A Grade auto parts represent the pinnacle of quality in the automotive industry, providing reliable, high-performance components for vehicle repairs and enhancements. As business owners navigate a marketplace filled with various auto parts, understanding the attributes and advantages of A Grade parts becomes essential. This article delves into three crucial aspects: first, we will explore the characteristics and quality of A Grade auto parts, shedding light on why they are considered the premium choice. Next, we will analyze the economic impact of A Grade auto parts on the automotive industry, revealing their role in driving profit margins and consumer trust. Finally, we will address the importance of reliability in A Grade auto parts for consumer safety, reinforcing the value of investing in high-quality components.

A Grade Auto Parts: Precision, Proven Durability, and the OEM-Equivalent Standard

A Grade auto parts represent a quiet benchmark in the world of replacement components. They are the answer for vehicle owners and mechanics who seek performance that mirrors OEM quality, reliability that endures, and an assurance that the part will perform when it matters most. This chapter unpacks what makes A Grade parts distinctive, how they are produced and tested, and why they matter in the broader ecosystem of vehicle maintenance. It also explores the practical considerations a reader might weigh when evaluating replacement parts, from selection criteria to the realities of sourcing, installation, and long-term value. In the simplest terms, A Grade parts are designed to function as if they were new from the factory, meeting or exceeding original specifications while offering a compelling balance of durability, fit, and performance. They are not merely refurbished or repurposed components; they are the culmination of stringent processes that align with the demanding expectations of modern automotive engineering. The idea is straightforward, but the implications are deep: when a part is labeled A Grade, it signals a level of scrutiny that translates into safer operation, fewer surprises on the road, and a vehicle that can maintain its performance envelope over time.

At the heart of A Grade parts is the commitment to precision. Precision engineering means that every component is manufactured to tight tolerances, ensuring a precise fit and predictable function within the vehicle’s systems. When a part fits as intended, the risk of misalignment, improper sealing, or compromised clearances diminishes. This is especially critical for components that endure high stresses, temperatures, or rapid cycling, such as engine-related parts, valvetrain elements, and transmission components. The emphasis on precision is not merely about average measurements; it is about consistency across production lots, so a customer can trust that the same part purchased at different times will perform in a similar way. Precision also extends to the surface finishes, threading, mounting points, and connection interfaces. If a part is off by a hair, the consequences can ripple through the system, reducing efficiency, increasing wear, or altering timing and response characteristics. A Grade parts are engineered to minimize those risks, delivering predictable performance that aligns with OEM tolerances.

The second pillar of A Grade parts is the use of superior materials. The strength, hardness, fatigue resistance, and thermal stability of a component determine how it will perform under load and in demanding conditions. High-grade alloys and carefully selected composites enable parts to resist deformation, wear, and heat-induced changes. This matters profoundly for components that operate under stress, such as pistons, connecting rods, cylinder heads, and critical transmission elements. Material quality influences everything from efficiency and power delivery to heat management and durability under extreme operating conditions. When a part is built from top-tier materials, its lifecycle tends to be longer, its performance more stable, and its risk of premature failure reduced. These attributes are particularly valuable for vehicles that are driven hard, in climates with wide temperature ranges, or in duty cycles that repeatedly push components to the edge of their design limits.

Coupled with material choices is a rigorous testing regime. A Grade parts undergo extensive testing to verify safety, reliability, and performance. Tests may span endurance, thermal cycling, vibration, and functional verification under real-world conditions. Endurance testing, for example, simulates extended operation to reveal wear patterns and potential failure modes long before a part is publicly sold. Thermal cycling ensures that parts can endure the temperature fluctuations that occur during normal operation, from cold starts to high-heat driving. Vibration testing checks resilience against the rhythmic stresses of road movement, engine torque, and drivetrain dynamics. The result is a body of evidence that a part can withstand the repetitive forces it will encounter in actual use. This testing also helps engineers identify areas for design improvement, so parts become more robust with every iteration. In practice, the combination of precision engineering, premium materials, and thorough testing creates a level of reliability that owners can feel when turning the key or pressing the accelerator.

Quality control is the third cornerstone. The production pipeline for A Grade parts emphasizes stringent checks at multiple stages. Incoming materials are inspected for composition and uniformity; components are measured to confirm tolerances; and finished parts are examined for surface integrity, fitment accuracy, and functional readiness. Quality control is not merely a final gate; it is a continuous thread that runs through design, fabrication, assembly, and post-production evaluation. The goal is to catch deviations early, prevent defects from propagating, and deliver a consistent product that aligns with OEM expectations. When a consumer reads a label declaring A Grade, the underlying assurance is that the part has survived a rigorous quality funnel, not a single-pass test. This meticulous approach to quality control is crucial because it underpins the reliability and safety that vehicle owners rely on, especially when aftermarket parts must substitute for factory-installed components.

