A&A Auto Parts and Service stands as a cornerstone for businesses reliant on automotive parts and services. This comprehensive guide will delve into the various facets of A&A Auto Parts and Service, exploring its business operations, the product range it offers, how it engages with customers, the accessibility of its location, and the broader impact it has within the industry. By understanding these elements, business owners can appreciate the value of aligning with a trusted supplier that enhances operational efficiency and customer satisfaction.

From Data to Drive: How A&A Auto Parts and Service Orchestrates Inventory Intelligence and Customer Care

At its core, A&A Auto Parts and Service operates as a dynamic, customer-centric enterprise within the automotive aftermarket. The business blends wholesale distribution with full-service vehicle care, placing it at the crossroads of efficient supply networks and dependable, hands-on support for both repair shops and everyday drivers. This blend is not accidental; it is the result of deliberate choices about sourcing, inventory discipline, and a service philosophy that treats each interaction as a moment to earn trust and repeat business. The operation rests on three pillars: strategic sourcing, disciplined inventory management, and responsive technical support, each aligned to meet the needs of a diverse set of customers who require reliability, speed, and clarity in a sector known for volatility. The orchestration of these elements creates an operating rhythm that feels both steady and adaptable, a balance that becomes visible not just in back-room figures but in walk-in conversations, repair schedules, and the pace of replenishment when a shop’s timeline tightens.

The company leverages modern BI tools to drive operational excellence across its value chain. Real-time data on product sales trends, pricing performance, and customer demand patterns allow A&A to tune its catalog with precision. Restocking becomes proactive rather than reactive, reducing the twin risks of overstock and stockouts and turning inventory turnover into a measurable competitive advantage. Managers and staff are empowered with insights that translate into better decisions, from pricing adjustments to targeted staff training. For instance, by flagging underperforming SKUs or surprising surges in demand, leadership can tailor promotions, adjust staff allocations, and streamline replenishment workflows so that service levels stay high even as market conditions shift. This data-driven mindset extends beyond the shop floor into the back office, shaping how the business plans purchases, negotiates with suppliers, and evaluates supplier performance over time. The aim is not just to move parts but to move the business forward with clarity and accountability. When paired with a rigorous feedback loop from customers and technicians, BI becomes a continuous improvement tool rather than a one-off report.

Operational agility also hinges on physical design choices that reflect how customers shop in a dynamic parts environment. A&A employs mobile auto parts display racks with locking casters in its showroom and service center lobbies. These flexible displays can be reconfigured in minutes to spotlight seasonal lines, promotional bundles, or new technology categories. The liquidity of space—how quickly a rack can be moved, how a display can be reshaped—translates into a front-end experience that feels intuitive and responsive. Staff can guide customers through an organized, visually engaging journey, reducing search time and reinforcing trust that the shop can meet both routine maintenance needs and sudden repair requirements. The approach marries form and function: a layout that invites browsing yet preserves the efficiency that professional repair shops demand when downtime costs money. This design mindset also supports safety, ensuring pathways stay clear and interactions remain orderly during peak periods.

Strategic sourcing anchors the supply network in a way that underpins resilience and value. A&A draws from a dual-sourcing model that encompasses suppliers in high-precision manufacturing hubs abroad and a robust American network in the Southern Corridor. The cross-border mix taps into the efficiency of established logistics corridors in China, where precision components and scalable capacity can help keep prices competitive and availability steady. Simultaneously, American suppliers in Southern states provide proximity, faster lead times for time-sensitive orders, and robust support structures near customers who operate service centers and fleets. The lure of these regions is not merely geographic; it is economic and strategic: favorable tax policies, lower operating costs, modern infrastructure, and ongoing investments in manufacturing capacity, including components aligned with evolving vehicle technologies such as electrification. This dual-sourcing strategy enhances supply chain resilience by reducing dependence on any single region, while broadening access to advanced tooling and components that keep the business aligned with industry trends. The result is a portfolio of partnerships that can adapt to disruptions, shifts in demand, and the emergence of new vehicle platforms, all while maintaining predictable pricing and dependable delivery windows for customers.

