Navigating the automotive parts supply landscape can be challenging for business owners. A and M Auto Parts stands out as a reliable brand known for providing high-quality, durable, and economical automotive components. This guide offers a thorough understanding of A and M Auto Parts, emphasizing their quality standards, supported vehicle models, economic impact on repair costs, comparison with OEM products, and global distribution. Each chapter delves into these facets, equipping business owners with the insights needed to make informed decisions about their automotive parts sourcing.

How A and M Auto Parts Meet Rigorous Quality Standards: From Global Rules to Customer Demands

Quality for A and M auto parts is created, measured, and enforced across layers. It begins with mandatory systems and laws, continues with technical criteria for each component, and finishes with exacting customer demands. This combined framework assures safety, reliability, and consistent performance whether parts are produced for original fitment or replacement.

At the foundation sits the regulatory and international framework. A dedicated automotive quality management system enforces a process-oriented, risk-focused approach to product realization. It requires documented controls over design, procurement, manufacturing, and delivery. The aim is clear: eliminate variation, capture failures early, and drive continuous improvement. Functional safety and environmental resilience are covered by international standards. Electronic modules must meet electromagnetic compatibility and electrical transient tests. Thermal cycling and environmental exposure are defined in test protocols so components survive real-world conditions. National and regional laws overlay this international baseline. Emissions rules, crash safety mandates, and chemical restrictions are compulsory. Compliance is not optional; it shapes material selection, supplier audits, and production controls.

Built on that foundation are industry-specific technical specifications. Each part category faces its own engineering priorities and test regimens. Powertrain components prioritize durability and sealing. For example, a cylinder head might need to pass a pressure test at one-and-a-half times operating pressure for a set time without leakage. Transmissions require wear and heat resistance over many duty cycles. Structural and safety parts focus on energy absorption and structural integrity. Typical impact tests replicate real collision loads. A bumper or crash beam often undergoes a pendulum impact at a specified speed where allowable deformation is capped and cracking is forbidden. These measurable criteria make repair and replacement parts predictable under crash conditions.

Electrical and electronic parts demand a different set of assurances. Sensors and control units must resist electromagnetic interference. They require testing for electrostatic discharge and electrical transients. Long-term reliability is verified through accelerated aging and humidity exposure. Connectors and harnesses face vibration, salt spray, and thermal shock tests. Interior and exterior trims are judged by appearance, emissions, and mechanical durability. Color matching, scratch resistance, and VOC emissions are all measured. Even soft-touch materials are tested for abrasion and odor.

Overlaying technical norms are customer-specific requirements. Automakers impose tailored tolerances, material specifications, and environmental profiles. These demands may be narrowly defined. Examples include extremely tight dimensional tolerances such as bore roundness within fractions of a thousandth of a millimeter, or magnetic core losses capped at precise watts per kilogram. Temperature cycling may be extended beyond standard ranges, sometimes spanning from well below freezing to high-operating extremes. Suppliers who want to win and keep business must fold these customer requirements into their management systems. That means traceability, lot control, and documented evidence that every shipment met the agreed profile.

This three-tiered model applies directly to the supply chain for A and M auto parts. Whether the parts carry an OEM mark or come from a trusted aftermarket brand, they are validated through the same architecture: legal compliance, technical verification, and customer acceptance. A supplier’s factory audit, process capability studies, and material certifications all trace back to these tiers. The result is measurable confidence, backed by test reports, inspection records, and corrective action histories.

Testing and verification are where theory becomes tangible. In production, incoming materials are sampled and validated. Critical dimensions are inspected with precision instruments. Functional tests run in lines and labs simulate thousands of cycles in compact timeframes. For safety parts, impact rigs reproduce crash forces and measure deformation, fracture, and energy absorption. For electronic modules, EMC chambers and transient test benches validate immunity and susceptibility. Environmental chambers run combined stress tests: heat, cold, humidity, and vibration together. These protocols shorten the path from prototype to field-proven component.

Traceability is another pillar. Good parts come with documentation that follows them from raw material to finished piece. Lot numbers, heat codes, and supplier certificates create a chain of custody. When issues arise, manufacturers can isolate and remove affected lots quickly. This capability reduces downtime and prevents costly vehicle recalls. It also enables continuous improvement, because feedback loops are short and corrective measures are targeted.