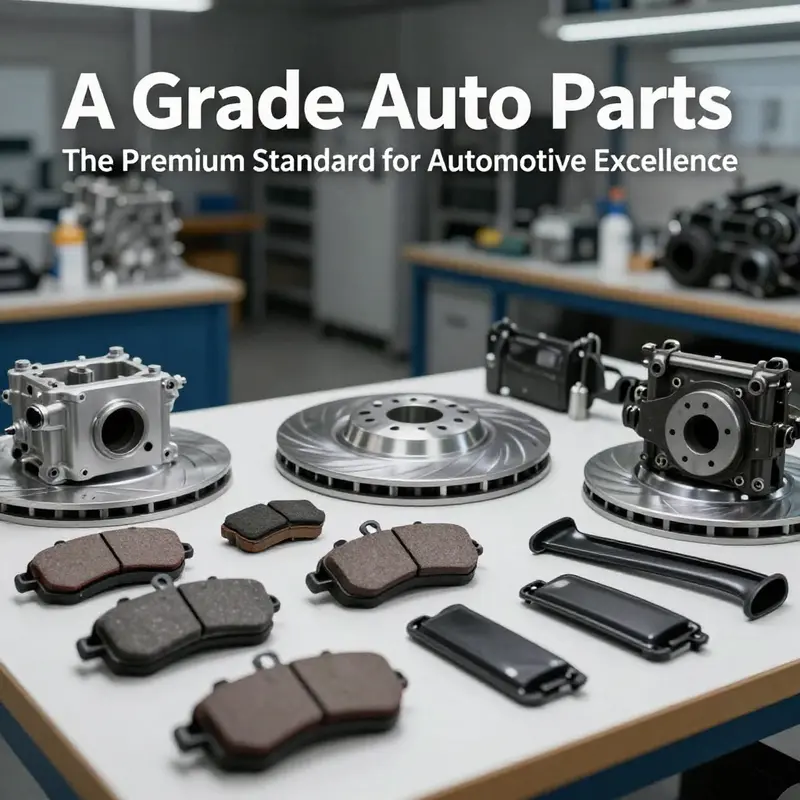

The spectrum of parts that commonly appear in the A Grade category spans several critical systems. Engine pistons must withstand high pressures and temperatures, maintaining a seal and tolerances that preserve combustion efficiency. Connecting rods must reliably transmit forces from the piston to the crankshaft without bending or failing under heavy load. Cylinder heads, with their complex geometry for gas flow and heat management, demand precise machining and surface finish to optimize performance and cooling. Transmission components, such as clutches and related assemblies, require exact friction characteristics and durability to deliver smooth shifting and long life. In each case, the A Grade standard implies more than a nominal equivalence to original equipment; it implies a confidence that the part will behave as the original did under similar conditions, and often with a margin of improvement in durability or consistency.

Global standards and compliance underpin the transition from concept to customer. A Grade parts are increasingly aligned with internationally recognized specifications and quality frameworks that aim to harmonize production, testing, and performance expectations across borders. The emphasis on standards fosters compatibility and predictability for buyers who may source parts from different regions. A practical illustration of this emphasis is the adoption of rigorous quality management schemes and industry-specific norms that emphasize traceability, repeatability, and performance verification. While the exact standards can vary by jurisdiction and by manufacturing lineage, the shared objective remains clear: to ensure that a part labeled A Grade can be expected to behave consistently, ensure a high level of safety, and contribute to the overall reliability of the vehicle. This international orientation is essential for a modern aftermarket landscape in which vehicles are valued not just for their performance in the showroom, but for their performance on the road years after purchase.

The value proposition for A Grade parts hinges on more than technical excellence. It rests on the quiet certainty that replacement components can restore, or even extend, a vehicle’s original performance envelope. For owners and technicians who prioritize performance and safety, replacing a worn part with an A Grade alternative can preserve the vehicle’s drivability, fuel efficiency, and dynamic response. The long-term benefits often include reduced maintenance surprises, more predictable operating costs, and a greater sense of vehicle reliability in daily driving or more demanding use. In environments where safety is paramount, such as roads with variable weather or demanding traffic patterns, the reliability of A Grade parts contributes to safer operation and fewer unplanned service interruptions. In this sense, A Grade parts offer more than a quick fix; they provide a sustainable path to maintaining the integrity of the vehicle’s design goals and performance expectations over time.

