A-1 Rylie Auto Parts, located on Ellenwood Street in Dallas, TX, serves an essential role in the automotive supply chain, offering both quality and sustainability. Understanding their diverse offerings, stringent quality assurance practices, and dedicated sustainability efforts is vital for business owners seeking reliable and eco-friendly automotive solutions. This article unfolds into four segments: an overview of A-1 Rylie Auto Parts, the types of automotive parts they offer, the quality assurance practices they utilize, and their sustainability initiatives.

Ellenwood Street’s Reliable Source: A-1 Rylie’s Recycled Auto Parts and Local Expertise in Dallas

A-1 Rylie Auto Parts sits at 1115 Ellenwood Street, a neighborhood address that reads like a practical compass point for anyone hunting dependable, recycled automotive parts in Dallas. The business specializes in salvaged late-model components compatible with a wide range of foreign and domestic vehicles. Visitors find an operation focused on two clear goals: providing trustworthy parts and making reuse an easy, cost-saving choice. That dual focus shapes every interaction, from the first phone call to the moment a part is installed and the car returns to the road.

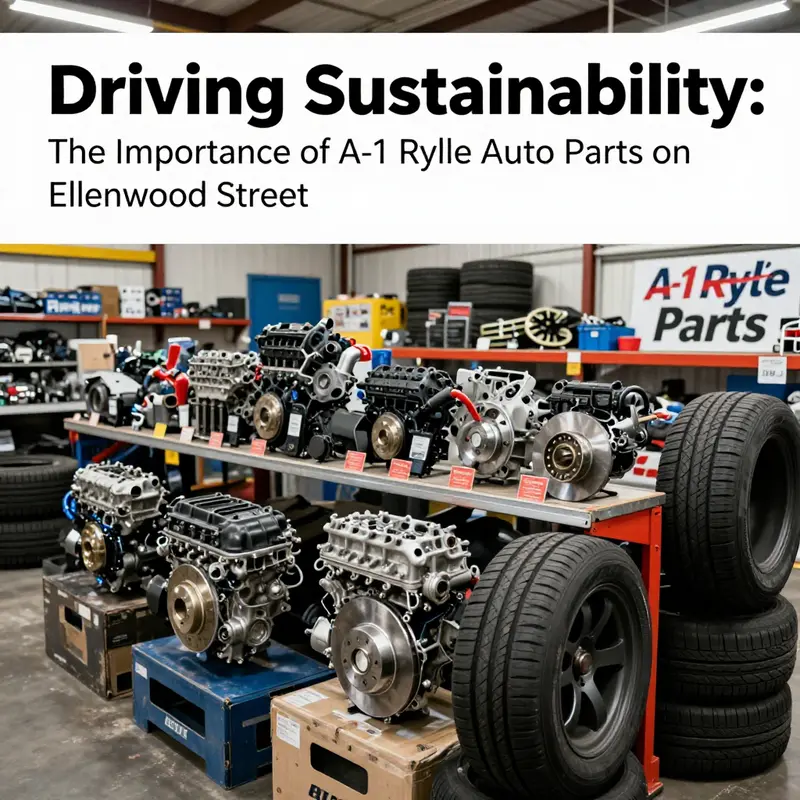

The lot and shop present the straightforward confidence of a place that has handled thousands of vehicle needs. Parts are pulled from late-model cars, trucks, and SUVs, then carefully inspected by experienced staff. Inspection is not a quick glance. It is a methodical, item-by-item review that looks for structural integrity, wear patterns, and functionality. Electrical components are tested where possible. Mechanical pieces are judged for play, leaks, and serviceability. Cosmetic parts receive honest descriptions to set correct expectations. This attention to detail reduces surprises for customers and shortens the time between purchase and proper installation.