Quality culture matters as much as standards and tests. A supplier compliant with formal systems still needs engaged operators, capable engineers, and disciplined supervisors. Root-cause analysis replaces blame. Statistical process control guides action. Preventive maintenance and poka-yoke devices reduce human error. When organizations pair strong culture with formal systems, they produce consistent output and adapt faster to new requirements.

The choices buyers make reflect these realities. Purchasing decisions weigh compliance certificates, test data, and production capabilities. A replacement bumper or a structural beam is evaluated not just by price, but by documented performance under prescribed tests. Fitment, finish, and functional attributes are validated against accepted benchmarks. For consumers and repairers, that means affordable parts can still meet OEM-level expectations if sourced from reputable suppliers who follow the full quality framework.

Practical examples help make the abstract concrete. Consider a rear bumper assembly. It must fit precisely, attach to the vehicle without interference, absorb specified impact energy, and exhibit consistent finish and color. Suppliers subject such assemblies to dimensional checks, impact testing, and visual inspections under controlled lighting. Fitment trials confirm the part installs cleanly on the target model. A supplier page showing available rear bumper options can be a useful resource for fitment and part selection; see the 2008–2015 Mitsubishi Lancer Evo X rear bumpers for a typical presentation of fitment-focused listings. Such listings, however, are only part of the decision. The underlying test evidence and supplier quality processes remain the true indicators of value.

Finally, certification and continuous monitoring keep quality durable. Formal audits, product sampling, and customer feedback all sustain performance. Standards evolve, and suppliers must adapt. New emissions rules, revised safety protocols, or updated functional safety frameworks drive product changes. The best suppliers invest in engineering, testing labs, and staff training to stay current. That investment translates into fewer warranty events, safer vehicles, and more satisfied customers.

The layered approach—global standards, technical specifics, and customer requirements—turns ambiguity into measurable quality. For A and M auto parts, this approach reconciles cost pressures with the non-negotiable need for safety and reliability. When suppliers combine certified systems, rigorous testing, traceability, and a strong quality culture, replacement and aftermarket parts can deliver predictable performance across the vehicle lifecycle.

For further reading on the primary automotive quality management framework, see the official IATF website: https://www.iatf.org/

Model Profiles and Part Partnerships: How A and M Auto Parts Serves a Diverse Fleet

A and M Auto Parts, as described in the research materials, occupies a space in the aftermarket ecosystem that straddles affordability and reliability. The branding discussion often encounters a quick confusion around terminology. In automotive parlance, AM can evoke ideas of automatic versus manual systems, but in this context the phrase points to a specific parts supplier or brand. The emphasis is on high-quality, durable components offered at costs that make routine maintenance and repairs more economically feasible. The narrative across available sources frames A and M Auto Parts as a wholesale-oriented enterprise with a catalog that spans a broad spectrum of vehicle types, from common sedans to widely distributed light trucks. The underlying philosophy is clear: align with the expectations of original equipment performance while trimming excess cost, so repair work does not become an undue burden for shop owners or DIY enthusiasts. This positioning matters because it situates the brand within a larger ecosystem where fit, finish, and real-world durability are weighed against price. In that light, the brand’s identity emerges not as a novelty but as a deliberate response to the practical constraints of modern vehicle ownership and upkeep.

From the available information, the catalog includes items that cater to both cosmetic updates and functional upgrades. The offering breadth hints at a strategic intent: to serve as a one-stop source for parts that restore or enhance a vehicle’s appearance and function without resorting to factory-new pricing. The brand’s emphasis on durability implies manufacturing choices that favor corrosion resistance, structural integrity, and finished surfaces that can withstand the rigors of daily use. Importantly, the supplier is described as a global wholesale player. That global stance signals a logistics framework designed to reach a wide network of repair shops and independent retailers, which in turn increases the chances that a given part can be sourced quickly when a repair needs to be completed. This ease of access, paired with OEM-equivalent performance, positions A and M Auto Parts as a practical option for shops balancing timelines, customer expectations, and cost containment.

