In an era where environmental accountability is more important than ever, A-Abco Fridley Recycled Auto Parts emerges as a leader in the auto parts recycling sector. Operating since 1946, this esteemed business not only offers a vast selection of used and recycled auto parts, but also champions sustainable practices that benefit both customers and the planet. The following chapters will delve into the comprehensive operations of A-Abco, exploring their unparalleled commitment to environmental responsibility, their distinctive customer service practices, and the longevity benefits they provide through robust warranties. Business owners can learn how embracing such practices can not only yield cost-effective solutions but also align their operations with the growing expectation for responsible business practices.

null

null

Salvage to Sustainability: How A‑Abco Fridley Turns End‑of‑Life Vehicles into Environmental Value

Environmental commitment in practice

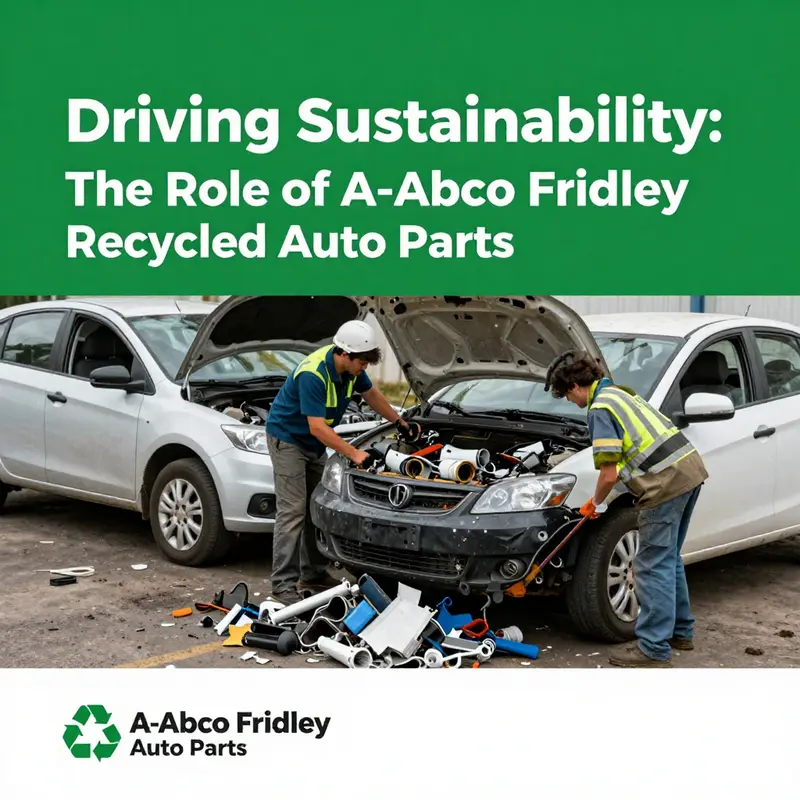

A-Abco Fridley Recycled Auto Parts treats each incoming vehicle as a source of value rather than a scrap problem. Their approach combines practical salvage techniques, clear incentives for vehicle owners, and systemic processes that reduce waste across the automotive lifecycle. Every car or truck arriving on the lot is evaluated not only for resaleable components, but also for parts that can be reused, remanufactured, or properly processed as recyclable material. This mindset shifts the environmental equation. Materials and components that would otherwise enter landfills are kept in productive circulation. Metals, rubber, glass, and working mechanical systems return to the market. Hazardous fluids and batteries are extracted and handled with care. The net result is a significant reduction in material loss and an extension of product life.

At the center of this effort is an emphasis on reuse. Salvaged components that meet safety and performance standards are made available to repair shops and vehicle owners. Tires with substantial tread life are repurposed. Take-off parts from vehicles declared total losses by insurers are cleaned and cataloged as high-quality, near-new items. That availability reduces demand for newly manufactured parts, cutting energy and emissions associated with raw-material extraction and production. The environmental benefits are cumulative. A single reused engine, transmission, or set of body panels prevents the manufacture of equivalent new parts. That saves mining, smelting, molding, machining, and the transport networks tied to new production.

