A-ABCO Fridley Auto Parts stands as a cornerstone in the automotive repair industry within the Greater Minneapolis/St. Paul area, leveraging over 75 years of expertise. With a commitment to quality and comprehensive selections of used and recycled auto parts, they have carved a niche for themselves that many in the industry admire. Each chapter unfolds the rich history of the company, showcases their expansive inventory and innovative services, highlights the technological milestones of their mobile app, and emphasizes the robust customer warranties and delivery services they provide. The deep-seated community impact further solidifies A-ABCO’s reputation as not just a business, but as a vital part of the local fabric.

A Century of Salvage and Service: The Enduring Legacy of A-ABCO Fridley Auto Parts

The story of A-ABCO Fridley Auto Parts unfolds like a long road trip through the practical, economy-minded spine of the American automotive ecosystem. Established in 1946, the business grew from a local, neighborhood yard into a cornerstone of the Twin Cities’ aftermarket landscape. Its evolution mirrors a broader shift in how owners, technicians, and fleets approach repair and renewal: instead of chasing pristine new components, they increasingly rely on durable, tested, recycled parts that keep vehicles on the road while saving resources and money. In Fridley, Minnesota, this approach has become a cultural habit as much as a business model, and it continues to influence how communities think about maintenance, sustainability, and reliability. The company’s longevity is not mere nostalgia; it is a testimony to careful stewardship—of inventory, of customers, and of the environment.

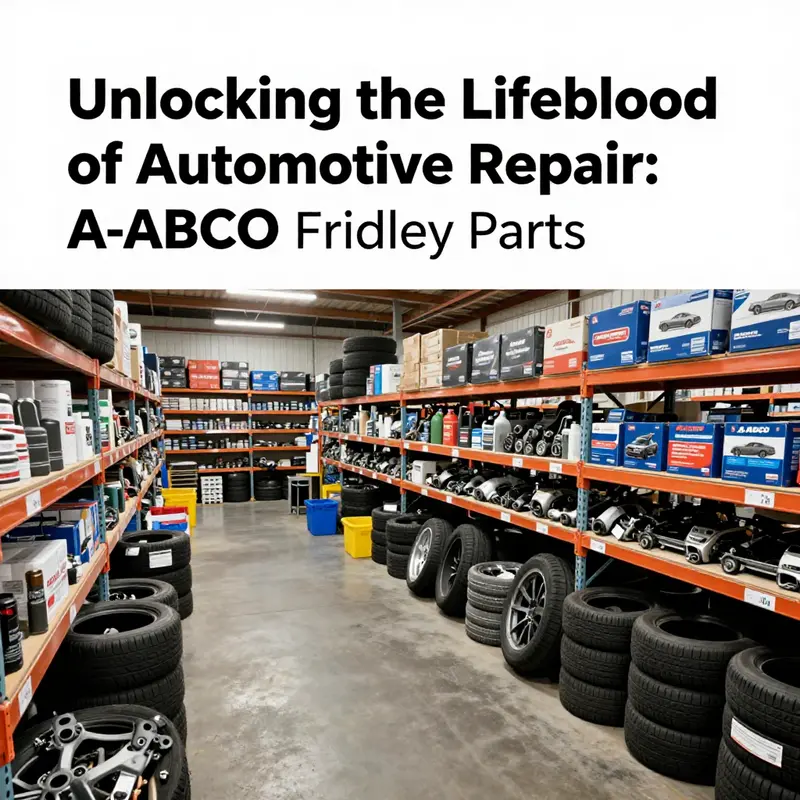

From the outset, A-ABCO Fridley Auto Parts established a mission that values breadth of choice alongside accountability. Today, the facility at 7300 Central Avenue NE sits as a hub where mechanics and do-it-yourself enthusiasts can access a vast universe of components without the downsides of new parts pricing. The breadth of inventory has always mattered in this line of work, and in an industry where the right fit can be a make-or-break moment, stock density translates into speed and confidence. The organization now proudly maintains what many in the region regard as the largest catalog of automotive and pickup parts in the area. This is no casual claim: it reflects a sustained investment in storage, sorting and shipping capabilities that keep thousands of customers moving every week. The inventory is more than numbers on a shelf; it’s a curated ecosystem where used, recycled, and salvage parts are vetted for compatibility and reliability, offering a practical alternative to purchasing new components when the latter are scarce or financially prohibitive.