A concrete example within the current listings points to a side step plate described as an aluminum component with a powder-coated black finish. The material choice—aluminum—speaks to a balance between weight savings and strength, while the powder coating suggests enhanced durability against chipping, abrasion, and moisture ingress. The finish also contributes to a cohesive look when installed on vehicles with dark exterior accents. While the precise fitment details are not exhaustively listed in every source, the documented compatibility aligns with a widely adopted full-size pickup platform produced in the late 2010s through the mid-2020s, configured with four-door crew/cab variants and extended cab options. This kind of alignment is typical in aftermarket catalogs that aim to cover the most common mounting points and step-in access configurations that owners rely on for practical use—especially on work-ready trucks that see cargo loading, frequent ingress and egress, and exposure to abrasive elements.

What this specific example communicates is multi-layered. First, it signals an intent to deliver aftermarket hardware that integrates with essential vehicle touchpoints—areas where aftermarket upgrades can affect both usability and perceived value. A side step, while seemingly ancillary, is a functional facet of vehicle ergonomics, offering safer access and a modest elevation of the vehicle’s stance. The aluminum construction reduces weight penalties, while the black finish harmonizes with a spectrum of color palettes and aftermarket styling choices. For repair shops and owners seeking to mitigate downtime, a product that promises straightforward installation, reliable mounting, and consistent finish provides a measurable advantage. In this context, A and M Auto Parts is presenting more than a part; it is a value proposition—a blend of fitment confidence, material performance, and price-conscious procurement that can translate into faster service and happier customers.

The broader significance of model-specific fitments in the aftermarket becomes evident when considering how shops navigate the complexities of vehicle platforms. Modern vehicles often share common chassis points and mounting locations across trims and years, yet subtle variations can affect fit. A brand that publicly highlights compatibility with a widely used configuration signals a pragmatic approach: target the most common demand and build out from there. It also implies a cautious engagement with the realities of aftermarket manufacturing where margins depend on predictable install success. For practitioners, this means fewer surprises on the workbench and more confidence in a part’s ability to align with the vehicle’s structural and aesthetic parameters. The familiarity of the target model category—an established, mass-market pickup—also points to steady demand for accessories and upgrade components that can be installed by technicians and capable DIYers alike.

At the same time, it is important to acknowledge the limits of the publicly available data. The record shows one explicit model compatibility example, rather than an exhaustive catalog spanning hundreds of models. That snapshot is informative: it reveals the brand’s current emphasis and likely its early-stage market focus. Yet it also invites prudent verification. For buyers and installers, the prudent path is to confirm fit through official product pages or authorized distributors before committing to a purchase. Authenticity, accurate fitment, and compatible mounting hardware matter as much as the material itself. In the absence of comprehensive fitment lists, a cautious buyer will seek confirmation that the specific part aligns with the vehicle’s mounting points, brace configurations, and any possible interference with nearby components. The cost savings offered by aftermarket parts hold appeal, but they are most compelling when paired with clear assurances about compatibility and installation.

This portrait of A and M Auto Parts, centered on a single but telling example, also illuminates the brand’s broader market proposition. The catalog’s breadth, described as covering components from engines to body parts, positions the company in a space where serviceability and customization co-exist. The emphasis on cost containment remains a core driver, yet the claim of OEM-equivalent quality anchors the narrative in reliability and long-term performance. Shops weighing this balance often face a straightforward calculus: will the part perform as needed over the life of the vehicle, and at what cost compared with alternatives? When a supplier can demonstrate a credible alignment with OEM expectations while delivering at a lower price, it helps partners deliver value to customers who are managing maintenance budgets without sacrificing the integrity of the repair. In a world where fleets, independent shops, and individual vehicle owners alike seek predictability, A and M Auto Parts positions itself as a practical ally—one that recognizes the importance of consistent fit, durable materials, and a transparent pathway from purchase to installation.

The chapter’s focus on model profiles remains a lens, not a limitation. As the catalog expands, the ongoing test of fitment will shape the brand’s reputation for reliability across a spectrum of vehicles. The single documented compatibility example does not imply an exclusive or exhaustive coverage; rather, it reflects a strategic starting point in a market where demand centers on widely used platforms. For readers and practitioners who are mapping the aftermarket landscape, this provides a baseline: there is value in parts designed to align with the core architecture of popular models, where the likelihood of standardized mounting points and predictable installation is highest. It also suggests that future expansions may extend the fitment matrix, opening opportunities for more vehicle profiles while preserving the brand’s core commitments to affordability and quality.