For readers interested in concrete exemplars of OEM-equivalent design ethos, one can observe how replacement components are positioned and presented in the market. A Grade parts are not marketed as mere substitutes; they are framed as high-fidelity replacements that retain the original instrument’s intent while leveraging modern materials and manufacturing capabilities. The emphasis on fit and function matters because it reduces the need for corrective work after installation. A part that fits correctly and performs as intended minimizes downtime, reduces the likelihood of warranty disputes, and supports a smoother maintenance experience overall. The reality is that a well-chosen A Grade part can feel indistinguishable from the original component in terms of both performance and the quiet assurance of reliability that comes with a clean install.

From a consumer’s perspective, evaluating A Grade offerings involves more than price and appearance. It requires looking at the claims around precision, materials, testing, and quality control. It involves asking whether the part is designed to OEM specifications, whether it has undergone rigorous performance verification, and whether the manufacturing lineage supports consistent quality across batches. It also means considering the broader ecosystem: how the part is supported by warranties, how readily it can be sourced, and how easily it can be integrated with existing vehicle systems. These considerations matter because modern vehicles rely on a network of interacting components that must work in concert. A Grade parts, when chosen with a clear understanding of their standards, can help preserve the harmony of this network rather than introduce mismatches that create friction in performance or reliability.

The sourcing story behind A Grade parts is a reminder of the downstream realities of the automotive aftermarket. Parts labeled A Grade are often drawn from components that have low mileage or are newly manufactured. This approach minimizes the assumed wear that could compromise performance and ensures that the part has not already accrued a level of fatigue that could shorten its life. In practical terms, the lifecycle of an A Grade part tends to be longer, with a reduced need for early replacement. This translates into cost savings over time, particularly for critical components where failure could carry significant consequences for safety or drivability. Yet, the price premium that some buyers associate with A Grade parts should be balanced against the value of the extended service life and the peace of mind that comes from quality control and consistent performance.

Which brings us to a subtle but important point: A Grade is not a blanket guarantee of perfection. It is a rigorous category that signals a high standard, but no part is immune to the realities of usage, environmental exposure, or installation practices. Buyers should verify compatibility with their specific vehicle model, confirm that the part meets relevant technical specifications, and consider the installation context, including tools, torque requirements, and any necessary software updates or calibration that may accompany a replacement. The right approach combines due diligence with the confidence that comes from a well-structured quality program. In this sense, A Grade parts empower owners to make informed choices, balancing performance expectations with practical considerations like availability, warranty terms, and total cost of ownership over the vehicle’s remaining life.

To bring this narrative back into practical reality, consider how a customer might connect this understanding to real-world decisions. The idea is to look beyond a label and toward the conditions that make a part trustworthy: the engineering rigor that supports precise fit and function, the material choices that resist wear and heat, the testing that exposes hidden failure modes, and the ongoing quality controls that ensure uniformity across production runs. When these factors align, a replacement part becomes more than a substitute for a worn element; it becomes a reliable enabler of sustained performance, safety, and value. The result is a vehicle that continues to deliver the driving experience its owner expects, with less risk of sudden breakdowns or performance dips that can erode confidence over time.

For readers who want a concrete point of reference while exploring the broader landscape of A Grade parts, an internal example you may encounter in market listings highlights how OEM-aligned design and high-quality production meet. For instance, a page documenting an OEM-style rear bumper for a specific model offers a window into how manufacturers frame and communicate the standards behind an A Grade designation. This page is part of a broader ecosystem where parts are positioned not merely as replacements but as faithful continuations of the vehicle’s original design intent. You can explore that reference here: 03-06-mitsubishi-evolution-8-9-jdm-rear-bumper-oem. This link provides a tangible sense of how a component might be described and presented in a market that values OEM-equivalent performance without demanding the same price as a brand-new part.

In summary, A Grade auto parts embody a disciplined synthesis of engineering precision, superior material science, rigorous testing, and stringent quality control. They are positioned to deliver reliability, durability, and performance that closely track OEM standards. The practical value for vehicle owners and professionals is clear: replacements that maintain drivability, safety, and long-term value. The chapter above has drawn out the threads that connect design intent to on-road performance, and it points toward a market where the most meaningful measure of quality is not just how a part looks on a shelf, but how it behaves inside a vehicle over time. The narrative invites readers to approach A Grade parts with both technical curiosity and practical judgment, recognizing that the ultimate payoff lies in fewer surprises, steadier performance, and a maintenance experience rooted in confidence.