Customers repeatedly praise the friendly staff and accurate parts descriptions. The store’s reputation is built on practical, measurable reliability. When someone asks for help, staff often recommend specific people, such as Mason or Riley, names that have become associated with efficient, honest service. This human element matters. It builds trust in an industry where quality varies widely. Friendly conversations, clear explanations, and practical advice help visitors make informed choices quickly.

Pricing is one of the strongest draws. Recycled parts are priced to reflect both value and condition. For customers managing tight repair budgets, this matters more than modest brand distinctions. The difference between a large repair bill and an affordable, safe replacement can keep a vehicle roadworthy for months or years. By keeping prices reasonable and descriptions accurate, the business creates real savings without forcing risky compromises.

Sustainability is more than a slogan here. Offering recycled parts reduces waste, lowers the demand for newly manufactured components, and extends the useful life of vehicles without new raw material consumption. The environmental benefit is straightforward: parts that would otherwise be scrapped instead find a second life. That approach aligns with a growing customer interest in sustainable choices—especially when those choices also save money. The store’s role in the local recycling ecosystem contributes to a broader, grassroots form of environmental stewardship.

Reliability and practicality combine in the way parts are presented. Each item comes with a straightforward assessment of condition. When needed, staff explain whether a part is suitable for daily driving or best reserved for temporary fixes. This transparency keeps expectations realistic and reduces returns. The store’s emphasis on correct descriptions reduces friction for DIY mechanics, independent shops, and vehicle owners who prefer to do the work themselves.

Accessibility is another quiet advantage. The location on Ellenwood Street is easy to find and straightforward to approach. Phone support is available for initial questions or to hold a part while customers travel. When you call, the conversation tends to be efficient and focused. The brief inspection details shared over the phone help customers decide whether a trip is worthwhile. This saves time and creates a better experience for everyone involved.

Beyond single transactions, A-1 Rylie fits into the local automotive community. Independent repair shops, hobbyists, and owners of late-model vehicles rely on the store as a predictable source for parts that are both functional and affordable. The store’s knowledge of common fitment issues for many vehicle makes helps customers avoid common mistakes. Staff familiarity with interchangeability and compatibility can be a real asset. It reduces the guesswork that often accompanies repairs when parts are sourced from multiple vendors.

There is also a practical rhythm to how the business operates. Vehicles arrive, are stripped of serviceable components, and those components enter a careful triage. Priority goes to parts that are in good working order and in demand. Components that require minor refurbishment are cleaned, tested, and then labeled with a clear description. Less serviceable parts are dispositioned responsibly. This efficient workflow keeps inventory moving and reduces clutter. It also helps maintain a wide selection across categories—electrical, mechanical, trim, and structural.

For someone preparing to visit, a few simple steps make the process smoother. Know the vehicle year, make, and model. Have the part number if possible. Take photos of the area in need of repair to show fitment or connection points. If you can describe symptoms rather than just name the part, staff can often suggest alternatives or correct part names. A quick phone call before driving in can save time and confirm availability.

The store’s customer service approach is grounded in practicality. Staff will explain whether a part is recommended for immediate installation or better used as a stopgap. They will also point out potential compatibility caveats and recommend inspection steps a buyer should perform after installation. That kind of guidance strengthens the safety and longevity of repairs, and it respects the customer’s need for honest advice.

One subtle advantage of buying recycled parts here is the balance between value and certainty. New parts can be appealing, but they do not always outperform quality recycled components when both are inspected and tested. This business emphasizes that a well-chosen used component, verified for fit and function, can often meet or exceed expectations at a fraction of the cost. The balance is practical and economical, not merely ideological.

A-1 Rylie maintains clear lines of communication about what they sell and why. Parts are described with enough detail to inform a buyer about condition and suitability. This clarity reduces return rates and builds confidence. It helps both DIY enthusiasts and professional mechanics rely on the store for repeat business.

The local context matters. Located in Dallas, the store serves a large and varied market. Weather, driving habits, and the variety of makes and models in the metro area mean that demand for different parts can shift quickly. Staff experience in navigating these local trends helps the store maintain relevant inventory. They keep an ear to the ground for what items become scarce after seasonal changes or local repair trends.