In sum, the current chapter of A and M Auto Parts’ story illustrates a pragmatic approach to the aftermarket. The emphasis on durability, OEM-like quality, and cost-effectiveness resonates with the practical realities of maintenance and repair. The model-specific example—while modest in its public footprint—offers a blueprint for how the brand positions itself within a diverse vehicle landscape. It reinforces the idea that compatibility, ease of installation, and reliable finishes can coexist with aggressive pricing, especially when a company leverages a global wholesale network to streamline sourcing and distribution. As the catalog evolves, readers can expect a widening portfolio that continues to balance fitment confidence with value, supporting a broad community of technicians and owners who rely on options that keep vehicles on the road without breaking the bank.

External reference: https://www.alibaba.com

Parts, Price, and Performance: How Aftermarket and OEM Choices Shape Automotive Repair Costs

When a car needs maintenance or a part wears out, the first hurdle many drivers face is not the defect itself but the price of fixing it. The choice between aftermarket parts and OEM components creates a ripple effect that travels from the parts bin to the repair bill and, ultimately, to the total cost of ownership. On the surface, the economics are straightforward: aftermarket parts generally carry lower up-front prices than OEM parts. But cost is not a single number. It is a dynamic balance among immediate expense, expected service life, performance, and the likelihood of subsequent repairs. The chapter explores how those trade-offs unfold in real-world repair scenarios, especially for compact and widely driven passenger cars, where maintenance frequency and part turnover are more predictable and thus more sensitive to pricing structures.

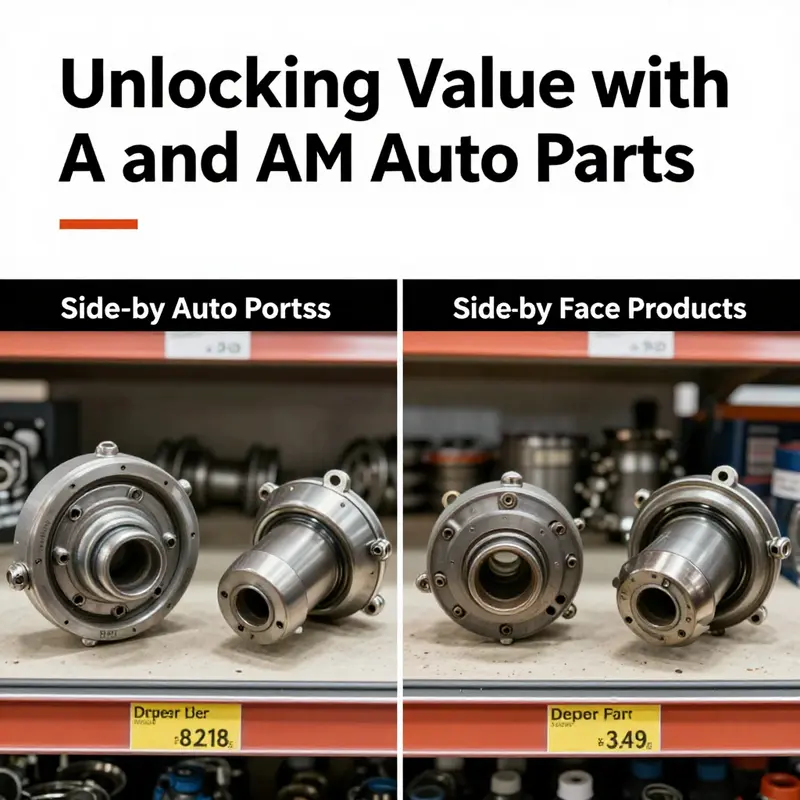

In the marketplace, the affordability of a repair often hinges on the price gap between aftermarket and OEM parts for commonly replaced components—brake pads, filters, hoses, belts, and similar wear items. When the price tag of an OEM part climbs, the initial appeal of aftermarket replacements grows stronger. For many drivers this translates into meaningful short-term savings. Yet the narrative does not end there. The durability and reliability of the chosen part color the long-term financial picture. A cheaper component that fails prematurely or performs suboptimally can drive up maintenance costs through more frequent replacements, higher labor charges, and additional diagnostic time. In situations where aftermarket parts approximate OEM performance, the long-run sum of lower upfront costs and reduced downtime can still be favorable. But when the aftermarket substitute falls short on fit, function, or warranty protection, the long-term economic advantage can erode, or even flip into a higher total cost.