External resources can provide additional context on the broader engineering and quality considerations that underlie A Grade parts. For readers seeking supplementary technical insight, an external reference that discusses the standards and characteristics of high-grade automotive components offers a complementary perspective. It can illuminate how industry practices translate into reliable performance in everyday driving. https://www.automotiveengineering.com.au/technical-guides/understanding-a-grade-auto-parts-quality-and-characteristics-2026

Premium A-Grade Auto Parts and the New Economic Landscape of the Automotive Industry

The market for A-grade auto parts sits at a curious intersection of quality, durability, and the shifting demands of a global industry in transition. These parts—defined by their near-original condition, low mileage, or fresh manufacture—do more than simply replace worn components. They embody a strategic capital within a complex value chain that is increasingly shaped by ACES: Autonomous, Connected, Electric, Shared. The economic footprint of A-grade parts, once viewed primarily through the lens of consumer savings or mechanical reliability, now radiates across corporate strategy, supplier networks, and national policy. As automotive design accelerates toward smarter, longer-lasting platforms, A-grade components become both signal and substrate for a broader industrial transformation, sustaining performance, enabling new service models, and sustaining profitability where it matters most: reliability, safety, and long-term value.

The spectrum of A-grade parts extends beyond cosmetic refinements or direct OEM replacements. It encompasses powertrains and battery components, sensors and control modules, high-precision electronics, and even performance-oriented trims and structural elements that are indistinguishable from new on appearance and function. In this light, the distinction between “new” and “A-grade” narrows. Owners seeking to protect the integrity of their vehicles face a crucial decision: invest in parts that preserve original performance and safety standards, or risk slower depreciation and potential reliability gaps. A-grade parts, by virtue of their meticulous selection and testing, offer a bridge between the immediacy of lower-cost aftermarket items and the assurance of OEM specifications. When a left driver side trim panel for a premium vehicle—one that has seen minimal use and remains visually pristine—carries an “A-grade” mark on reputable marketplaces, it signals more than what meets the eye. It signals a disciplined scoping process, traceable provenance, and a readiness to meet stringent performance and safety criteria. This is not mere sentiment; it is a practical promise that resonates through the procurement decisions of fleets, independent shops, and individual owners alike.

From the supply chain perspective, A-grade parts anchor a new wave of value creation that aligns with both efficiency and resilience. The modern automotive ecosystem is increasingly sensitive to the cost of downtime. A-grade parts, with their high reliability and near-OEM performance, reduce the incidence of return visits, warranty claims, and service recalls. They shorten the cycle from failure to repair, which, in a world of tight dealer networks and constrained service capacity, translates into measurable productivity gains for repair shops and OEMs alike. More than that, these parts contribute to a more predictable maintenance cost profile for vehicle owners, a factor that carries weight in both consumer budgeting and corporate fleet management. In other words, the economic calculus surrounding maintenance shifts: the premium of higher-quality components is offset by lower total cost of ownership over the vehicle’s life due to fewer unexpected failures and longer intervals between major repairs.

The current industrial landscape amplifies the importance of high-quality parts in a way that older market narratives could scarcely envision. The ACES trend line—especially the electrification drive and the rapid pace of autonomous and connected technologies—has elevated the bar for component reliability. Batteries, power electronics, sensors, communication chips, and firmware updates now sit at the core of vehicle function. A-grade components for these technologies are not simply replacements; they are critical enablers of system integrity. They must withstand higher duty cycles, more stringent safety standards, and the demands of software-driven performance. In this context, A-grade parts act as a verifying layer between ambitious vehicle architectures and real-world durability. They provide a closer-to-OEM benchmark for performance and safety that aftermarket supply chains can reliably reproduce, while still offering a distinct value proposition in terms of cost and availability.

A 2024 exploratory study on the Chinese automotive industry illuminates this shift. The rise of ACES has opened new markets for premium components, delivering greater value and enabling higher margins for manufacturers and suppliers capable of meeting strict performance and safety standards. The study highlights a paradox: while the average aftermarket income per vehicle may dip due to longer vehicle lifespans and a reduced incidence of mechanical failures, the total value generated by the stock of vehicles remains robust. As EV adoption climbs and fleets accumulate more units, the cumulative demand for reliable, high-quality replacement parts grows even as each individual vehicle may require fewer interruptions. This dynamic creates a fortified aftermarket ecosystem where A-grade components play a central role in sustaining growth, supporting longer product cycles, and enabling manufacturers to extract value from a longer tail of vehicle ownership.

In the broader global market, the expansion of the aftermarket is nothing short of transformative. Projections that the aftermarket could surpass trillions in regional markets reflect not just macroeconomic trends but the underlying reliability and performance expectations of modern vehicles. A-grade parts underpin this expansion by providing a dependable avenue for owners and operators to maintain and refresh vehicles without compromising safety or efficiency. The interplay between longer vehicle lifespans and a steady demand for high-quality replacements is a key driver of investment within supply chains. Firms that align with rigorous quality standards and demonstrate consistent performance across a diverse set of platforms find themselves well-positioned to capture durable margins in a market that values precision and consistency as much as price.