Community trust is earned through consistent performance. Repeat customers cite not only affordability but also the steady quality of the parts and the approachable staff. When a vehicle returns to service without incident, the store’s reputation grows. Word of mouth plays a large role in bringing new customers through the door.

For those who value both economy and environmental responsibility, this store represents a practical choice. It allows owners to extend the lifespan of vehicles affordably. It reduces the need for new manufacturing and reduces landfill pressure. The result is a local business that supports both personal budgets and community sustainability.

If you want to check a specific part or learn more before visiting, calling ahead is encouraged. Staff can verify availability and provide condition details. The store’s website also offers a basic resource for contact and direction. For a deeper look at how similar components are treated and reused, you might find value in this practical overview of an industry-specific component: evo-x halfcut details (https://mitsubishiautopartsshop.com/evo-x-halfcut/).

For direct contact and the most current information about inventory, hours, and services, visit the business site: http://www.a1rylieautoparts.com

Repurpose and Reliability: How A-1 Rylie Auto Parts on Ellenwood Street Keeps Dallas Moving

On a quiet stretch of Ellenwood Street in Dallas, a modest storefront hides a larger truth about how modern repair works. A-1 Rylie Auto Parts sits not at the edge of the city’s automotive ecosystem but at its core, quietly powering countless vehicles with parts that have already carried thousands of miles. The emphasis here is not novelty but stewardship: the idea that cars, like people, can extend their lives through careful repair and renewal. The business model rests on quality recycled and used late-model foreign and domestic parts, a deliberate choice that blends practicality with responsibility. The parts arrive from a network of salvage and sourcing channels that are meticulous in their selection, and every item is subjected to a rigorous process before it finds a second life in someone’s vehicle. The address, 1115 Ellenwood St, is more than a marker on a map; it marks a commitment to reliability, affordability, and sustainability in a city where every mile matters, where families and businesses alike depend on dependable wheels to move daily life forward. The atmosphere around the lot suggests a blend of old-world shopcraft and forward-looking efficiency. Metal parts glint under the shop lights, engines rest securely on clean surfaces, and the hum of well-worn machinery murmurs a promise: what comes in will come out ready to perform. The folks who work here know that the value of a part is not merely in its raw piece count but in the integrity it brings to a repair. This is a place that reads the specifics of a vehicle as carefully as a physician reads a chart, seeking compatibility, reliability, and the possibility of saving money without compromising safety. In Dallas, where traffic volumes and maintenance costs can be high, the allure of recycled parts becomes less about frugality and more about resilience. The shop’s philosophy mirrors a larger shift in the automotive world, where sustainability is becoming a practical standard rather than a principled outlier. The advantages are clear to anyone who has replaced a component only to see a bill climb or a project stall: recycled and used parts can offer substantial savings, while still delivering performance that keeps a car roadworthy for miles to come. Yet the savings are not achieved by chance; they are earned through careful inspection, testing, and thoughtful integration. Every engine or transmission that leaves the yard has been evaluated for reliability, with technicians listening for unusual sounds, checking compression, and confirming compatibility with a broad range of late-model systems. The aim is not to patch up a ride for a moment but to restore it to a dependable cadence that can endure the demands of daily driving and occasional longer trips. The inventory is varied, reflecting the needs of a broad customer base in a city of diverse makes and models. A-1 Rylie Auto Parts carries engines and transmissions, but the reach goes far beyond those components. Drivetrain parts that control how power moves from the engine to the wheels are kept in reserve for those moments when a car’s performance begins to waver. Body panels and bumpers, often among the most visible signs of repair, are sourced with an eye toward fit and finish as much as affordability. Headlights and other essential lighting components are not merely cosmetic; they are critical for safety and visibility. The gathering, testing, and cataloging of these parts are performed with a sense of stewardship, as if every bolt and gasket might become a lifeline for another driver’s journey. The process begins at the sourcing stage, where the team looks for late-model parts that still have meaningful life left in them. The emphasis on late-model vehicles is deliberate, recognizing that modern cars are built with integrated systems where the wrong component can ripple across an entire electrical or control architecture. Once a part arrives, it enters a careful inspection protocol. Panels are checked for dents, corrosion, and stress fractures that could compromise a repair or lead to future failure. Mechanical components undergo functional testing, with exchangeable hoses, mounts, and seals scrutinized to ensure that a replacement won’t degrade quickly under normal operating conditions. This attention to detail is not merely procedural; it is a promise to customers that choosing recycled parts does not equate to compromising quality. It is a pledge that reliability remains at the heart of every diagnostic and every hand that touches a car’s repair. The practice is grounded in transparency. For customers who want to understand what they are purchasing, the staff explains the part’s history when possible, including its prior vehicle context, known wear patterns, and any reconditioning steps that were taken to restore