The complexity of the decision becomes clearer when we consider how some vehicles interact with parts pricing. There is evidence that, across brands, OEM parts can be substantially more expensive, and that the price differential may be particularly pronounced for certain models or configurations. A notable 2018 analysis of compact cars used numerical experiments to compare prices of commonly worn parts and to map how those price differences affected the total repair burden. The study did not merely tally sticker prices; it traced how more expensive OEM parts, when coupled with similar aftermarket alternatives, shifted the economics of routine maintenance. In some brands, the higher price of OEM components raised repair costs more than the corresponding savings from aftermarket equivalents. In others, the aftermarket option proved almost indistinguishable in total cost over the life of the part. The core message was less about absolutes and more about the relative economics: the same car in the same repair scenario can end up more expensive or cheaper depending on which path a consumer chooses for parts. This insight is critical for drivers who view ownership cost as a cumulative burden rather than a snapshot of a single purchase.

From a consumer’s perspective, the calculus should be framed around four pillars: price, reliability, system compatibility, and warranty. Price is the most visible pillar, but reliability carries a heavier weight over time. If a cheaper part fails early, it can trigger added labor, towing, diagnostic time, and the risk of collateral damage to adjacent components. Cars today rely on tightly integrated systems—engine management modules, braking by wire, and emissions sensors—that demand precise specifications. An aftermarket part that does not meet the exact tolerances or fails to interact correctly with electronic controls may cause unexpected fault codes or degraded performance. Compatibility matters because even minor deviations can compromise safety-critical functions or the smooth operation of ancillary systems. Finally, warranty coverage provides a form of price protection. OEM parts often come with manufacturer-backed warranties that can cushion the owner against future failures, while trustworthy aftermarket suppliers may offer robust warranties as well, though the terms can vary considerably.

The economic impact thus emerges as a balancing act. If a vehicle’s most frequently replaced parts are priced aggressively in the aftermarket segment, the immediate cost relief can be substantial. For drivers with limited upfront budgets, this relief translates to more affordable repairs and less disruption to daily life. Yet for those who seek the peace of mind that comes with a longer service life and predictable performance, investing in OEM parts—or high-quality aftermarket equivalents with proven reliability—can yield lower long-term costs through reduced failure rates and extended intervals between replacements. The choice is not binary; it is a spectrum defined by brand reputation, part certification, and the specific demands of the vehicle in question.

To ground this discussion in real-world dynamics, consider how many retailers describe the aftermarket and OEM parts landscape. Listings on global wholesale platforms often promise OEM-equivalent quality at markedly lower costs, aiming to unlock maintenance affordability without sacrificing critical performance benchmarks. The challenge for consumers is to discern genuine quality from marketing. Certification and brand reputation become practical tools in this discernment. Independent testing and third-party validations can provide objective assurances about fit, materials, and long-term durability. In addition, buyers should verify compatibility with their vehicle’s model, trim level, and the year of manufacture, because even small differences in a part’s design can lead to mismatches or degraded function. A cautious approach—prioritizing parts that carry recognized certifications and documented performance benchmarks—reduces the risk that the immediate savings fade when a component fails early or underperforms in critical conditions.

For readers seeking concrete examples of aftermarket and OEM accessibility in the broader parts market, a practical reference can be found in public-facing product listings and catalogs. For instance, manufacturers and distributors occasionally publish OEM-equivalent items that claim parity with factory parts while offering a lower price point. These cases illustrate the tension between affordability and assurance. The evidence from the 2018 compact-car study reinforces a prudent principle: the cost advantage of aftermarket parts varies by brand and by the part category. Consumers who want to optimize repair costs should examine not only the price tag but also the supplier’s quality controls, the part’s material composition, and the warranty framework that accompanies the purchase. The optimal strategy blends a careful cost analysis with a measured risk assessment about potential future maintenance needs.

In the end, the economic impact of choosing between aftermarket and OEM parts is a matter of personal finance as well as vehicle performance. For some drivers, the lowest possible upfront cost is the right path, particularly when the vehicle’s duty cycle and maintenance interval favor frequent but inexpensive replacements. For others, committing to higher-quality parts—whether OEM or high-grade aftermarket—may yield lower total costs through fewer repairs, better fuel efficiency, and steadier resale value. The evidence suggests that this decision can be model- and part-specific, rather than universal. Readers should approach it with a clear set of criteria: price trajectory, expected lifespan, compatibility guarantees, and the terms of any warranty or return policy. When these factors are weighed together, the repair bill evolves from a single transaction into a longer-term budget planning exercise that aligns with each driver’s risk tolerance and financial priorities.