All of these elements work in concert to fuel sustainable growth and a competitive edge. Data analytics, flexible physical design, and a globally informed supplier network create an integrated operating rhythm. The outcome is not a mere catalog of parts, but a reliable capability: speedier fulfillment, clearer communication with customers, and the confidence that parts and service are available when needed most. In a market where reliability matters as much as price, A&A demonstrates that excellence is achieved through deliberate integration of people, processes, and technology. The local footprint matters too—the Brentwood address serves as a hub where logistics meet personalized service, where technicians and sales staff coordinate to diagnose needs, source parts, and schedule service in a way that respects customers’ time. The shop’s hours reflect this practicality, opening weekdays to accommodate both walk-in customers and professional repair shops seeking timely solutions. This operational cadence is reinforced by a culture that values feedback, continuous improvement, and the willingness to adapt in response to what the data, staff experience, and customers reveal. The emphasis on real-world responsiveness means the business can pivot as preferences shift—from quick-turn repairs to longer-term fleet-support programs—without sacrificing service quality or efficiency.

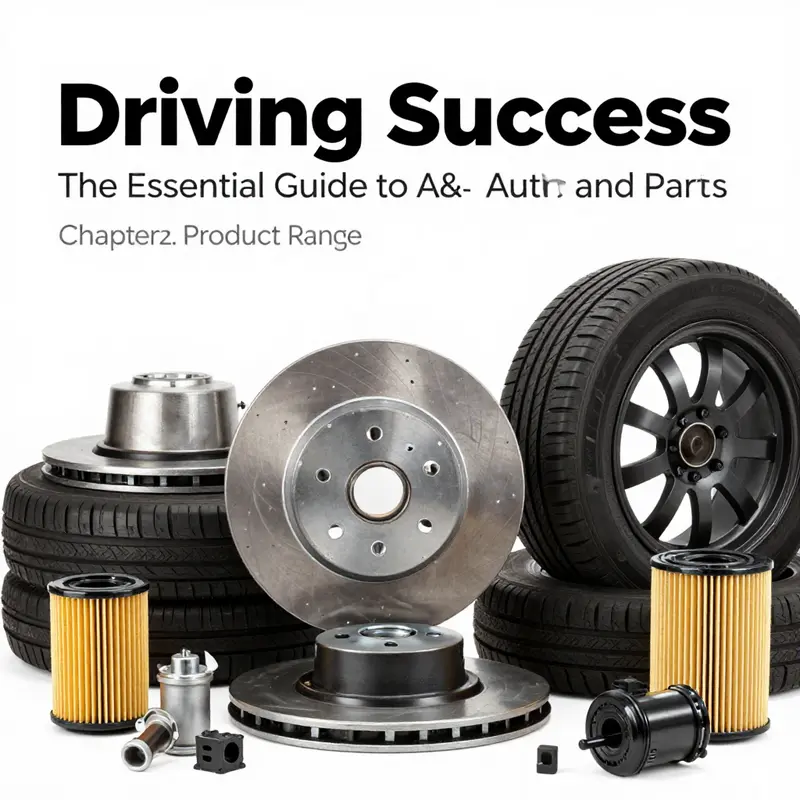

Within this ecosystem, inventory variety becomes a conscious strength rather than a passive catalog. The breadth of available parts reflects a commitment to supporting a wide spectrum of vehicles and configurations. In practice, that means stocking items that may only appear periodically but play a crucial role in keeping vehicles on the road. Inventory decisions are guided by analytics but tested in the field through direct customer interactions. A well-curated mix includes rare or specialty items that can transform a stalled project into a timely repair, underscoring the value of proactive procurement and flexible stocking policies. In a tangible reminder of what “variety with reliability” looks like, a representative catalog item might surface in the showroom as a high-demand component that can be sourced quickly, illustrating how stock availability translates into customer outcomes. For those who want to glimpse the breadth of catalog options, a representative item such as brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x can serve as a concrete example of how a shop reframes a sourcing challenge into an opportunity for value creation.