performance. This dialogue is essential because it helps buyers make informed decisions about compatibility and longevity. It also creates a sense of trust, a rare commodity in a market where parts can be complex and where the cost of a mistake is measured in time, money, and vehicle safety. The environmental impact of this business model is equally tangible. Recycling auto parts reduces waste by extending the lifespan of components that would otherwise end up in landfills. It lowers the demand for new production, which in turn can reduce energy use and emissions associated with manufacturing. In a city with the varied climate and road conditions of Dallas, the value of sustainable repair work grows with every passing season. The circular economy at work here is not abstract; it is visible in the way customers return to the yard for their next repair, in the way the shop advises on the proportion of recycled parts that can safely replace new equivalents, and in the careful attention paid to documentation and warranties that accompany many used components. The relationship with customers is built on a foundation of reliability and accessibility. The team understands that a repair decision is rarely about the cheapest part in the moment. It is about the long run: how many miles the replaced part will carry, the vehicle’s performance over time, and the peace of mind that comes with knowing the repair is solid. To support this, they maintain a straightforward line of communication. Customers can reach the shop by phone at (972) 286-0004 to inquire about current stock, availability, and compatibility with their specific make and model. They can also visit in person to inspect parts, compare options, and discuss whether a recycled solution is appropriate for their vehicle’s particular needs. The in-person experience matters, particularly when dealing with larger components like engines or transmissions, where the physical condition and fitment must be assessed directly. The local community benefits from having a resource that is both practical and principled. For many residents, car maintenance is a central concern that intersects with work, school, and family life. A-1 Rylie Auto Parts provides an access point to repair solutions that are affordable without compromising safety. In a broader sense, the store embodies a philosophy that aligns with contemporary needs: durability, accountability, and a cautious optimism about the future of driving. The parts are not manufactured anew; they are reimagined for use in new contexts, a reminder that the automotive landscape is not a straight line from invention to obsolescence but a looping story of reuse and adaptation. The shop’s approach also invites a broader reflection on how communities can manage resources more wisely. By keeping viable components in circulation, the city reduces the pressure to mine new materials, to transport heavy parts over long distances, and to expend energy on manufacturing processes that contribute to emissions. Each successful repair carries a microcosmic benefit: the vehicle runs as it should, the owner saves money, and a resource that might have been wasted remains functional. It is a chain of small, responsible decisions that adds up when multiplied across hundreds or thousands of similar repairs. This is not mere rhetoric. It translates into tangible outcomes for customers who walk through the door with a worn-out piece and leave with a repaired ride confident that the part they chose is dependable. The surrounding ecosystem—mechanics, insurers, and even DIY enthusiasts—benefits from a steady supply of vetted, compatible components. The practice of careful sourcing and testing helps reduce returns and warranty issues, strengthening trust between the shop and its customers. It also supports the broader economic fabric of the neighborhood, where small businesses rely on steady demand and word-of-mouth to sustain their operations. In the end, what makes A-1 Rylie Auto Parts on Ellenwood Street more than a simple supplier is the narrative of care embedded in every interaction. The business does not merely sell parts; it sustains journeys. It helps a family keep their daily commutes intact, a small business keep its delivery schedule, and a teenager learn to repair a first car with guidance that emphasizes safety and responsibility. The relationship between the shop and its customers is built on the shared understanding that a recycled part, when properly sourced and tested, can be as trustworthy as a new component. This belief permeates the atmosphere—quietly, persistently, and with practical outcomes that extend beyond the price tag on a receipt. For anyone who has walked the aisles of the yard and spoken with the technicians, the message is clear: a well-chosen recycled part can be a smart, sustainable, and reliable choice. The conversation is not about compromise; it is about smart trade-offs and informed decisions that respect both the consumer’s budget and the vehicle’s long-term health. The shop’s story, anchored on Ellenwood Street, is a reminder that modern repair culture can harmonize affordability with high standards of performance. It invites customers to consider not only what fits their budget today but what will keep their cars safe, dependable, and roadworthy for seasons to come. For those who are curious about current stock or who want to understand how a specific part might fit into their plan, the door is open, and the conversation awaits. The practical, patient, and principled approach of A-1 Rylie Auto Parts embodies a local solution to a national conversation—the viability of recycling as a practical strategy for maintaining mobility, reducing waste, and preserving the integrity of the vehicles that anchor daily life in Dallas. External resources that help place these practices in a wider context can be found through the storefront’s public presence online, including the listing on Google Maps, which provides directions and a snapshot of the location for prospective customers and curious passersby who want to verify the site before visiting. See the storefront here: A-1 Rylie Auto Parts on Google Maps.