For those curious about how specific parts and models play into this calculus, a practical example highlights the spectrum of options available in the market. A widely referenced example of OEM and aftermarket interchangeability appears in public listings for vehicle parts, where a classic Mitsubishi Evolution rear bumper is shown as an OEM option within an aftermarket catalog. Such listings underscore the broader message: even when a part is marketed as OEM-equivalent, the surrounding quality controls, shipping, and after-sales support influence the perceived value and the actual cost over time. See an example here: 03-06 Mitsubishi Evolution 8-9 JDM rear bumper OEM.

As research continues to shed light on how prices shape repair decisions, readers are encouraged to consult peer-reviewed analyses that quantify cost differences across brands and regions. A foundational external resource that discusses the economic dimensions of spare part pricing and repair costs can be found in the scholarly literature, which offers methodological insights and empirical findings relevant to this topic: https://www.sciencedirect.com/science/article/pii/S1877042818300795. This study provides a rigorous context for understanding how part pricing feeds into total ownership costs, complementing the practical considerations discussed here and guiding more informed choices when planning future repairs.

null

null

Global Distribution and Availability of A and M Auto Parts: Navigating OEM and Aftermarket Networks in a Globalized Supply Chain

The map of A and M auto parts stretches far beyond a few regional warehouses, revealing a living tapestry shaped by OEM parity, aftermarket demand, and the relentless pace of globalization. In this chapter, the distribution and availability of these parts are not mere logistics trivia but a reflection of how industry players connect factories, distributors, and repair shops across continents. The landscape is defined by a deliberate separation between original equipment manufacturer (OEM) parts and aftermarket (M) parts, yet both streams are interwoven through a shared ambition: to deliver reliable components at scale, when customers need them, and at costs that keep maintenance affordable. The global spine of this network rests on manufacturing and distribution centers concentrated in three broad regions—North America, Europe, and Asia—yet the actual flow of parts ripples through many more economies. Within this framework, several regional strengths emerge. In large, export-driven economies, there is a pronounced capability for high-precision engineering, powertrain components, and safety systems. In others, the focus is on electronics, sensors, and rapidly evolving ADAS technologies. In yet more markets, cadence and flexibility dominate, enabling rapid customization and local adaptation. Across these regions, the same underlying forces shape availability: the drive toward just-in-time manufacturing, the push for digital inventory management, and the growing importance of aftermarket channels that serve an aging vehicle fleet and repair needs that are not always tied to brand-authorized networks. The result is a tiered yet interconnected system in which a handful of central hubs—where manufacturing, quality assurance, and distribution converge—pump components into OEM supply chains and into aftermarket catalogs simultaneously. This centralization accelerates efficiency, yet it also obliges suppliers to manage a delicate balance between global scale and local responsiveness. When a factory in one region ramps up production for a new model or a new generation of electronics, the ripple effects are felt by OEMs and independent repair shops the world over. Production shifts, supplier diversification, and inventory buffering become strategic instruments to keep assembly lines moving and repair bays stocked. A nuanced consequence of this scale is the emergence of digital platforms that provide real-time visibility into stock across the network. Real-time inventory data, combined with predictive analytics, allows distributors to anticipate shortages, reroute shipments, and compress lead times. This digital layer is not a luxury but a necessity in a market increasingly driven by variability in demand, disruptions, and the new era of electrification. The automobile is changing, and the supply chain is learning to change with it. The growth of electric propulsion and advanced electronics has broadened the scope of what constitutes a “part.” Battery modules, power electronics, and lightweight materials now coexist with traditional components like body panels, engine covers, and suspension parts. This expansion challenges the old notion of a fixed catalog and presses the industry toward modular, interoperable interfaces. In practice, that means a broader ecosystem where OEM-equivalent parts and high-quality aftermarket equivalents must align on fit, durability, and performance standards. A and M auto parts producers and distributors have responded by widening their product ranges, investing in quality assurance, and building closer relationships with repair networks that require dependable supply chains. The aftermarket segment—where M parts flourish—continues to grow as the vehicle parc ages and drivers seek affordable, fast, and convenient replacement options. The dynamic is not simply about price. Availability now includes the ability to source compatible components quickly, with clear documentation on compatibility, warranty