The company also designs incentives to encourage responsible end-of-life decisions. Paying competitive prices for junk vehicles motivates owners to choose legal and environmentally responsible disposal. Instead of abandoning cars or selling them to unregulated facilities, owners are more likely to bring vehicles to a licensed recycler. This practice prevents the leakage of pollutants into soil and groundwater. It also ensures components and materials are tracked through proper recycling streams. Those financial incentives are a simple, effective way to align individual choices with broader environmental goals.

Operational discipline backs every step. Before components re-enter service, they undergo inspection, cleaning, and testing where appropriate. Fluids are drained and recycled. Batteries are removed and sent through safe disposal or reclamation channels. Airbags and other safety items are handled with regulatory compliance in mind. By maintaining strict processing standards, the facility reduces the risk of secondary environmental harm. It also builds confidence among buyers and repair professionals who depend on reliable used parts. That reliability helps the circular model scale, because trust reduces barriers to choosing reused components over new ones.

Recycling systems cannot succeed without logistics that prioritize efficiency and low emissions. A-Abco Fridley’s delivery services, which reach customers across the United States, are organized to minimize redundant trips and unnecessary vehicle miles. Consolidated shipments and regional routing reduce fuel use per part delivered. Locally, transporting parts from yard to warehouse follows planned flows that limit idling and excess handling. These logistics choices may seem incremental, but they compound when thousands of parts move through the system each year. Together they lower the overall carbon intensity of redistributed automotive parts.

Beyond operational measures, the environmental impact is measurable at scale. Reused auto parts eliminate the need for fresh raw materials. That reduces greenhouse gas emissions from mining and manufacturing processes. It also decreases cumulative energy consumption. Even modest salvage rates translate to meaningful savings when applied to the volume of vehicles processed annually. This multiplier effect benefits communities, municipal waste systems, and the global climate. It is also economically sensible: customers save money on replacement parts while reducing their carbon footprint.

Community engagement strengthens the environmental mission. The facility works with local repair shops and independent mechanics who prefer cost-effective, dependable parts for their clients. This network encourages repairs rather than vehicle replacement. Extending the useful life of a vehicle avoids the energy cost of manufacturing a new car. Moreover, repairs that keep older vehicles functioning can be important for households with limited budgets. By connecting salvage operations to local service providers, the recycler reinforces both economic resilience and environmental stewardship.

Proper management of hazardous materials remains a core responsibility. Waste oil, coolant, transmission fluid, and refrigerants require safe collection and disposal. A-Abco Fridley follows regulatory protocols to ensure none of these substances contaminate soil or water. Proper handling also captures value. Reclaimed oils and certain fluids can be sent for processing and reuse, transforming a potential pollutant into a feedstock. Batteries are especially sensitive; they contain heavy metals and electrolytes that demand careful reclamation. The facility’s procedures minimize leaks and exposures. These controls protect workers, neighbors, and local ecosystems.

Another element is the stewardship of tires. Used tires are often overlooked, yet their disposal can cause serious environmental problems if not handled correctly. The yard stocks thousands of used tires and provides options that keep them circulating. Tires with adequate tread are resold. Damaged tires are collected and routed to recycling channels where materials are repurposed for playground surfaces, road construction, or energy recovery under regulated conditions. This reduces illegal dumping and prevents tire piles that breed pests or become fire hazards.

Transparency and education amplify the environmental impact. Staff explain salvage benefits to sellers and buyers. Clear information about warranties, part conditions, and installation expectations reduces misuse and return rates. Lifetime warranties on many parts encourage confidence and uptake. When consumers understand that reused components are both reliable and guaranteed, they are more likely to choose them. That behavioral shift makes reuse mainstream rather than niche. Over time, mainstream acceptance changes supply chains and manufacturing incentives.

Technology supports this transition. Inventory systems track more than location and availability. They record part provenance, testing history, and compatibility data. That traceability helps mechanics locate the right part faster. It also supports quality controls that maintain safety standards. When parts can be identified and verified quickly, repair times fall. Faster repairs reduce the time vehicles spend out of service, which lowers associated energy and transport burdens. Improved data also helps quantify environmental outcomes. Tracking how many parts leave the yard rather than being scrapped feeds calculations on material saved and emissions avoided. Those metrics inform process improvements and community reporting.