The narrative around small, agile players in the parts ecosystem adds texture to this picture. A company with limited initial capital, yet a diversified service model that includes production, recycling, and intelligent online distribution, can carve out a meaningful niche in this space. By concentrating on cost efficiency without sacrificing core quality, such firms illustrate how niche capabilities can scale within the broader A-grade framework. Their success also signals to larger manufacturers and distributors that premium, reliable parts do not require a monopoly on distribution; instead, a well-calibrated mix of sourcing, processing, and digital sales channels can yield sustainable returns. The case for diversified services—combining manufacturing with recycling to close the loop—aligns with the sustainability imperatives driving policy and consumer preference today. It positions A-grade parts not merely as a maintenance choice but as a strategic asset within a circular economy that reduces waste, extends the life of vehicles, and preserves value across the supply chain.

Within this context, the role of branding and traceability becomes pronounced. Consumers and technicians alike rely on clear indicators of quality, provenance, and compatibility. A-grade status signals not only inspection standards but a rigorous selection process. Brands and marketplaces that can demonstrate consistent eligibility, low defect rates, and transparent mileage histories gain trust and premium pricing. In turn, this trust fuels demand, enabling higher turnover for reputable suppliers and creating incentives for investment in better testing, quality control, and post-sale support. The quality narrative thus evolves from a binary choice—new vs. used—to a spectrum where A-grade stands as a robust middle ground that preserves performance parity with OEM parts while offering differentiated benefits in reliability, traceability, and value retention.

The interdependencies across the automotive value chain become more evident when we consider the way these parts propagate through repair and replacement ecosystems. A-grade components affect the economics of repair shops, insurance models, and consumer decisions in a few key ways. First, the reliability of A-grade parts reduces the risk of rework, which is a cost centers for service providers. Fewer returns and fewer call-backs translate into more predictable labor scheduling and better utilization of technician skill sets. Second, the availability of high-quality parts with clear provenance supports faster turnarounds, enabling service providers to serve more customers with the same capacity. Third, insurers and fleet operators increasingly recognize the value of longer vehicle life and reduced downtime, which translates into premium terms for clients who can demonstrate a reliable supply of A-grade replacements. These dynamics create a virtuous cycle: higher perceived value and lower risk lift demand for premium replacements, which in turn incentivizes manufacturers and distributors to invest in better quality controls and broader assortments.

The economic implications extend into how supply chains adapt to accommodate A-grade parts in a world oriented toward digitalization and data connectivity. The ACES-inspired emphasis on connected systems requires parts that can interact seamlessly with vehicle software, telematics, and maintenance platforms. Sensors, connectors, and control modules must not only meet mechanical tolerances but also integrate with software ecosystems that govern safety and performance. For suppliers, this means investing in traceable production histories, robust testing protocols, and compatibility documentation that reduces the friction of cross-brand servicing. The result is a more reliable aftermarket that can scale with the rate of vehicle electrification and the deployment of advanced driver assistance systems. In environments where data transparency becomes as important as physical fit, A-grade parts function as a crucial bridge that ensures vehicles operate consistently, even as software and hardware ecosystems evolve rapidly.

The significance of A-grade parts is also evident in how they influence sustainable practice and resource efficiency. The modern automotive industry is increasingly mindful of its environmental footprint. A-grade parts contribute to circularity by enabling refurbishment, recycling, and remanufacturing at higher quality levels. When a component is refurbished to an A-grade standard, its service life can be extended substantially, reducing material extraction and energy use associated with manufacturing new parts. This aligns with broader policy currents and consumer expectations around sustainable mobility. The long-term advantage is clear: as manufacturers and policymakers align incentives toward durable, maintainable platforms, the demand for high-quality, reusable components becomes a strategic lever for national economies pursuing green growth and technological leadership.

As the market evolves, there is a natural tension to manage: longer vehicle lifespans and higher-quality replacements can compress certain traditional revenue streams for aftermarket players. Yet the data and industry narratives suggest a different outcome. The supply chain is adapting by broadening its offering, embracing low-capital, high-value niches, and leveraging digital marketplaces to reach customers who demand reliability and clarity. The expansion of the aftermarket beyond traditional mass replacement into smarter, longer-lasting components demonstrates how premium quality can sustain growth even as vehicle lifecycles lengthen. In this sense, A-grade parts become not merely a maintenance choice but a strategic instrument for resilience, enabling manufacturers and suppliers to weather cyclical shifts and technological upheavals alike.