terms, and return policies. In this sense, the distribution system doubles as a consumer confidence machine: buyers want assurance that the parts they order are correct, safe, and backed by a credible supply chain story. The geographic distribution patterns mirror these expectations. In China and neighboring regions, battery technology, lightweight materials, and interior components have become focal points for manufacturers seeking scale and cost efficiency. In Europe and North America, the emphasis often lies on precision-engineered powertrain modules, chassis systems, and safety technologies that require tight tolerances and rigorous testing. Japan and South Korea contribute strength in electronics, sensors, and advanced control systems, while France and Canada bring specialized capabilities in suspension design and vehicle integration. These regional strengths create a layered supply network in which large, integrated players—without naming particular brands—act as central hubs. They source raw materials globally, conduct quality assurance at scale, and distribute finished components to OEMs and aftermarket retailers alike. The continuum from factory floor to repair bay depends on an intricate choreography of logistics, manufacturing timing, and risk management. Just-in-time delivery, for example, is still a cornerstone for many OEMs. Suppliers must ensure that components arrive as needed to keep assembly lines turning, which places enormous importance on schedule reliability, transport reliability, and cross-border compliance. At the same time, the aftermarket ecosystem thrives on rapid fulfillment. Digital catalogs and online marketplaces have democratized access to a vast array of parts, allowing independent shops and individual car owners to source items that previously required close-knit dealer networks. In this setting, the value proposition extends beyond the piece price. It encompasses documentation quality, compatibility guarantees, and after-sales support. Customers increasingly demand clear, transactable information about fit, warranty, and post-purchase assistance. The interplay of these demands pushes suppliers to develop more transparent pricing, better return policies, and stronger quality controls. It also incentivizes distributors to maintain robust, diversified supplier bases, so that a disruption in one region does not cascade into a global shortage. The human element remains central, even as digital tools proliferate. Teams across regions coordinate to manage regulatory compliance, ensure traceability, and verify that aftermarket parts maintain parity with OEM standards where required. This is not simply about cost-saving pressure; it is about delivering reliable, durable parts that can be trusted across a broad spectrum of vehicles and use cases. The global distribution story for A and M auto parts, therefore, is one of scale and adaptability. It requires the careful orchestration of manufacturing strengths, regional specialization, and intelligent logistics. It requires clear communication with repair shops and fleets, ensuring that the right part is available at the right time, in the right specification. It demands a mature approach to quality assurance, so customers do not have to compromise on safety or performance when choosing between OEM and aftermarket options. In such an environment, one small but telling detail helps illustrate the broader trend: the existence of online catalogs that carry items with astonishing specificity. A single listing in a catalog can reflect a global supply chain’s reach—paralleling how a common body part can be sourced in one market and a high-precision electronic module in another. This is the new normal for global parts distribution, where broad access meets exacting standards. For readers who want to explore catalog diversity first-hand, consider the following example from an online listing that demonstrates how niche demand travels through global channels: Authentic JDM Evo 9 MR taillights. Such listings show how specialized items can be tied to broader supply networks, illustrating the ecosystem’s flexibility and resilience. The overarching message is clear: availability now hinges on a sophisticated blend of regional expertise, digital inventory control, and a willingness to embrace both OEM parity and credible aftermarket alternatives. As electrification accelerates and software-driven features proliferate, distributors will continue to refine their networks, pursuing greater transparency, faster fulfillment, and steadier supply. The A and M auto parts landscape is evolving toward more modular, interoperable ecosystems that can support the next generation of vehicles without sacrificing reliability or affordability. External resources that map these market dynamics provide additional context for how global platforms, broker networks, and catalog-driven sales align with real-world repair needs. External resource: https://www.alibaba.com

Final thoughts

A and M auto parts represent a compelling choice for business owners seeking high-quality automotive components at competitive prices. By understanding their quality standards, supported models, and economic impact, industry professionals can make informed decisions that enhance their operational efficiency. As A and M continues to expand its global distribution, embracing this brand can lead to substantial cost savings and improved customer satisfaction, ensuring a stronger position in the automotive market.