the work is tangible, the conversations are honest, and progress comes with every visit. For anyone who depends on a well-tuned vehicle—whether for daily transportation, weekend restoration, or a long-term project—the message from Kenosha is clear: a local partner with experience and integrity can make the difference between hesitation and forward motion. The narrative is not about pride in inventory alone; it is about the steady, dependable presence that empowers people to push their automotive ambitions forward, one informed decision at a time.

External resource: For a broader context on sourcing specialized automotive parts from outside the immediate area, see this external reference: External automotive parts reference

Finding Don’s Auto Parts & Machine Shop in Kenosha: Directions, Hours, and Practical Access Tips

Finding Don’s Auto Parts & Machine Shop in Kenosha: Directions, Hours, and Practical Access Tips

Don’s Auto Parts & Machine Shop sits at a clearly marked spot in Kenosha, Wisconsin. The full address, 6814 39th Avenue, Kenosha, WI 53142, places the shop inside a practical commercial stretch that drivers will recognize. For anyone planning a visit, the location is simple to plug into a GPS or mapping app, and it appears reliably on major services. That visibility matters when you need parts or service without delay.

The shop keeps steady hours. It is open Monday through Wednesday, from 8:00 AM to 5:00 PM. These hours create a predictable window for planning pickups, consultations, and drop-offs. If you prefer to avoid the morning rush, mid-afternoon visits often provide quieter service. Conversely, arriving early increases the chance of speaking with knowledgeable staff before the day gets busy.

Parking and vehicle access at the site are designed with drivers in mind. The property offers straightforward vehicle access from the avenue, and there is room for short-term parking near the front. For larger vehicles, the driveway and bays accommodate common pickup sizes and small trucks used to transport parts. If you are driving a passenger car, you should find a spot quickly. If you arrive in a larger vehicle, take it slow when navigating driveway turns and watch for loading areas.

Navigation tools make finding Don’s effortless. Enter the street address into Google Maps, MapQuest, or your preferred app. These services present turn-by-turn instructions and estimated travel times. For those unfamiliar with Kenosha, mapping apps also reveal nearby cross streets and landmarks, which help when approaching from different directions. If you rely on a navigation unit that supports voice search, the shop’s name and address work well because it is properly indexed by mapping providers.

Public transit options are not detailed in public listings for the business. That said, the shop sits within a commercial district that local transit routes commonly pass through, so checking Kenosha Transit schedules is worth a quick call or a visit to their website. If you depend on buses, give yourself extra travel time. Transit connections sometimes require walking a short distance from the nearest stop to the shop. Rideshare services are another reliable choice for those without a car. They drop off and pick up directly at the address, removing worries about parking.

When planning your trip, consider a few practical tips that make the visit smoother. First, call ahead if you need a specific part or want to arrange machine shop work. A short phone call can confirm stock and provide an estimated wait time. Second, if you’re bringing a vehicle for diagnostic or machine work, ask whether the shop prefers drop-off in the morning. Early drop-offs help technicians schedule work efficiently and often shorten turnaround.

Signage at the location assists first-time visitors. The storefront and exterior display the business name and working hours. Approach the entrance at a safe speed and watch for signage indicating customer parking and bays. If a service vehicle is being loaded or unloaded, staff members often help direct cars into appropriate spots, which keeps traffic moving and prevents congestion.

The neighborhood around the shop offers convenient amenities. Nearby businesses and service centers make brief errands easy to combine with your visit. If you need to wait for the completion of a small repair or parts search, local cafés and convenience stores lie just a short walk or drive away. This proximity makes multi-stop trips practical and reduces downtime when your vehicle is being serviced.

Safety and accessibility details matter for every visit. The property is on a public avenue with standard sidewalks and curb cuts. If mobility concerns are a factor, call ahead to confirm specific accessibility features such as ramp availability or level entry points. Staff are generally able to accommodate reasonable needs and may offer to bring items to a vehicle if accessibility limits movement.

For drivers who prefer to plan their route in advance, MapQuest and Google Maps both offer clear directions and satellite views that help you visualize the approach. Satellite imagery shows parking layout, loading areas, and nearby structures. Street view imagery is often available and provides a ground-level look at parking and entry points. These visuals reduce surprises on arrival and help drivers choose the best approach lane and turn.

Timing your visit with local traffic patterns also helps. Kenosha experiences heavier traffic during morning and evening commutes. Visiting mid-morning or mid-afternoon on the shop’s open days can avoid peak congestion. If you are transporting bulky items or require loading assistance, aim for times when staff can give more attention, typically earlier in the day.