In the wider discourse, the interplay between supply, demand, and quality standards appears as a recurring theme. The A-grade label, when consistently applied, reduces asymmetry of information between buyers and sellers. It helps buyers differentiate between parts that meet rigorous performance benchmarks and those that do not. This clarity benefits service providers, regulators, and end consumers, building trust in the aftermarket ecosystem. It also creates a disciplined marketplace where quality is measurable, provenance verifiable, and warranty support coherent. From the perspective of a policy-maker or industry analyst, A-grade parts are a signal of a mature, professionalized sector capable of sustaining high performance across a spectrum of platforms and conditions. They reflect a market that recognizes that the economics of quality—though potentially premium in the short term—can deliver durable value over the vehicle’s life and across the lifecycle of the broader mobility system.

The specific business models that emerge around A-grade parts illustrate a pragmatic synthesis of cost control, risk management, and value creation. Some players focus on core competencies in sourcing and testing to guarantee a near-OEM quality standard at a competitive price, while others emphasize end-to-end service packages, including inspections, fitment guarantees, and post-sale support. The common thread is a commitment to reliability and a robust traceability framework that can stand up to the demands of modern vehicles, from combustion engines to electric powertrains and beyond. In this environment, strong suppliers become strategic partners to OEMs and large fleets who are seeking to minimize downtime, maximize reliability, and protect the long-term value of their investments. The resulting collaboration patterns—between manufacturers, distributors, service networks, and digital platforms—shape a resilient ecosystem that can absorb supply shocks, navigate regulatory changes, and fuel ongoing innovation.

The notion of value, in this framework, extends beyond price. It encompasses the peace of mind that comes with knowing a part will perform as intended when it matters most. It includes the assurance of compatibility across multiple vehicle generations and the confidence that a replacement will preserve the performance envelope the owner expects. And it includes the social and economic benefits of a robust aftermarket that supports skilled labor, sustains employment, and sustains local businesses. When a consumer chooses an A-grade part, they participate in a broader economic story—one where quality, trust, and accountability reinforce growth while reducing waste and uncertainty. In a world where autonomy and electrification will redefine what vehicles are capable of, the reliability and predictability of A-grade components become as essential as the energy that powers the car itself.

Internal link to illustrate practical, real-world presence of premium options can help readers connect theory with tangible choices. For example, a page dedicated to a brand-new carbon fiber hood—marked by its pristine finish and compatibility with contemporary performance platforms—offers a concrete reference to the kind of high-quality, near-OEM replacements that define A-grade standards. See the page described as brand-new carbon fiber hood page for Evo X for a sense of how premium replacements are presented and evaluated in the market. brand-new carbon fiber hood page

In sum, the economic impact of A-grade auto parts within the ACES era reflects a broader recalibration of value in the automotive industry. These parts support higher performance and safety thresholds, stabilize maintenance costs, and enable a more resilient, data-driven aftermarket. They empower suppliers to pursue advanced manufacturing and quality-control practices, encourage investment in research and development, and help shift the industry toward a circular, sustainable model that aligns with policy objectives and consumer expectations. As the grid of mobility becomes more complex, A-grade parts provide the anchor of reliability and trust that keeps the system functioning smoothly. They are not merely replacements; they are enablers of a new economic logic where quality, accountability, and long-term value converge to sustain growth across a transforming automotive landscape.

For readers who wish to explore the broader policy and market dynamics shaping these trends, a comprehensive external resource offers an in-depth look at how ACES trends reshape the automotive value chain and the resulting economic implications. See Deloitte Insights for a detailed analysis of ACES trends and their impact on the broader ecosystem: https://www2.deloitte.com/insights/us/en/focus/industries/automotive/aces-trends-economic-impact.html

Reliability as a Lifesaving Standard: How A Grade Auto Parts Protect Drivers and Vehicles

Reliability and Safety: the Case for A Grade Parts

Reliability is the core promise of A Grade auto parts. These components are selected or manufactured to the highest standards, often matching original equipment quality closely. Their defining traits—low mileage, near-new condition, and stringent inspection—translate directly into safer, more predictable vehicle behavior. This chapter explains why reliability matters, how A Grade parts achieve it, and what drivers and technicians should expect when choosing them.

A reliable part performs consistently across conditions. It responds as intended whether the vehicle is driven on a dry highway, a wet urban street, or over rough terrain. Consistency matters most in systems that affect vehicle control and occupant protection. Brakes, steering linkages, suspension mounts, airbag modules, and key sensors all fall into that category. When such parts meet A Grade expectations, they reduce the odds of sudden, dangerous failures.