What makes the Fridley operation especially relevant today is not just size but versatility. The catalog spans components for a broad spectrum of vehicles beyond passenger cars, including trucks and work vehicles that keep small and mid-sized businesses in motion. The true value proposition rests in the mix of options—used parts that come with the reassurance of being inspected, recycled pieces that meet safety standards, and salvage finds that have been tested in real-world service. This approach resonates with mechanics who want to minimize downtime and with DIYers who want a sense of control over quality and price. It also aligns with a growing appreciation for a circular economy in which materials and parts are reintroduced into use rather than discarded. The lifelong commitment to minimizing waste while maximizing reliability has become a defining characteristic of the business.

The operational backbone of A-ABCO Fridley Auto Parts is a combination of careful sourcing, rigorous inspection, and a logistics network that stretches beyond state lines. The company’s reputation for reliability has a practical counterpart in its logistics: nationwide delivery guarantees that extend the reach of a local supplier to customers across the United States. This is not incidental; it is a deliberate strategy to provide convenient access to a one-million-plus inventory. When a customer in another state needs a compatible part for a hard-to-find repair, A-ABCO’s scale matters because it translates into a higher probability of finding the exact match or a suitable alternative in the same family of components. In an era where rapid repair cycles can minimize downtime, having the ability to source the right part quickly is a critical differentiator.

The commitment to quality that accompanies that expansive catalog is reinforced by a lifetime warranty on most parts. This warranty policy is more than a marketing promise; it is a statement about confidence in the parts’ long-term performance. For technicians who rely on consistent, dependable replacements, a lifetime warranty reduces the financial risk associated with repairs and rebuilds. It also signals an understanding that the market’s needs are evolving toward reliability as a baseline expectation, not a luxury feature. The warranty helps create a trust bridge between seller and buyer: customers feel protected, and the seller remains accountable for the outcome of a repair job, which in turn sustains long-term relationships and repeat business.

In an increasingly digital marketplace, A-ABCO Fridley Auto Parts has embraced technology as a core component of its customer experience. The company offers a mobile app developed in collaboration with Car-Part.com, allowing users to search the entire inventory, scan their vehicle’s VIN for faster and more precise part matching, and view detailed part information and images when available. The app represents a natural extension of the company’s core strengths—comprehensive inventory, meticulous part data, and a user-friendly path to purchase. It makes the process more transparent and efficient by enabling customers to identify the exact parts they need before they reach the yard or place an order remotely. The app’s VIN scanning capability, in particular, is a meaningful enhancement for precision. VIN-based matching reduces misidentification, which lowers returns and tinkers less with the repair timeline. Yet, as with any new tool, reviews and user feedback matter. While the app is feature-rich and well-integrated with the broader Car-Part ecosystem, its reputation in the review space is still developing, a reminder that digital tools require ongoing optimization and user engagement just as physical parts do.

The digital dimension also extends to the company’s image of sustainability. Recycling and recycling-driven resales are central to A-ABCO Fridley Auto Parts’ identity. By reintroducing used and salvaged components into the repair market, the business helps stretch the lifespan of vehicles, reduces the demand for new manufacturing, and minimizes waste. For many customers, especially fleet operators, recycled parts offer predictable performance at a fraction of the cost of new equivalents, without compromising on safety and reliability. This philosophy resonates across the broader automotive community where repair cycles, maintenance budgets, and environmental considerations intersect. The company’s focus on sustainability is not a throwaway line; it is embedded in the way inventory is gathered, stored, inspected, and delivered, and it shapes the conversations that mechanics and DIYers have about long-term ownership costs.