If you use a phone or tablet for navigation, save the address in your contacts or place a pin in your mapping app. That small step saves time on repeat visits. Many drivers like to screenshot the shop’s hours and address for quick reference. If you anticipate returning for parts or repeated service, ask whether the business can reserve inventory or set aside a slot for machine work. Advance arrangements reduce guesswork and help you stick to a schedule.

For those coming from neighboring towns, the route into Kenosha is direct. Main arteries feed into the commercial zone where the shop is located. If you’re unfamiliar with the area, look for 39th Avenue and use local cross streets as guideposts rather than trying to memorize complex turn sequences. Local signage and mapping cues will lead you to the storefront.

If first-time visitors want to read what others experienced, online reviews provide helpful context. They often mention parking convenience, wait times, and the clarity of directions. Reviews also offer practical hints such as which entrances are used for deliveries and which are for customer parking. For precise driving guidance, an official listing on review platforms includes the correct address and can link to mapping directions.

When a visit requires towing or a commercial pickup, let the shop know in advance. That way, staff can prepare loading areas and coordinate with your carrier. Advance notice also helps the shop plan work bays and avoids unnecessary delays. For machine work that requires repeated trips, ask whether the shop provides updated ETA messages by phone.

Reasonable planning turns a routine visit into an efficient trip. Confirm hours, verify the address, and consider traffic patterns. Use mapping tools to preview parking and approach lanes. If public transit is a must, check local schedules and prepare for a short walk from the nearest stop. Calling ahead for special requests eliminates guesswork and may speed service.

For those who want quick access to directions and customer feedback, an online listing provides the address, mapping, and reviews. You can view that information directly to plan your route and check recent visitor impressions. For additional directions and to read recent reviews, see the shop’s listing on Yelp: https://www.yelp.com/biz/dons-auto-parts-machine-shop-kenosha-wisconsin

These practical steps ensure your trip to Don’s Auto Parts & Machine Shop is predictable and productive. Whether you need parts, advice, or machine work, the address is straightforward, the hours are consistent, and local mapping tools make navigation simple. Small preparations yield a smoother visit and save valuable time on the day you arrive.

Choosing the Right Time to Visit Don’s Auto Parts & Machine Shop: Practical Timing Tips for Faster Service

Don’s Auto Parts & Machine Shop sits at 6814 39th Ave in Kenosha, a compact, experienced shop where timing your visit matters. The shop’s regular hours run Monday through Friday, from 8:00 AM to 5:00 PM, and it is closed on weekends. Knowing those hours is the basic first step. Planning the time of day you go, and what you bring with you, will save time. It will also help staff respond faster and more accurately to your needs.

Visit weekday mornings when possible. The best window is generally between 8:00 AM and 10:00 AM, when the shop is often quieter and staff can give more focused attention. Early arrivals let you beat the mid-morning rush that comes when local mechanics and fleet customers stop by. If you need detailed parts matching, measurements, or a quick consultation about a machining job, that early morning period usually provides the most attentive service.

Midday can be busier. Between roughly 11:30 AM and 1:30 PM many shops and local repair businesses place parts orders or come by for pickups. During this interval, staff juggle customer service, order processing, and phone calls. If you must come at midday, call ahead to confirm that the part you need is in stock. Calling saves a trip, and it lets staff set aside time to help you when you arrive.

Afternoons after 2:00 PM are often steady but can vary. Some days afternoons are slower, and staff can work through more involved requests. On other days the shop may be fulfilling orders and completing machine work for pick-up before closing. If your task requires drop-off of a component for machining, try to arrive early in the afternoon. That timing increases the chances the techs can inspect your item and offer a realistic pickup window.

Plan around the 5:00 PM closing time. Don’s closes promptly at 5:00 PM, which makes it important to complete transactions well before that hour. If you arrive late in the day, staff must prioritize tasks to finish daily paperwork and secure equipment. For anything that requires special ordering or detailed quoting, give the team a full business day or two to follow up. If you need to collect parts after hours, ask whether the shop can hold the item until the next morning.

Phone ahead for clarity and speed. The shop’s number, (262) 658-3737, is your quickest way to confirm current stock, get a price estimate, or arrange a convenient pick-up time. Calling before you go helps the team prepare parts or gather the information you need. It also prevents wasted trips when parts are out of stock or when a technician needs more time to assess a machining job.