As the business moves forward, the integration of data, space, and sourcing continues to evolve. The outcome is a practical, customer-centered model of parts and service that can adapt to shifting demand, new vehicle technologies, and changing regulatory or tax environments. It is a model built on clarity—clear communication with customers about what is in stock and when it can be delivered; clear expectations within the team about how inventory will be managed; and clear accountability for how service timelines align with shop schedules. In the end, the success of A&A Auto Parts and Service rests on the daily alignment of these elements: the right parts available at the right time, the right support to install them, and the right information to guide every customer conversation. That alignment, lived out in Brentwood and refined through its supplier network, marks the core of a modern, resilient automotive aftermarket business. In the ongoing dialogue with customers, suppliers, and service partners, the chapter on operations remains focused on turning data into dependable outcomes, space into efficiency, and sourcing into value that a diverse customer base can trust week after week.

External perspective, including customer voices, can be found in the shop’s consumer reviews. For a local sense of the experience, see the shop’s Yelp profile: https://www.yelp.com/biz/aa-auto-parts-and-service-brentwood.

null

null

Turning Encounters into Loyalty: The Customer Engagement Engine at A&A Auto Parts and Service

The physical and operational environment matters as a direct and moderating influence on customer engagement. Clean, navigable aisles, clearly labeled sections, and a front-desk presence that communicates readiness set a tone of respect and clarity. When customers see staff who listen first, ask clarifying questions, and explain options in practical terms, they feel empowered to explore rather than retreat. This sense of agency matters because maintenance decisions often involve trade-offs—between urgency and budget, between speed and completeness, between the current need and potential future risks. A&A’s staff behavior is proven to influence how customers perceive the value of their time, how confidently they compare alternatives, and how open they are to seeking expert guidance. The service environment becomes a living laboratory for engagement: it shapes customers’ willingness to linger, to compare, and to consult, rather than to hurry and finalize a checkout script. When a consumer experiences transparency and courtesy in the shop, that experience resonates with broader expectations about service quality and reliability, reinforcing positive attitudinal and behavioral outcomes over repeated visits.

Brand equity emerges as a quiet but powerful force in this setting. The research on service marketing underscores that brand equity functions as a moderating variable; it amplifies trust and satisfaction, and helps stabilize loyalty when customers face competing choices. For A&A, equity is built through a combination of consistent product quality, predictable pricing, and dependable after-sales support. These elements create a perception of reliability that stands up to market fluctuations and to competing shops. It is not the occasional discount that sustains loyalty; it is the daily perception that the shop is honest, precise, and dependable. In practice, this translates to clear catalogs or information on what parts fit what systems, transparent timelines for orders and returns, and follow-through if a part proves faulty or needs adjustment. Over time, customers come to rely on A&A not merely as a source for parts but as a partner in keeping their vehicles—or their specialized equipment—operational. This deepened trust supports both attitudinal loyalty, expressed as trust and satisfaction, and behavioral loyalty, evidenced by repeat visits and referrals. The outcome is a brand relationship where customers feel confident making a commitment to the shop even when convenience competes with other options.

The internal machinery behind that trusted relationship—resource management and service innovation—gives A&A its competitive edge. Inventory management across diverse vehicle systems, robust supplier partnerships, and the digital tools that organize customer histories and service notes together reduce friction at the moment of need. When a customer returns for recurring maintenance, staff can quickly retrieve prior transactions, track parts histories, and recall preferred communication channels. This back-end clarity translates into front-end speed and precision: faster service, fewer misunderstandings, and more personalized recommendations that align with a customer’s maintenance philosophy. It is a practical demonstration of how a service ecosystem can be designed to elevate the customer experience rather than merely support it. The result is a cycle in which confidence grows, enabling customers to engage more deeply with the shop—asking questions, seeking deeper explanations, and accepting longer-term maintenance plans that align with their risk tolerance and schedules. In this sense, the shop’s efficiency and its commitment to transparent processes work together to deliver a dependable experience that customers can anticipate and rely upon.