Beyond the Parts Counter: Building Trust Through Quality and Sustainability at A-1 Rylie Auto Parts on Ellenwood Street

On Ellenwood Street in Dallas, a compact storefront hides a serious commitment to reliability in the automotive ecosystem. A-1 Rylie Auto Parts operates with a practical focus on recycled and late-model parts, serving cars, trucks, and SUVs. What sets this operation apart is not only breadth of inventory but the disciplined quality mindset that runs through intake, inspection, and after-sale service. The shop’s market position rests on a simple promise: customers deserve parts they can trust. In a world where a used component carries a history, trust is earned through careful checks, clear commitments, and transparent practices that endure beyond the moment of purchase.

The heart of the strategy is a standard warranty that signals confidence. A-1 Rylie Auto Parts offers a six-month warranty on all parts, with options for extended coverage that can include labor. This warranty is more than a marketing hook; it is a concrete commitment that the business stands behind its inventory. The term invites proactive attention to quality, encouraging both shop and customer to observe performance early in a part’s life. When extensions are discussed, they reflect a deliberate calibration of what constitutes reliable performance, how issues are identified, and how remediation is delivered. The warranty acts as a bridge between procurement discipline and customer experience, translating QA into tangible value for drivers.

Beyond the visible warranty, the shop treats quality as an organized discipline rather than a slogan. Public documentation may be sparse, but the operational reality is a structured process for sourcing, inspection, and testing that aligns with customer expectations for reliability. The absence of a public QA manual does not erode confidence; it signals a culture where QA methods are woven into daily routines. The guarantee is the overt signal; the practices are the hidden backbone that support it.

In practice, the workflow combines triage, tactile inspection, and function-minded reasoning. Incoming inventory is screened to prioritize safety-critical components for verification. Fitment checks ensure parts mount and interface correctly; functional tests verify that a component performs as intended under realistic conditions. Sustainability also informs QA: recycled parts must meet longevity and safety standards, balancing reuse with the risk of unseen wear. By emphasizing durability, the shop reduces returns and minimizes environmental impact while maintaining customer safety.