The business model also accommodates evolving automotive technologies. As vehicles change, salvage operations adapt. Hybrid and electric vehicles introduce new considerations for batteries, motors, and electronic control units. Proper handling and eventual material recovery from high-voltage batteries require specialized procedures. Preparing for that future involves staff training and partnerships with qualified recyclers for battery modules. A forward-looking facility invests in knowledge and equipment so it can responsibly process emerging vehicle types. This readiness ensures salvage operations remain an environmental good as the fleet becomes more complex.

Collaboration extends to regulatory and industry groups. Aligning practices with local and federal requirements ensures safe operations. It also opens pathways to pilot programs that enhance sustainability. For example, participation in community recycling initiatives or municipal vehicle take-back events raises awareness and channelizes end-of-life vehicles into legitimate streams. These collaborations can also improve access to incentives or grants that support environmental infrastructure upgrades. The result is a continuous improvement loop where compliance, innovation, and community benefit reinforce one another.

Economic benefits and environmental gains are not separate. Diverting parts from landfills and reselling them generates revenue. That revenue supports better processing, safer workplaces, and outreach programs. It also creates jobs in logistics, inspection, and refurbishment. Local employment tied to circular economy activities keeps value within the community. When those jobs come with training in safe handling and environmental standards, the social returns multiply. Residents gain skills that remain valuable even as technologies shift.

Practical examples illustrate the scale of impact. Consider a single popular part: a used transmission or engine. Salvaging one unit can avoid dozens of tonnes of material processing. Multiply that by the thousands of parts in inventory, and the environmental savings are substantial. Tires, batteries, alternators, radiators, and collision panels all add to the total. Even small parts saved from production eliminate the emissions of manufacturing a new equivalent. Credible estimates based on industry averages show that significant greenhouse gas reductions result from high salvage and reuse rates.

Consumer choices complete the cycle. When drivers choose recycled components, they reward a system that values resource efficiency. Affordable replacement parts also mean more vehicles can be repaired rather than replaced. That reduces the demand for new vehicles, which are resource-intensive to produce. The ripple effects touch raw-material markets, manufacturing schedules, and even vehicle design, as more manufacturers recognize the value and demand for reused components.

Finally, continuous improvement guides the operation. Regular audits of material flows reveal opportunities to increase reuse. Investments in better testing equipment raise the proportion of parts eligible for resale. Partnerships with remanufacturers expand the options for parts that require refurbishment. And engagement with community stakeholders ensures the facility’s practices remain aligned with local needs and environmental priorities. This iterative approach keeps salvage operations effective and credible, ensuring that recycling remains a durable part of the automotive ecosystem.

For those who want to explore inventory, policies, or contact information, the facility maintains an informational profile that details services and hours. For up-to-date inventory access and further contact details, visit the facility’s listing on Car-Part.com: https://www.car-part.com/abco-fridley-auto-parts

For a practical example of used assemblies and how they re-enter the market, see this listing for a vehicle halfcut used in repairs and rebuilds: evo-x-halfcut.

Through careful processing, responsible incentives, and ongoing investments in systems and people, A-Abco Fridley Recycled Auto Parts turns salvage into measurable environmental value. The work reduces landfill burden, lowers demand for new materials, and offers affordable repair solutions. It also creates economic and social benefits for the local community. That combination makes salvage yards a pivotal part of a more sustainable automotive future.

Wheels of Trust: Service, Warranties, and the Eco-Conscious Promise at A-Abco Fridley Recycled Auto Parts

Wheels of trust and the quiet force of a long-standing presence—these are the ambitions that anchor A-Abco Fridley Recycled Auto Parts in the Twin Cities’ automotive landscape. Since 1946, this Fridley-based recycler has built more than a catalog of parts; it has forged a relationship with local mechanics, do-it-yourself enthusiasts, and fleets that rely on a steady supply of dependable components to keep vehicles on the road. The facility at 7300 Central Ave NE is more than a warehouse; it is a nexus where history, science, and service converge to support a wide region that stretches beyond Minnesota borders through nationwide delivery. The company’s mission centers on connecting customers with used and recycled auto and truck parts while anchoring every interaction in transparency, durability, and environmental stewardship. In a market often defined by price alone, A-Abco frames value as a blend of accessibility, accountability, and the confidence that comes with knowing a part is backed by a robust warranty. The story of how the business operates—its scale, its people, and its promises—offers a window into a model where longevity and responsibility intersect with practical repair needs.