The human element remains at the center of the Fridley operation. The business has earned a reputation for reliability through a blend of practical knowledge and responsive service. It is managed by Used-Car-Parts.com, Inc., a name that signals a larger network and a shared ethos around quality and accountability. This affiliations-based structure ensures that customers have access to a depth of experience, not simply a catalog. A customer who needs a specific part for a complex rebuild will often benefit from the combined expertise of a regional yard and a national network. It is in this synergy—the local touch, the expanded catalog, and the reliability of a widespread supply chain—that A-ABCO Fridley Auto Parts finds its strongest selling point.

The dialogue with customers naturally shifts toward the practical realities of repair work. Vehicles age, technologies evolve, and the demand for cost-effective, reliable components remains steady. In this context, salvage and recycled parts serve as essential components of the maintenance ecosystem. They provide access to components that may no longer be manufactured new, while still meeting the safety and performance expectations of today’s vehicles. The take-off tires, the reconditioned or lightly used parts, and the tested salvaged components create a continuum of options for a broad audience—from independent shop operators to weekend hobbyists who work within a budget but refuse to compromise on quality. In this way, A-ABCO Fridley Auto Parts is not just a supplier; it is a facilitator of practical, sustainable car ownership.

For readers curious about how the broader world of aftermarket components intersects with salvage yards, consider the range of parts that often appear in high-performance discussions and fixed-gear builds. In forums and catalogs that celebrate the potential of used components, there are instances where salvaged, tested parts enable creative, economical projects. One example can be found in the long-tail catalog of aftermarket listings that mirrors the same spirit of thoughtful reuse. For enthusiasts exploring aftermarket parts, mitsubishi-evolution-evo-4-9-shock-block-short-motor-engine-complete-4g63-1000b075 demonstrates how salvage parts can fit high-performance builds. While the example speaks to a specific model family, the underlying principle is widely applicable: careful matching, verification, and compatibility checks turn a salvage find into a reliable repair or performance upgrade. This kind of cross-pollination between salvage yards and performance-minded catalogs helps broaden the appeal of recycled components while keeping the focus squarely on safety, fit, and value.

If one looks ahead, the arc of A-ABCO Fridley Auto Parts suggests a future where the convergence of inventory depth, digital tools, and environmental responsibility continues to redefine the economics of auto maintenance. The yard’s capacity to source and verify parts rapidly will be increasingly valuable as vehicles incorporate newer electronics and more complex assemblies. The app will likely evolve to deliver even richer data, better imagery, and more precise fitment indicators. The logistics network will expand to support even faster delivery timelines, ensuring that a regional hub can keep pace with national demand. Amid these changes, the fundamental idea will endure: repairing and extending the life of current vehicles through intelligent reuse, careful validation, and transparent customer service.

In sum, A-ABCO Fridley Auto Parts stands as a practical landmark in the world of automotive repair and recycling. Its century-long presence—rooted in a local yard, scaled through larger networks, and modernized through digital tools—offers a template for how the automotive parts industry can be both affordable and responsible. It is a narrative about adaptability: embracing new modes of access, while preserving the core values that have made salvage and recycled parts a trusted option for countless drivers. The result is a durable, evolving business that continues to connect people with the parts they need, when they need them, and at a price that makes repair feasible rather than prohibitively expensive. That blend of history, scale, reliability, and forward-looking practice is what keeps A-ABCO Fridley Auto Parts relevant in a market that keeps changing, while still honoring its roots in Fridley and the wider region it serves.

External resource: A-ABCO Fridley Auto Parts on the App Store

null

null

Precision on the Go: How A-ABCO Fridley Auto Parts’ Mobile Tools Streamline Part Matching

A-ABCO Fridley Auto Parts has turned an extensive physical inventory into a true mobile advantage. The company’s mobile tool places one million plus parts inside a customer’s pocket. It blends careful inventory management with smart, purpose-built technology. The result is a faster, more accurate way to find, verify, and order recycled and salvage parts for cars and trucks.

At the heart of the mobile experience is a method that removes guesswork. Customers often struggle to identify the right parts. Make, model, year, trim level, and engine options create many compatibility pitfalls. Manual searches and vague descriptions lead to wasted time and wrong purchases. The mobile tool solves these problems with a fast vehicle identification method. Users simply capture a vehicle identifier. The system reads that code and matches it against the inventory. This process reduces human error and shortens search times dramatically. It also helps parts professionals confirm compatibility before they place an order.