The supplier relationship is another thread in the QA tapestry. A robust program depends on reliable upstream practices and transparent downstream verification. A shop that stocks recycled components builds partnerships with recyclers, salvage yards, and refurbishers who share traceability and careful sorting. In Dallas, with a dense vehicle population and fast-paced repair cycles, dependable sourcing becomes a competitive edge that does not sacrifice integrity. The warranty complements this edge by offering predictable remedies when issues arise, sustaining long-term loyalty.

Traceability matters too. Even when parts are recycled, customers deserve to know provenance and the path to the repair bay. A comprehensive internal traceability framework may not be public, but its effects show up in smoother transactions and faster resolution of claims. Inspectors annotate origin, prior service history if known, and the checks performed before resale. Such documentation reduces ambiguity and supports fair, transparent exchanges with customers.

The customer experience at A-1 Rylie Auto Parts is shaped by assurance language—clear explanations of what is offered, how it was tested, and what protections accompany the purchase. The six-month horizon provides a practical reference, while extended options invite deeper conversations about life expectancy and total cost of ownership. The conversation is not just about price; it is about peace of mind, about knowing the shop takes responsibility for reliability over time. The result is a sense of security that the vehicle will perform, that a plan exists if issues arise, and that the business behind the part remains accountable after the sale.

Feedback is treated as data, not as personal critique. When a part does not meet expectations, responses focus on diagnosis—was the issue due to the part, installation, or vehicle systems? This diagnostic mindset mirrors the scientific approach that underpins strong QA programs: hypothesize, test, verify, adapt. Clear instructions, transparent timelines, and follow-through are part of the experience, turning a potential problem into an opportunity to demonstrate accountability and improve processes.

Sustainability runs through every layer—from how inventory is sourced to how older components are repurposed. Recycling is treated as a strategic orientation toward waste reduction and resource stewardship, not a reaction to waste. QA practices align with environmental objectives, safety, and performance standards. Sorting to maximize reuse, testing to extend life, and transparent communication about what can be reused vs. replaced illustrate a balance between repair speed and environmental responsibility. When customers see sustainability as part of the practice rather than a branding claim, trust in sourcing and handling deepens.

The narrative of quality at A-1 Rylie Auto Parts is not a single moment but a sustained practice. The six-month warranty is a public contract; extended options invite long-term conversations about performance and ownership. The implicit QA framework binds supplier relationships, intake scrutiny, functional testing, and post-sale service into a coherent system that supports drivers in Dallas and beyond. In a marketplace crowded with choices, quality—guarded by a practical warranty and reinforced by consistent process—remains the decisive differentiator that helps keep wheels turning and customers returning.

For readers exploring the broader landscape of quality and parts integrity, the A-1 Rylie Auto Parts model demonstrates how disciplined practice, transparent guarantees, and responsible stewardship translate into trust and value over time.

Closing the Loop on Ellenwood: A-1 Rylie Auto Parts and the Circular Life of Dallas Vehicles

On the east side of Dallas, where 1115 Ellenwood St marks a quiet doorway to a bustling workshop, A-1 Rylie Auto Parts sits at the intersection of practicality and principle. The shop’s everyday task is straightforward: keep cars rolling while keeping waste out of landfills. Yet the approach behind that task is anything but simple. It is a disciplined embrace of sustainability, a deliberate reshaping of how people think about “new” parts, and a practical demonstration of how a local business can influence broader environmental outcomes through every part salvaged, inspected, and resold. This chapter won’t just catalog what the business does; it will illuminate why a circular mindset matters to Dallas residents, to families who repair instead of replace, and to the larger ecosystem of vehicle maintenance that keeps roads safer while conserving resources. The core idea is as clear as the sign on the door: parts are precious, and their value endures when they are reused with care and accountability. In that light, the Ellenwood Street operation becomes more than a storefront—it is a model of how recycled and late-model components can contribute to both reliability and responsibility in modern driving.