For enthusiasts who arrive with a specific aim—whether it is a performance enhancement, a particular upgrade, or a repair that requires precise parts—the shop acts as a bridge to wider possibilities. A&A’s network of relationships with suppliers means staff can guide customers through options with clarity, ensuring compatibility and quality while respecting budgets and timelines. This guidance matters because it demonstrates that the shop values informed decision-making as a core service, not an afterthought. To illustrate how the engagement mindset translates into tangible choices, consider how the shop can connect customers to specialized upgrades through its partner channels. For example, consider a high-value component that may appeal to a devoted enthusiast; customers can explore targeted options in partnership with trusted suppliers, and the shop can facilitate the conversation to ensure fit and performance expectations are aligned with the customer’s vehicle and their intended usage. To provide a concrete sense of the kind of sourcing that underpins this engagement, the shop can direct curious readers to resources such as brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x. This link, while specific, exemplifies how the broader network can be navigated with confidence when trust and transparency are the anchors of the relationship. It signals to customers that the store is not a gatekeeper but a curator of options—someone who helps translate needs into informed, feasible choices rather than simply pushing a sale.

The ongoing payoff of this approach appears in the steady rhythm of customer conversations, the reduction of uncertainty during purchasing decisions, and the growth of loyalty as customers experience a predictable, fair, and respectful process. Yelp and similar public signals add to this narrative by validating that the shop consistently operates with open hours, professional service, and accessible information. But the real metric of success lies in the daily practice of each staff member: listening intently, naming the next best steps, and delivering on promises with precise timing. When customers sense a collaborative relationship rather than a transactional exchange, they are more likely to view maintenance as a shared responsibility—an approach that elevates engagement from a fleeting moment to an ongoing partnership. The environment, the brand, and the operational backbone come together to create this sense of partnership, which in turn reinforces a cycle of trust and participation that outlasts competing offers and evolving market pressures.

Looking forward, the path to deeper engagement rests on extending this philosophy through deliberate attention to digital touchpoints and continuous learning. Personalization matters because it reflects the shop’s memory of customers—their histories, their preferences, and their service goals. When the team can greet a familiar client with a concise, informed plan, the encounter feels smoother and more respectful of time. Equity continues to play a central role here: customers who trust the shop’s integrity will stay engaged even as options diversify, and they will likely share their positive experiences with peers who seek reliable, transparent partners for their vehicles and equipment. The location, the open hours, and the visible readiness to help collectively reinforce the core message: A&A Auto Parts and Service is a neighborhood anchor that treats maintenance as a collaborative journey, not a mere transaction.

External perspective on these dynamics helps place A&A’s approach in a broader context. For researchers and practitioners interested in how the service marketing mix and customer engagement unfold in real-world settings, a meta-analytic synthesis offers valuable insights into the mechanisms by which service environment and brand equity translate into engagement outcomes. See the following resource for a rigorous examination of these dynamics: Service marketing mix and customer engagement: A meta-analysis.

null

null

Chapter 5: The Industry Footprint of A&A Auto Parts and Service in a Changing Mobility Era