Consider the human cost. A single component failure at speed can cascade into a loss of control. A worn or substandard brake pad may still stop the car under routine braking but fail when repeated stops are required. A deteriorated suspension bushing can change wheel alignment subtly. That change multiplies tire wear, alters handling, and can increase stopping distance. A Grade parts minimize these hidden degradations because they start life at or near original performance levels. That margin matters when seconds or fractions of a second decide outcomes.

The path to reliability begins with selection and sourcing. A Grade parts are typically taken from vehicles with very low mileage or supplied new from manufacturers. Low mileage is an indicator, not a guarantee. It suggests limited use, but it must be validated by visual and functional inspection. When suppliers mark parts as A Grade, they signal that components have passed a rigorous vetting process. That process includes damage checks, wear assessments, and often functionality tests.

Inspection protocols vary by supplier, but the best practices are consistent. Visual checks look for cracks, corrosion, deformation, and repair marks. Mechanical components undergo movement and load testing. Electrical parts are examined for connector integrity, continuity, and correct signal behavior. Body panels and trim are checked for fit and finish, ensuring that paint, clips, and mounting points match OEM tolerances. When selection criteria are strict, parts that leave the yard are less likely to fail prematurely.

Testing is the next layer of assurance. Original equipment manufacturers typically require 100% testing of critical subcontracted parts. This is expensive, but the cost protects reputations and lives. A Grade suppliers mirror that approach where possible. They may run brake tests under load, confirm steering precision, cycle airbags’ connectors, and bench-test electronic modules. These procedures detect latent defects that visual inspections would miss. The result is a better understanding of how a part will perform once installed.

Reliability is also a matter of traceability. Knowing a part’s origin, service history, and mileage provides context. A reclaimed component with documented low mileage differs markedly from an unverified used item. Traceability supports confidence in long-term behavior. It also streamlines warranty and recall processes. When a supplier can produce records for a part, technicians can make informed choices and vehicle owners can expect predictable outcomes.

Durability and longevity follow reliability. A Grade parts are less likely to require early replacement. That reduces the risk of secondary failures that hurt safety. For example, replacing a worn but not failed control arm with an A Grade unit prevents the misalignment that could stress adjacent components. In many cases, the upfront cost of an A Grade part is offset by reduced labor for repeat repairs. More importantly, it lowers the chance that an overlooked issue will cause an accident.

Maintenance philosophies intersect with part reliability. Replacing certain components during major engine repairs is a recommended practice in professional service guides. Even when the component still appears serviceable, swapping it for an A Grade replacement during a substantial repair can prevent near-term failures. This approach is common for belts, hoses, sensors, gaskets, and some engine components. It reflects an understanding that conditional reliability is not the same as absolute reliability. When a technician chooses A Grade parts proactively, they reduce future risk for the vehicle owner.

Supply chain integrity is a critical factor. Parts can degrade from improper storage, rough handling, or exposure to harsh environments. An A Grade supplier maintains controlled storage conditions, uses protective packaging, and employs careful logistics. Those steps preserve part condition from yard to workshop. A chain of custody that includes temperature control, anti-corrosion measures, and secure transport reduces the chance that a part will arrive compromised.

Certification and standards matter as well. Many jurisdictions require specific safety tests, emissions checks, and performance standards. Compliance with regulatory frameworks strengthens the case for A Grade parts. Suppliers who adopt recognized testing standards demonstrate they treat safety as more than a marketing claim. Certification provides technicians and vehicle owners with a measurable benchmark for reliability.

Failure modes are instructive. Not all failures are sudden or catastrophic. Many begin as small deviations in measurable behavior. For example, a wheel bearing might develop a faint hum that worsens over months. If replaced with a subpar unit, the new part could fail sooner, sometimes unpredictably. A Grade parts reduce the variability in these failure curves. The statistical distribution of lifetimes tightens around the expected mean, making failures less likely in the short term and more predictable over time.

Risk reduction through reliability is not binary. A Grade parts lower probability but do not eliminate risk. The overall reliability of a repair depends on correct diagnosis, proper installation, and compatible supporting components. Even an A Grade part will underperform if installed incorrectly or paired with worn associated hardware. That is why reputable suppliers and shops emphasize complete repairs, not piecemeal fixes. The long-term safety of a vehicle follows from a systems view, where each reliable part complements others in the vehicle.

Another important aspect is the human factor. Technicians rely on trustworthy parts to apply their skills effectively. A Grade components let technicians focus on precision work instead of contingency planning for premature failures. When installers know a part meets high standards, they can follow manufacturer torque specs and calibration procedures without adapting for uncertainties. That reduces the chance of installation-induced failures and streamlines diagnostics if problems arise.