A-Abco’s inventory is the backbone of its claims to reliability. Boasting over one million automotive and pickup parts in the warehouse, the operation is designed to meet a remarkable range of requests with speed and accuracy. The sheer volume translates into a practical advantage for customers who might fear a long, uncertain search for a single component. The staff’s expertise is the second pillar supporting that advantage. Experienced technicians and knowledgeable specialists become navigators in a vast sea of possibilities, helping customers articulate what they need and translating it into the right part. This collaborative approach—where a customer’s description is expanded by technical cross-checks and a precise understanding of vehicle compatibility—often results in a resolution within minutes. It is not merely about finding a part; it is about confirming that part will f it, fit, and function as intended in the customer’s specific vehicle context.**

The trust customers place in A-Abco rests as much on transparency as on inventory breadth. Detailed information accompanies every listing, including the part’s origin, its current condition, and how it interacts with a vehicle’s systems. This commitment to openness is reinforced by the way the company presents its used tires and “like-new” take-offs from vehicles that were declared insurance total losses. Each item undergoes inspection and cleaning before it reaches a customer, and the documentation attached to a listing aims to remove guesswork from the buying process. The result is a buying experience that minimizes post-purchase uncertainty and promotes confidence in what can be a cost-conscious decision. In practical terms, this means that a customer can understand whether a part is a salvage recovery, a remanufactured component, or a solid used option that still has life left in it. The clarity of the information supports an informed choice, making the transaction more predictable for both a DIY auditor and a professional shop that must manage warranties and downtime for its own customers.

Technology plays a central role in translating that transparency into seamless service. A-Abco has embraced a digital approach that complements its brick-and-mortar strengths. The company maintains a dedicated mobile application available on the Apple App Store, a tool that broadens access beyond the local showroom and into the hands of users who need parts while they are on a job site, in a shop, or at home. The app enables users to search the entire inventory, verify part availability in real time, and schedule pickups or deliveries with a few taps. This digital layer is not merely about convenience; it enhances accuracy by providing an immediate reference point for compatibility checks and part specifications. For mechanics coordinating multiple orders or DIYers racing against a repair deadline, the app shortens the distance between intent and fulfillment, reducing the friction that often accompanies salvage shopping. The synergy between a massive, carefully curated inventory and a modern, user-friendly interface creates a shopping experience that feels both traditional and forward-thinking at once.

The backbone of A-Abco’s value proposition is its lifetime warranty on most parts. This warranty is not a short-term assurance or a one-off guarantee that expires with some seasonal window; it is pitched as a long-range commitment to quality and durability. If a part fails due to defects in materials or workmanship, the company promises replacement or repair at no cost—regardless of how long the vehicle has been in use. Such a policy is a bold statement in a market that often hedges on time limits or warranty carve-outs. It communicates a philosophy: the recycler stands behind the parts they sell because they are confident in the standards of inspection, cleaning, testing, and compatibility verification that precede a listing. For customers, that means reduced financial risk and greater peace of mind as they undertake repairs—especially when budgets are tight and downtime is expensive. The warranty also reframes the relationship between seller and buyer as a partnership. When a part is warranted for life, both parties are invested in making sure it remains a dependable component of the vehicle, with a shared incentive to address any fault quickly and fairly.

The practical operations that enable such a warranty to feel real are anchored in the way A-Abco processes and manages its parts. The scale of the warehouse allows a nimble approach to sourcing, even for unusual or less common models. When a customer is seeking a specific part, the staff leverages cross-reference tools and cataloging practices to confirm that a candidate piece will be compatible before it is shipped or picked up. That verification step helps reduce returns and warranty claims that can arise from misfits, and it reinforces the reliability customers associate with the shop. The company’s transparency extends to the logistics of delivery. With nationwide delivery options, customers who are outside the Twin Cities can still rely on the same level of service and accountability that local customers enjoy. The dream of convenient, responsible auto repair crosses county lines, and A-Abco’s capacity to coordinate shipping across the United States makes this promise tangible for a broad audience of drivers, fleets, and repair professionals who depend on consistent access to recycled parts.