This identification method is more than convenience. It aligns a buyer’s needs with the exact part data in the warehouse. Instead of relying on recollection or incomplete notes, the app pulls in specific vehicle attributes. It checks for exact model years, engine types, and factory options. That level of precision prevents a common scenario: a part that looks right but does not fit. For workshops and individual do-it-yourselfers, this precision translates into fewer returns and faster repairs.

Real-time inventory visibility is the other pillar. The mobile tool connects directly to the company’s warehouse database. Users see current availability and pricing in seconds. That live connection matters when parts move quickly. Because the inventory is constantly updated, a mechanic can confirm that a needed part is actually on the shelf before driving across town. Dealers and installers can schedule repairs with confidence. The app also displays condition notes and location details when available. That reduces unnecessary phone calls and saves labor time for both customers and staff.

Combining live stock status with precise vehicle matching changes ordering patterns. Customers are less likely to over-order spare parts. They can plan visits around confirmed availability. When parts aren’t available locally, the app guides users to delivery or to similarly compatible options. This flow improves first-time fixes and helps shops keep bays moving. It also taps the company’s strength: a large, regional inventory with a wide selection of recycled and salvage components.

Visual information is another capability that enhances decision making. Where possible, images are attached to part listings. A clear photo can confirm cosmetic condition, mounting points, or connector types. For used parts, an image can show whether a piece is a salvage-quality match or a take-off in near-new condition. That visual cue gives buyers the confidence to choose less expensive recycled options when appropriate, or to opt for a like-new take-off when aesthetics matter. In practice, images combined with VIN-based matching lower the risk of receiving an incorrect or unacceptable part.

The app’s data presentation is intentionally compact and meaningful. Detailed part notes appear beside availability and price. Compatibility indicators are highlighted to reduce scanning. When a match is found, the app shows exact fitment data, part numbers, and any interchange references. This structured display helps both novice users and seasoned parts professionals. Novices benefit from clear confirmation. Pros benefit from quick access to the technical details they need.

Speed and accuracy benefit from the mobile tool’s user interface choices. Search is optimized for short, targeted actions. Quick-scan features let users capture the essential vehicle data in one step. Filters refine results by condition, location, and price. Saved searches and recent vehicles speed up repeat tasks. Notifications inform users when a previously unavailable part arrives or when a watched item drops in price. Those small workflow improvements compound into significant time savings for frequent users.

For logistics, the app supports delivery planning. When ordering parts directly, customers can select delivery options during checkout. Live inventory combined with delivery capability allows remote ordering for out-of-state repairs. This feature leverages the company’s national delivery service and extensive parts pool. It makes the inventory accessible to a much wider customer base. For repair shops, it means parts can arrive on a specific schedule to match labor bookings.

Security and data integrity receive attention behind the scenes. Vehicle identification and part matching rely on accurate data links. The app is built to protect those connections and to ensure consistent lookups. Error handling is designed to surface ambiguous matches rather than to guess. When a scan returns multiple possible fits, the interface presents the choices clearly. Users can then refine the search by selecting engine type or trim. This conservative approach reduces costly errors and preserves trust between the parts provider and its customers.

The mobile tool also supports warranty transparency. Parts sold with a lifetime coverage or with specific guarantees show that information clearly. Users can view warranty terms and any exclusions before they finalize a purchase. That built-in transparency reduces confusion during returns or exchanges. It also reinforces the supplier’s reputation for quality and reliability.

Under the hood, the system uses an efficient architecture. It handles a very large parts database without slowing the user experience. Caching strategies and selective image loading prioritize responsiveness. The design favors quick, readable search results over heavy graphics. This makes the app practical for use in repair bays where connectivity may be variable. It also allows users to quickly switch between vehicles and parts without delay.

There is also room for continuous improvement. Predictive search features could anticipate repairs based on vehicle age and mileage. Machine learning models may someday prioritize likely replacement parts based on common failure patterns. Telemetry from repair shops could refine stock forecasts. These enhancements would build on the current strengths: accurate identification, live inventory, and clear data presentation. The existing platform creates a logical path for these capabilities to be layered in over time.