Warranties and return policies create a practical safety net. Suppliers who stand behind A Grade parts provide warranties that reflect confidence in their products. Warranty terms often include specific conditions for installation and use. Accurate documentation and professional installation typically preserve warranty coverage. For vehicle owners, these warranties offer financial protection and encourage careful selection of parts and service providers.

Economics shape decision-making. A Grade parts are often more expensive than lower-grade alternatives. But when safety and long-term value are priorities, the higher initial cost is justified. Choosing cheap components can lead to repeated repairs, greater cumulative expense, and increased safety risk. The calculus should weigh direct costs against potential consequences, including injury, legal liabilities, and vehicle downtime. A Grade parts frequently offer the best balance between upfront expense and lifecycle value.

Transparency in grading builds trust. Clear definitions of what “A Grade” means reduce ambiguity. A reliable grading system describes the source conditions, tests performed, and cosmetic criteria. Customers should expect accessible documentation that explains why a part earned its grade. This transparency supports informed choices and makes it easier to compare suppliers.

Marketplace dynamics influence availability. Sourcing A Grade items requires skilled reclamation and efficient logistics. Low-mileage donor vehicles are rarer than ever, and careful dismantling matters. Where choices are limited, the selection process becomes critical. Suppliers who invest in skilled inspectors and modern testing equipment can maintain A Grade inventories more consistently. For buyers, relationships with such suppliers are valuable.

Legal and regulatory implications cannot be ignored. When a vehicle part fails and causes harm, liability flows through manufacturers, suppliers, installers, and sometimes vehicle owners. Using A Grade components and following recommended service practices reduces legal exposure. Proper documentation of parts and repairs also aids in post-incident investigations. In some cases, using certified or compliant parts may be legally required, particularly for safety systems.

Communication with vehicle owners is part of safety management. Consumers often choose parts based on price alone. Clear explanations from technicians about the benefits of A Grade replacements help owners make safer decisions. Discussing the expected lifespan, warranty coverage, and potential risks of lower-grade parts can shift choices toward better outcomes without resorting to jargon.

The rise of advanced safety systems changes the stakes. Modern vehicles rely heavily on sensors, actuators, and electronic control units. These components are sensitive to manufacturing tolerances and calibration. An A Grade electronic module verified for correct code versions and functional performance is far safer than an untested alternative. Incorrect or incompatible modules can disable safety features or introduce unexpected behavior. In this context, A Grade standards must extend beyond mechanical fit to include software and signal integrity.

Repair quality standards are evolving. Professional bodies and industry groups increasingly emphasize documented procedures, calibrated tools, and verified parts. A Grade components align well with these practices. They make it easier to follow prescribed steps and demonstrate compliance with repair protocols. For fleet operators, public agencies, and safety-conscious consumers, this alignment is a powerful argument for choosing top-tier parts.

Operational resilience is another benefit. Vehicles that receive A Grade parts in critical systems are less likely to fail during intense use. That matters for emergency vehicles, commercial fleets, and long-distance travel. Downtime avoidance has economic and safety implications. The predictability of performance reduces the probability of being stranded or involved in preventable incidents.

In the end, reliability is a moral and practical choice. It protects lives, preserves assets, and supports responsible stewardship of vehicles. A Grade auto parts are not a guarantee, but they are a deliberate step toward the lowest reasonable risk. They reflect an ecosystem of careful sourcing, thorough inspection, rigorous testing, and transparent documentation.

When selecting parts, look for clear evidence of these practices. Ask suppliers about their inspection criteria, testing methods, and return policies. Request traceability and records when possible. Prioritize components that come with warranty coverage and require professional installation for validity. Recognize that the cheapest option is rarely the safest when vehicle control and occupant protection are at stake.

For further authoritative information on vehicle safety and the role of high-quality components in preventing accidents, refer to the U.S. National Highway Traffic Safety Administration resource: https://www.safercar.gov

For a practical example of sourcing low-mileage, reliable replacement components, consider exploring available options for low-mileage engines that maintain higher integrity than generic used parts, such as those described in this listing for genuine low-mileage JDM engines: https://mitsubishiautopartsshop.com/genuine-jdm-low-mileage-1995-1999-jdm-mitsubishi-4g63t-2-0l-dohc-turbo-engine-evo-7-bolt-eclipse-talon-awd-automatic-transmission-and-ecu-attached/

Final thoughts

In summary, A Grade auto parts are not just premium components; they represent quality, reliability, and safety within the automotive sector. By understanding their characteristics, recognizing their economic significance, and acknowledging the importance of their reliability, business owners can make informed choices that lead to enhanced consumer trust and satisfaction. Investing in A Grade parts not only meets the demands of the present but secures a safer and more prosperous future for the automotive industry.