Behind these operational strengths lies a culture built on long-standing relationships and a clear sense of responsibility to the environment. The eight-decade history of the business is more than a timeline; it is a living testament to a model that treats vehicles as resources rather than waste. The company’s environmental credentials rest on the principle of recycling as much of each vehicle as possible, a stance that resonates with customers who are mindful of sustainability and cost. Reclaiming usable components from end-of-life vehicles reduces the demand for new parts and lowers the environmental footprint of repairs. In practice, this eco-conscious approach translates into careful disassembly, sorting, cleaning, and testing processes that ensure recycled parts perform well while contributing to a cleaner local and regional ecosystem. The “green” dimension is not a marketing line but a core operating discipline that aligns with the broader values of customers who want to repair responsibly and minimize waste.

A-Abco’s services also speak to the professional circle of the auto repair world. For independent mechanics, small shops, and larger service centers, the ability to source reliable recycled parts quickly matters as much as the part’s price. The company’s delivery network and its extensive catalog become a responsive extension of a shop’s purchasing function, helping it maintain schedules and reduce project downtime. This is especially valuable when dealing with insurance-insured vehicles or fleet maintenance that depends on rapid turnarounds. The relationship with professional customers is bolstered by an easy-to-navigate process for locating compatible parts, clear documentation of part histories, and the assurance that the warranty coverage applies across applicable scenarios. In a sector where a single wrong part can derail a repair timeline, the combination of inventory depth, knowledge-driven guidance, and warranty certainty offers a practical and dependable path to getting vehicles back on the road.

The scale and steady reputation of A-Abco also reflect a broader community function. As a longstanding fixture in Fridley and the greater Minneapolis–St. Paul area, the business has become a resource not only for individual motorists but for local repair ecosystems. It supports workshops, car clubs, and salvage-related trades by ensuring they have access to parts that meet performance expectations without creating untenable cost barriers. The physical presence of a large, well-organized yard paired with a robust digital interface sends a message to customers: this is a place where longevity matters, where people take the time to verify what is being offered, and where the promise of a fair, transparent transaction is part of the service. In short, it is an enterprise that looks to the future while cherishing a history rooted in the practical realities of repair work.

The experience of choosing a recycled part at A-Abco is never a solitary act. The company’s emphasis on transparency means customers are empowered to participate actively in the decision-making process. The staff’s willingness to explain how a part was sourced, what tests it has undergone, and how it will integrate with a particular vehicle’s systems is a hallmark of the business. This approach is reinforced by the company’s technology-enabled interface, which enables real-time checks for compatibility and availability, and by the assurance that the part’s condition is clearly disclosed. For someone who is balancing budget considerations with the need for reliability, this clarity makes a meaningful difference. The process becomes less about guesswork and more about informed, confident selection, with a warranty that stands as an ongoing commitment to that confidence.

In the chapters that follow, readers will see how these core elements come together in the practical steps of purchasing and using recycled parts—from identifying the right part and confirming compatibility to arranging delivery and navigating warranty coverage when a repair hits a snag. The narrative remains anchored in the everyday realities of repair work and the broader ambitions of sustainable automotive practice. Yet it also points to the human side of the business—the people who answer calls, pull parts from a towering repository, and coordinate a nationwide logistics network with the same calm efficiency they bring to a local pickup. This is not merely a story about a parts supplier; it is a story about a community-elevating approach to repair, one that treats every vehicle as deserving of a second life and every customer as a partner in that ongoing mission.

To explore the catalog in more detail and to see how a single listing can reflect the wider approach to reliability and service, readers can browse the Car-Part listing associated with the shop. For a snapshot of the catalog and to get a sense of how the system presents part histories, availability, and compatibility notes, visit the Car-Part listing linked here: Car-Part listing for A-Abco Fridley Auto Parts in Fridley, MN.

External resource: Learn more about their broader inventory and approach through Car-Part’s catalog reference. https://www.car-part.com/abco-fridley-auto-parts-fridley-mn

Final thoughts

A-Abco Fridley Recycled Auto Parts stands out in a crowded market by combining robust environmental practices with exceptional customer service. Their extensive inventory not only meets immediate auto parts needs but does so in a way that champions sustainability, making them a valuable ally for businesses looking to reduce their ecological footprint. With a commitment to quality supported by lifetime warranties, A-Abco ensures that business owners receive not just products, but lasting partnerships built on trust and shared values. As the auto parts industry continues to evolve, aligning with companies like A-Abco can enhance competitive edge and corporate responsibility.