The industry is not a ledger of numbers alone; it is a living network of parts, people, and places that keeps people moving. A&A Auto Parts and Service sits at a crucial intersection of that network, translating macro trends into practical, local impact. When we talk about the industry’s impact, we mean more than GDP figures or production cycles. We are looking at a system that fuels repair shops, enables small businesses to thrive, and sustains a diverse set of markets—from everyday passenger cars to off-road rigs, boats, and industrial equipment. In this light, A&A’s contribution goes beyond supplying components; it helps sustain the reliability and resilience of the transportation ecosystem in which every driver relies. The shop’s blend of high-quality parts and hands-on service embodies a broader industry movement: precision, accessibility, and adaptability in a market that demands both speed and accuracy. The company’s location in Brentwood situates it within a dense web of suppliers, distributors, and customers who expect a quick turn around and dependable advice. In that sense, the industry impact is tangible—felt in the lanes of daily commute as surely as in the back rooms of service bays and warehouse floors that keep inventory flowing toward those who need it most. A&A, with its emphasis on off-road, marine, and industrial gear as well as standard automotive components, illustrates how a modern parts and service provider operates with breadth and depth in a dynamic economy.

The historical arc of the U.S. auto sector helps illuminate the contemporary role of independent shops like A&A. After World War II, vehicle ownership surged from 31 million in 1945 to nearly 60 million by 1954 and reached about 100 million by the late 1960s. Cars became more than transportation; they were social spaces and cultural touchstones that shaped neighborhoods, commerce, and daily life. Those decades saw the automotive ecosystem expanding production capacity, creating jobs, and forging the complex supply chains that underwrite today’s service-driven model. At its peak in the early 1970s, motor vehicle output represented a sizable slice of GDP, underscoring the industry’s dominant economic position. Although this share declined as global competition intensified, auto-related value-added remained a meaningful fraction of the economy, and it continues to anchor manufacturing, employment, and innovation. A&A’s operations reflect this enduring footprint: even as the industry evolves toward digitization and electrification, the core needs—reliable parts, skilled labor, and efficient service—remain constants that local shops fulfill with increasing sophistication. The Brentwood shop’s capacity to serve passenger cars, off-road vehicles, boats, and industrial equipment illustrates how a single seller can mirror broader sectoral diversification and resilience.

Recovery after the financial crisis of 2007–2009 demonstrated the sector’s capacity to adapt and rebound. The downturn pressured production and demand, prompting strategic adjustments across manufacturing, distribution, and repair services. Government interventions and private-sector reinvestment fostered a climate where technology and process improvements could flourish. For A&A, this translated into embracing digital inventory systems that reduce backorders, improve accuracy, and shorten the path from order to installation. Predictive maintenance concepts began to migrate from large fleets and industrial accounts into the shop floor, enabling technicians to anticipate wear, stock commonly needed items, and schedule work with fewer interruptions. For a business that touches multiple markets—cars, off-road, marine, and industrial equipment—the ability to forecast demand and align staffing with maintenance cycles translates into more dependable service and steadier cash flow. This operational discipline also minimizes waste and strengthens the local supply chain, which is especially valuable in a regional economy that relies on small businesses to deliver comprehensive mobility solutions. As electrification and advanced diagnostics accelerate, the industry’s revival is less about returning to a past peak and more about building a modern, adaptable framework that can support a wide spectrum of vehicle systems and usage patterns.

Beyond macro resilience, the industry’s vitality rests on the connective tissue of employment and supply chains. A&A’s diversified portfolio helps sustain a broad set of jobs—from parts specialists who can identify the exact fit for a niche model to technicians who perform precise repairs in challenging environments. Local and regional shops anchor the mobility economy by delivering accessible maintenance and repair, which keeps families and workers on the road and reduces downtime. The impact on small businesses extends to distributors, warehousing networks, and logistics providers that coordinate just-in-time deliveries and returns. When the parts ecosystem functions smoothly, the entire community experiences more predictable costs and improved service quality. Digital catalogs, cross-reference databases, and streamlined ordering systems mean technicians can spend less time hunting for parts and more time delivering value to customers. The ability to train and retain skilled staff in a rapidly changing space—where EVs, hybrids, and advanced driver-assistance systems are becoming commonplace—also underpins regional economic health. A&A’s commitment to EV-compatible training signals a practical path for a local business to contribute to national momentum toward sustainable mobility, while maintaining the personalized, familiar customer experience that defines neighborhood shops. In this way, every successful repair or stocked part becomes a thread in a larger fabric of economic stability and regional prosperity.