A-1 Rylie Auto Parts specializes in recycled and used late-model foreign and domestic parts for cars, trucks, and SUVs. The emphasis on late-model components is not about chasing the newest trend; it is a deliberate choice to balance availability with performance. Late-model parts tend to carry current safety and compatibility standards, which helps customers maintain reliability without sacrificing modern expectations. Every item that moves through the shop’s bays is subjected to a careful inspection process designed to verify fit, function, and durability. This isn’t rummaging through a bin and hoping for a miracle; it is a trained system that screens for hidden wear, prior impacts, and potential failure modes. The result is a curated inventory where customers can shop with confidence, knowing that the part they purchase has been evaluated for performance in a way that minimizes risk and maximizes value. In an industry where parts can be costly and supply chains volatile, this blend of accessibility and accountability stands out as a pragmatic response to contemporary automotive needs.

The environmental arithmetic behind recycled parts is compelling. Manufacturing a new part often involves resource extraction, energy-intensive processing, and considerable emissions. Each recycled component represents a saved expenditure of energy and materials—the aluminum, steel, plastics, and interior materials that would otherwise cycle through a manufacturing plant or an outdated supply chain. By extending the life of components already in circulation, the Dallas shop helps reduce the demand for fresh raw materials, gradually shrinking the energy footprint associated with car repair at a local scale. Importantly, this approach aligns with broader environmental objectives that aim to decouple vehicle maintenance from unsustainable production patterns. The lifecycle impact is not abstract; it translates into fewer emissions from kilns, smelters, and forging equipment, and a reduction in the volume of waste that would otherwise fill landfills. When viewed in aggregate with other local businesses pursuing similar strategies, the effect compounds, contributing to a measurable shift toward a more circular economy in the region.

Quality control remains at the heart of the operation. The team understands that recycled parts must meet or exceed the performance expectations of modern vehicles to be a credible alternative to new equipment. That is why the inspection routines are rigorous and continual. Parts are assessed for structural integrity, compatibility with current models, and safe operation under real-world conditions. The emphasis on reliability helps to dispel myths about recycled components and encourages more vehicle owners to consider reuse as a viable option. For consumers who value cost savings alongside safety, the approach offers tangible benefits. When a shop can guarantee that a reused late-model part functions as intended, it reduces the anxiety that sometimes accompanies secondhand purchases and increases the likelihood that customers will view repair as a sustainable, prudent choice rather than a last resort.

The local dimension of sustainability cannot be overstated. Ellenwood Street is not a showroom that exists in isolation; it operates within a community of neighbors, technicians, and DIY enthusiasts who frequent the area for repairs and maintenance. The circular model embraced by A-1 Rylie Auto Parts supports these nearby ecosystems by creating a steady source of affordable, vetted parts. This, in turn, lowers the financial barriers to keeping older vehicles on the road, which can have meaningful social benefits for families and small businesses that rely on dependable transportation. When people keep their cars longer, they often become more thoughtful about maintenance schedules, parts compatibility, and the long-term costs of ownership. The shop’s approach helps cultivate a culture of responsibility, where the best option is not always the newest, but the most thoughtfully maintained.

The sustainability narrative at Ellenwood Street also extends to how parts are sourced and processed. Salvage yards, recycling streams, and dismantlers play a critical role in feeding the inventory, and the shop’s careful selection ensures that only components with verified condition enter circulation. This careful curation reduces waste and supports a more efficient use of existing resources. It also demonstrates that ethical procurement and responsible disposal can go hand in hand with competitive pricing and reliable performance. In this way, the business contributes to a broader shift in consumer expectations: that reliability and environmental stewardship can travel together, that choosing a recycled part can be the sensible path to keeping a vehicle safe and road-ready without surrendering modern standards.