Bring useful information with you. Have the vehicle year, make, model, and engine details handy. A VIN is ideal when you need exact fitment. Retain part numbers when possible, and bring photos of the part or the location on the vehicle. Clear, concise information speeds up identification. For machining requests, bring the component and any reference measurements. If you aren’t sure what’s needed, expect a short inspection at the counter.

Understand the difference between retail counter visits and machine shop work. Counter service typically involves parts sales and quick advice. Machine shop work is more involved and requires scheduling. If you bring a rotor, brake component, or other item for machining, the team will often need to inspect, quote, and schedule the work. Allow lead time; some machining jobs complete the same day, while others require more careful setup and might need to be picked up later.

Expect local trade customers early. Local mechanics and repair shops often visit early to place parts orders for the day’s work. Their presence can create a short-lived spike in activity during the early morning. If you prefer a quieter visit, aim for just before or after that spike. Early morning is still the best bet for focused one-on-one help, provided you arrive soon after opening.

Use online mapping and review tools to refine your plan. Popular map and review sites show location and directions, which help with parking and timing. Check those listings for real-time navigation and customer reviews that may highlight peak times. If your trip requires a tight schedule, consulting a map app for traffic patterns can shave minutes from your drive and reduce stress.

Prepare for holidays and unexpected closures. Hours may change on public holidays or during shop events. When planning around a major holiday, call ahead to verify hours. A quick phone check prevents wasted trips and ensures the staff can accommodate special needs.

If you need a part that might not be in stock, ask about ordering timelines. Many shops can order a part and notify you when it arrives. If the part needs to be machined, the combined timeline includes both the shipping time and the machining lead time. Ask for an estimated ready date. Good communication with the shop means you can schedule your vehicle downtime and pick-up accordingly.

Respect busy windows when possible. If you see a steady flow of trade customers, consider returning later. Shops run most efficiently when staff handle a continuous stream of similar requests. Dropping in for a complex question during a busy period may delay service for everyone, including you.

Make use of staff knowledge. Don’s staff often have practical experience beyond parts sales. A short conversation at the counter can clarify whether a simple replacement will work or if a machining solution is required. Use your morning visit to ask these questions while staff can give undivided attention.

Think about pickup strategies. If you place an order or drop off a part, agree on a clear pickup time. Ask whether the shop can call or text when your item is ready. If no after-hours pickup option exists, plan to arrive during open hours to avoid missing the collection.

For repeat visits, develop a relationship. Regular customers who provide clear vehicle details and part histories tend to get quicker service. If you frequently work with the shop, staff will better anticipate your needs and reduce lookup time.

Parking and access are typically straightforward at the Kenosha location. Arrive with a general sense of what you need and be ready to explain specifics. If you are unsure about the component, hand it to the staff for inspection rather than guessing. Accurate information shortens the transaction and improves results.

Finally, remember that flexibility helps. If a quick job becomes more complex, the staff will propose options and timelines. Being prepared to wait until the next morning for a thorough fix can be better than a rushed, temporary solution.

If you want to preview parts and accessories while you plan your visit, consult a nearby parts catalog for reference, such as this front bumper catalog: https://mitsubishiautopartsshop.com/front-bumper-mitsubishi-outlander-19/. For directions, customer experiences, and up-to-date information about hours, check the shop’s listing on Yelp: https://www.yelp.com/biz/dons-auto-parts-machine-shop-kenosha-2. Calling ahead to (262) 658-3737 remains the simplest way to confirm availability and get precise guidance for your trip.

Grounded in Community, Driven by Craft: Positioning Don’s Auto Parts & Machine Shop in Kenosha’s Competitive Aftermarket

In Kenosha, a small storefront that doubles as a machine shop anchors Don’s Auto Parts & Machine Shop as a dependable, local hub where inventory, on-site machining, and straightforward service meet the needs of families and fleets alike. The story highlights how a community-driven shop can compete with larger distributors by offering breadth of in-stock parts, precision fabrication, and transparent pricing, turning proximity and trust into a durable advantage in a marketplace defined by scale.

Final thoughts

Don’s Auto Parts & Machine Shop provides invaluable services to business owners seeking reliable automotive parts and expertise in Kenosha. Its customer-focused approach and a wide variety of offerings distinguish it from competitors. Understanding its operational strengths, customer satisfaction, and optimal visit times can help businesses maximize their partnership with this essential local resource. As you consider your automotive needs, keep Don’s Auto Parts & Machine Shop at the forefront for quality solutions and dependable service.