The shift toward electric propulsion and smarter mobility offers both challenge and opportunity. Industry dynamics now privilege distributors and retailers who can blend product breadth with technical guidance, data-driven stock management, and flexible service offerings. For a business like A&A, the opportunity lies in expanding beyond traditional parts to include high-efficiency, long-life components, diagnostic software, and charging compatibility knowledge. The emphasis on quality—both in components and in workmanship—remains a nonnegotiable value, even as the mix of products evolves. A diversified approach that includes off-road and marine equipment helps insulate the business from localized demand shocks and creates a more resilient revenue base. Training programs and partnerships with distributors become essential to staying current with new vehicle architectures, battery technologies, and safety protocols. In this evolving landscape, the neighborhood auto shop becomes a crucial partner in the transition, offering consumers practical pathways to maintain, upgrade, or repurpose vehicles and gear as needs and technologies change. The result is a more dynamic, responsive marketplace in which customers gain reliable access to parts and expertise, and local economies benefit from steady employment and ongoing demand for skilled services.

Consumer expectations drive the industry toward speed, accuracy, and trust. Customers today want assurance that the right part will fit correctly, perform reliably, and last under typical use. A&A’s emphasis on high-quality parts and service, combined with its cross-market expertise in off-road, marine, and industrial equipment, aligns with these expectations. The shop’s operational model—emphasizing inventory accuracy, transparent pricing, and clear communication—helps ensure that a customer’s time is valued. When a customer arrives with a repair need, they expect not only the exact component but also concise guidance on installation and maintenance. This trust is earned through consistent supply chains, dependable turnaround, and ongoing technician education. Digital tools—from inventory dashboards to order-tracking systems—lower costs and speed up delivery, delivering a tangible return for customers who face increasingly tight schedules. The broader industry benefits when more local shops compete on service quality and knowledge, expanding access to reliable parts across neighborhoods and regions. In that sense, A&A’s choices about partnerships, training, and inventory strategy contribute to a healthier, more inclusive mobility economy where families, commuters, and small businesses all find dependable support.

The interplay between local shops and national trends is further illustrated by the availability of specialized parts that respond to evolving consumer interests. For example, components designed for performance cars, off-road builds, and specialty marine equipment reflect a market that values customization and durability. The ability to access such parts through a trusted local supplier reduces dependence on distant retailers and strengthens community resilience. A practical example of this trend can be seen in parts catalogs that feature niche items such as wheels designed for specific models. See this listing for an detailed example of how wheels are matched to particular applications: 17-rims-fit-mitsubishi-eclipse-wheels-2018-2019-2020-2021-2022-2023-17×7-5-new. Such a resource highlights how a modern auto-parts business integrates product variety with customer guidance, turning a catalog into a reliable planning tool for enthusiasts and professionals alike.

In a broader context, the auto industry’s current and future trajectory is illuminated by leading industry analyses that emphasize the economy-wide impact of mobility and the critical role of suppliers and service providers. For additional perspective on how the auto sector contributes to GDP, employment, and innovation, see Deloitte Insights’ analysis of the auto industry’s impact on the economy: https://www2.deloitte.com/us/en/insights/focus/industrial-strength/auto-industry-impact-on-economy.html

Final thoughts

Understanding A&A Auto Parts and Service highlights not just a reliable supplier but a partner committed to enhancing operational success. From their vast selection of high-quality parts to their exceptional customer service and strategic location, A&A represents a model for business owners looking to streamline their supply chain. Engaging with such a provider can only bolster a business’s reputation and operational reliability, cementing A&A’s critical role in the automotive sector and beyond.