The intersection of sustainability and practical repair becomes even more engaging when we consider the narrative beyond Dallas. The ecosystem of recycled auto parts has a wider resonance because it shows how communities can respond to the environmental costs of a transportation-heavy society. By reframing repair as a long-term, resource-conscious activity, A-1 Rylie Auto Parts invites customers to participate in a larger conversation about consumption, waste, and the value of repair skills in the 21st century. This is not about romanticizing the past; it is about leveraging the best of what already exists to keep people moving with fewer environmental penalties. It is a story about stewardship—of machinery, of resources, and of the urban landscape that supports both.

Within this framework, it is instructive to draw a connection to how a similar philosophy manifests in other areas of automotive culture. A practical example can be seen in the way enthusiasts and professionals increasingly rely on carefully sourced, remanufactured or recycled components to maintain performance while avoiding the environmental costs of new parts. A link to a real-world reference point illustrates this transition without stepping away from the central thread of Ellenwood Street. For readers who want to see how a specific long-standing part category is approached in practice, consider exploring a detailed example from a reputable automotive parts source that emphasizes OEM quality and compatibility in late-model contexts. This reference, while outside the Dallas setting, mirrors the same careful balance of value, reliability, and environmental responsibility that defines A-1 Rylie Auto Parts on Ellenwood Street. You can learn more about these standards at the external resource provided at the end of this chapter.

An interesting facet of the shop’s approach is how it speaks to consumer empowerment. By offering reliable recycled parts with thorough inspection, the business reduces financial stress for car owners who might be faced with the choice between a high-priced new part and a less certain used alternative. The transparency that accompanies the inspection process builds trust and encourages informed decisions. It is a practical education in value: worth is not solely determined by the part’s age but by its performance, reliability, and the broader environmental cost of the alternative. In many cases, customers who opt for recycled late-model components find that the savings are substantial enough to allow modest, safer maintenance plans to proceed—an outcome that benefits families, fleets, and the local economy alike. The result is a win-win scenario: a safer vehicle, a lower environmental footprint, and a customer base that understands that sustainability can be an integral part of everyday maintenance rather than a distant ideal.

The chapter would not be complete without recognizing the ongoing potential for collaboration and learning that emerges from a shop like this. As more vehicle owners seek out sustainable options, the demand for transparent, dependable recycled parts is likely to grow. This creates opportunities for partnerships with local nonprofits, educational programs, and community workshops focused on maintenance and repair skills. It also invites broader discussion about waste reduction, circular supply chains, and the ways in which urban infrastructure can support sustainable automotive practices. In Dallas, and across similarly situated communities, the model demonstrated on Ellenwood Street can inspire replication and adaptation, encouraging other independent parts suppliers to deepen their commitment to environmental responsibility while preserving the economic viability that makes such work possible.

To bring the thread back to a concrete takeaway: the sustainability story at A-1 Rylie Auto Parts is grounded in a straightforward premise. Reuse is not a compromise; it is a strategic, value-driven approach to keeping vehicles reliable and affordable while reducing the environmental burden of the automotive industry. By focusing on late-model parts, maintaining rigorous quality controls, and building a local ecosystem that rewards repair and responsible consumption, the business on Ellenwood Street embodies a practical, scalable form of sustainability. It is a reminder that the road to a more sustainable transportation future runs through community-centered businesses that treat every salvaged component as a resource rather than a throwaway artifact. In this sense, the chapter of Dallas begins with the work done in a modest storefront but carries forward into a wider narrative about how cities can reimagine maintenance as a durable, low-waste practice.

Internal link reference (for context and related practice): 03-06-mitsubishi-evolution-8-9-jdm-rear-bumper-oem

External resource for further reading on sustainability in auto parts: https://www.a1rylie.com

Final thoughts

A-1 Rylie Auto Parts stands out as a valuable resource for business owners in the automotive industry, not only for their extensive selection of quality recycled parts but also for their dedication to sustainability and quality assurance. By choosing A-1 Rylie, businesses can access cost-effective solutions that align with environmentally-conscious practices, thereby fostering a sustainable future in the automotive sector.