Beyond tech, the mobile tool supports a broader operational shift. It encourages customers to trust used and recycled parts when appropriate. By making fitment data and visuals transparent, the app reduces hesitation about non-new components. That helps the company to maximize reuse and to serve customers seeking cost-effective solutions. It also supports environmental benefits by extending the life of serviceable components.

Adoption is eased by intuitive onboarding. New users are introduced to the scanning and search functions through simple prompts. Help topics and quick tips explain how to read fitment results. Support channels remain available for complex cases. This human support, combined with a mobile-first approach, ensures that the app serves a wide audience. It fits both mobile-savvy DIYers and busy shop managers who need quick, accurate answers.

In sum, the mobile tool translates a vast physical inventory into fast, reliable decisions. It reduces the friction inherent in used-parts purchasing. It brings exact vehicle matching, live stock visibility, clear images, and warranty transparency into a single workflow. For customers and partners, this combination saves time, lowers mistakes, and supports smarter repair choices.

For more details about the app listing and its features, see the official app listing: https://apps.apple.com/us/app/a-abco-fridley-auto-parts/id1628970543

Warranty that Endures: A-ABCO Fridley Auto Parts and the Lifespan of Used Parts

In Fridley, Minnesota, A-ABCO Fridley Auto Parts has built a reputation for durability and reliability in the salvage parts market. Since 1946, this corner of the Minneapolis area has become a hub for technicians and DIYers who need a broad inventory and practical terms. The companys core strengths rest on three pillars: a vast selection of used, recycled, and salvage auto parts; a customer friendly warranty policy that backs many parts for life; and a delivery network that reaches across the United States. Taken together, these elements form more than a sales pitch; they create a dependable ecosystem for repair shops and vehicle owners who depend on getting the right part at the right time.

To the warranty, the lifetime warranty on most parts signals more than a slogan. It reflects the stores confidence in its sourcing, inspection, and cataloging processes. When a customer buys a part a take-off, a salvage rebuilt component, or a used module this warranty offers redress or replacement if it fails under normal use. The phrase lifetime warranty is thus a commitment to durable parts, not a mere time frame. It underpins decision making, encouraging customers to weigh long term reliability and total cost of ownership rather than just the sticker price.

The catalog depth matters just as much as the warranty. The warehouse houses an enormous range of automotive and pickup parts, including thousands of used tires and select like new take offs from insured total loss vehicles. This breadth increases the odds of finding an exact match, reduces search friction, and shortens repair timelines. For technicians and hobbyists alike, it means more precise compatibility decisions and faster deliveries when time matters most.

Technology is the connective tissue. The Abco Fridley Auto Parts app lets customers search the full catalog, scan VINs to speed matches, view detailed part information and images, and initiate contact with the sales team for delivery arrangements. This digital layer complements the physical inventory, creating a transparent, auditable purchase journey while preserving the practical, hands on service customers expect.

Local access remains important too. The Fridley operation sits alongside a dense repair ecosystem, with a nearby storefront, live staff, and a local phone line for questions and on the spot collaboration. Yet the real value lies in the lifecycle approach: fast, reliable delivery nationwide so a part is not just available, but arrives in time to support a repair plan. The result is a cohesive experience that blends warranty confidence, inventory breadth, and dependable delivery into a single customer journey.

Resilience, Reuse, and Reliability: The Community Ripple of A-ABCO Fridley Auto Parts in the Twin Cities

External resource: https://www.yelp.com/biz/abco-fridley-auto-parts-minneapolis

Final thoughts

Through its rich history, wide-ranging services, and strong community ties, A-ABCO Fridley Auto Parts exemplifies the significance of trusted suppliers in the auto parts industry. Their innovative mobile app and commitment to customer satisfaction create a seamless experience for business owners and automotive enthusiasts alike. As they continue to grow and adapt, A-ABCO remains a vital resource, not only for quality used parts but also for fostering relationships that strengthen the local automotive community.